Dual-curing polyurethane hot melt adhesive and preparation and using methods thereof

A polyurethane hot-melt adhesive and dual-cure technology, which is applied in the field of polyurethane hot-melt adhesives, can solve problems such as low initial adhesion and long curing time, and achieve the effects of improved compatibility, high bonding strength, and good toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

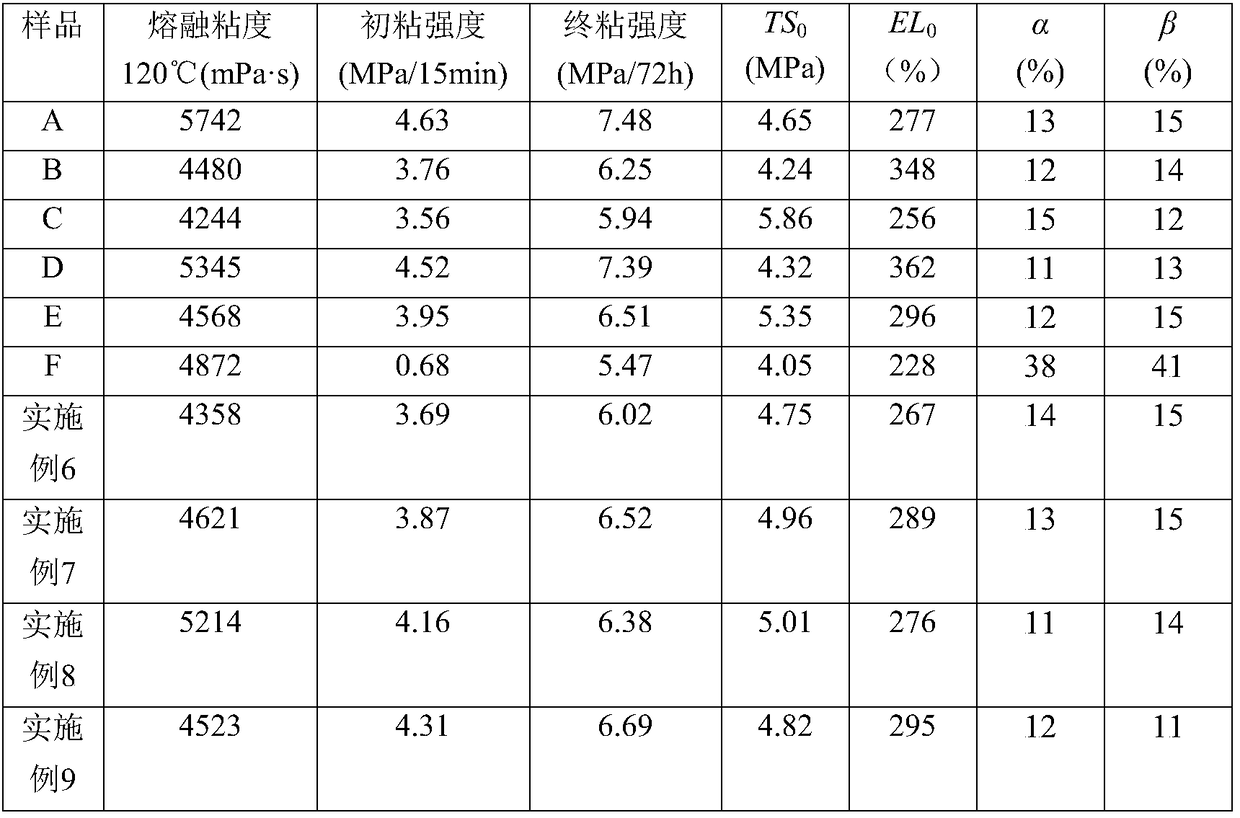

Examples

Embodiment 1

[0053](1) Take by weighing molecular weight 2000 polyhexamethylene adipate diol 90.00g, molecular weight 3000 polyhexamethylene adipate diol 13.50g, molecular weight 2000 polytetrahydrofuran ether diol 18.00g, antioxidant 1010 1.70g 17.00g of acrylic resin, 13.80g of tetrahydrofuran acrylate and 8.29g of ethoxyethoxyethyl acrylate were added to a 1.0L four-necked flask, stirred and heated to 110-120°C, and vacuum dehydrated at an absolute pressure of 80Pa for 120min .

[0054] (2) Cool down to 80°C, blow in nitrogen to release the vacuum, add 37.80g of 4,4'-diphenylmethane diisocyanate (MDI), 3.73g of isophorone diisocyanate (IPDI), catalyst dibutyltin dilaurate 1.70g, then turn off the nitrogen and react for 60min at 85-95°C and absolute pressure less than 100Pa;

[0055] (3) Introduce nitrogen to release the vacuum, add 5.50 g of 2-(4-benzoyl-3-hydroxyphenoxy) ethyl methacrylate, 1.42 g of chain extender 1,4-butanediol, and silane coupling Agent KH-560 1.50g, KH-570 1.05g,...

Embodiment 2

[0059] (1) Weigh 90.00g of polyhexamethylene adipate diol with a molecular weight of 2000, 20.25g of polyhexamethylene adipate diol with a molecular weight of 3000, 9.00g of polytetrahydrofuran ether diol with a molecular weight of 2000, and 1.72g of antioxidant 1010 25.72g of acrylic resin, 10.97g of tetrahydrofuran acrylate, and 16.45g of ethoxyethoxyethyl acrylate were added to a 1.0L four-neck flask, stirred and heated to 110-120°C, and vacuum dehydrated at an absolute pressure of 80Pa for 120min .

[0060] (2) Cool down to 80°C, blow in nitrogen to release the vacuum, add 33.36g of 4,4'-diphenylmethane diisocyanate (MDI), 9.88g of isophorone diisocyanate (IPDI), catalyst dibutyltin dilaurate 1.72g, then turn off the nitrogen and react for 60min at 85-95°C and absolute pressure less than 100Pa;

[0061] (3) Introduce nitrogen to release the vacuum, add 7.71g of 2-(4-benzoyl-3-hydroxyphenoxy)ethyl methacrylate, 1.22g of chain extender 1,4-butanediol, and silane coupling A...

Embodiment 3

[0065] (1) Take by weighing molecular weight 2000 polyhexamethylene adipate diol 90.00g, molecular weight 3000 polyhexamethylene adipate diol 27.0g, molecular weight 2000 polytetrahydrofuran ether diol 27.0g, antioxidant 1010 2.00g 24.0g of acrylic resin, 20.00g of tetrahydrofuran acrylate and 19.99g of ethoxyethoxyethyl acrylate were added to a 1.0L four-necked flask, stirred and heated to 110-120°C, and vacuum dehydrated at an absolute pressure of 80Pa for 120min .

[0066] (2) Cool down to 80°C, blow in nitrogen to release the vacuum, add 41.34g of 4,4'-diphenylmethane diisocyanate (MDI), 9.18g of isophorone diisocyanate (IPDI) and catalyst dibutyltin dilaurate 2.00g, then turn off the nitrogen and react for 60min at 85-95°C and absolute pressure less than 100Pa;

[0067] (3) Introduce nitrogen to release the vacuum, add 4.41g of 2-(4-benzoyl-3-hydroxyphenoxy)ethyl methacrylate, 1.01g of chain extender 1,4-butanediol, silane coupling Agent KH-560 0.60g and KH-570 0.40g, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com