High-hardness photosensitive resin composition used for light curing rapid prototyping

A technology of photosensitive resin and composition, which is applied in the field of high hardness photosensitive resin composition to achieve the effects of low water absorption, fast speed and small volume shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

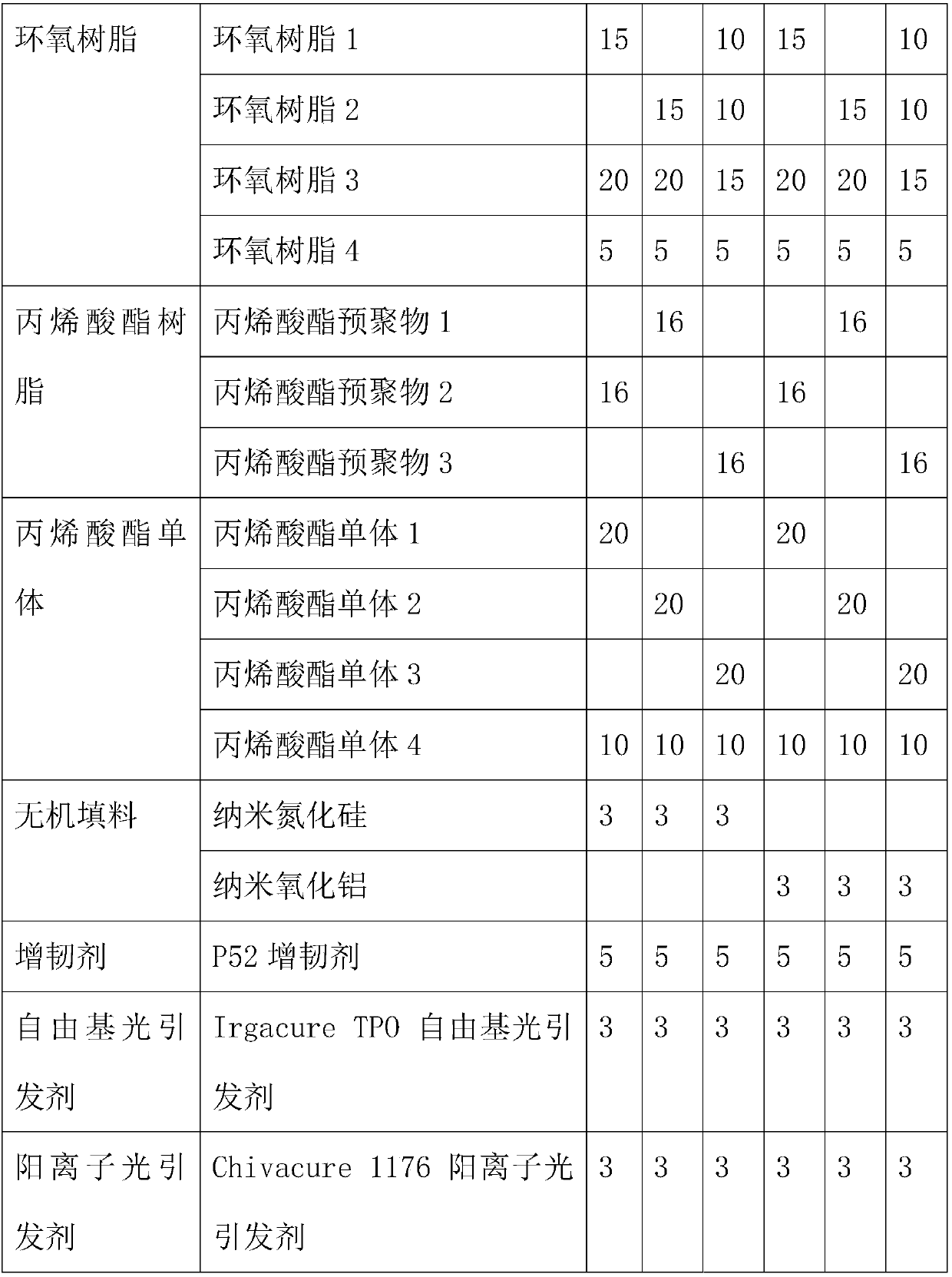

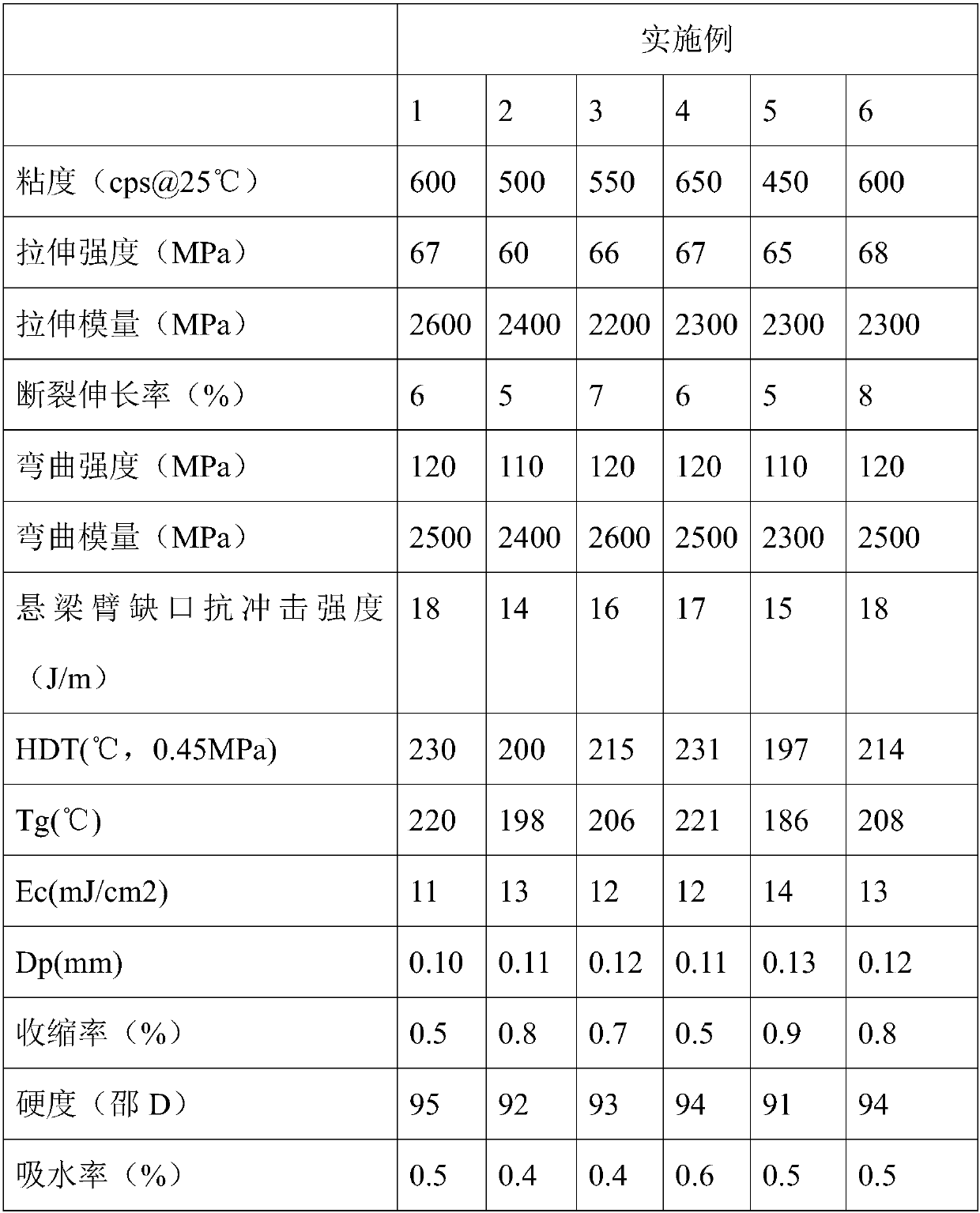

[0031] The following table is six embodiments, respectively adopting different mass percentages to make photosensitive resin compositions;

[0032]

[0033]

[0034] in,

[0035] Epoxy resin 1: poly[(2-oxiranyl)-1,2-cyclohexanediol]-2-ethyl-2-hydroxymethyl-1,3-propanediol ether

[0036] Epoxy 2: Dicyclopentadiene diepoxide

[0037] Epoxy 3: 3,4-epoxycyclohexylmethyl-3,4-epoxycyclohexyl carboxylate

[0038] Epoxy Resin 4: Pentaerythritol Tetraglycidyl Ether

[0039] Acrylate Oligomer 1: o-cresol novolac epoxy acrylate

[0040] Acrylate Oligomer 2: Aliphatic Urethane Acrylate

[0041] Acrylate Oligomer 3: Aromatic Urethane Acrylate

[0042] Acrylate Monomer 1: Acryloylmorpholine

[0043] Acrylate monomer 2: Isobornyl acrylate

[0044] Acrylate monomer 3: Bornyl acrylate

[0045] Acrylate monomer 4: Tris(2-hydroxyethyl)isocyanurate triacrylate

[0046] Toughener: silicone core-shell particles

[0047] Free radical photoinitiator: 2,4,6-trimethylbenzoyl-diphenylpho...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com