Composite material with holographic anti-counterfeiting effect and manufacturing method thereof

A holographic anti-counterfeiting and composite material technology, which is applied in the field of composite materials with holographic anti-counterfeiting effects and its production, can solve the problems of unsatisfactory wear resistance and bending resistance, low technical content, counterfeiting by counterfeiters, etc., and achieve difficulty in production Large, high-tech content, anti-piracy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

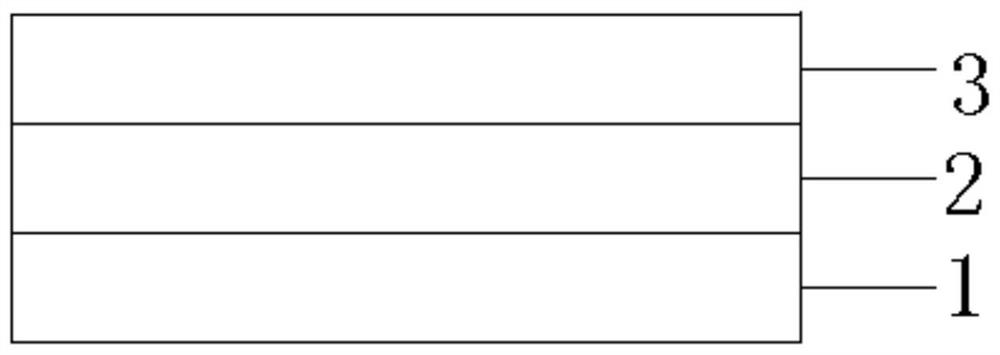

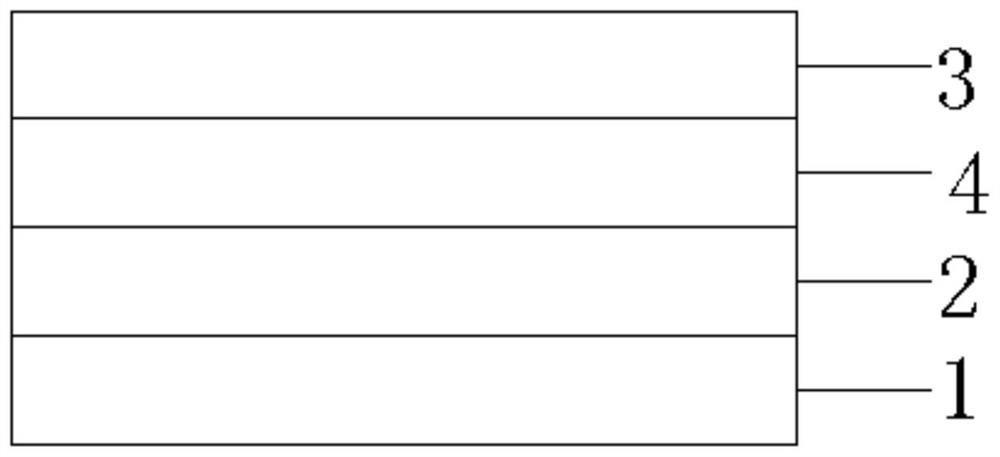

[0037] Attached below Figure 1-2 and the preferred embodiment to describe the technical solution of the present invention in detail.

[0038] like Figure 1-2 , where the references are:

[0039] 1. Holographic layer; 2. Transparent medium layer; 3. Protective layer; 4. Adhesive layer.

[0040] like Figure 1-2 As shown, this embodiment discloses a composite material with holographic anti-counterfeiting effect, including a holographic layer, a transparent medium layer, and a protective layer; Nanostructure; the transparent medium layer is formed on the holographic layer and covers the holographic anti-counterfeiting micro-nano structure; the protective layer is formed on the transparent medium layer, and the protective layer is formed by UV photocurable paint coating and / or The coating of thermosetting paint is cured.

[0041] The composite material with holographic anti-counterfeiting effect in this embodiment can realize the full-page holographic anti-counterfeiting se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com