Microwave plasma vacuum film coating device and using method

A microwave plasma and vacuum coating technology, applied in gaseous chemical plating, metal material coating process, coating and other directions, can solve the problems of poor coating uniformity and consistency, chemical substances easily polluting the environment, and low sedimentation rate. , to achieve the effect of improving uniformity and consistency, improving coating production efficiency, and increasing sedimentation rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

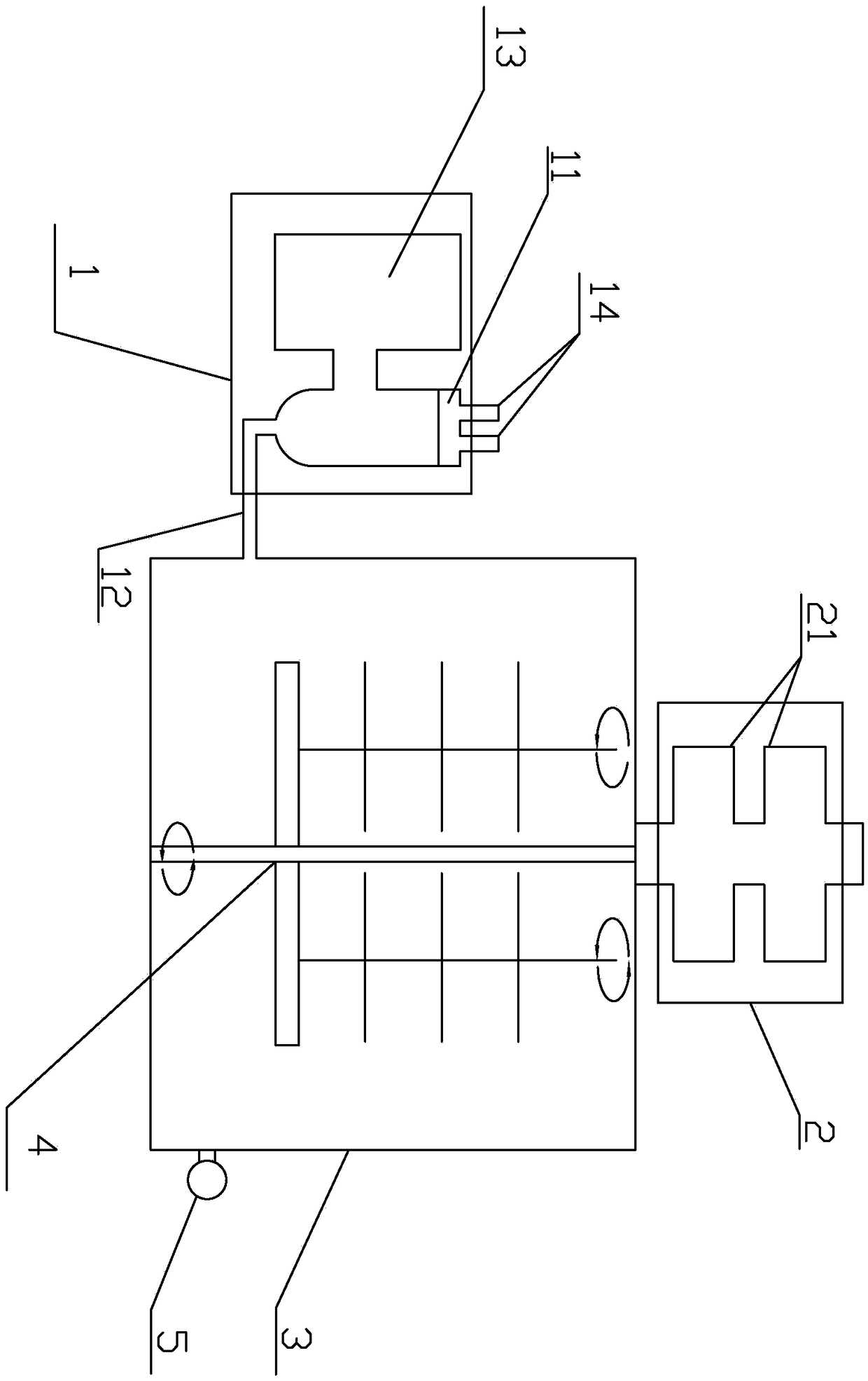

[0031] A microwave plasma vacuum coating equipment, used for coating the motherboard of mobile phone, including plasma generation system 1, vacuum exhaust device 2, plasma vacuum chamber 3 and movement device 4, plasma generation system 1, vacuum exhaust device 2 are set Outside the plasma vacuum chamber 3 , the moving device 4 is arranged inside the plasma vacuum chamber 3 .

[0032] The plasma generation system 1 includes an air inlet 11, an air outlet 12, a plasma field generator 13 for microwave discharge, the air inlet 11 is connected to the outside gas through an air inlet pipe 14, the air outlet 12 and the plasma vacuum chamber 3 connected.

[0033] The air inlet 11 of the plasma generation system 1 has two air inlet pipes 14 .

[0034] The microwave plasma vacuum coating equipment is provided with a plasma generation system 1, and each plasma generation system 1 is connected to a vacuum plasma chamber 3 through a pipeline.

[0035] The vacuum exhaust device 2 include...

Embodiment 2

[0047] A microwave plasma vacuum coating equipment, used for coating the automobile control board, including plasma generation system 1, vacuum exhaust device 2, plasma vacuum chamber 3 and motion device 4, plasma generation system 1, vacuum exhaust device 2 It is arranged outside the plasma vacuum chamber 3 , and the moving device 4 is arranged inside the plasma vacuum chamber 3 .

[0048] The plasma generation system 1 includes an air inlet 11, an air outlet 12, a plasma field generator 13 for microwave discharge, the air inlet 11 is connected to the outside gas through an air inlet pipe 14, the air outlet 12 and the plasma vacuum chamber 3 connected.

[0049] The air inlet 11 of the plasma generation system 1 has five air inlet pipes 14 .

[0050] The microwave plasma vacuum coating equipment is provided with six plasma generation systems 1, and each plasma generation system 1 is connected to a vacuum plasma chamber 3 through a pipeline.

[0051]The vacuum exhaust device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com