Water-in-oil-in water emulsions of hydroxamated polymers and methods for using the same

A polymer, hydroxime technology, applied in the field of flocculants, can solve problems such as poor supernatant clarity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

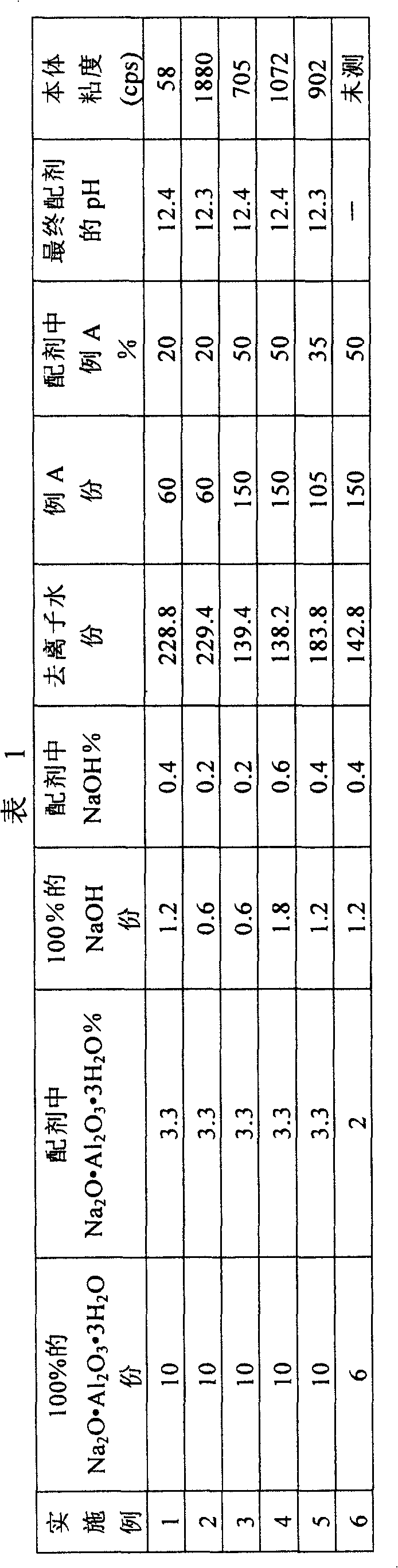

[0028] Preparation of the water-in-oil-in-water polymer emulsion of embodiment 1-6 hydroxamation

[0029] Six (6) samples of stable hydroxamated water-in-oil-in-water polymer emulsions were prepared according to the following procedure

[0030] Taste. The concentrations of the components in each sample are shown in Table 1. Sodium aluminate trihydrate (Na 2 O·Al 2 o 3 ·3H 2 O) Powder and sodium hydroxide were dissolved in deionized water. followed by HF80 is rapidly added to a vigorously stirred solution of sodium aluminate and sodium hydroxide to form a stable water-in-oil-in-water emulsion of the hydroxamated polymer.

Embodiment 7-15

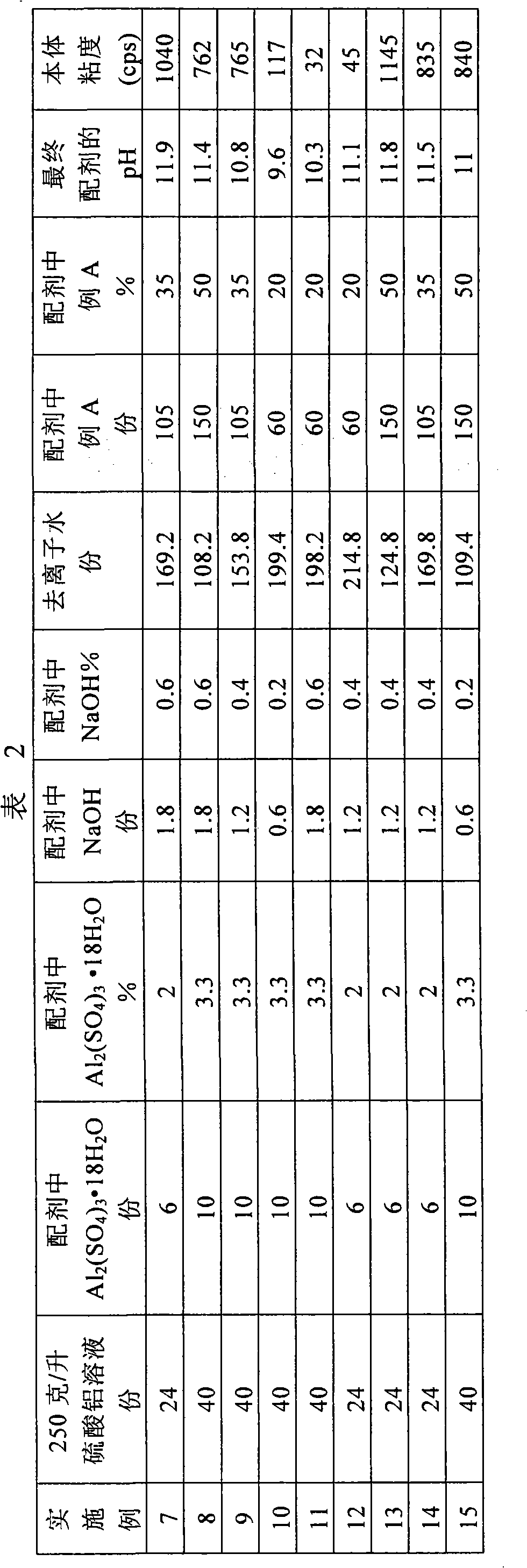

[0031] Example 7-15 Preparation of hydroxamated water-in-oil-in-water polymer emulsion

[0032] Stable water-in-oil-in-water emulsions of hydroxamated polymers were prepared according to the following procedure. 250 g / L aluminum sulfate hydrate [Al 2 (SO 4 ) 3 18H 2 O] solution and 100% NaOH dissolved in deionized water. The emulsion described in Example A was then added rapidly to the caustic aluminum sulfate solution with vigorous stirring. Table 2 lists several water-in-oil-in-water formulations prepared according to this procedure.

[0033]

[0034]

Embodiment 16

[0035] Preparation of the water-in-oil-in-water polymer emulsion of embodiment 16 hydroxamation

[0036] Stable water-in-oil-in-water emulsions of hydroxamated polymers were prepared according to the following procedure. With vigorous stirring, 150 parts of the aluminum sulfate solution was added to 150 parts of the comparative example A emulsion at a constant rate over 30-40 minutes. Aluminum sulfate solution uses 18.6 parts of 48% aluminum sulfate hydrate [Al 2 (SO 4 ) 3 14H 2 O] and 131.4 parts of deionized water were prepared. The concentration of Comparative Example A in the final product is 50%, Al 2 (SO 4 ) 3 14H 2 The concentration of O is 2.97%. The final product had a bulk viscosity of 780 cp and a pH of 10.1. This example demonstrates that it is possible to add an aqueous phase to a water-in-oil hydroxamated polymer emulsion to produce a stable water-in-oil-in-water hydroxamated polymer emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com