Spraying dust-falling device for constructional engineering

A technology of construction engineering and dust suppression device, which is applied in the direction of separation method, use of liquid separation agent, separation of dispersed particles, etc., can solve the problems of insufficient comprehensive components in the dust reduction process, small spraying range, and inability to adjust, etc., to achieve the improvement of dust reduction range, Improve the settlement rate and adjust the effect flexibly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

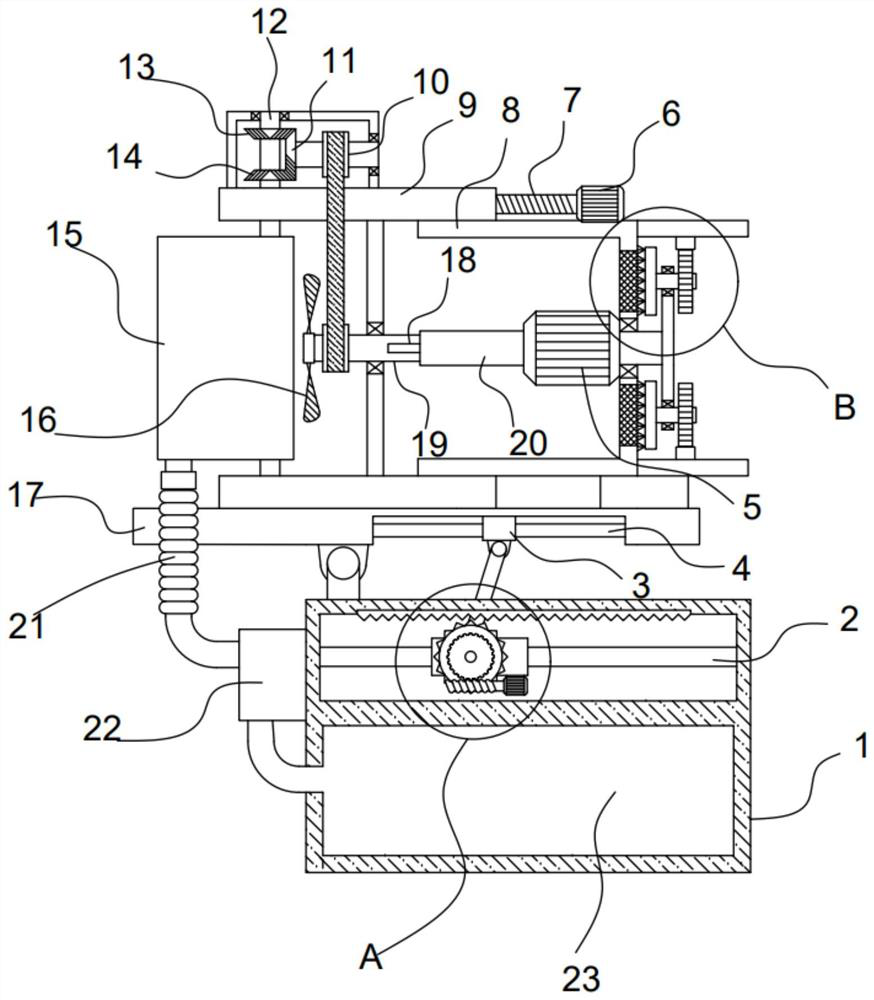

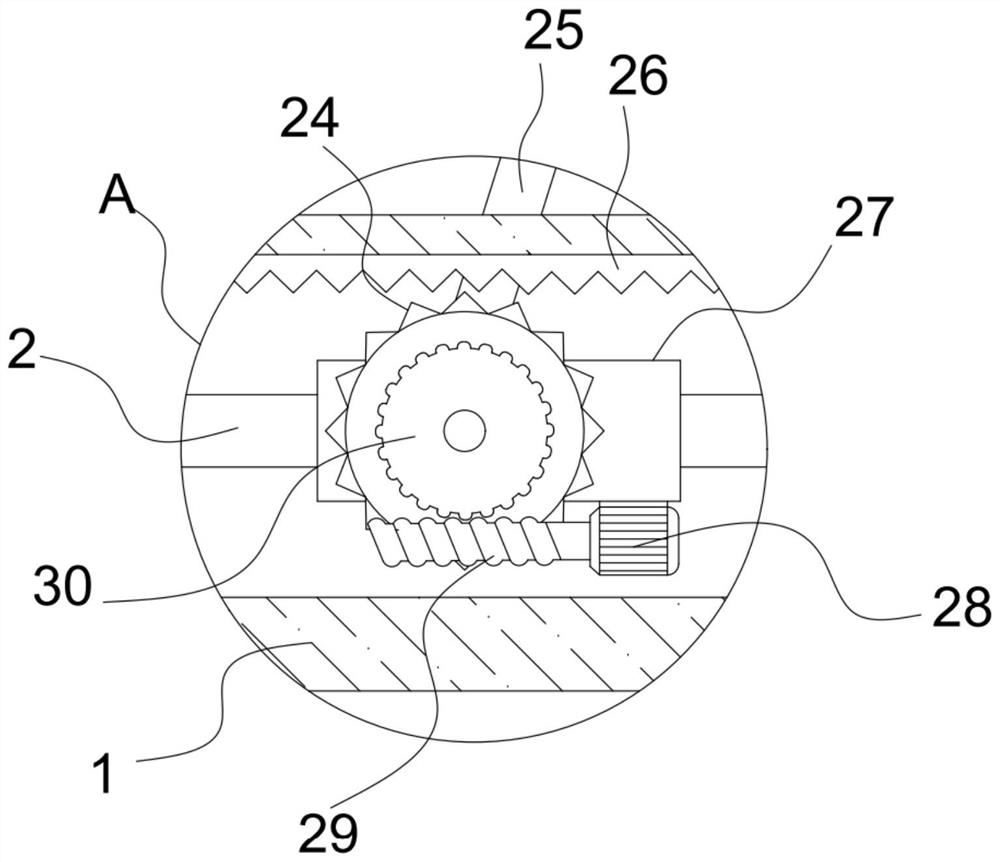

[0024] see Figure 1-5 , a sprinkler and dust suppression device for construction engineering, comprising a support box 1, a water tank 23 for storing clean water is provided in the support box 1, a support plate 17 is hinged on the support box 1, and a fixed Sleeve 8, the sliding sleeve on the fixed sleeve 8 is provided with an extension sleeve 9, a telescopic adjustment mechanism is arranged between the fixed sleeve 8 and the extension sleeve 9, and a biaxial motor 5 is fixed inside the fixed sleeve 8 , an output shaft of the biaxial motor 5 is driven and connected with a blower mechanism, and the inside of the extension sleeve 9 is driven and connected with a guide air duct 15 through a swing mechanism, and the guide air duct 15 is provided with a spray mechanism communicating with the water tank 23, so The air collecting pipe 31 is fixed between the fixed sleeve 8 away from the guide air duct 15, and the side wall of the fixed sleeve 8 is embedded with a filter screen 33, ...

Embodiment 2

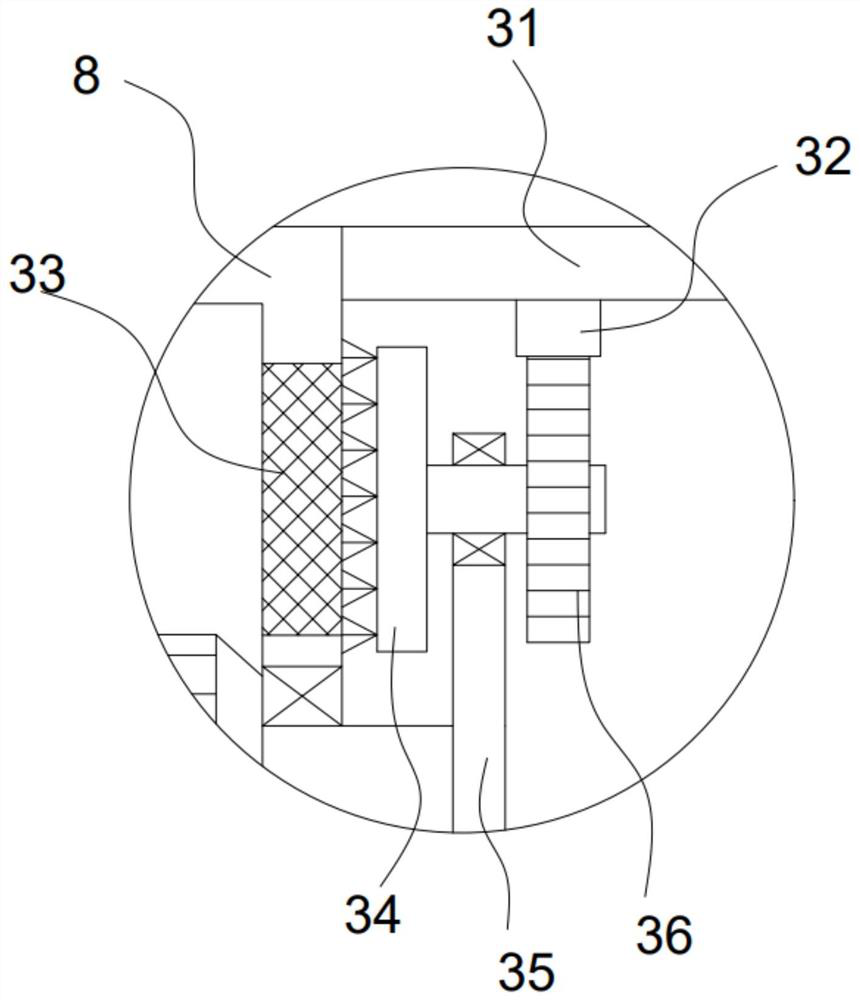

[0032] On the basis of Embodiment 1, in addition, the cleaning mechanism of the device includes a rotating plate 35 driven by a biaxial motor 5, on which a brush rotating plate 34 in contact with the filter screen 33 is installed, and the brush A rotating gear 36 is coaxially fixed on the brush rotating plate 34 , and an inner ring gear 32 fixed on the inner wall of the air collecting pipe 31 is engaged with the rotating gear 36 .

[0033] When the blower mechanism performs the blowing function, the external air passes through the filter screen 33 and enters the inside of the fixed sleeve 8 to realize the conveying and circulation of the air. The dust in the air gathers on the filter screen 33 and is blocked. During this period, the rotating plate 35 is The two-axis motor 5 is driven to realize the rotation effect. When the brush rotating plate 34 on the rotating plate 35 rotates around the center of the rotating plate 35, the rotating gear 36 is meshed with the ring gear 32 to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com