Microwave plasma vacuum coating equipment and use method

A microwave plasma and vacuum coating technology, applied in gaseous chemical plating, metal material coating process, coating, etc., can solve the problems of poor uniformity and consistency of coating, easy pollution of chemical substances to the environment, and low sedimentation rate. , to improve uniformity and consistency, improve coating production efficiency, and increase sedimentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

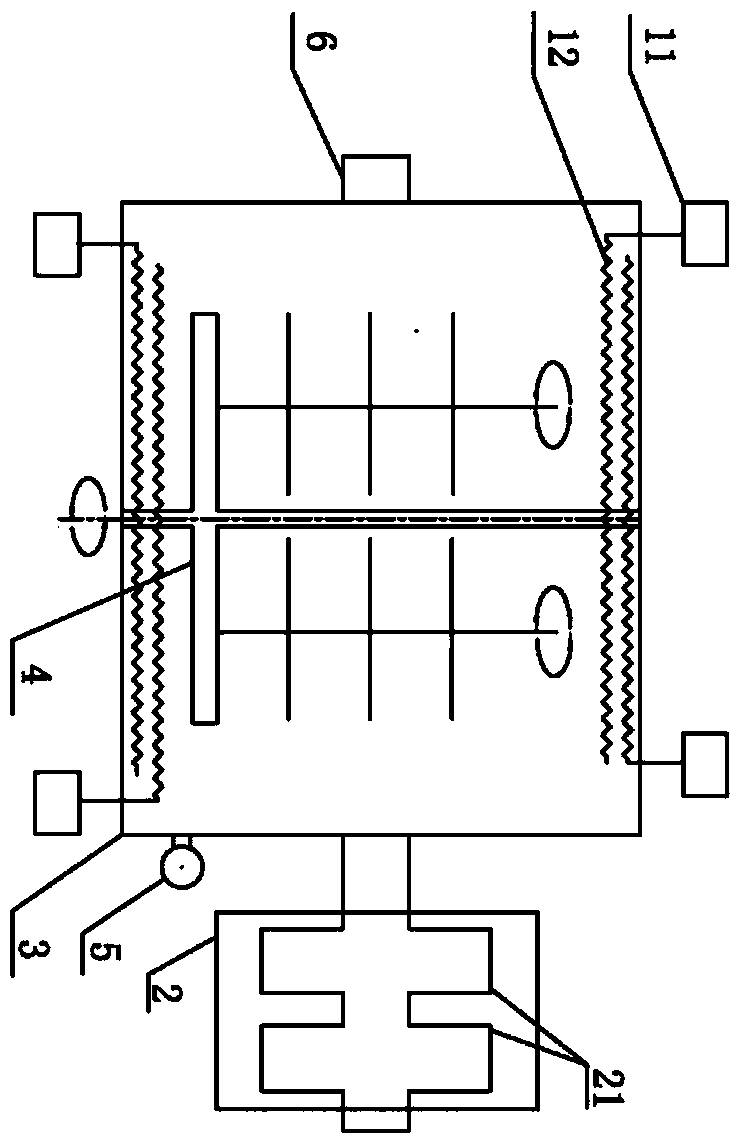

[0031] A microwave plasma vacuum coating device, comprising a microwave antenna 12, a microwave source 11, an air intake device 6, an exhaust device 2, a plasma vacuum chamber 3 and a moving device 4, the vacuum exhaust device 2 is arranged on the plasma vacuum chamber 3 The outside is connected to the cavity through pipes, the microwave antenna 12 and the moving device 4 are arranged inside the plasma vacuum cavity 3, and the microwave source 11 is arranged outside the cavity and connected to the microwave antenna in the cavity.

[0032] The microwave source 11 is placed outside the cavity 3, the microwave antenna 12 is placed inside the cavity 3 and connected with the external microwave source 11, and there are two pairs of microwave antenna and microwave source.

[0033] The air intake device 6 is a channel through which external air or steam enters the cavity.

[0034] The vacuum exhaust device 2 includes a vacuum pump 21 and an exhaust pipe. The vacuum pump 21 is divided ...

Embodiment 2

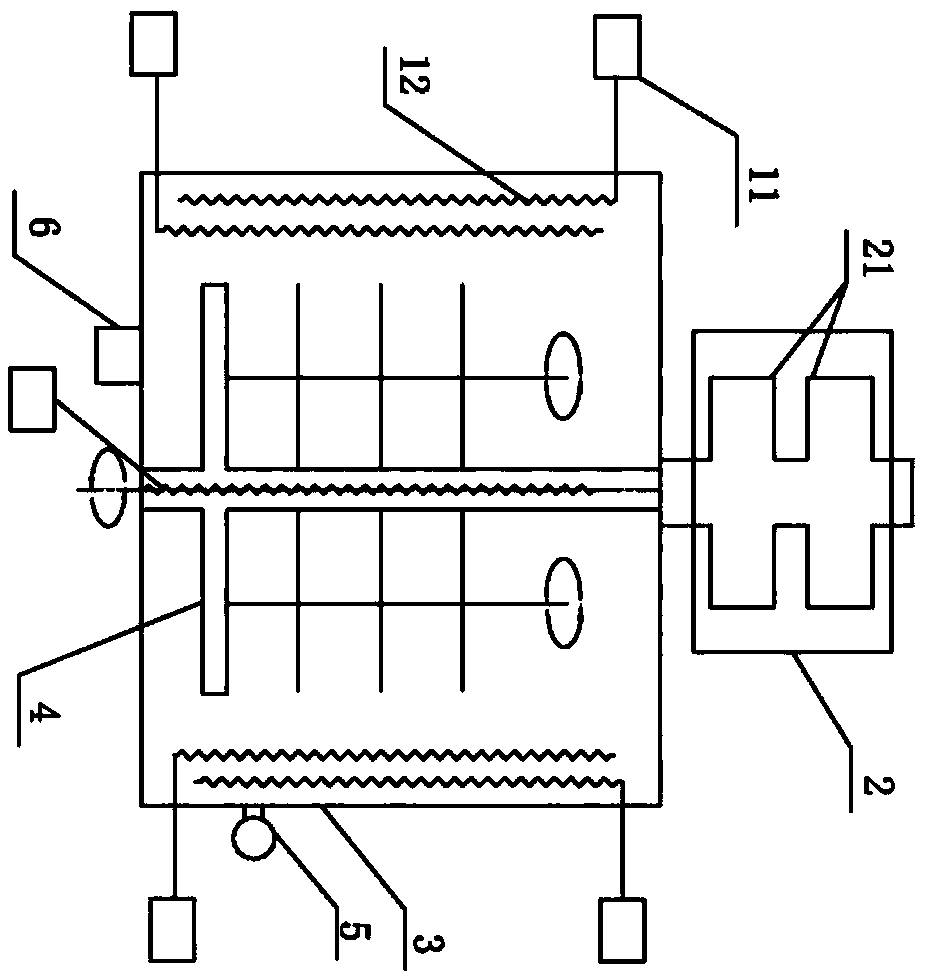

[0046] A microwave plasma vacuum coating device, comprising a microwave antenna 12, a microwave source 11, an air intake device 6, an exhaust device 2, a plasma vacuum chamber 3 and a moving device 4, the vacuum exhaust device 2 is arranged on the plasma vacuum chamber 3 The outside is connected to the cavity through pipes, the microwave antenna 12 and the moving device 4 are arranged inside the plasma vacuum cavity 3, and the microwave source 11 is arranged outside the cavity and connected to the microwave antenna in the cavity.

[0047] The microwave source 11 is placed outside the cavity 3, the microwave antenna 12 is placed inside the cavity 3 and connected with the external microwave source 11, and there are three pairs of microwave antennas and microwave sources.

[0048] The air intake device 6 is a channel through which external air or steam enters the cavity.

[0049] The vacuum exhaust device 2 includes a vacuum pump 21 and an exhaust pipe. The vacuum pump 21 is divi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com