Method and device for treating heavy metal waste water by ambient-temperature ferrite cycle treatment process

A cyclic treatment, ferrite technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of low effluent standard and high energy consumption, and achieve high drainage quality , low sedimentation rate, the effect of performance optimization can be used

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

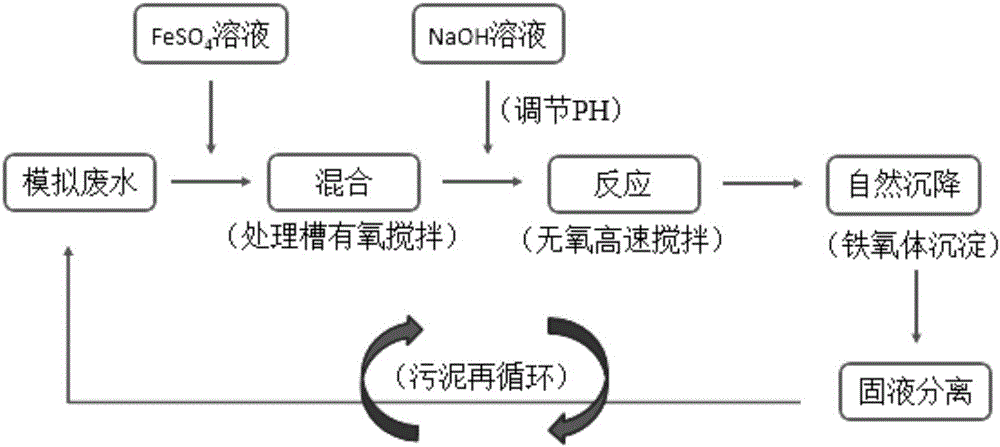

[0039] Embodiment 1: a kind of method of normal temperature ferrite circulation processing heavy metal sewage, such as figure 1 shown, including the following steps:

[0040] S1, 0.75g ferrous sulfate heptahydrate is added in 600mL, the sewage that heavy metal total content is 50mg / L (described sewage is the sewage that contains Cu, Zn, Cr and Ni ion), aerobic stirring is uniform under normal temperature (not more than 2min); then add 131.25ml of sodium hydroxide solution with a molar concentration of 1mol / L, and stir for 30min without air;

[0041] S2, then carry out natural settlement of sewage for 24 hours, after settlement, carry out solid-liquid separation;

[0042] S3, after the solid-liquid separation, the supernatant liquid (ie sewage) is discharged, and the sludge of the lower floor 100ml is taken out for subsequent use;

[0043] S4, adding heavy metal ion content to the sludge is 600ml of sewage with a content of 50mg / L (the amount of sewage is determined by the to...

Embodiment 2

[0050] Embodiment 2: a kind of method of normal temperature ferrite circulation processing heavy metal sewage, such as figure 1 shown, including the following steps:

[0051] S1, add 0.75g of ferrous sulfate heptahydrate into 600ml of sewage containing 50mg / L of heavy metal Cu, and stir evenly with oxygen at room temperature; then add 131.25ml of sodium hydroxide with a molar mass of 1mol / L, and stir in isolation from the air 30min;

[0052] S2, then carry out natural settlement of sewage for 24 hours, after settlement, carry out solid-liquid separation;

[0053] S3, after the solid-liquid separation, the supernatant liquid (ie sewage) is discharged, and the sludge of the lower floor 100ml is taken out for subsequent use;

[0054] S4, adding 500ml of sewage containing 10mg / L of heavy metal Cu and 91.88ml of sodium hydroxide solution with a molar mass of 1mol / L to the sludge, and aerobic stirring for 15min to obtain magnetic sludge;

[0055] S5, this magnetic sludge is added...

Embodiment 3

[0059] Embodiment 3: a kind of method of normal temperature ferrite circulation processing heavy metal sewage, such as figure 1 shown, including the following steps:

[0060] S0, under normal temperature conditions, add hydrated lime to the sewage (the sewage contains one or more substances in Cu, Zn, Cr, Ni, Cd or Pb) for neutralization pretreatment, so that the pH value of the sewage is 5 ~8;

[0061] S1, add 0.8g of ferrous sulfate heptahydrate into 833ml of sewage with a heavy metal content of 80mg / L, and stir evenly with oxygen at room temperature; then add 120ml of sodium hydroxide solution with a molar mass of 1mol / L, and stir for 15min without air ;

[0062] S2, then carry out natural settlement of sewage for 24 hours, after settlement, carry out solid-liquid separation;

[0063] S3, after solid-liquid separation, the supernatant liquid (ie sewage) is discharged, and the lower layer of sludge is taken out for standby;

[0064] S4, add 96ml, the sodium hydroxide sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com