Room-temperature addition silicon rubber putty-type dental impression material applied to primary impression

An oral impression material, silicone rubber technology, applied in the field of medical materials, can solve the problems of poor dimensional stability, poor hydrophilicity, easy shrinkage, etc., and achieve the effects of good elastic recovery, high accuracy, and reduced volume shrinkage rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The formula of the room temperature added silicone rubber putty type oral cavity impression material of the present embodiment is shown in the following table:

[0041]

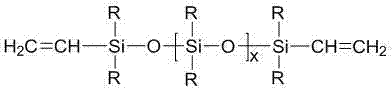

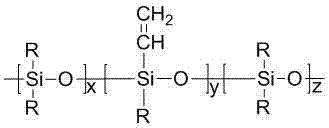

[0042] The vinyl silicone oil described in this example has a viscosity of 10,000 mPa·s and the vinyl silicone oil is a vinyl silicone oil with a double bond terminated or a double bond branched chain. Its structural formula is as shown in I or II. The container is 5000 mesh quartz powder, and the reinforcing agent has a specific surface area of 10 m 2 / g of fumed silica, the release agent is white oil, and the inhibitor is tetramethyldivinyldisiloxane.

Embodiment 2

[0044] The formula of the room temperature added silicone rubber putty type oral cavity impression material of the present embodiment is shown in the following table:

[0045]

[0046] The vinyl silicone oil described in this example has a viscosity of 60000 mPa·s, and the vinyl silicone oil is a vinyl silicone oil with a double bond terminated or a double bond branched chain, and its structural formula is as shown in I or II. The compatibilizer is 5000 mesh quartz powder, and the reinforcing agent has a specific surface area of 10 m 2 / g of fumed silica, the release agent is white oil, and the inhibitor is tetramethyldivinyldisiloxane.

Embodiment 3

[0048] The formula of the room temperature added silicone rubber putty type oral cavity impression material of the present embodiment is shown in the following table:

[0049]

[0050] The compatibilizer described in this embodiment is 5000 mesh quartz powder, and the described reinforcing agent has a specific surface area of 10 m 2 / g of fumed silica, the release agent is white oil, and the inhibitor is tetramethyldivinyldisiloxane.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com