Medical hot melt adhesive and preparation method thereof

A technology of hot-melt adhesive and formula, which is applied in the field of medical hot-melt adhesive and its preparation, can solve the problems of poor water and sweat resistance and affect the service life, and achieve strong repeated stickiness, good sweat resistance and short preparation cycle shortened effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0027] Preparation of grafted products of SIS and PEG:

[0028] In a three-necked flask equipped with a reflux condenser, an electric stirrer, and a dropping funnel, add 60 parts of a mixture of purified SIS and toluene solvent, wherein the weight ratio of SIS to toluene is 5:1; start the stirrer and a water bath, after raising the temperature to 60±5°C, dropwise add 10 parts of ethyl acetate mixture dissolved in BPO, wherein the weight ratio of BPO to ethyl acetate is 20:1; continue to stir, and raise the temperature to 80 After ℃, stir at constant temperature for 0.5h, start to drop 30 parts of the mixed solution of MMA, PEG and BMA dissolved in BPO, the weight ratio of BPO, MMA, PEG and BMA is 1:3:20:3, the molecular weight of PEG It was 400; under the protection of nitrogen, after 20 hours of stirring at constant temperature, the temperature was naturally lowered and cooled to about 50°C, and the grafted product of SIS and PEG was obtained.

Embodiment 1

[0030] Utilize above-mentioned SIS and PEG graft product to prepare medical hot-melt adhesive, its raw material is composed according to the following parts by weight: 30 parts of graft product of SIS and PEG, 12 parts of naphthenic oil, 1 part of antioxidant, 52 parts of hydrogenated petroleum resin, 5 copies of SAP.

[0031] Among them, naphthenic oil 4010 is selected, which has good compatibility; antioxidant 1010 is selected; C5 hydrogenated petroleum resin is selected, and the hydrogenated petroleum resin has high aging resistance and will not form spots when heated.

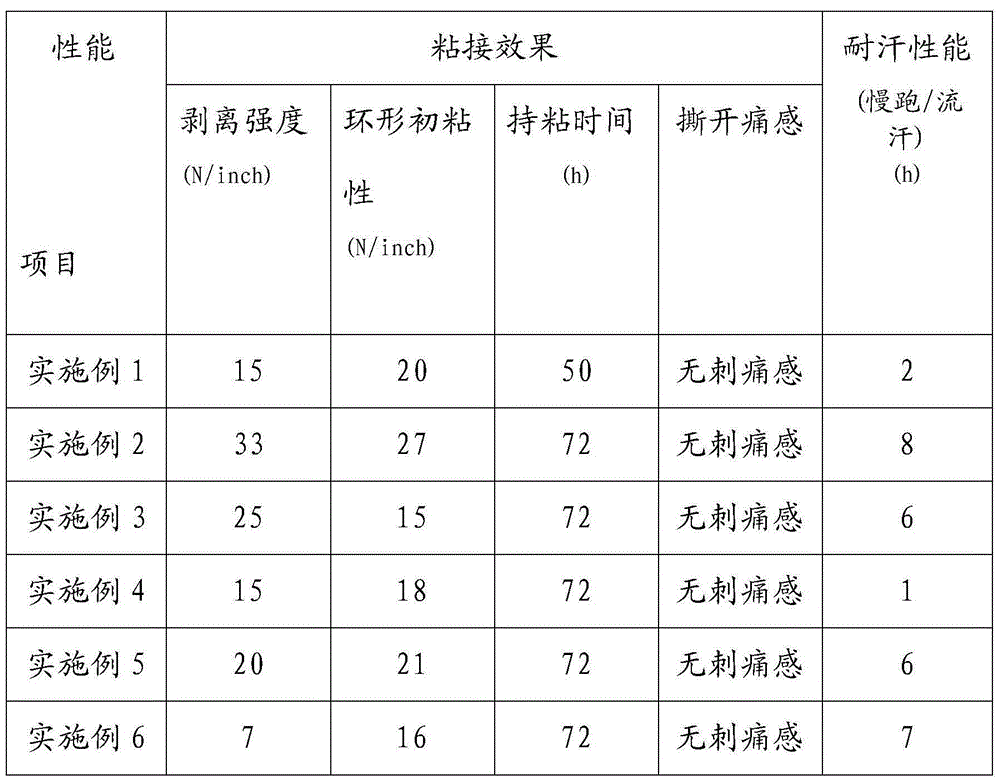

[0032] The specific properties of the obtained medical hot melt adhesive are shown in Table 1.

Embodiment 2

[0034] Utilize above-mentioned SIS and PEG graft product to prepare medical hot-melt adhesive, its raw material is composed according to the following parts by weight: 45 parts of graft product of SIS and PEG, 12 parts of naphthenic oil, 1 part of antioxidant, 38 parts of hydrogenated petroleum resin, 5 copies of SAP.

[0035] Among them, use naphthenic oil 4010, antioxidant 1010, C5 hydrogenated petroleum resin.

[0036] The specific properties of the obtained medical hot melt adhesive are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com