Patents

Literature

526 results about "Plant sap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sap is a fluid transported in xylem cells (vessel elements or tracheids) or phloem sieve tube elements of a plant. These cells transport water and nutrients throughout the plant. Sap is distinct from latex, resin, or cell sap; it is a separate substance, separately produced, and with different components and functions.

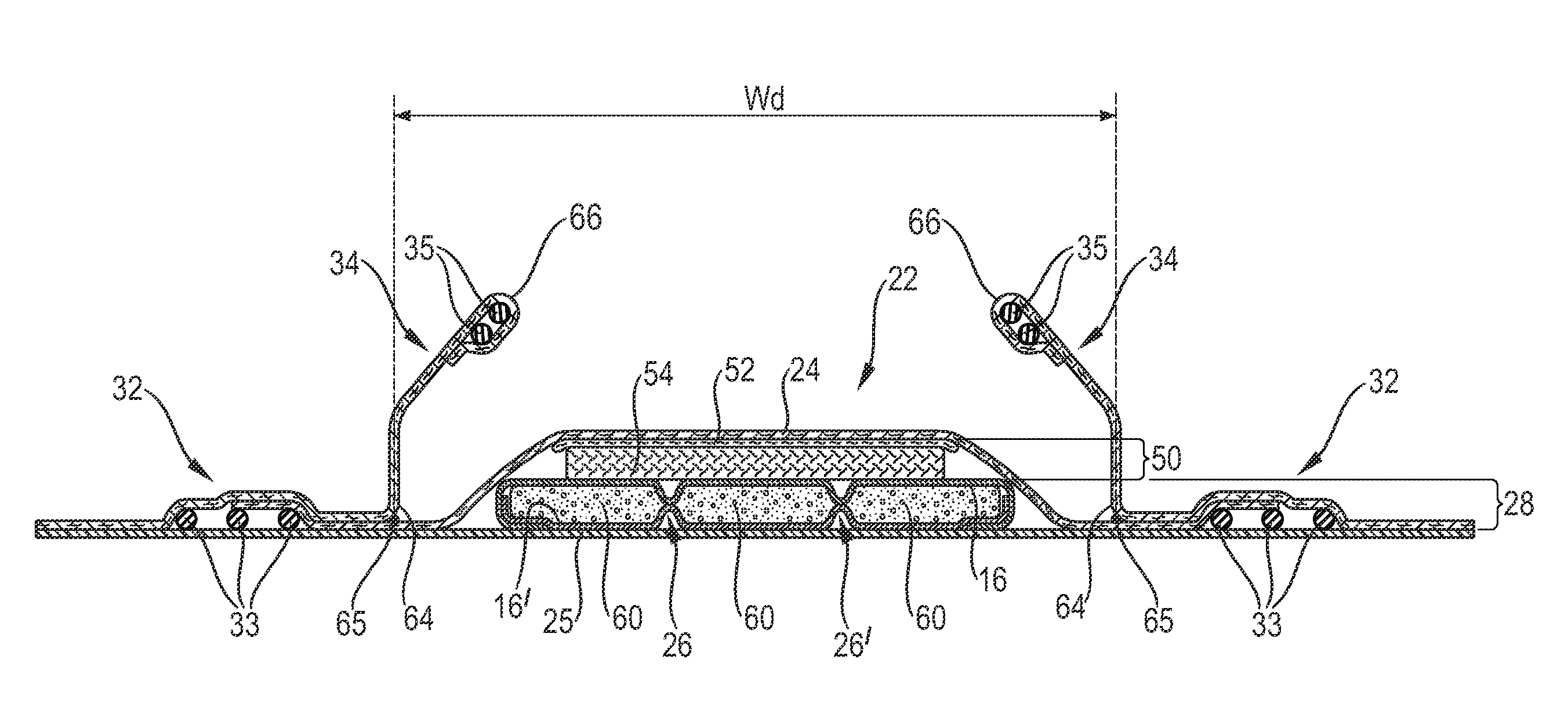

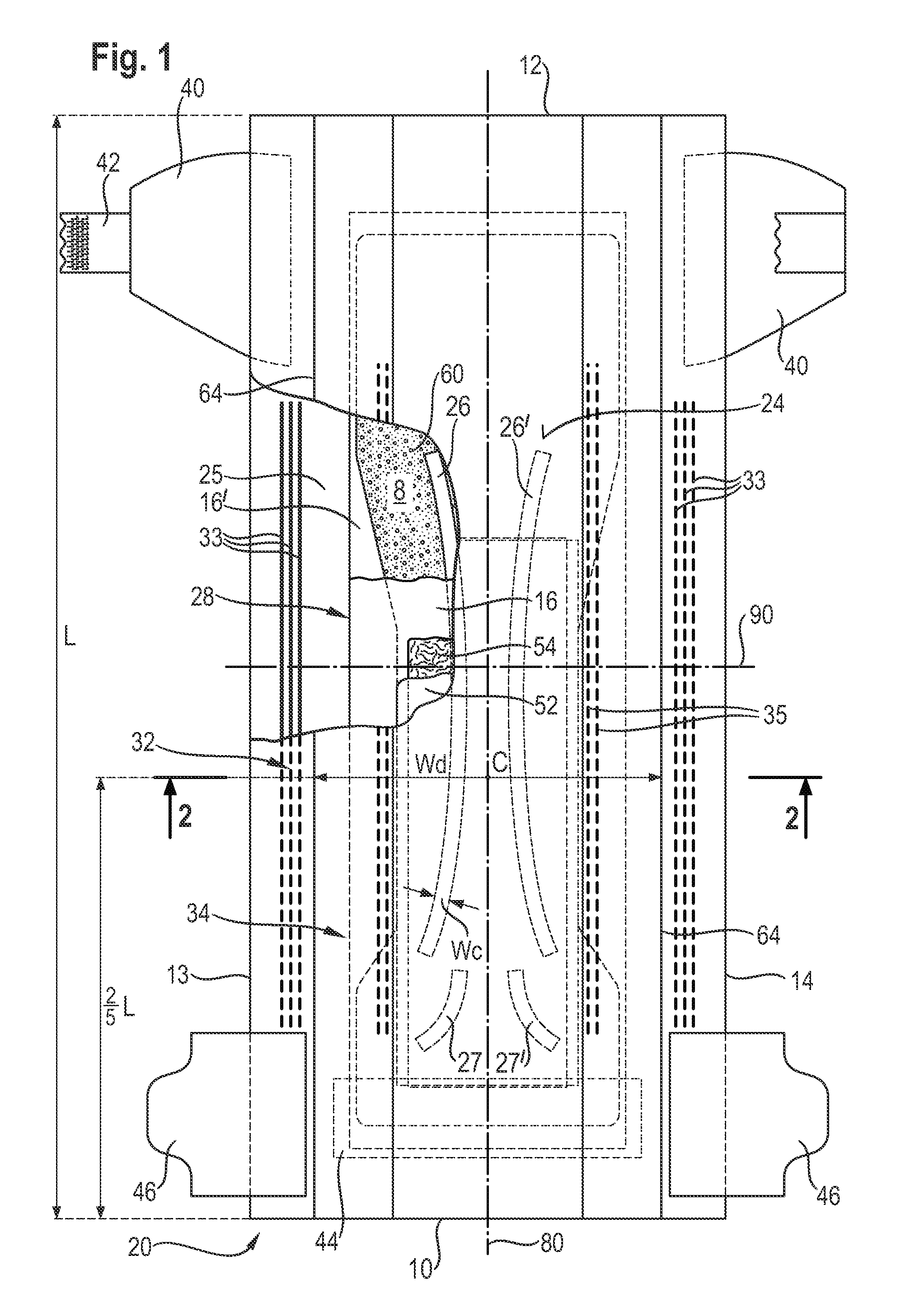

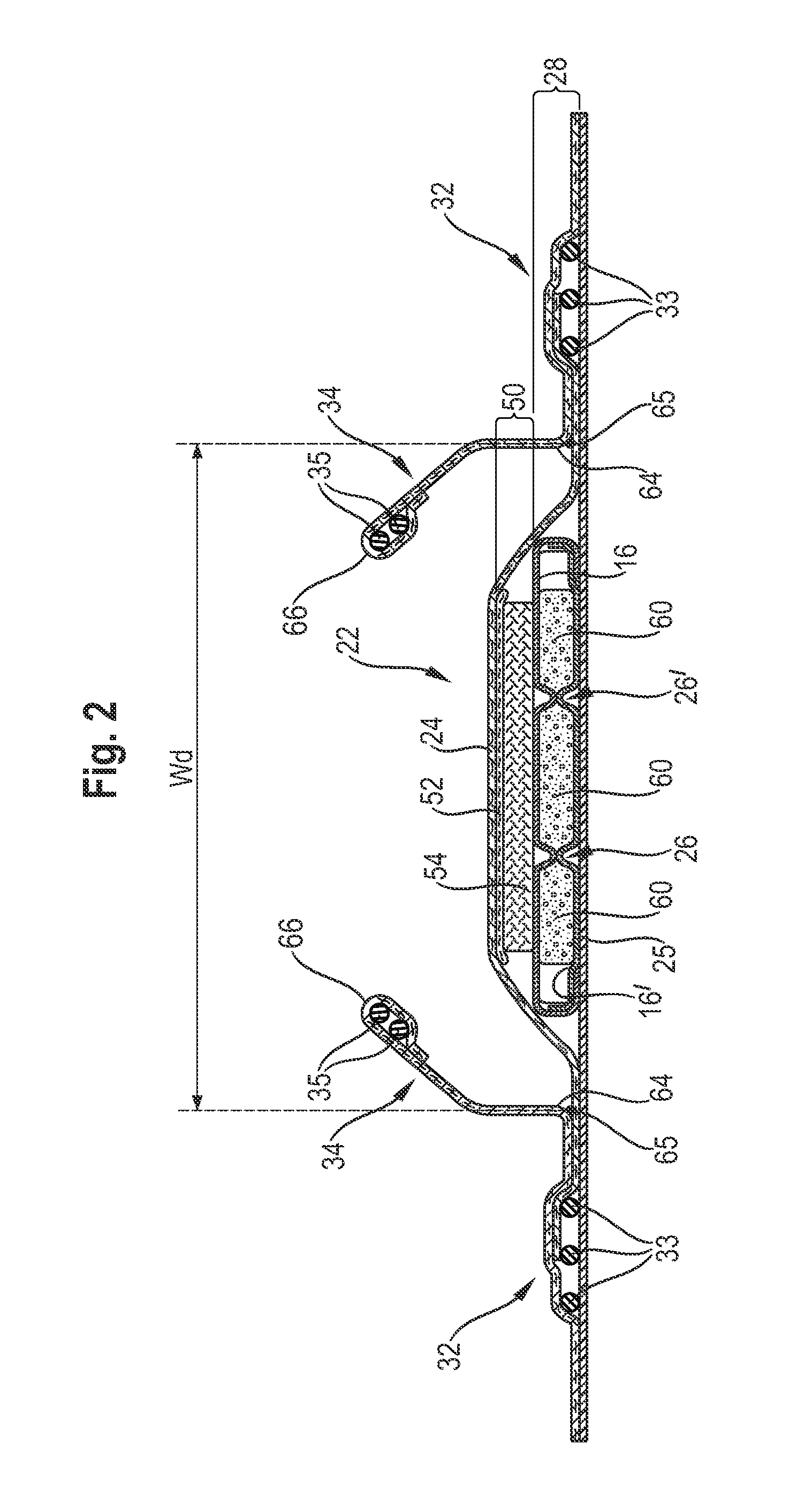

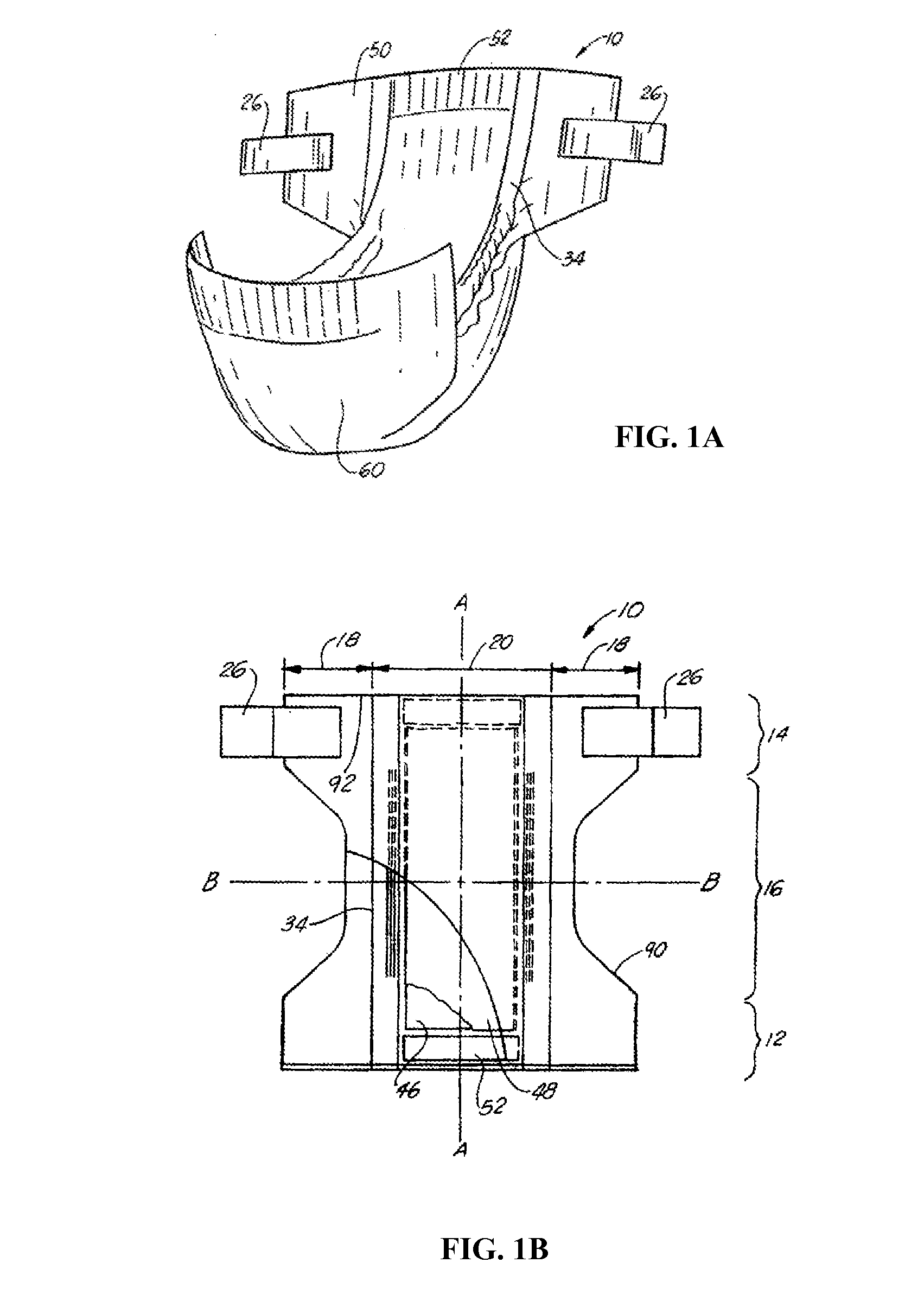

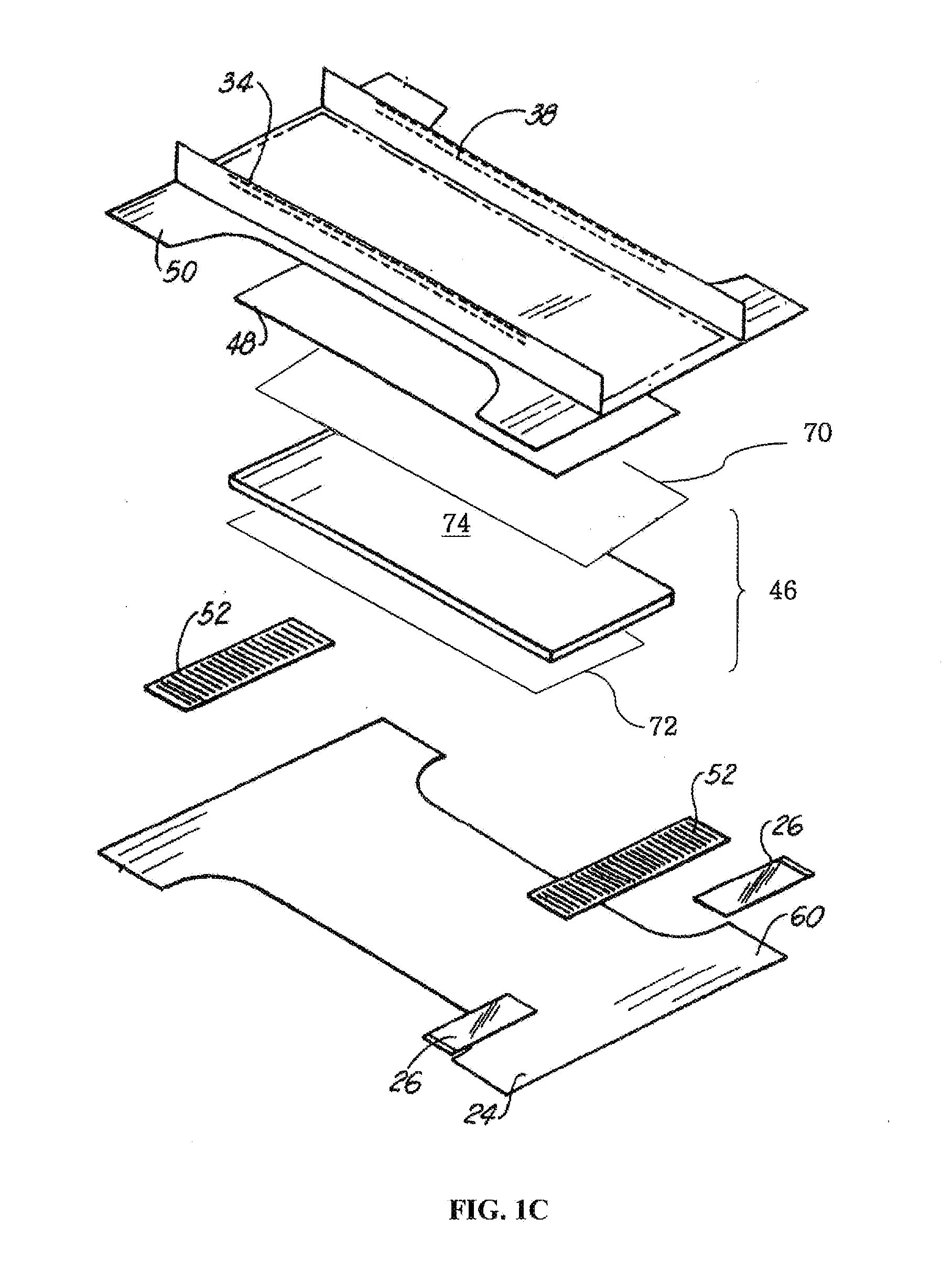

Absorbent article with high absorbent material content

An absorbent article having an absorbent core comprising a core wrap (16, 16′) enclosing an absorbent material (60), which comprises at least 80% of superabsorbent polymers (“SAP”) by weight. The absorbent core further comprises at least one channel (26, 26′) and an acquisition-distribution system (ADS) between the topsheet and the absorbent core, the ADS comprising one, two or more layers wherein the ADS does not comprise a layer comprising at least 50% by weight of synthetic fibers and having a basis weight above 150 gsm.

Owner:THE PROCTER & GAMBLE COMPANY

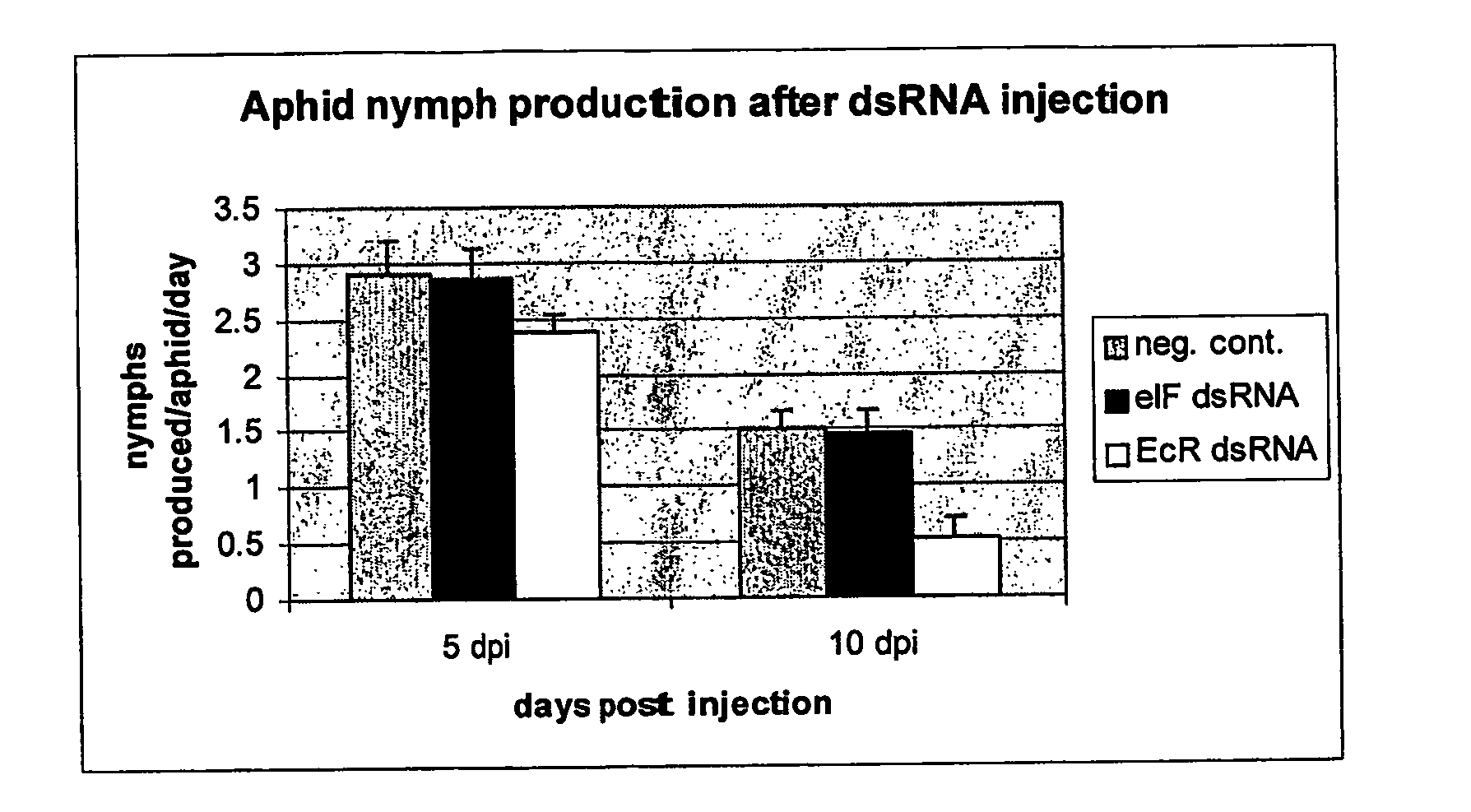

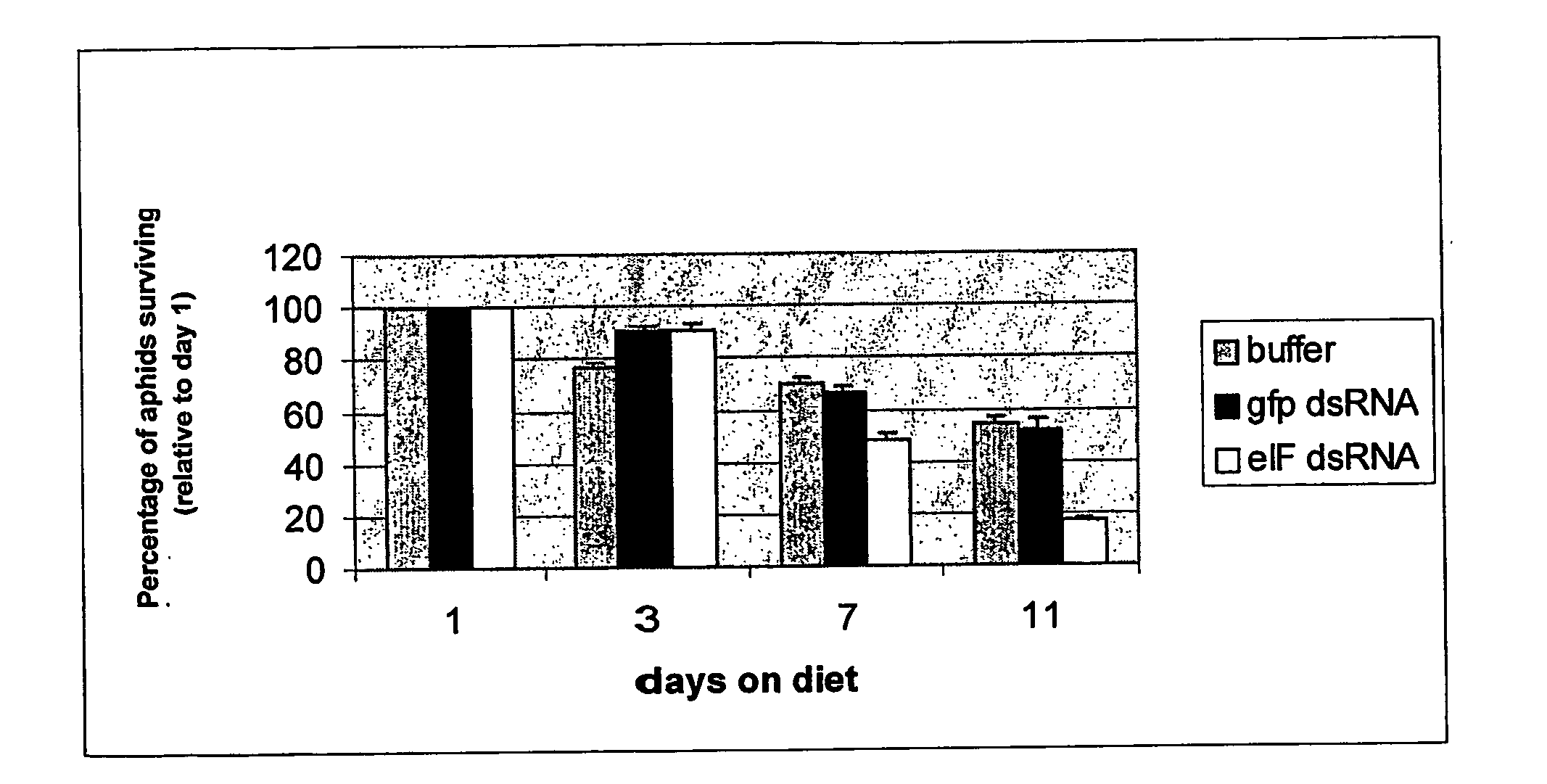

Insect resistance using inhibition of gene expression

The current invention provides methods to silence insect genes by using unpackaged dsRNA or siRNA, in one embodiment such dsRNA or siRNA is present in plant vascular tissue, preferably phloem, more particularly phloem sap, and the insect is a plant sap-sucking insect. Also provided are DNA sequences which when transcribed yield a double-stranded RNA molecule capable of reducing the expression of an essential gene of a plant sap-sucking insect, methods of using such DNA sequences and plants or plant cells transformed with such DNA sequences. Also provided is the use of cationic oligopeptides that facilitate the entry of dsRNA or siRNA molecules in insect cells, such as plant sap-sucking insect cells.

Owner:BASF AG

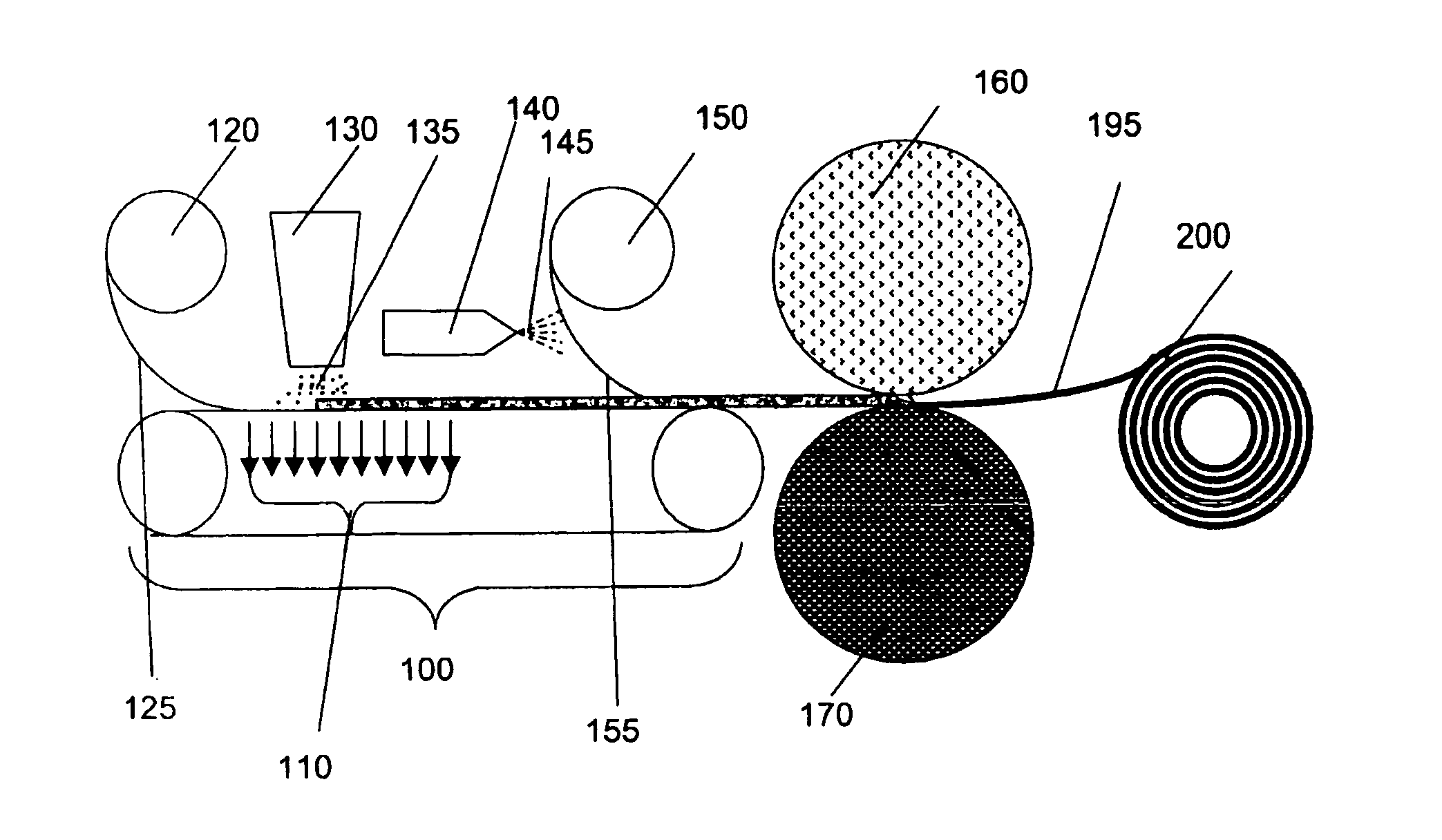

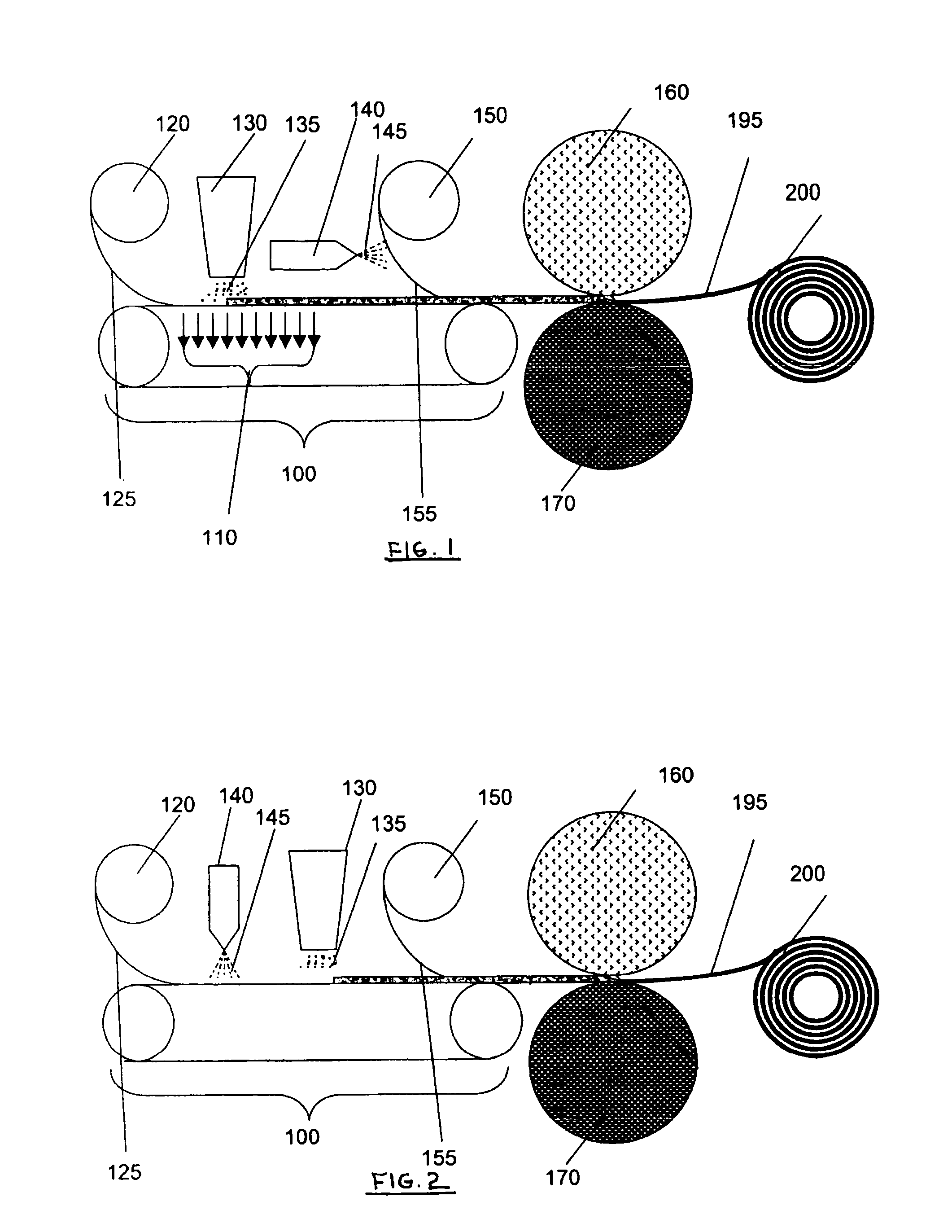

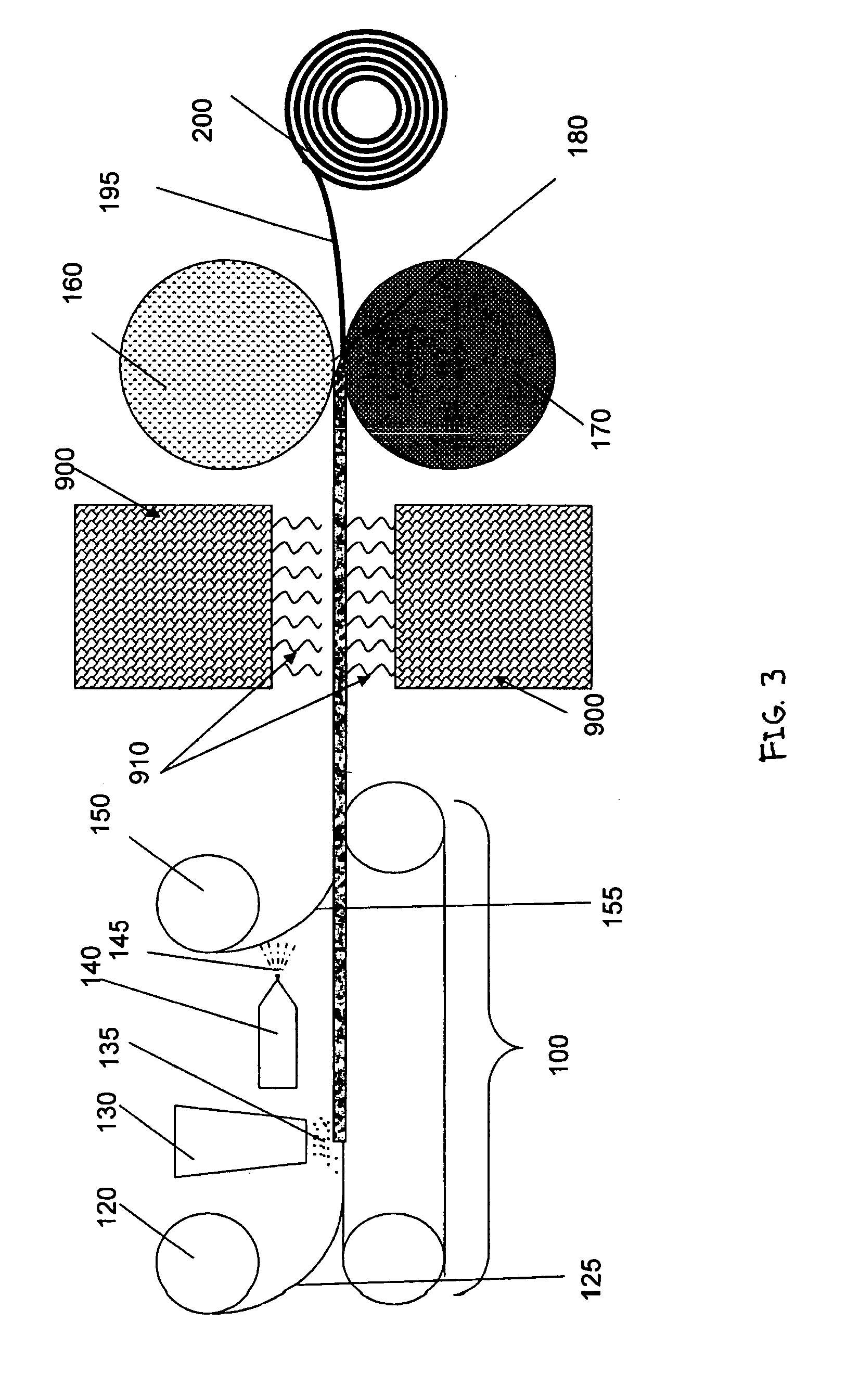

Method of making an absorbent composite and absorbent articles employing the same

Owner:DSG TECH HLDG

Continuous manufacture of superabsorbent/ion exchange sheet material

InactiveUS20020007166A1Increase in sizeNon-fibrous pulp additionWood working apparatusPapermakingIon exchange

A continuous sheet having a combination of acidic and basic water-absorbing resin particles that are essentially not neutralized and can be continuously manufactured on conventional papermaking apparatus, using a wet, dry, or wet-dry process to manufacture a water-absorbent sheet-like substrate containing 50%-100% by weight of the combination of acidic and basic water-absorbent particles. The acidic and basic essentially unneutralized resins can be contained in the sheet material articles of the present invention as separate acidic and basic resin particles, or as multicomponent particles containing both the acidic and basic resins. The sheet materials can be manufactured having new and unexpected structural integrity, with little or no shakeout or loss of superabsorbent particles during or after manufacture while exhibiting exceptional water absorption and retention properties. The sheet materials have an ability to absorb liquids quickly, demonstrate good fluid permeability and conductivity into and through the resin particles, and have a high gel strength such that the hydrogel formed from the SAP particles resists deformation under an applied stress or pressure, when used alone or in a mixture with other water-absorbing resins.

Owner:BASF AG

Superabsorbent polymers and method of manufacturing the same

InactiveUS20050245393A1Continuous processingSmall particle sizeOther chemical processesAbsorbent padsPolymer scienceSuperabsorbent polymer

Surface-crosslinked superabsorbent polymer (SAP) particles having a clay in the vicinity of the surfaces of the SAP particles a clay are disclosed. The clay is added to SAP particles during surface crosslinking to substantially reduce the generation, and recycling, of SAP fines, and to provide SAP particles having an improved acquisition rate of fluids and an improved permeability of a fluid through the swollen SAP particles. Diaper cores and absorbent articles containing the surface crosslinked SAP particles also are disclosed.

Owner:BASF AG

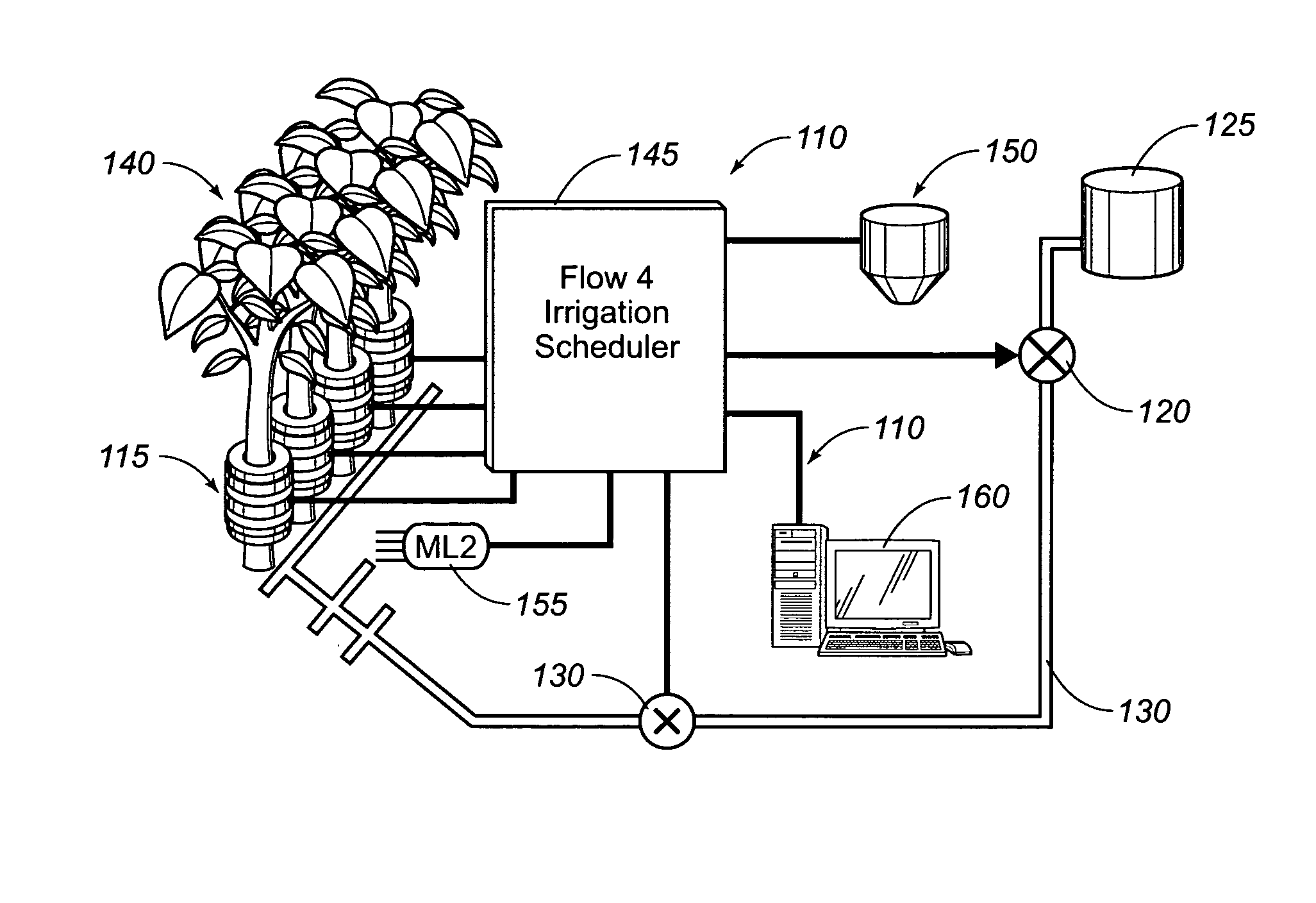

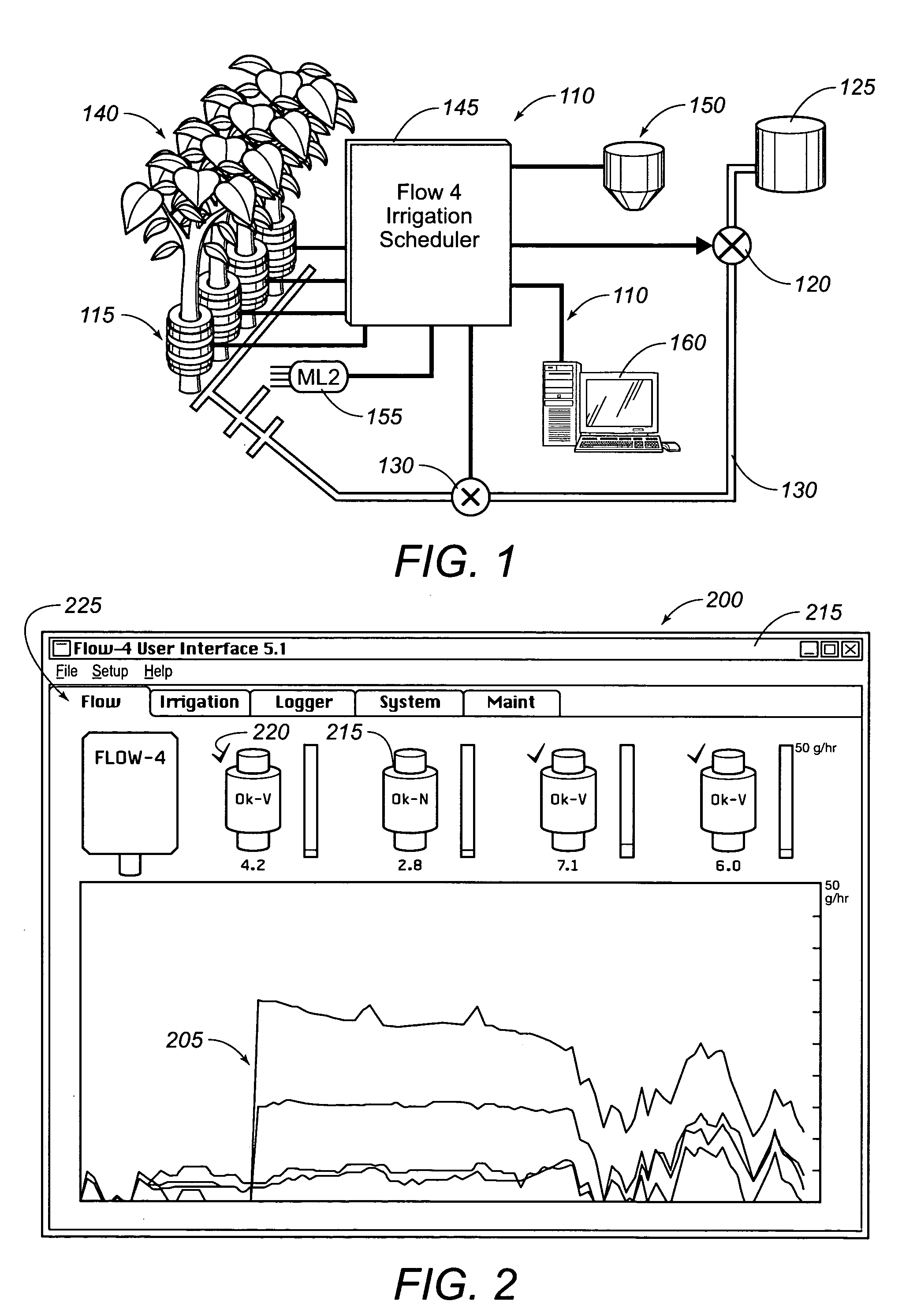

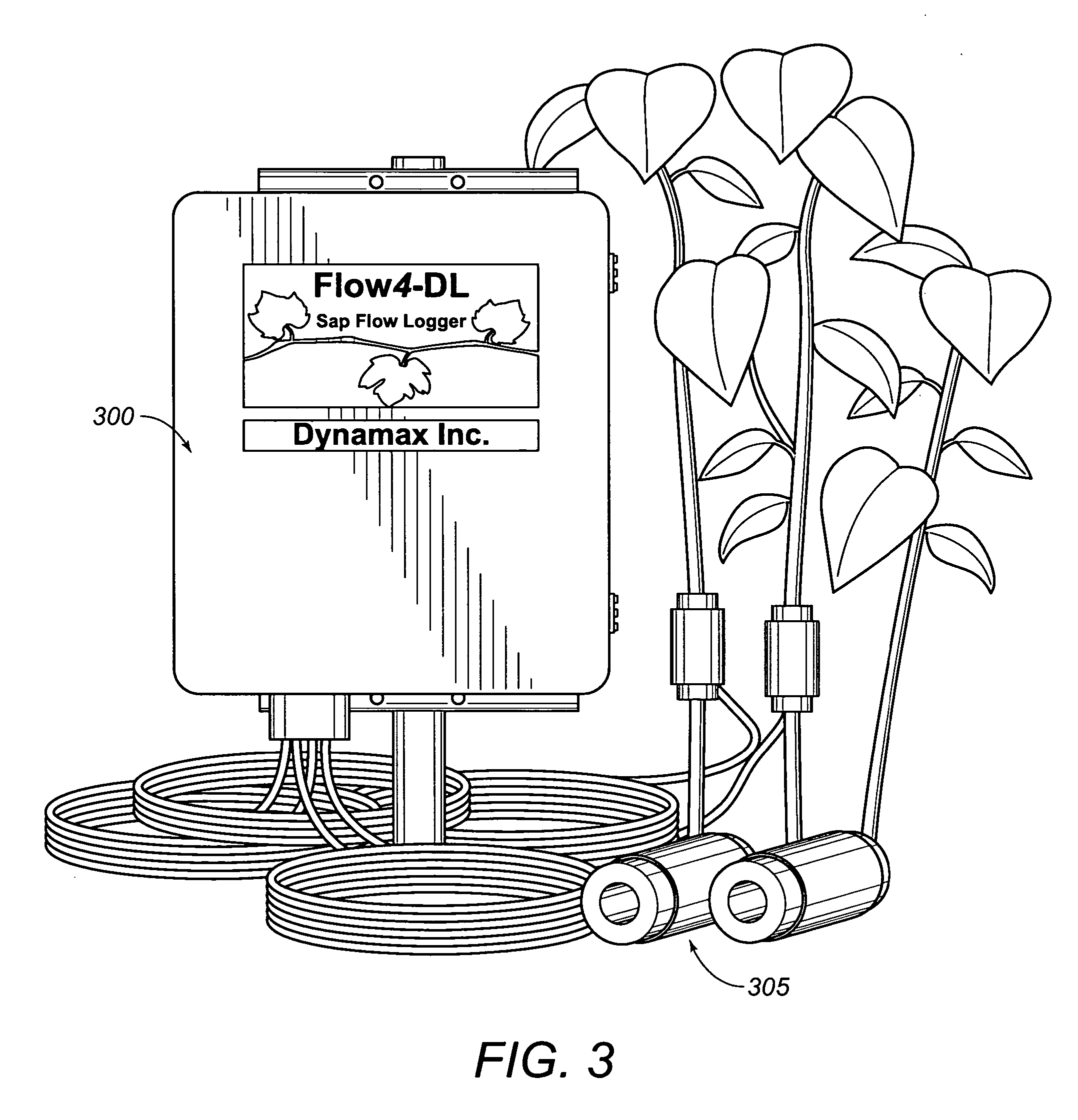

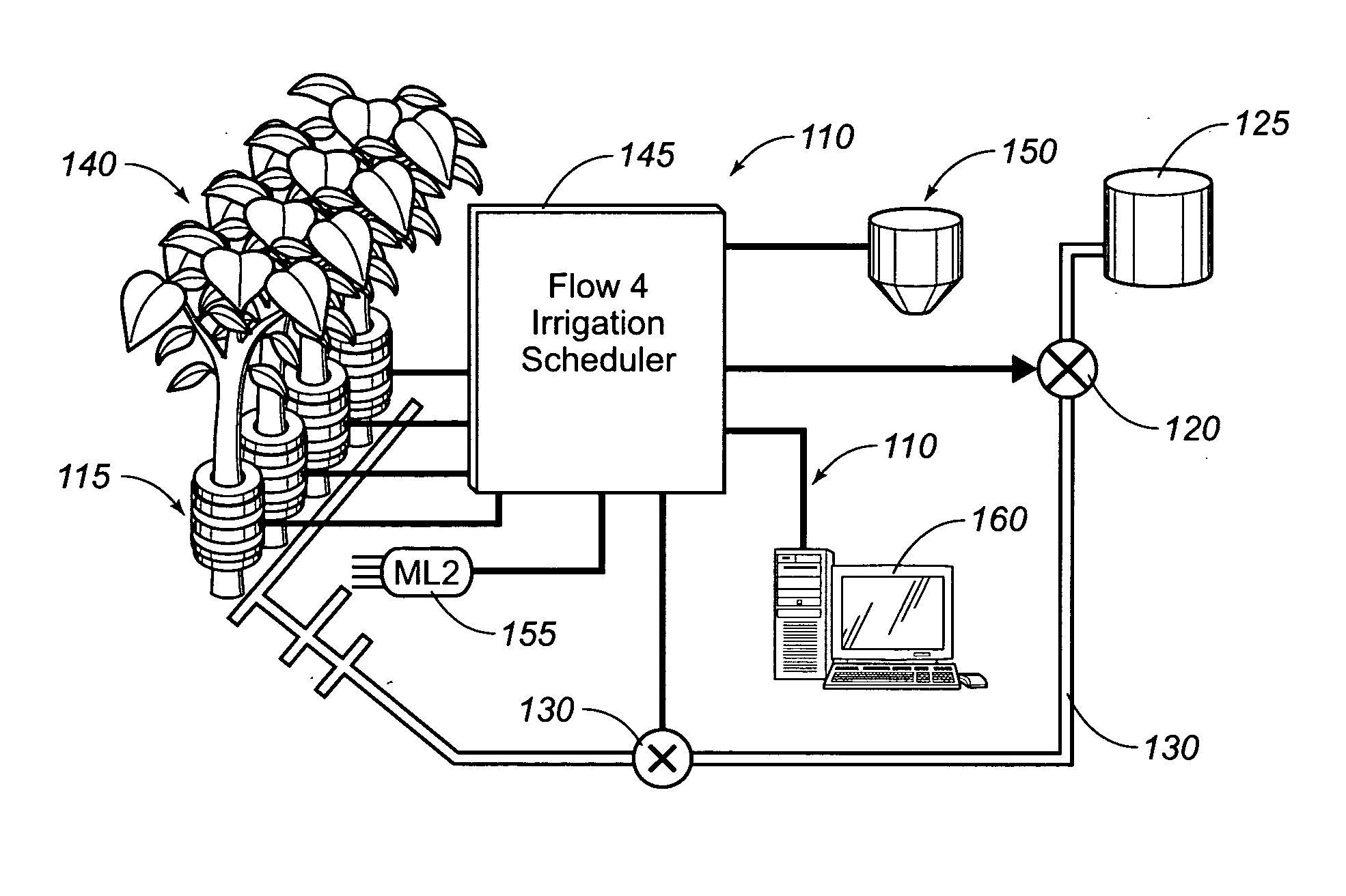

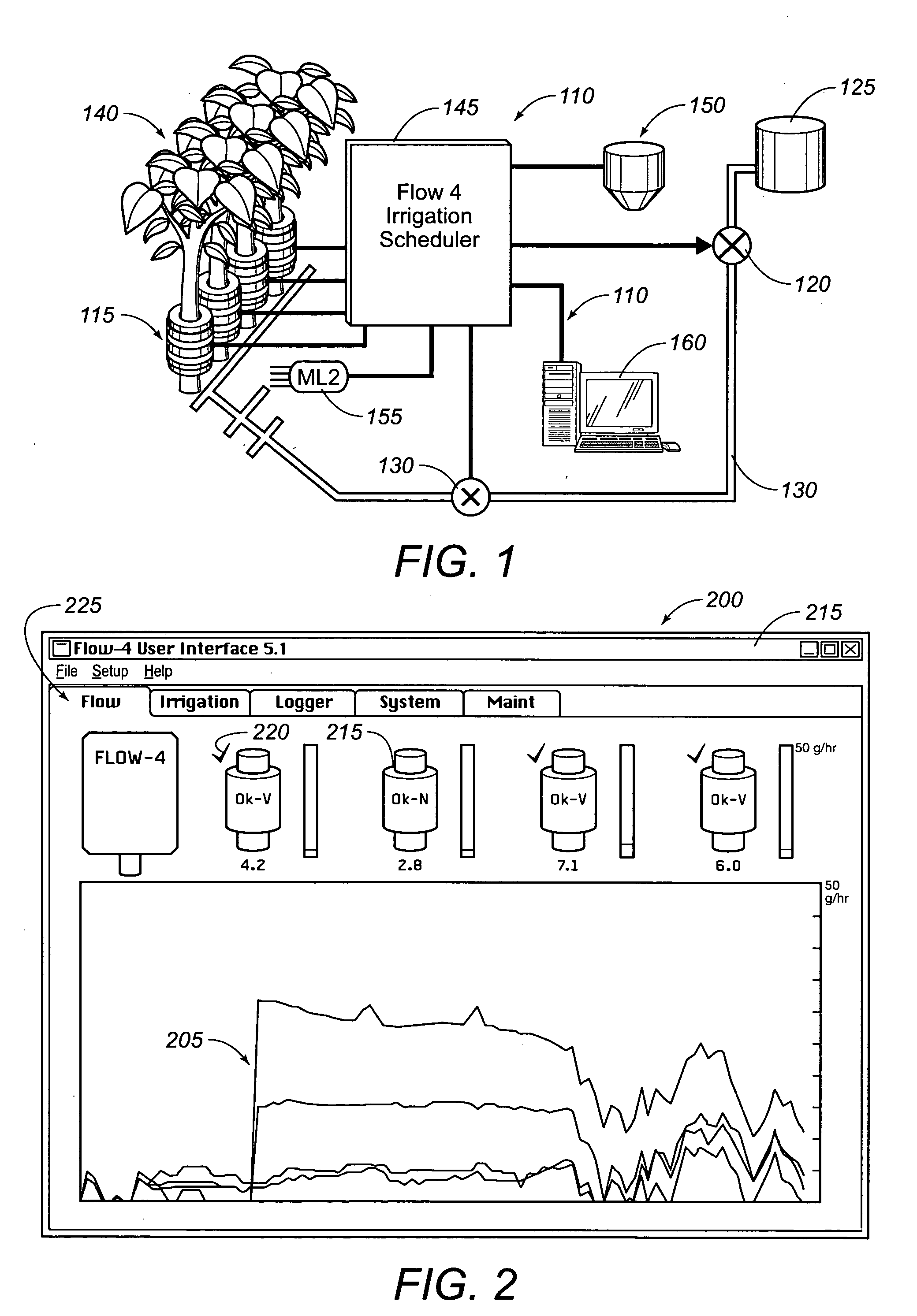

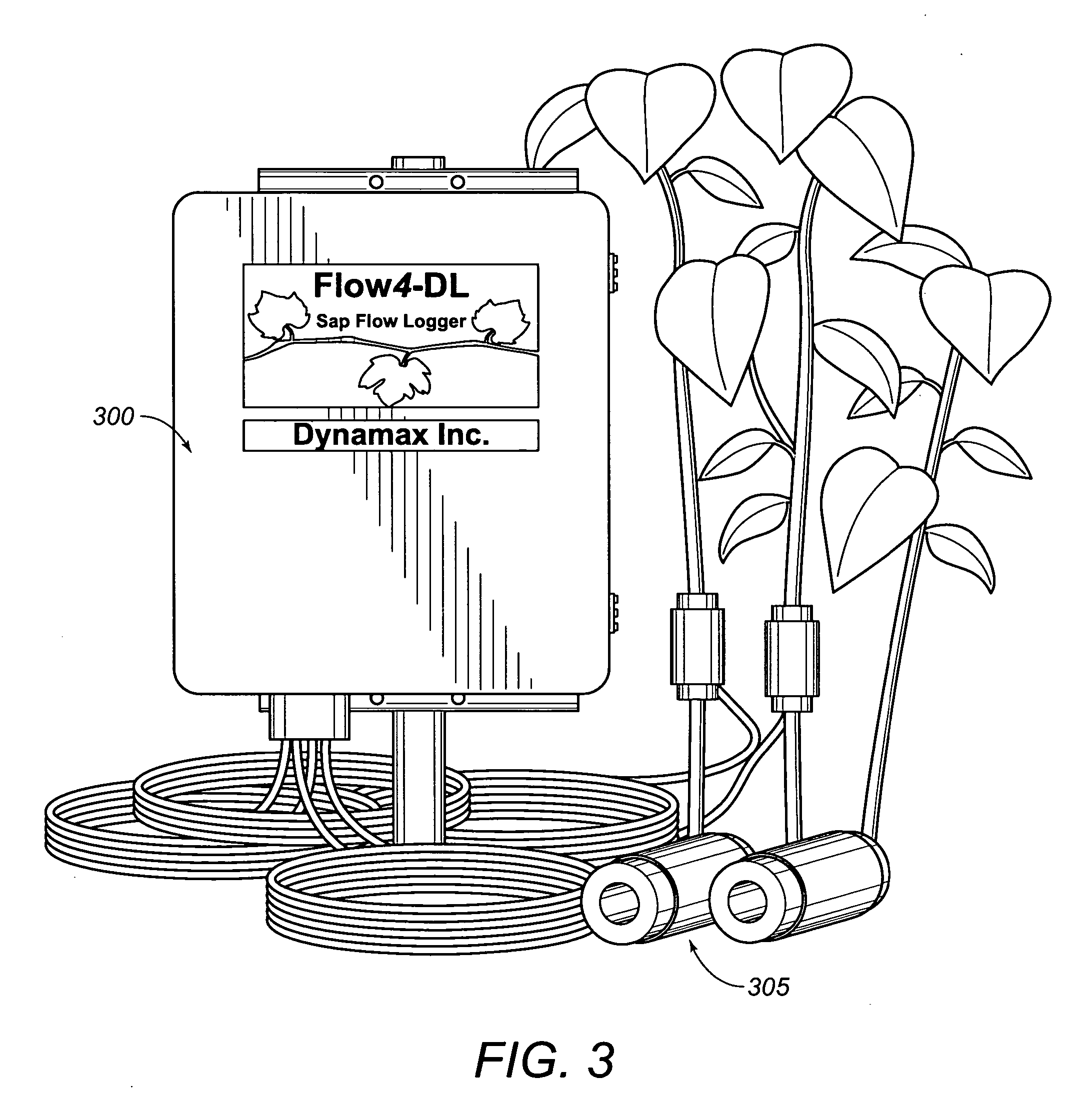

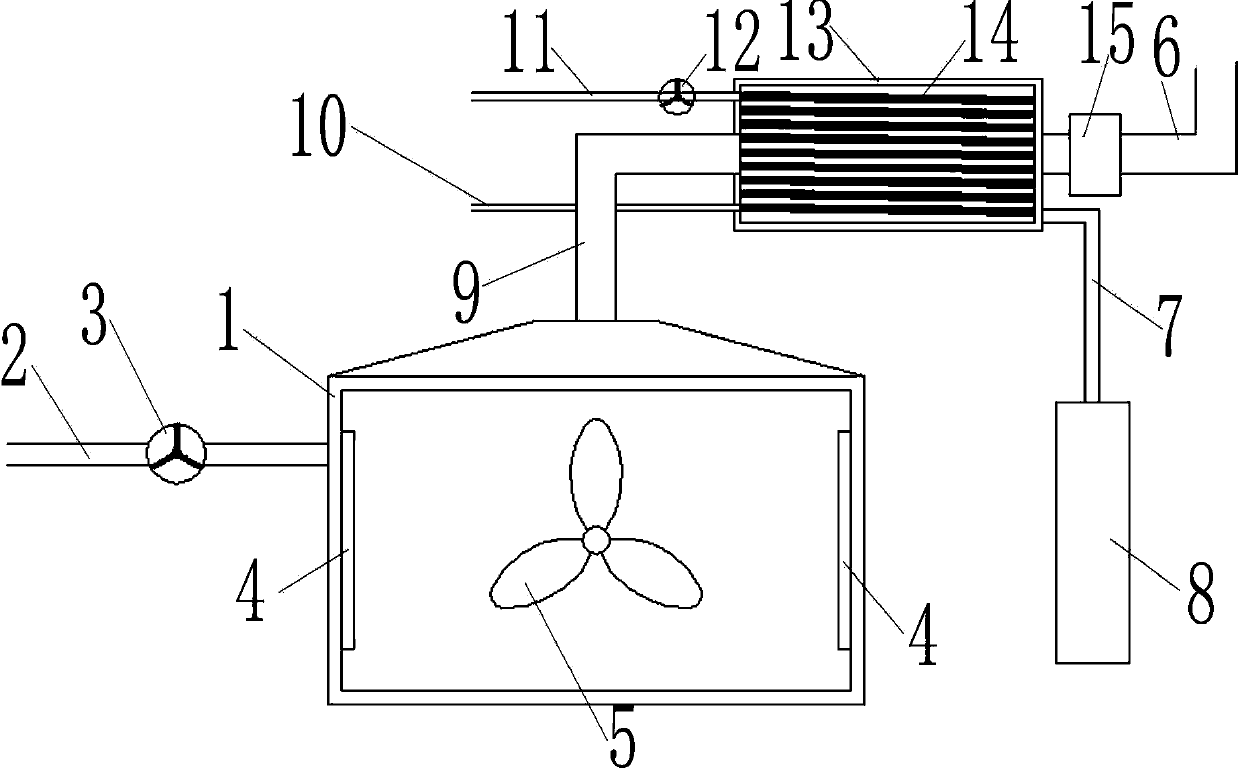

Integrated sap flow monitoring, data logging, automatic irrigation control scheduling system

ActiveUS7280892B2Accurate measurementReduce errorsSelf-acting watering devicesWatering devicesClosed loopUser interface

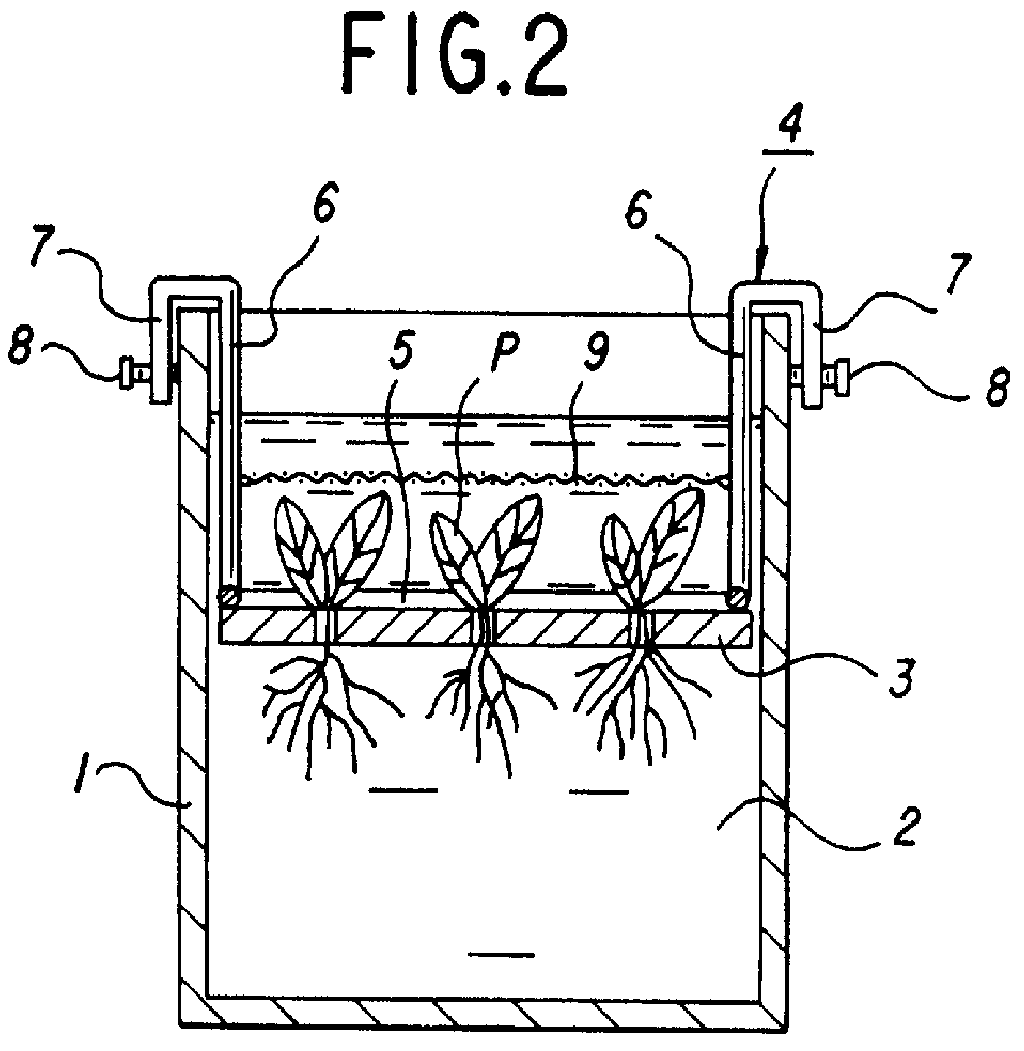

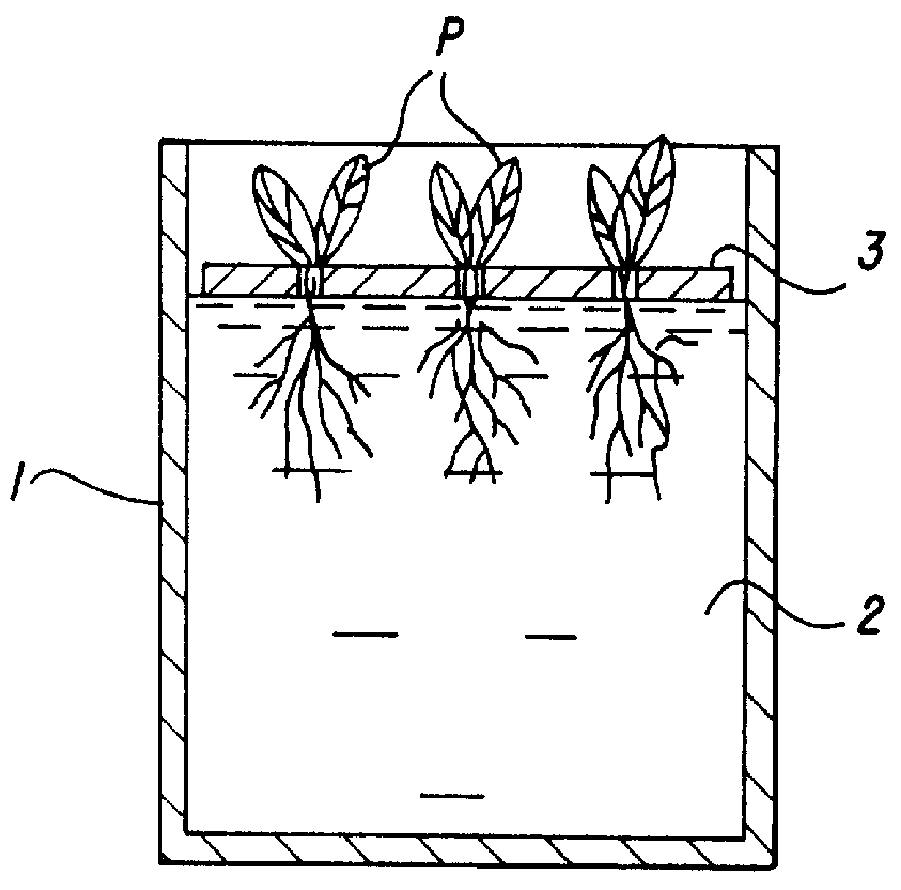

An integrated system for monitoring sap flow and simultaneously performing data-logging and automatically scheduling irrigation in a field; comprising a plurality of in situ sap flow gauges that perform its comprehensive computer-controlled tasks in the field being irrigated. This plurality of sap flow gauge can be detached from and reattached to a like plurality of plant stems as appropriate. A scaling mechanism is used to calculate crop water usage in variously-sized fields. An integrated portable computer apparatus is programmed to perform a plurality of actions including sap flow monitoring via a controller and data-logger; data-logging and automatic irrigation scheduling; a plurality of sap flow gauges; an automatic rain gage; a water meter; an irrigation valve actuator; and any auxiliary and independent weather or soil monitoring sensors. The system is connected to a PC, mounted in a weatherproof enclosure, and powered by rechargeable battery, solar panel, or AC mains power with battery backup. Computerized monitoring and control procedures are initialized via a custom-developed graphical user interface. At any predetermined interval set by a user, the depth or volume of water required to balance transpiration losses is calculated and irrigation is then automatically triggered. The system affords closed loop control with water flow from soil through plant to atmosphere and from irrigation—and having the benefit of a feedback loop.

Owner:BAVEL MICHAEL VAN

Aqueous coating composition for golf ball and golf ball using the same

InactiveUS6509410B2Simple designIncrease stickinessPolyurea/polyurethane coatingsGolf ballsWater dispersibleAcrylic resin

The aqueous coating composition of the present invention can form a high crosslink density owing to the high hydroxyl value, contains a soft urethane structure and alicyclic structure possessed by the water-soluble urethane polyol and the water-dispersible urethane resin, and also contains tough isocyanurate ring structures possessed by the water-dispersible acrylic resin and the hydrophilic polyisocyanate; accordingly, can give a coating film which is high in impact resistance, abrasion resistance, contamination resistance, etc., which has properties equivalent to those possessed by the films produced from organic solvent type coatings, and which has high durability; therefore, is most suitable for coating a golf ball to be hit by a golf club. A golf ball coated with the aqueous coating composition of the present invention is free from cracking or film peeling when hit by a golf club; is low in scratch, abrasion and contamination with grass sap; therefore, can retain gloss and fine appearance.

Owner:BRIDGESTONE SPORTS

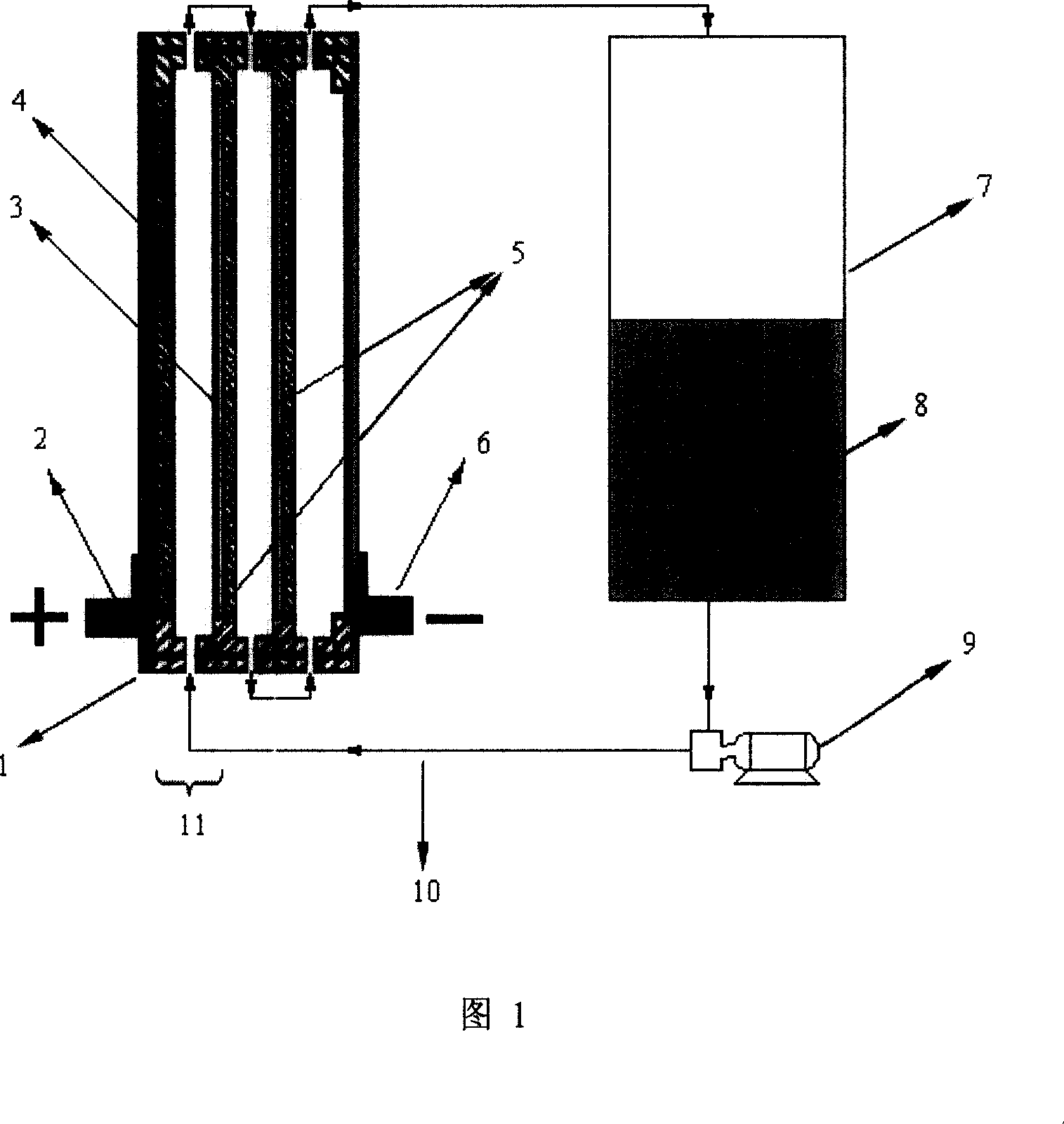

A Zn-Ni liquid battery

ActiveCN101127393AIncrease transfer speedDetoxificationElectrolyte moving arrangementsAlkaline accumulatorsEngineeringNickel electrode

The utility model relates to a zinc-nickel sap fluid cell, which comprises a galvanic pile which is a multi-section series connection of cell monomers, electrolyte, a storage tank, a liquid pump and a plurality of pipelines; wherein, the cell monomer comprises a nickel electrode anode, a cathode current collector of deposit zinc, and electrolyte; wherein, the electrolyte is a zincous alkaline solution, and two cell monomers are connected in series via a bipolar plate. In the process of charge and discharge, the electrolyte continuously flows between the storage tank and the galvanic pile via the pipelines driven by the liquid pump. Zinc settles onto the cathode current collector and becomes a cathode active substance from the electrolyte at the time of charging, while zinc dissolves into the electrolyte from the cathode current collector at the time of discharging. The utility model has the advantages of simple fabrication technology, low cost, high cycle life and other advantages.

Owner:NO 63971 TROOPS PLA +1

Superabsorbent polymers and method of manufacturing the same

InactiveUS20050239942A1Small particle sizePromote absorptionOther chemical processesAbsorbent padsPolymer scienceSuperabsorbent polymer

Superabsorbent polymer (SAP) particels containing a clay are disclosed. The clay is added to an SAP hydrogel prior to SAP neutralization to provide particles having improved fluid acquisition rates and an improved permeability of a fluid through the swollen SAP-clay particles. Diaper cores and absorbent articles containing the SAP-clay particles also are disclosed.

Owner:BASF AG

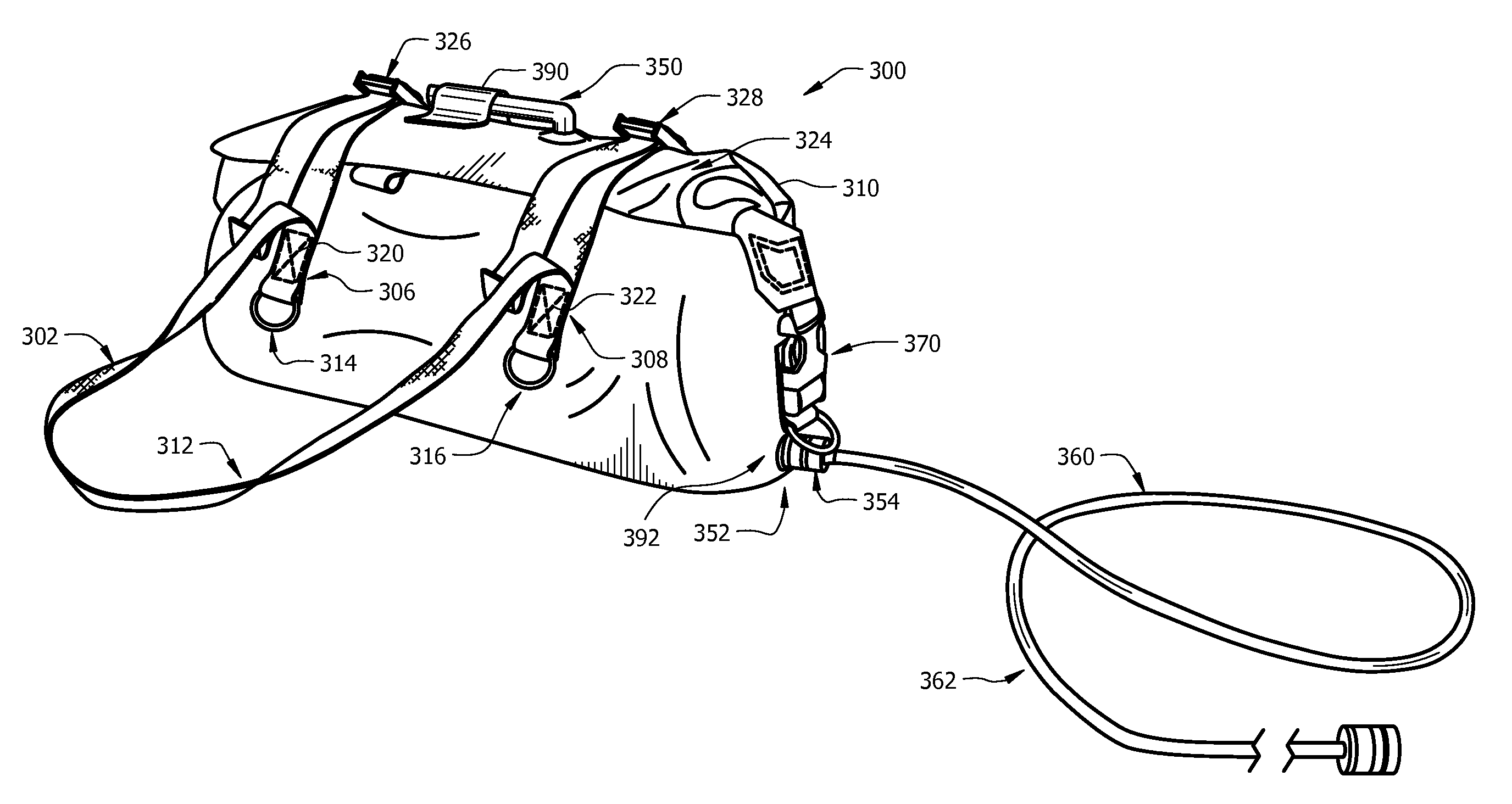

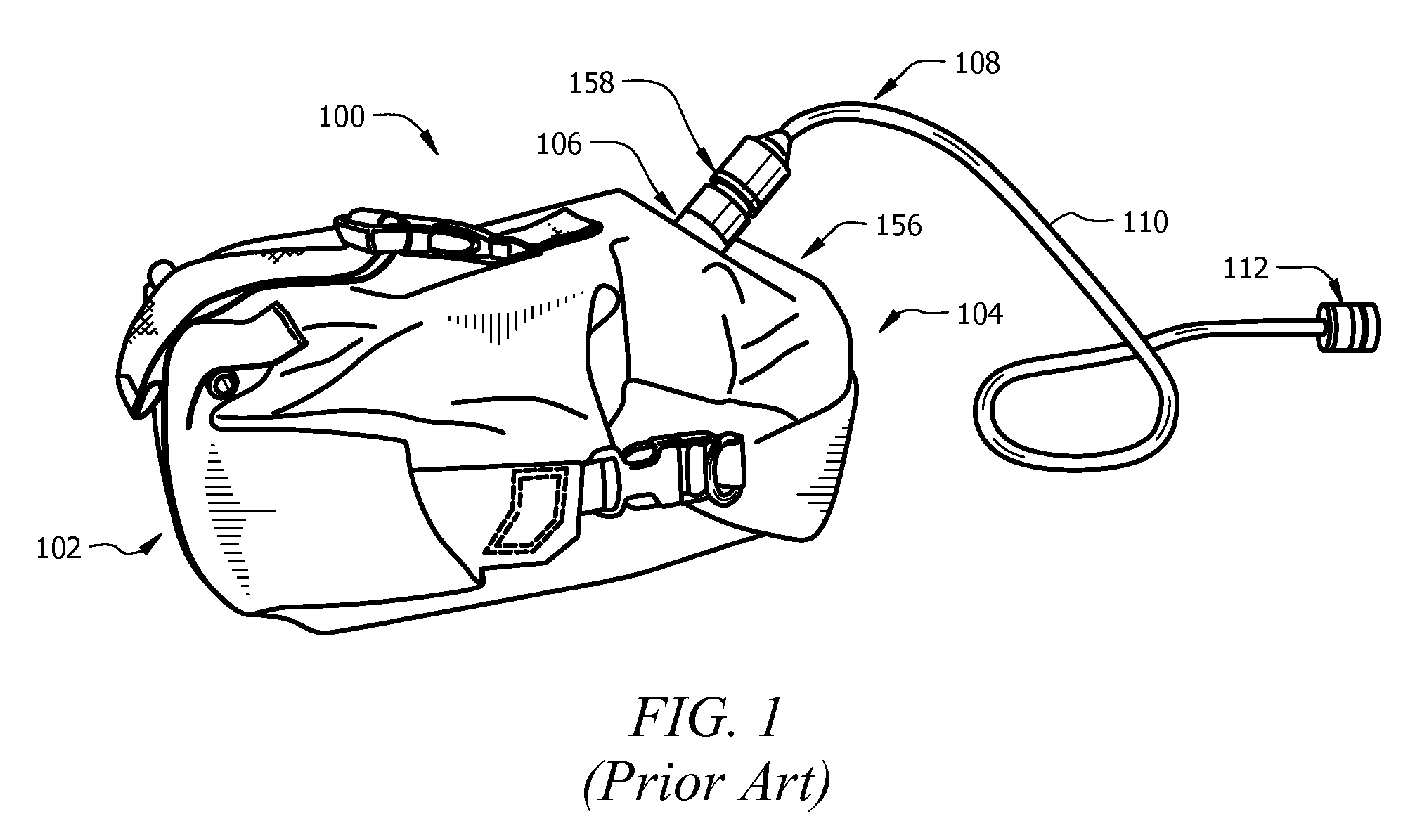

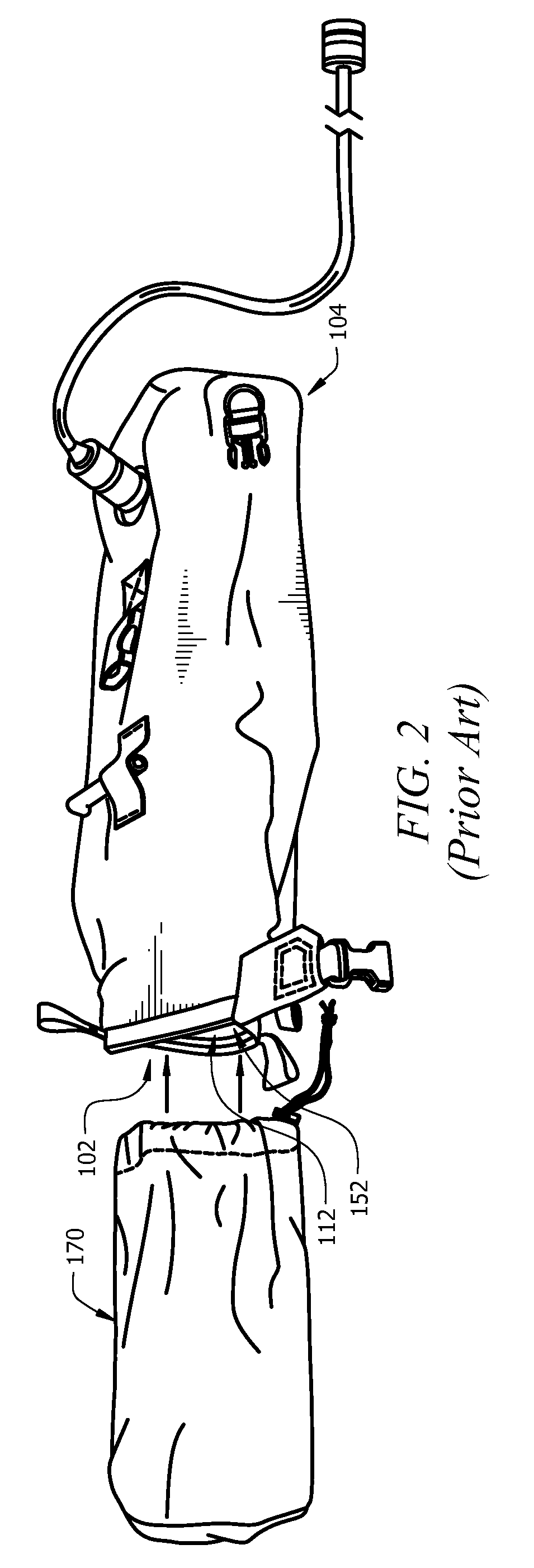

Battery bag

A battery bag assembly including an elongated watertight bag (WTB), a sealable access port (SAP), a battery tray (BT), a power feed-through (PFT), and an electric power conduit (EPC). SAP (402) has an elongated configuration extending along an elongated length of the WTB. BT (600) is disposed within the WTB so that its elongated configuration is aligned with the elongated length of the WTB. BT has electrical connector sockets (EPSs) mounted thereon for mating with oppositely sexed connectors provided on batteries. PFT (352) is disposed on a wall of the watertight bag. PFT is configured to provide a watertight seal for an electrical conductor passing from an interior of the watertight bag to an exterior of the watertight bag. EPC (360) is electrically connected for coupling electric power from the EPSs on the BT to a remote device.

Owner:HARRIS CORP

Dry composition based on mineral binder and intended for the preparation of a hardenable wet formulation for the construction industry

ActiveUS20140371351A1Easy to getEasy to useTransportation and packagingMixing methodsBuilding productFoaming agent

Owner:PAREXGROUP SA

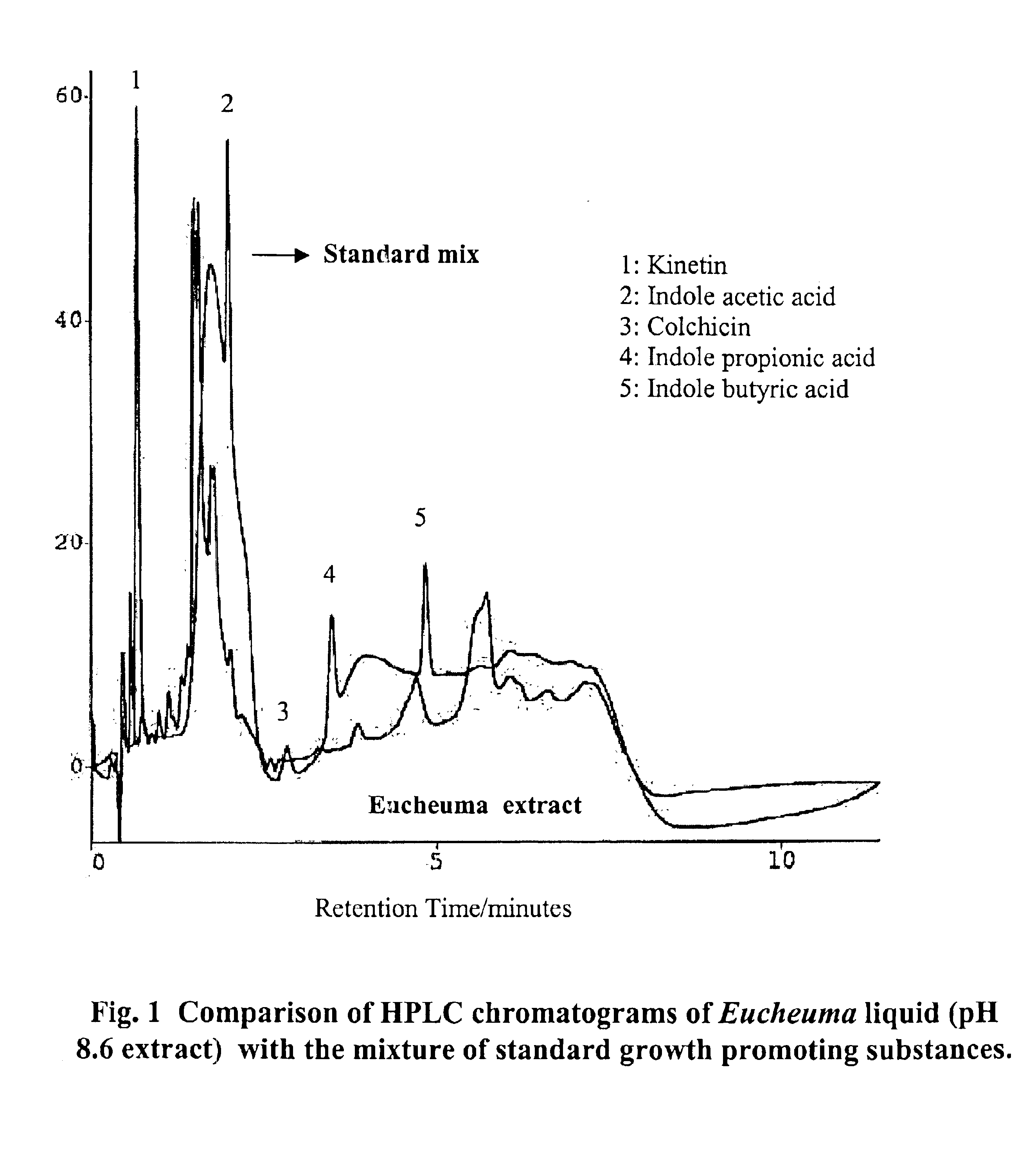

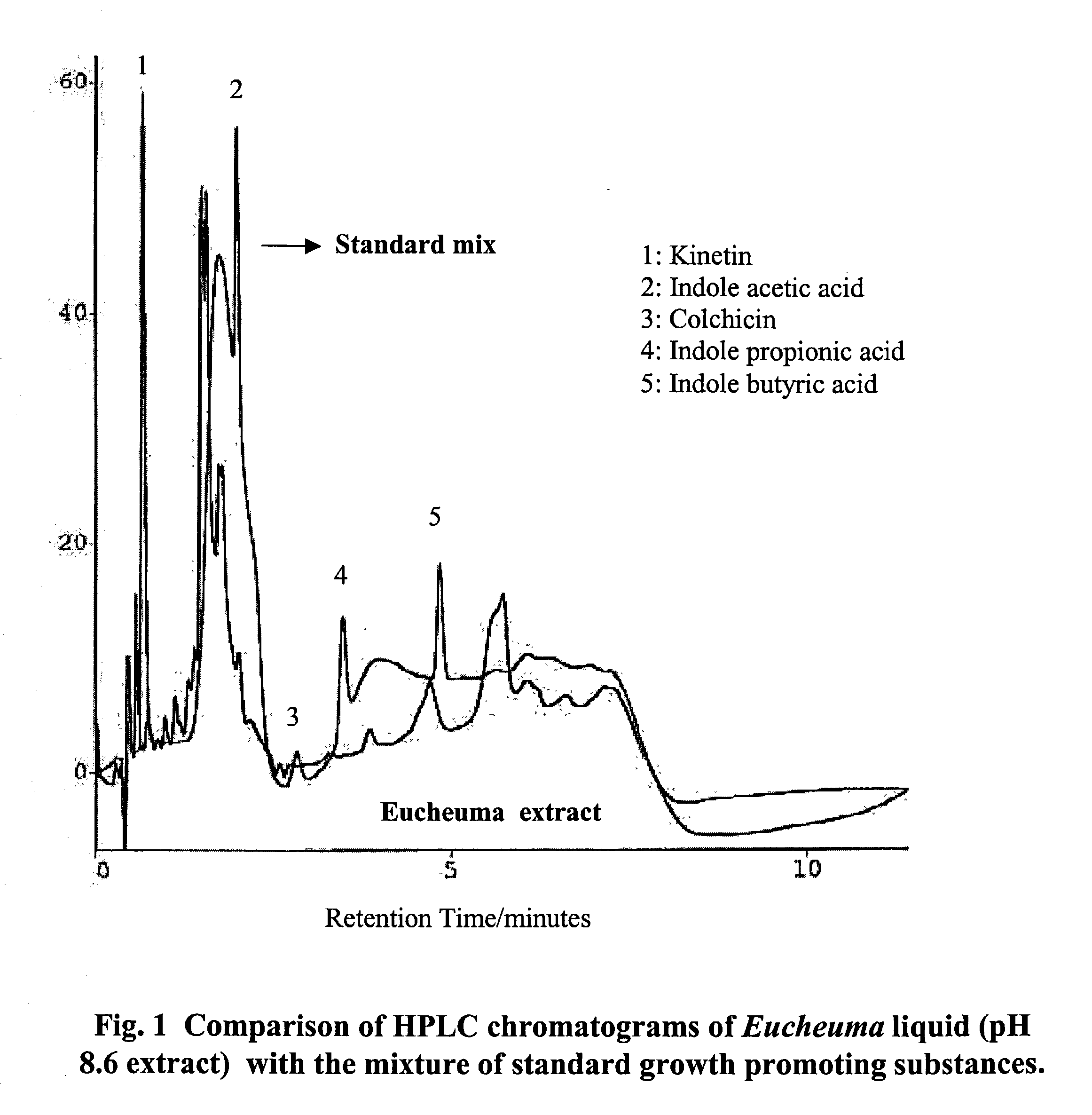

Integrated method for production of carrageenan and liquid fertilizer from fresh seaweeds

An integrated method is developed to utilize to a maximum extent the fresh biomass of seaweeds such as Kappaphycus alvarezii that can be crushed to release sap and where the sap is useful as a potent liquid fertilizer after suitable treatment with additives and dilution while the residue is a superior raw material for extraction of κ-carrageenan, thereby enhancing the value of the seaweed. Other advantages of the invention include a reduced drying time and drying area to obtain the raw material for κ-carrageenan production in dry and storable form, a reduced cost of transporting and storing this raw material because of its lesser bulk, easier handling due to its free flowing granular nature, and its direct use for gel preparation in certain applications.

Owner:COUNCIL OF SCI & IND RES

Superabsorbent polymers in agricultural applications

Superabsorbent polymer (SAP) products for use in agricultural applications, and methods of making and using the same are disclosed. Certain of the SAPs include a monomer or a mixture of monomers, other than acrylonitrile, that is graft polymerized onto a starch in the presence of an initiator to form a starch graft copolymer that is cross-linked and the SAP product is isolated.

Owner:ABSORBENT TECHNOLOGIES INC

Integrated sap flow monitoring, data logging, automatic irrigation control scheduling system

ActiveUS20050121536A1Accurate measurementReduce errorsSeed and root treatmentSelf-acting watering devicesClosed loopUser interface

An integrated system for monitoring sap flow and simultaneously performing data-logging and automatically scheduling irrigation in a field; comprising a plurality of in situ sap flow gauges that perform its comprehensive computer-controlled tasks in the field being irrigated. This plurality of sap flow gauge can be detached from and reattached to a like plurality of plant stems as appropriate. A scaling mechanism is used to calculate crop water usage in variously-sized fields. An integrated portable computer apparatus is programmed to perform a plurality of actions including sap flow monitoring via a controller and data-logger; data-logging and automatic irrigation scheduling; a plurality of sap flow gauges; an automatic rain gage; a water meter; an irrigation valve actuator; and any auxiliary and independent weather or soil monitoring sensors. The system is connected to a PC, mounted in a weatherproof enclosure, and powered by rechargeable battery, solar panel, or AC mains power with battery backup. Computerized monitoring and control procedures are initialized via a custom-developed graphical user interface. At any predetermined interval set by a user, the depth or volume of water required to balance transpiration losses is calculated and irrigation is then automatically triggered. The system affords closed loop control with water flow from soil through plant to atmosphere and from irrigation—and having the benefit of a feedback loop.

Owner:BAVEL MICHAEL VAN

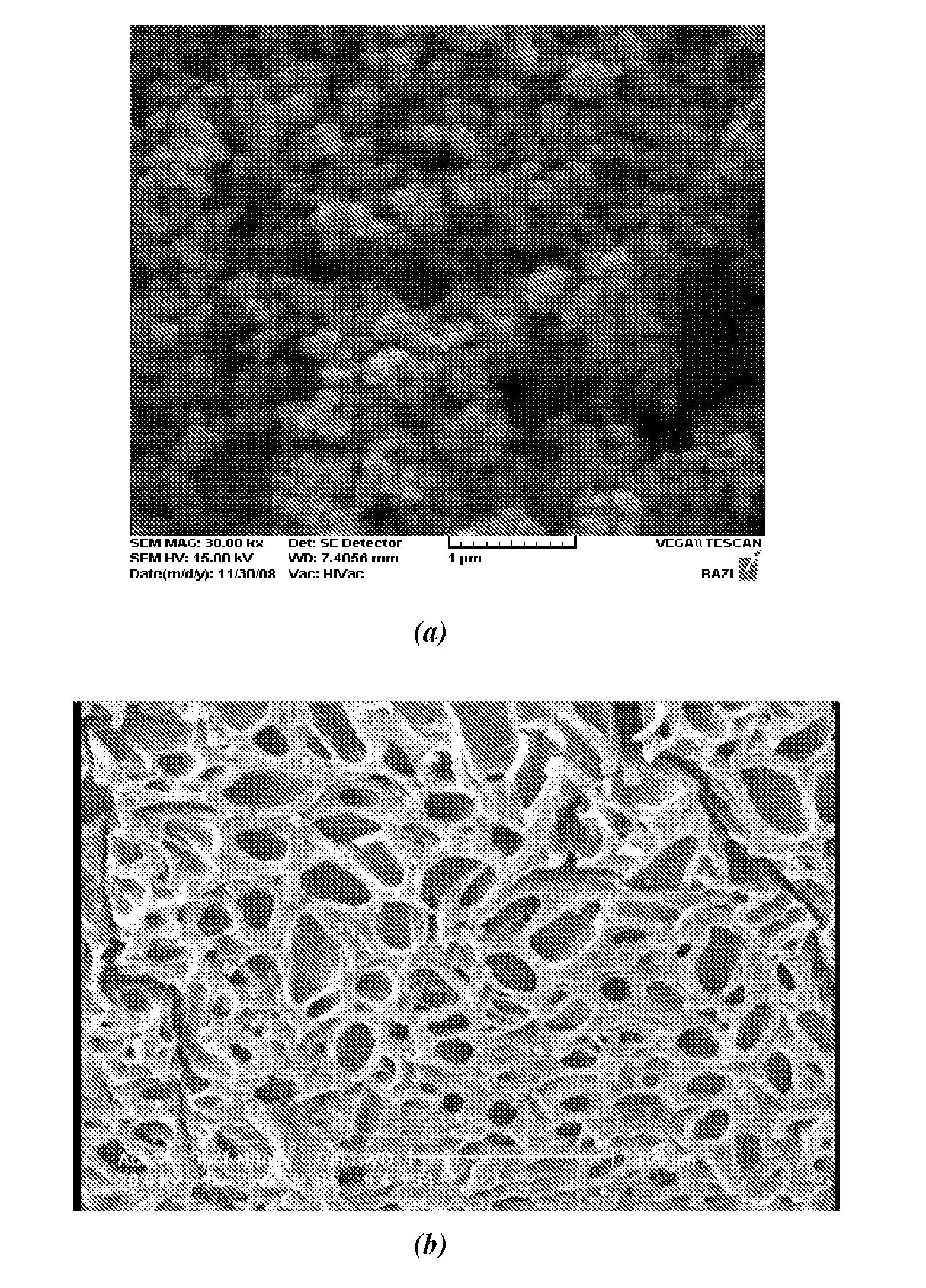

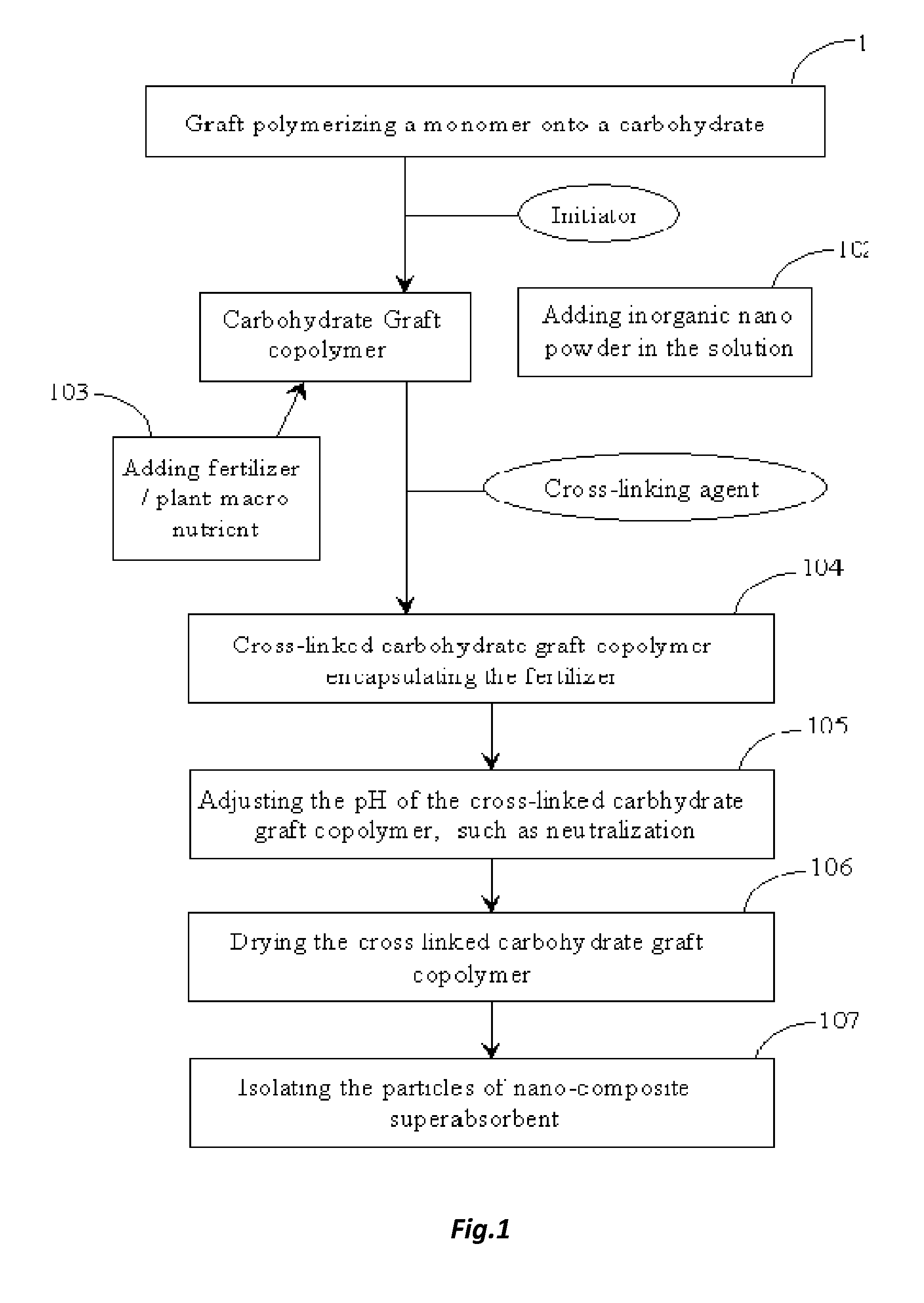

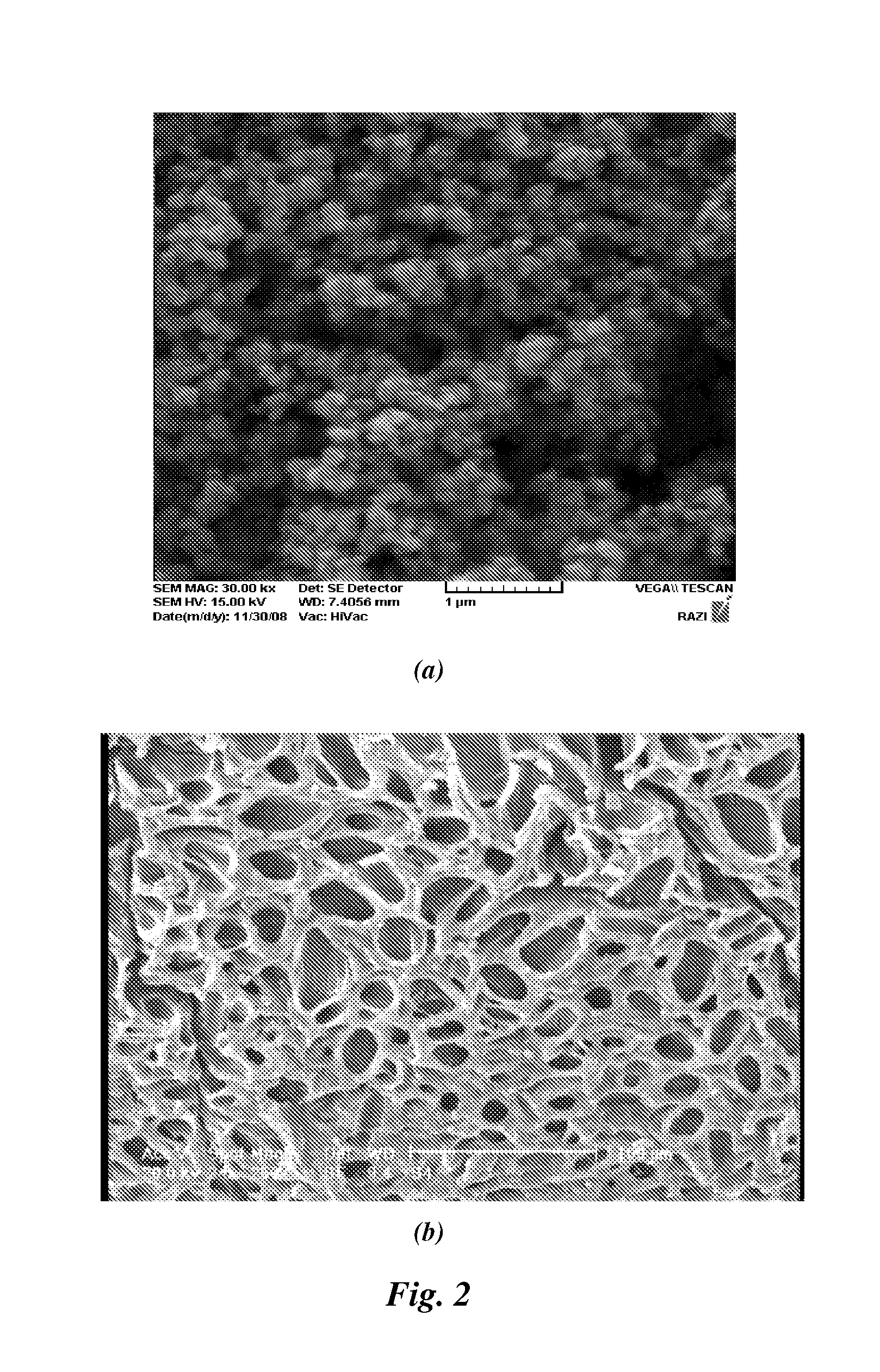

Nano-composite superabsorbent containing fertilizer nutrients used in agriculture

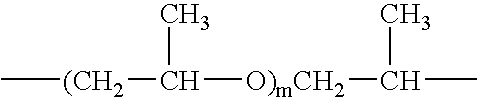

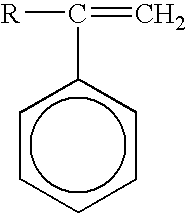

InactiveUS20100139347A1Slow release/controlled release of a plant nutrientBio-organic fraction processingWaste based fuelCross-linkAcrylonitrile

The embodiments herein disclose a nano-composite superabsorbent polymer (NC-SAP) composition encapsulating fertilizer / plant nutrient products and a method of producing NC-SAP based products. According to one embodiment, the method involves graft polymerizing a monomer, other than acrylonitrile, onto a carbohydrate in the presence of an initiator to form a graft carbohydrate copolymer, dispersing an inorganic nano powder, adding fertilizer nutrient to the reaction mixture, cross-linking the carbohydrate graft copolymer by adding a cross-linking agent, such as methylene bis-acrylamide, adjusting the pH of the cross-linked nano-composite carbohydrate graft copolymer and isolating the nano-composite carbohydrate graft copolymer. The method also includes drying the nano-composite carbohydrate graft copolymer, to yield particles that are NC-SAP containing fertilizer. The isolation of particles of NC-SAP polymer product may occur by the methods, including, but not limited to, granularization, extrusion and pelletization.

Owner:BARATI ABOLFAZL

Scion disposal preservation method

InactiveCN101189965AEarly germinationAdjustable grafting timeDead plant preservationHorticultureDiseaseShoot

The invention relates to a cion treating and preserving method. Annual shoots or secondary shoots of over 0.3cm thickness that grow well and are free from damage by disease and insect are selected and cut off 0.5cm above sprout; cut-off shoots are sterilized and socked in 50ppm of solution of growth regulating agent for green plants for 2h, taken out and dried by airing, then mixed with commercial wax of 54 degrees, refined lard and colophony, ratio of which is 1:0.5:0.2, and heated to 100-200 DEG C; then the cion acquired is dipped into wax, wrapped by white thin film and put into a refrigerator for 1-6 months at the temperature of 0 DEG C to 4 DEG C; the cion is taken out, heated and transplanted as by a normal method in due time for grafting. Cion preservation: wax-sealed cion is stored at the temperature of 0 DEG C to 4 DEG C for further use; grafting is carried out when tree sap flows. The invention can prolong the preservation time of the cion and improve grafting survival rate; branches qualified for grating are treated in combination with winter pruning, and are taken out and grafted in due time.

Owner:张掖市林业科学技术推广站

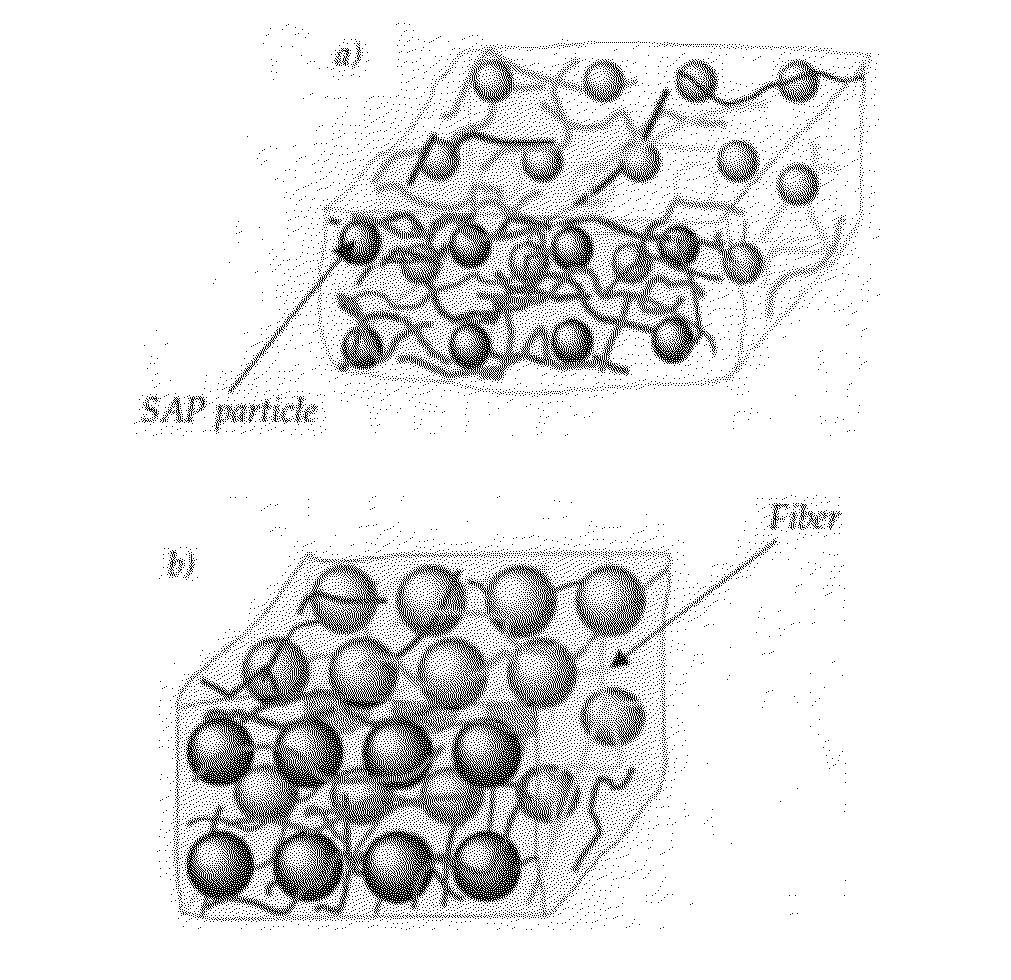

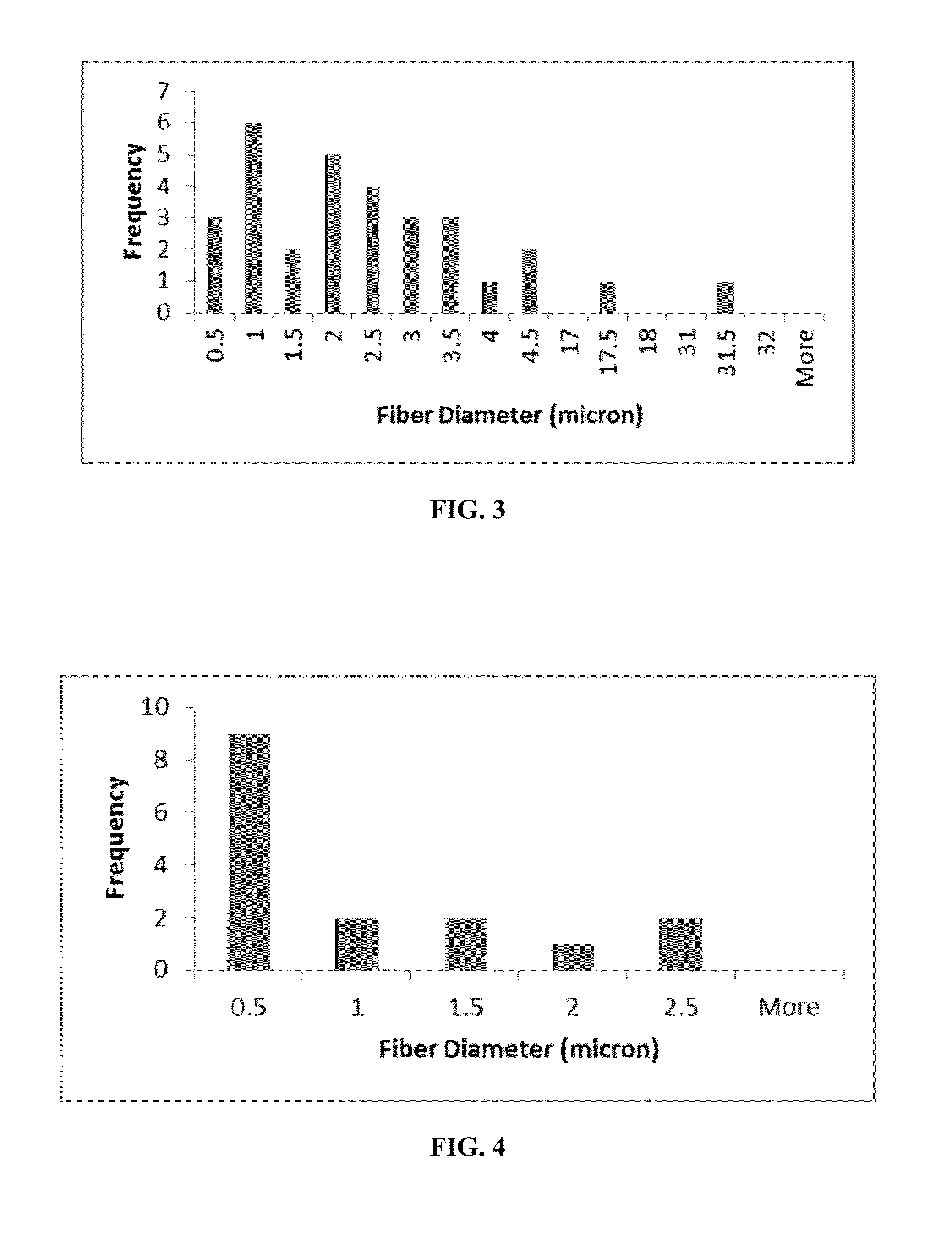

Coform nanofibrous superabsorbent materials

InactiveUS20150190543A1Easy to manufactureImprove performanceNatural cellulose pulp/paperSpinnerette packsPolymer scienceSuper absorbent

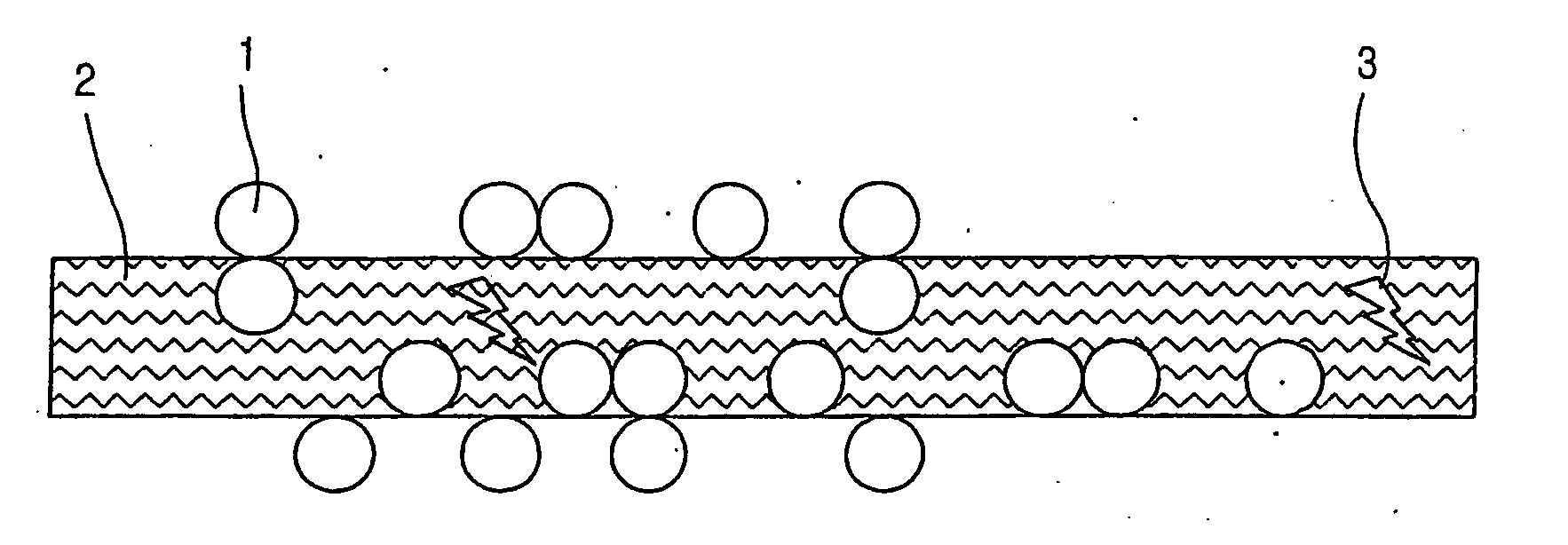

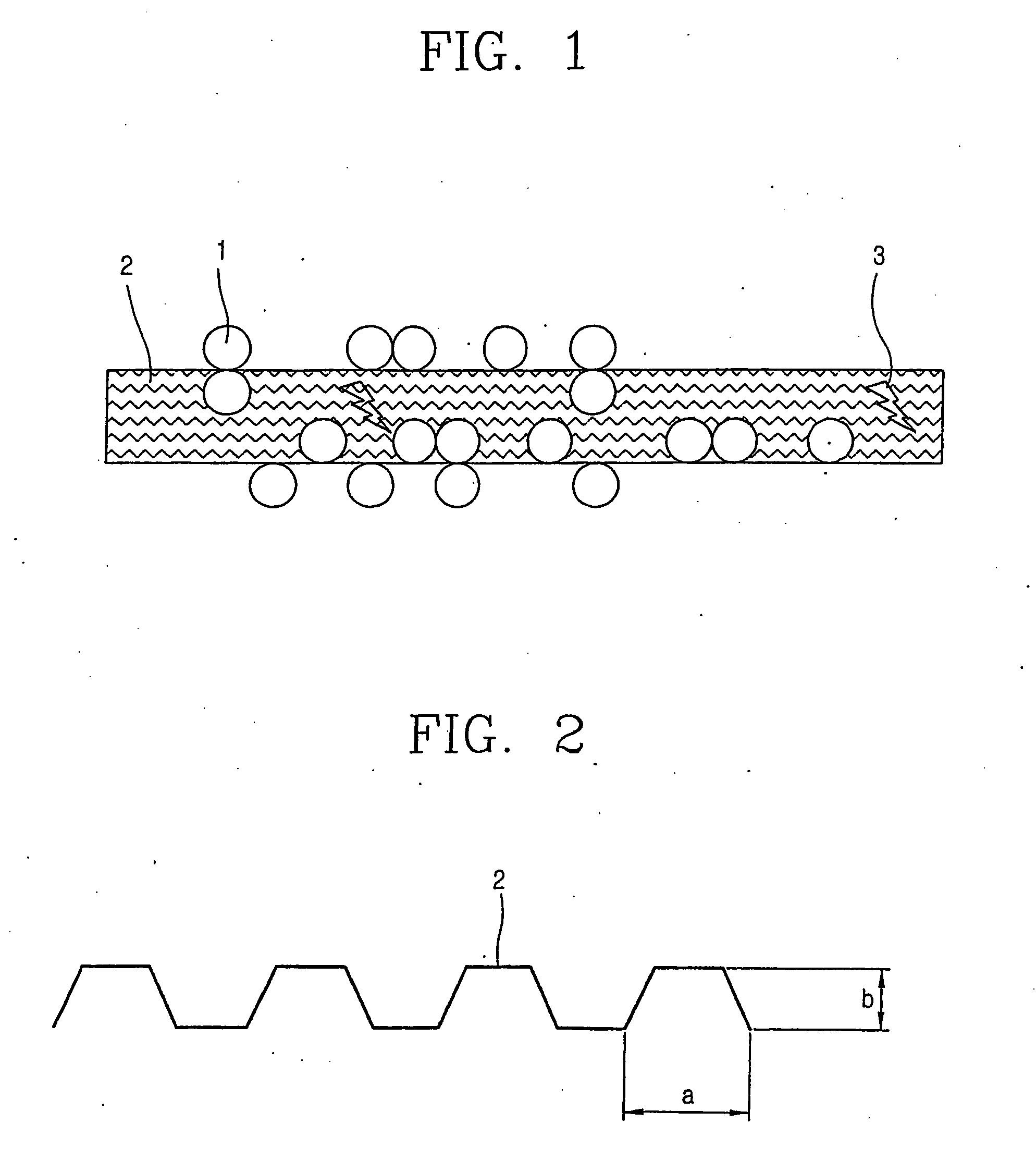

A fibrous super absorbent material is disclosed including a) a hydrophilic three-dimensional fibrous web consisting of a first population of fibrillated nanofibers, and a second population of fibrillated microfibers, both populations uniformly distributed throughout the three-dimensional fibrous web where the first population comprises at least 50% of the total fiber population and b) a population of superabsorbent polymer (SAP) particles with a median size of less than 40 microns dispersed throughout the fibrous web. In various embodiments, a plurality of coarse (greater than 40 microns in diameter), fine from about (40 μm to about 10 μm in diameter), ultrafine (from about 10 μm to about one μm in diameter) and nanosize (less than one μm in diameter) particles are dispersed into the fibrous structure to absorb liquids or remove contaminants or bacteria from the fluids.

Owner:VERDEX TECH

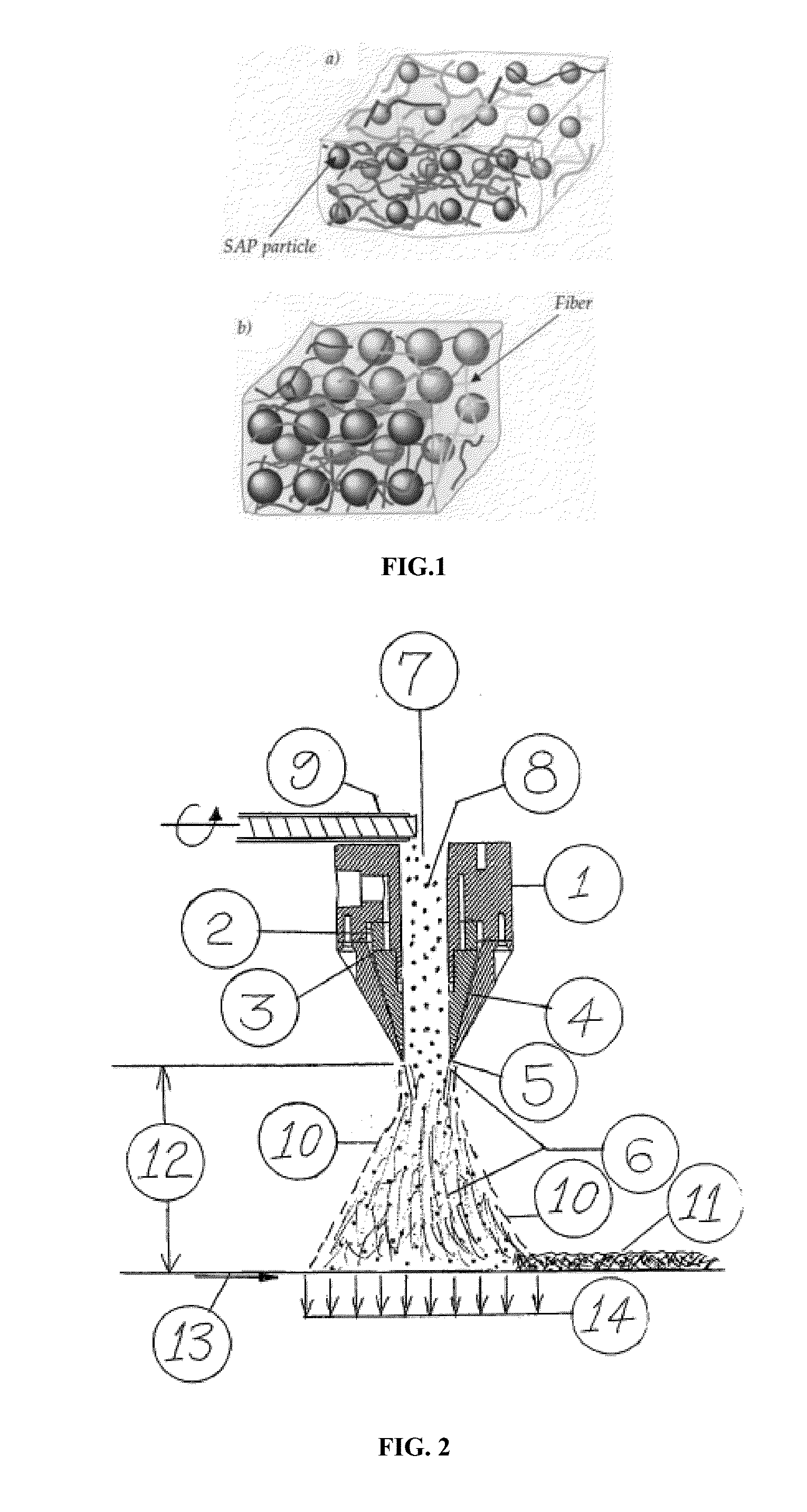

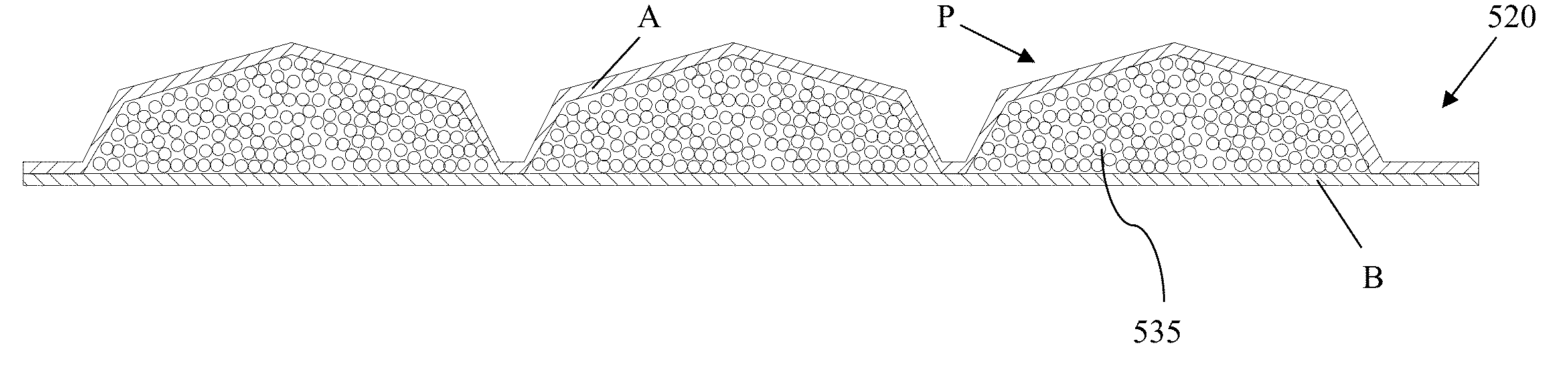

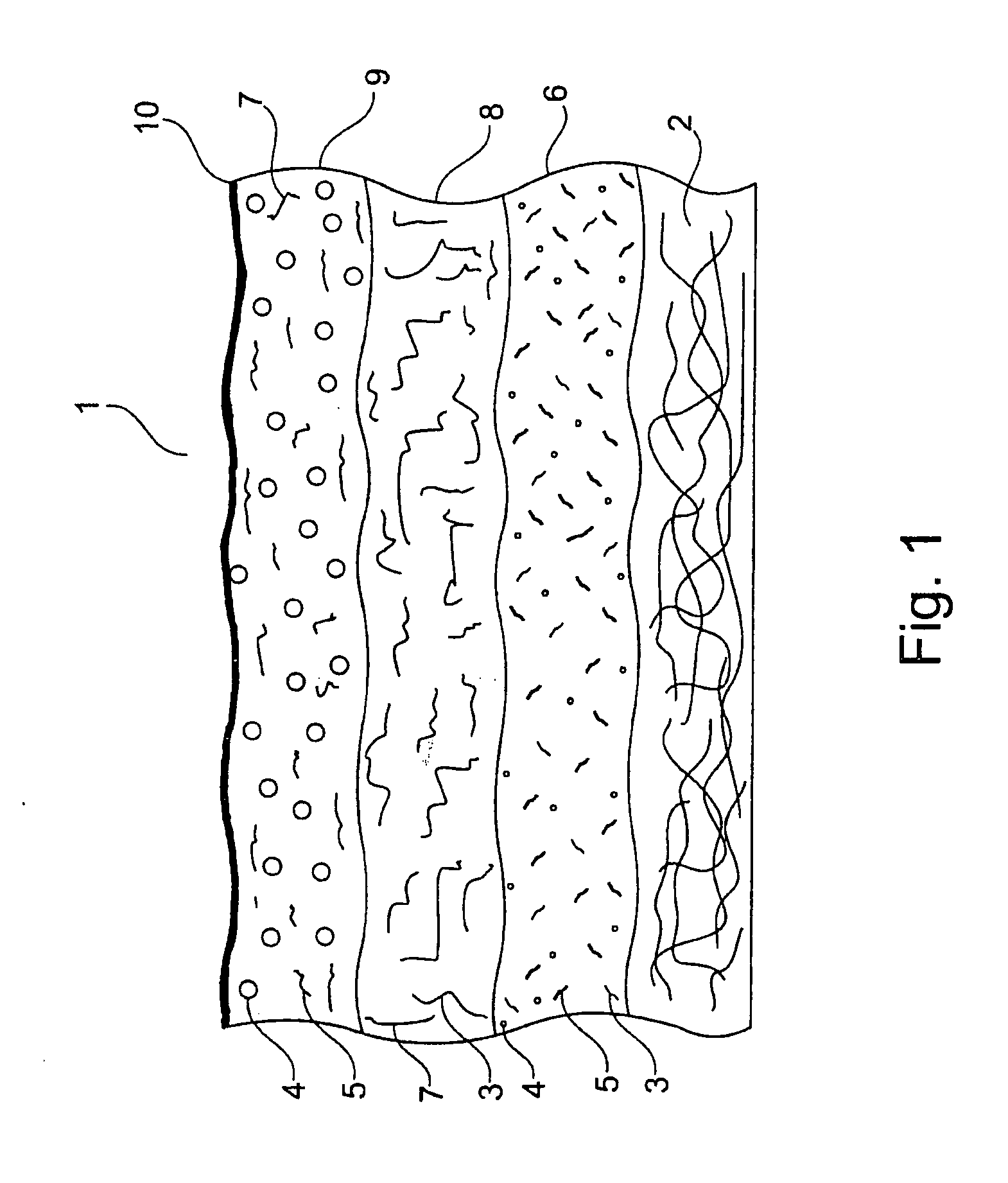

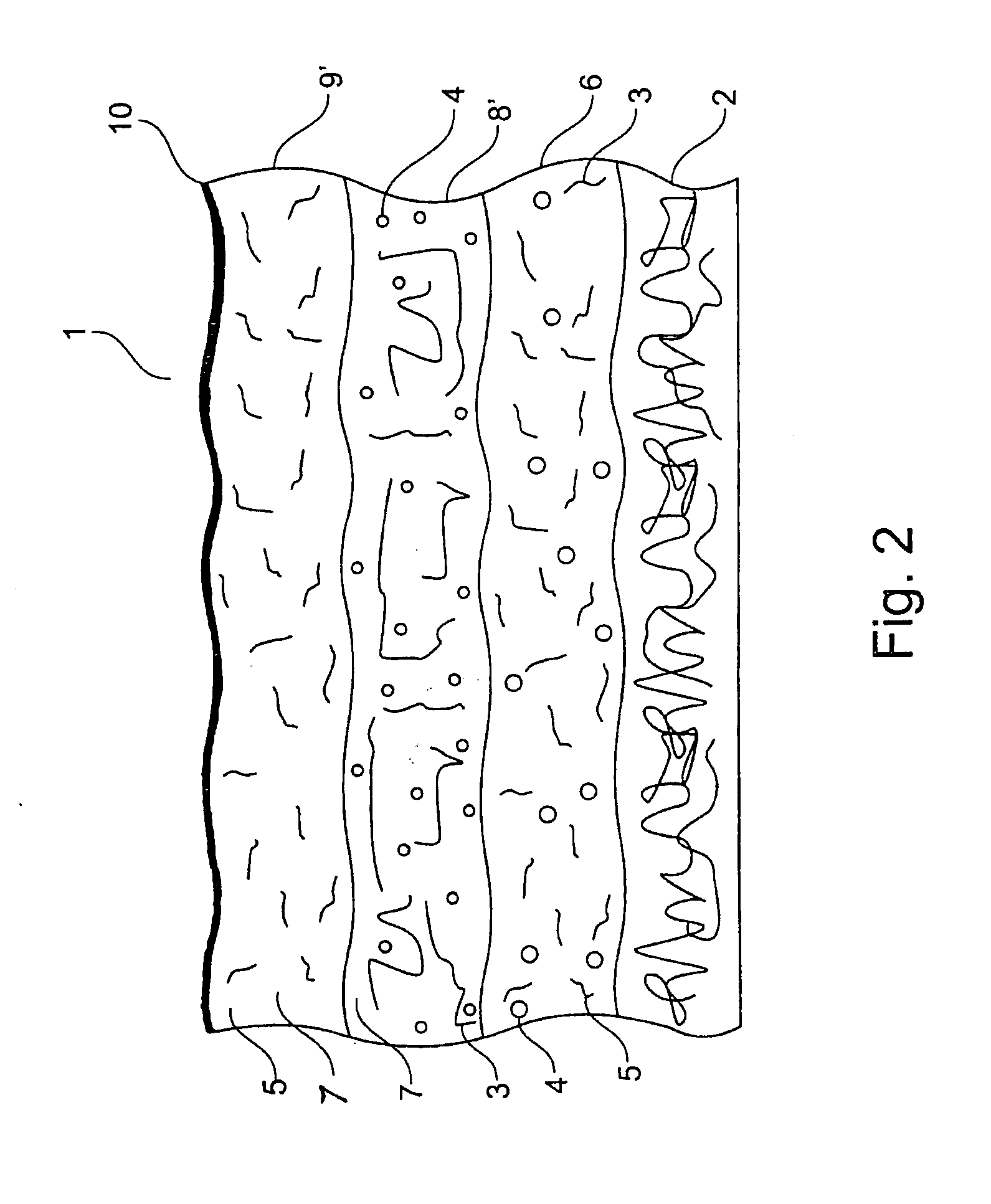

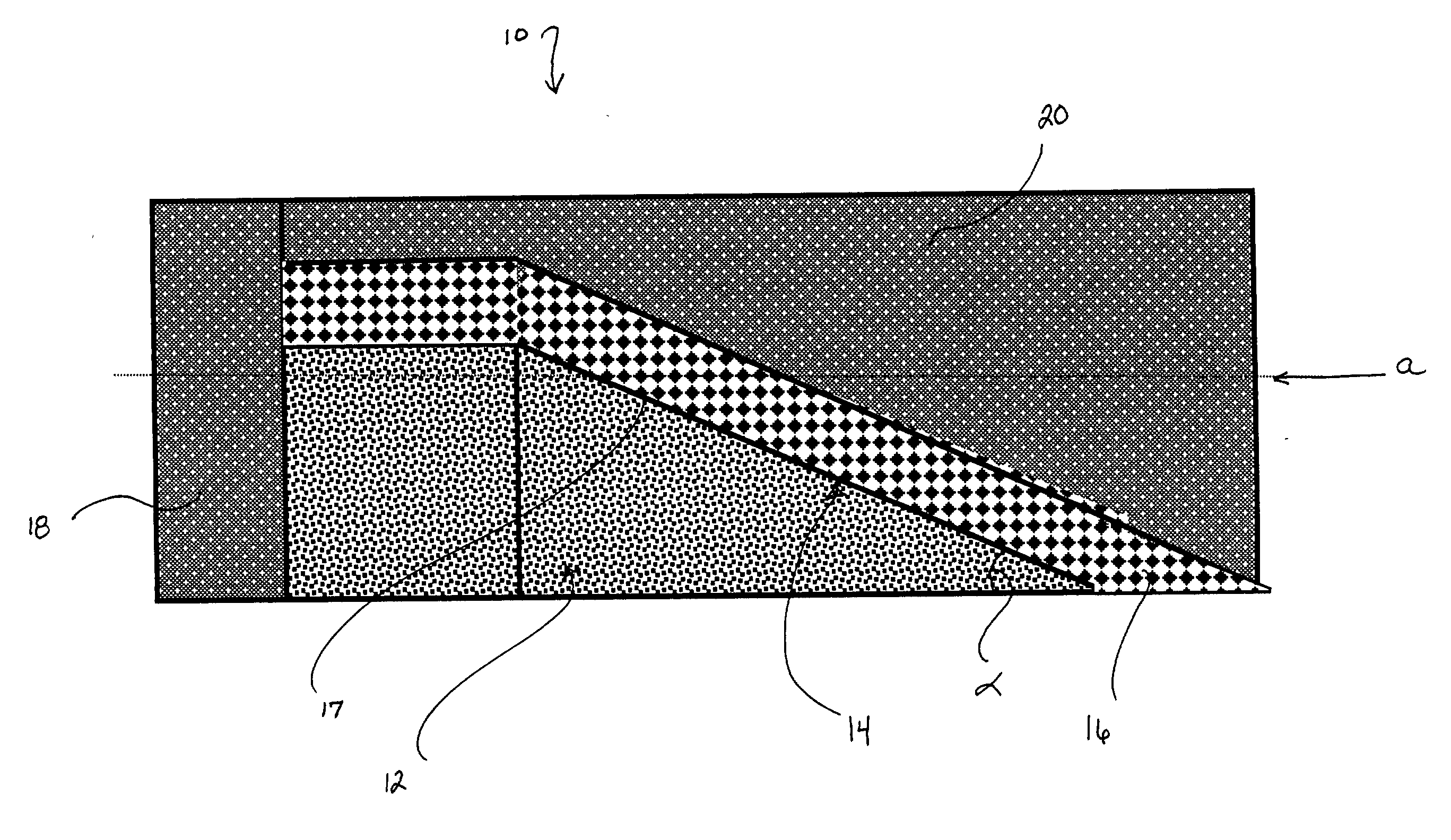

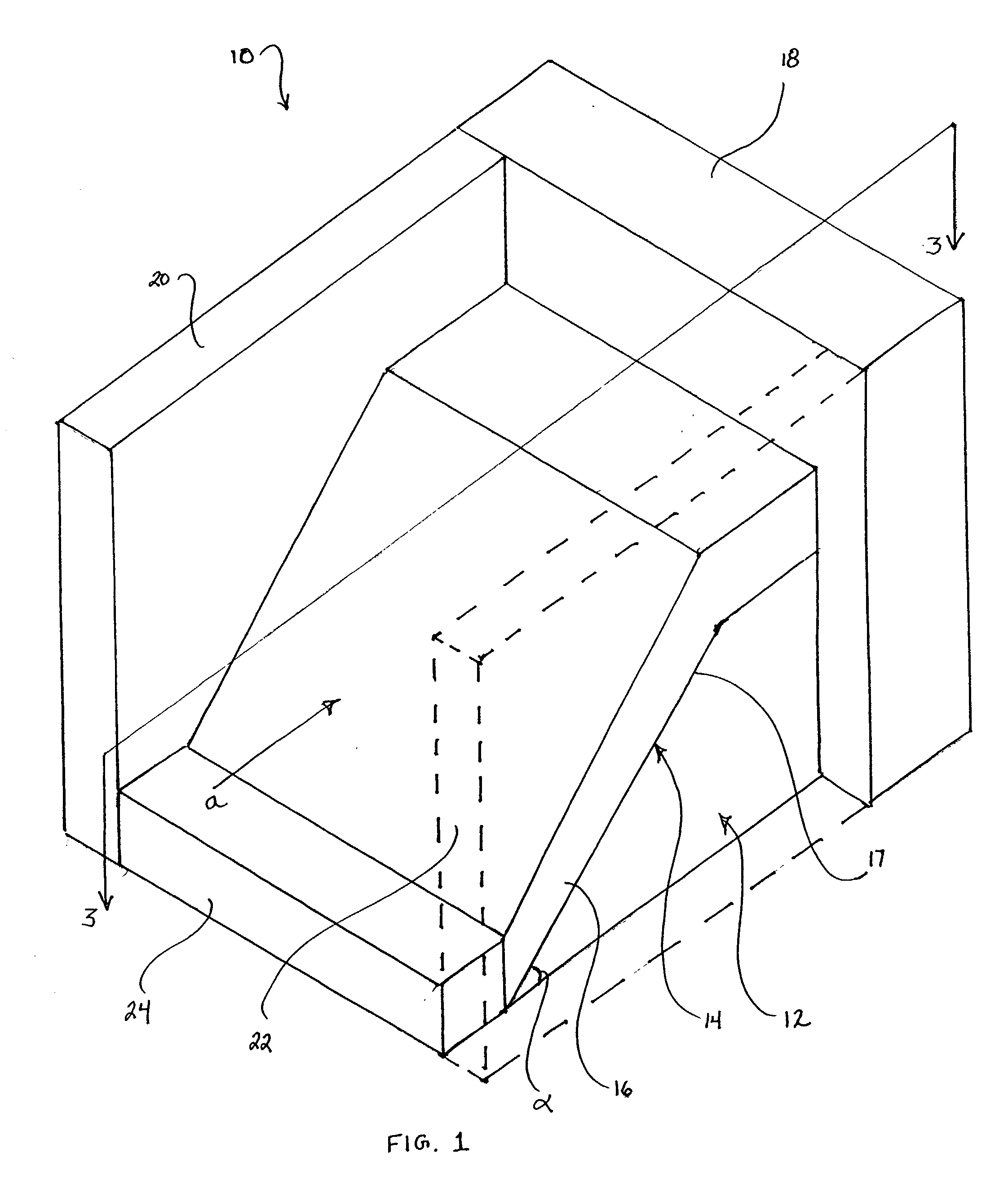

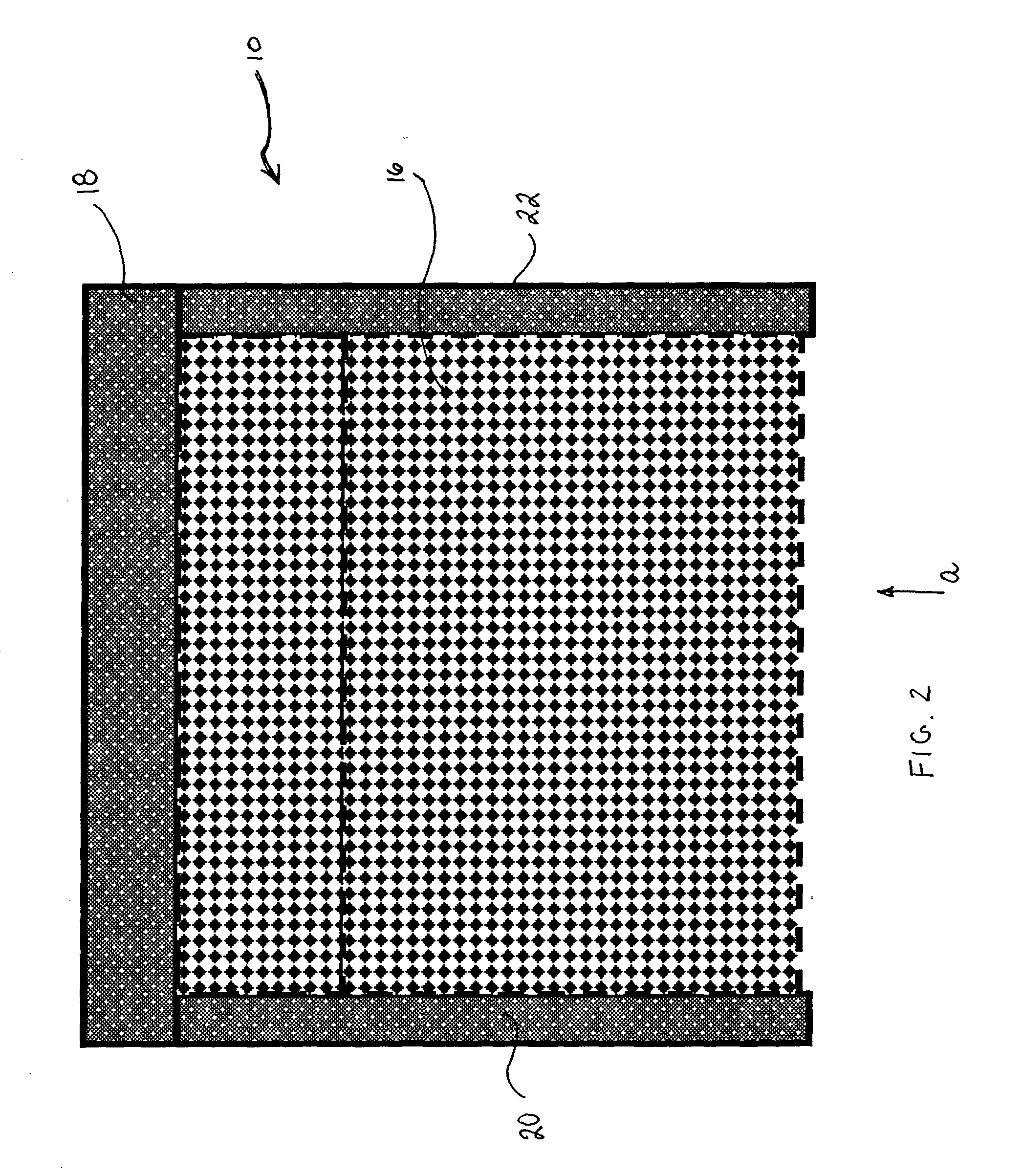

Absorbent Composite, an Absorbent Article Employing the Same, and Methods, Systems, and Apparatus for Making the Absorbent Composite and/or Article

ActiveUS20150045756A1Improve functionalityImprove retentionOther chemical processesAbrasion apparatusPlant sapBiomedical engineering

An absorbent core composite is disclosed for incorporation into a disposable absorbent article. The composite includes a first material layer and a second material layer (preferably nonwoven) partially secured to the first material layer to define at least one pocket therebetween. Preferably, multiple pockets are defined, except in the case of where a generally uniform layer or bed of absorbent is preferred or better suited fro the application. The pocket is said have a fixed initial volume. Further, an aggregate of absorbent particles is provided in the pocket(s) to occupy a portion of the fixed initial volume. The absorbent particles are preferably SAP particles and is characterized by a dry volume associated with a dry state and a swell volume associated with a liquid saturation state. In respect to or for the pocket, the aggregate is characterized by a collective dry volume and a collective swell volume, wherein the pocket has an initial configuration that retains the aggregate therein.

Owner:DSG TECH HLDG

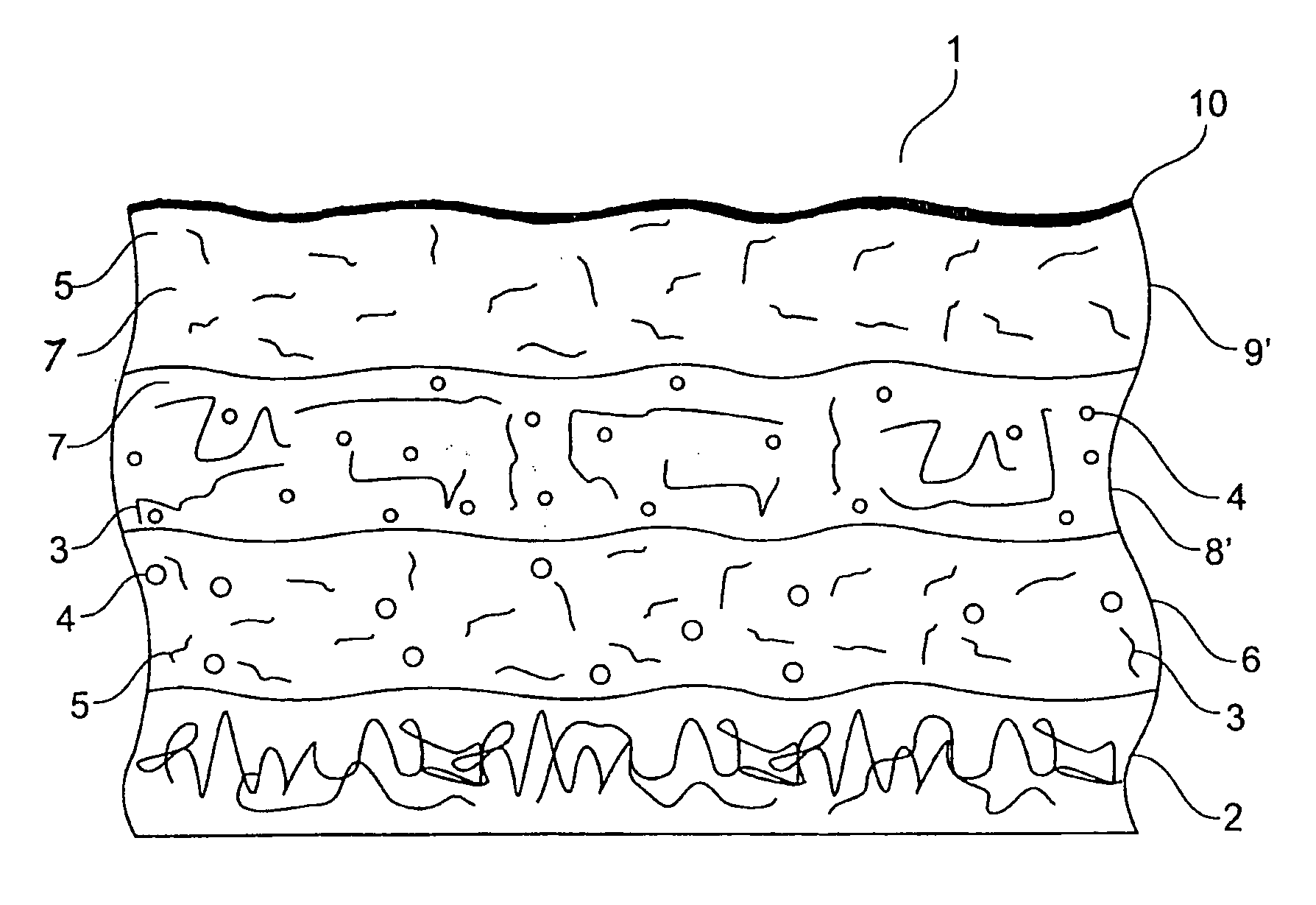

Flexible, highly absorbent material

InactiveUS20110184365A1Avoid impairmentEasy to useLayered productsConfectioneryAbsorbent materialCellulose fiber

An absorbing structure has a sequence of layers, including at least first and second outer layers with at least a liquid storage layer disposed therebetween. The layers are disposed on top of one another and form a layered structure. At least the liquid storage layer has a cellulose material, preferably cellulose fibers, and a super absorbing polymer SAP, preferably SAP particles and / or SAP fibers. The liquid storage layer uses at least less binder material than the other liquid storing plies of the absorbing structure. The liquid storing plies are adjacent to the liquid storage layer. Preferably, the liquid storage layer does not have binder material.

Owner:GLATFELTER FALKENHAGEN GMBH

Integrated method for production of carrageenan and liquid fertiliser from fresh seaweeds

InactiveUS20040031302A1Raw materials are simpleArea minimizationBiocideAnimal repellantsKappa-CarrageenanCost of transport

An integrated method is developed to utilise to a maximum extent the fresh biomass of seaweeds such as Kappaphycus alvarezii that can be crushed to release sap and where the sap is useful as a potent liquid fertilizer after suitable treatment with additives and dilution while the residue is a superior raw material for extraction of kappa-carrageenan, thereby enhancing the value of the seaweed. Other advantages of the invention include a reduced drying time and drying area to obtain the raw material for kappa-carrageenan production in dry and storable form, a reduced cost of transporting and storing this raw material because of its lesser bulk, easier handling due to its free flowing granular nature, and its direct use for gel preparation in certain applications.

Owner:COUNCIL OF SCI & IND RES

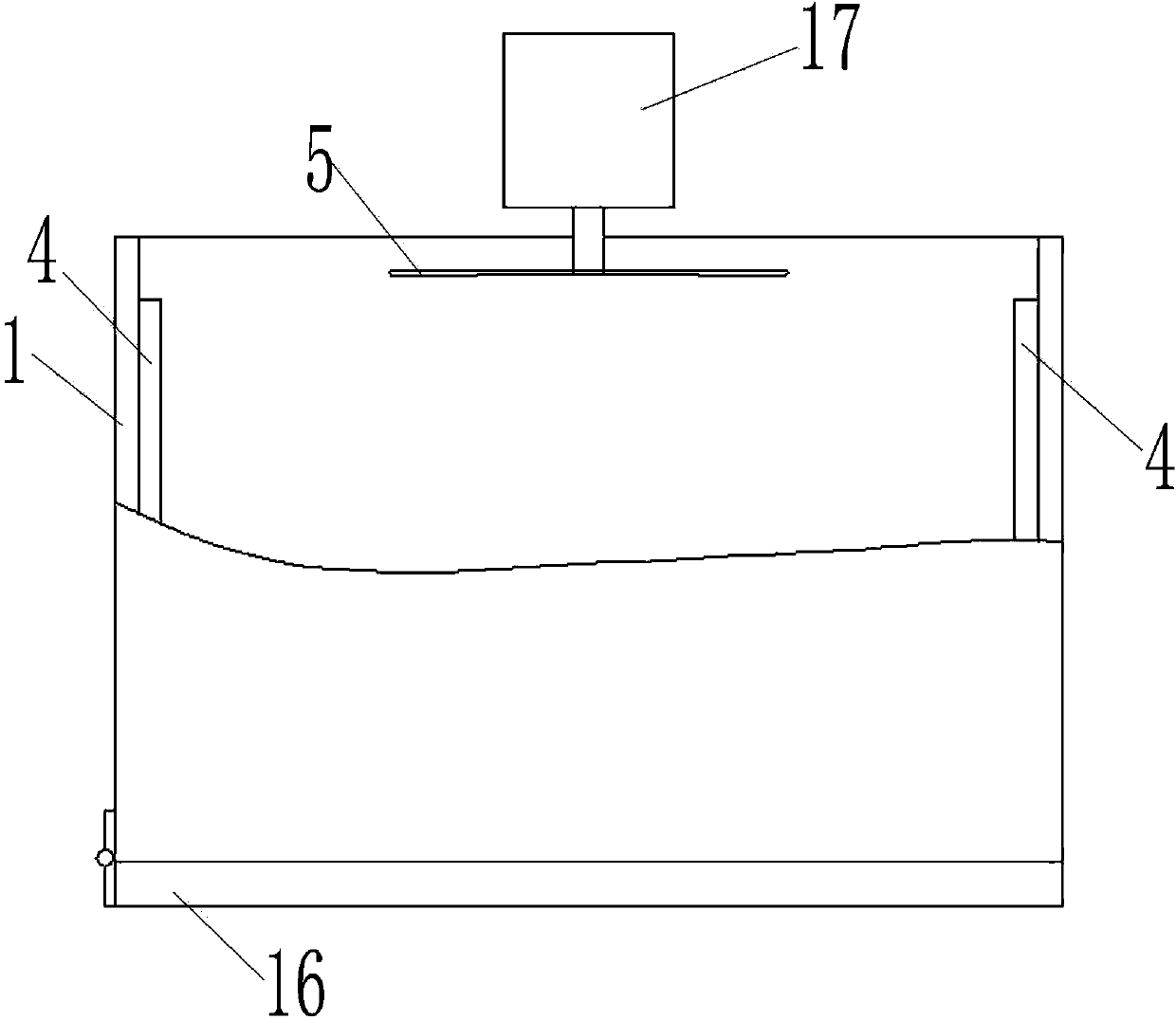

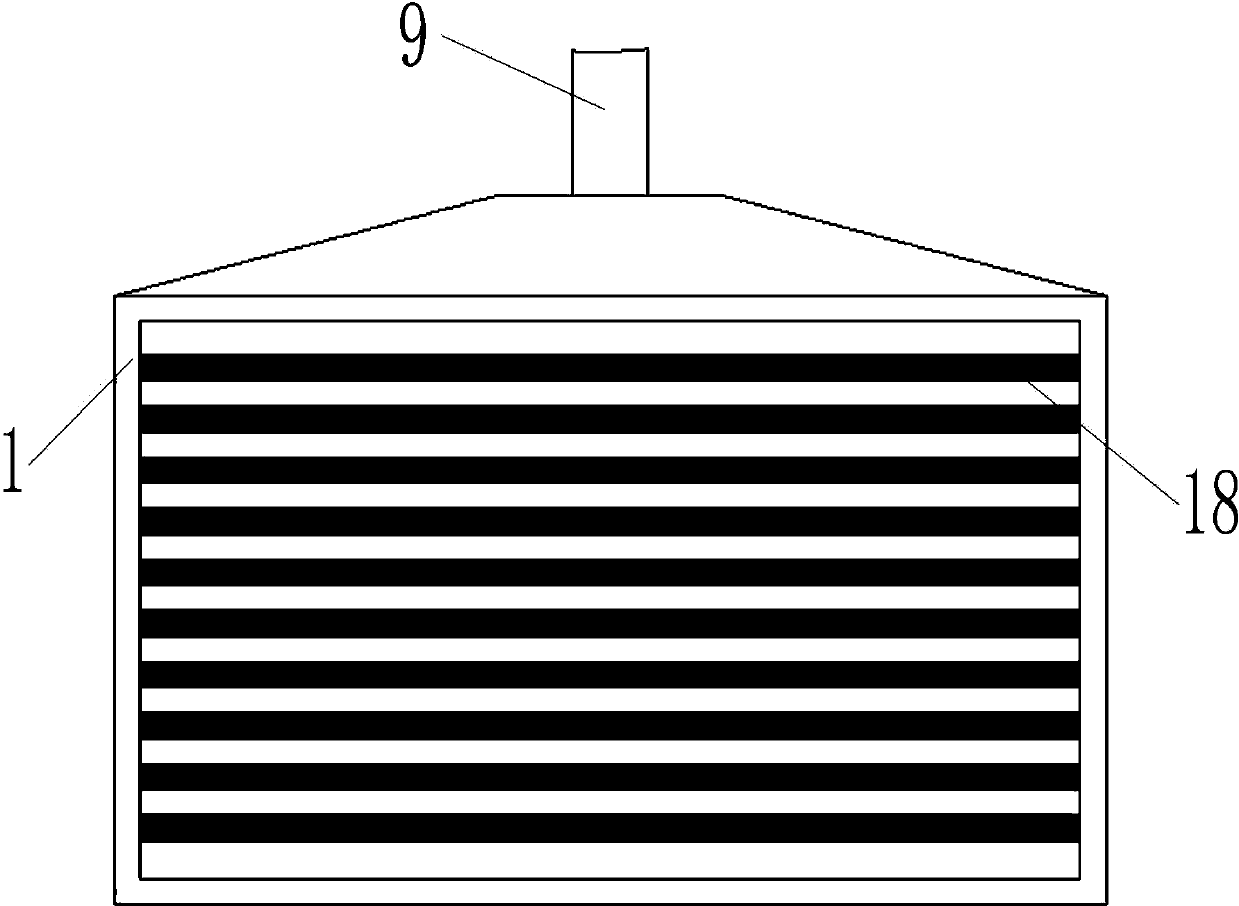

Production process for drying rosebuds at low temperature and recovering effective constituents and production equipment thereof

ActiveCN103461556AAvoid a destructive situationAchieve comprehensive utilizationPre-extraction tea treatmentTea substituesBudEngineering

The invention relates to a production process for drying rosebuds at a low temperature and recovering effective constituents. The production process comprises the following sequential steps of: (1) evenly spreading fresh rosebuds on trays provided with meshes on the bottoms; (2) gradually placing the trays in an airtight drying oven layer by layer; (3) heating so that the temperature in the drying oven is in the range from 38 to 45 DEG C for 2 hours; (4) heating so that the temperature in the drying oven is in the range from 60 to 70 DEG C for 5 hours, and consequently, separating out the cell sap of the rosebuds and forming steam; (5) heating so that the temperature in the drying oven (1) is in the range from 50 to 55 DEG C for 2 hours, and consequently, changing the rosebuds into dry buds; and (6) stopping heating in the drying oven (1), taking out the trays after the temperature in the drying oven falls to the environmental temperature, and then hermetically packaging the buds. Finally, the steam formed by the separated-out cell sap of the rosebuds in the steps (3), (4) and (5) is condensed through a condenser, the condensed water is collected and stored, and therefore, recovery and utilization of the cell sap are realized.

Owner:山东惠农玫瑰股份有限公司

Method for exterminating pests injurious to plants

The method for exterminating plants pests comprises making an adjustment for causing the aqueous solution for exterminating pests to have the concentration within the range between the upper limit of being, by 0.4 mol / l, higher than the concentration of the said cell sap of plants and the lower limit of 0 concentration, and dipping the said plants in the said aqueous solution adjusted at the above concentration for a period of time required for exterminating pests. When the concentration of the said aqueous solution is adjusted within the ranged mentioned above, the pests gathering on the said plants may be suffocated to death without doing any harm to the plants dipped in the said aqueous solution.

Owner:SEIBUTU KINO KOGAKU KENKYUSHO

Method of manufacturing the super-absorbent polymer (SAP) which is powdery, insoluble in water, and able to absorb water, blood and urine and has slight soluble things

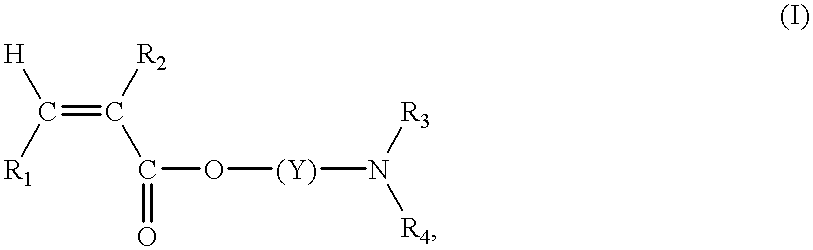

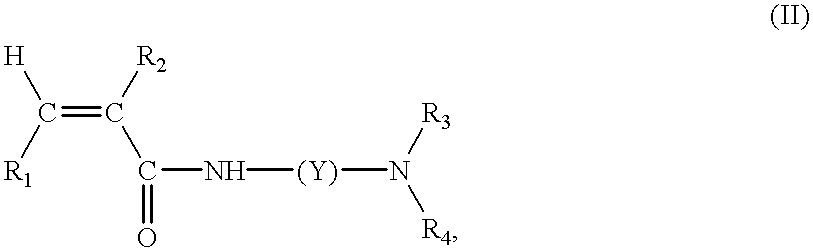

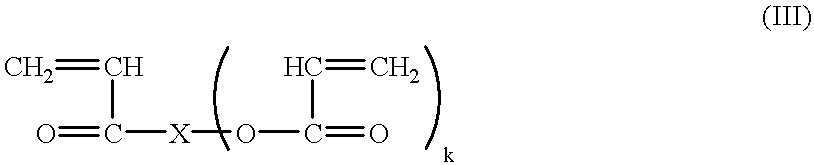

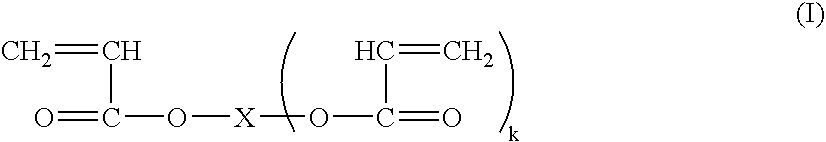

ActiveUS20080081848A1Moderate heat of reactionThe polymerization process is stableOther chemical processesPhotomechanical apparatusEpoxyCross-link

Owner:FORMOSA PLASTICS CORP

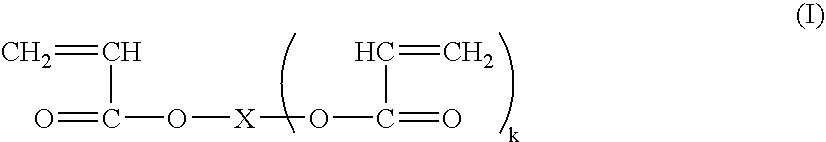

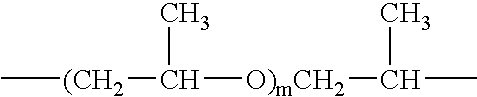

Super absorbent polymer and a preparation method thereof

ActiveUS20150087742A1Good absorption rateMaintain good propertiesOther chemical processesAbsorbent padsSuper absorbentDiol

The present invention relates to a super absorbent polymer (SAP) and a preparation method thereof. More specifically, the present invention provides a SAP satisfying the overall properties required to a SAP and especially the superior initial absorbency and absorbing rate under load at the same time, and a preparation method thereof, by treating the surface of the SAP with a surface treatment solution including water and a diol-based or glycol-based surface crosslinking agent.

Owner:LG CHEM LTD

Dehumidifying element and manufacturing method for the same

InactiveUS20050155491A1High absorption rateMaintenance characteristicAir treatment detailsOther chemical processesHigh humidityEngineering

A dehumidifying element includes a super absorbing polymer (SAP), and a hygroscopic base, thereby maintaining hygroscopic characteristics regardless of aging and a high humidity absorbing rate and needing a smaller amount of energy for regeneration.

Owner:KOREA INST OF SCI & TECH

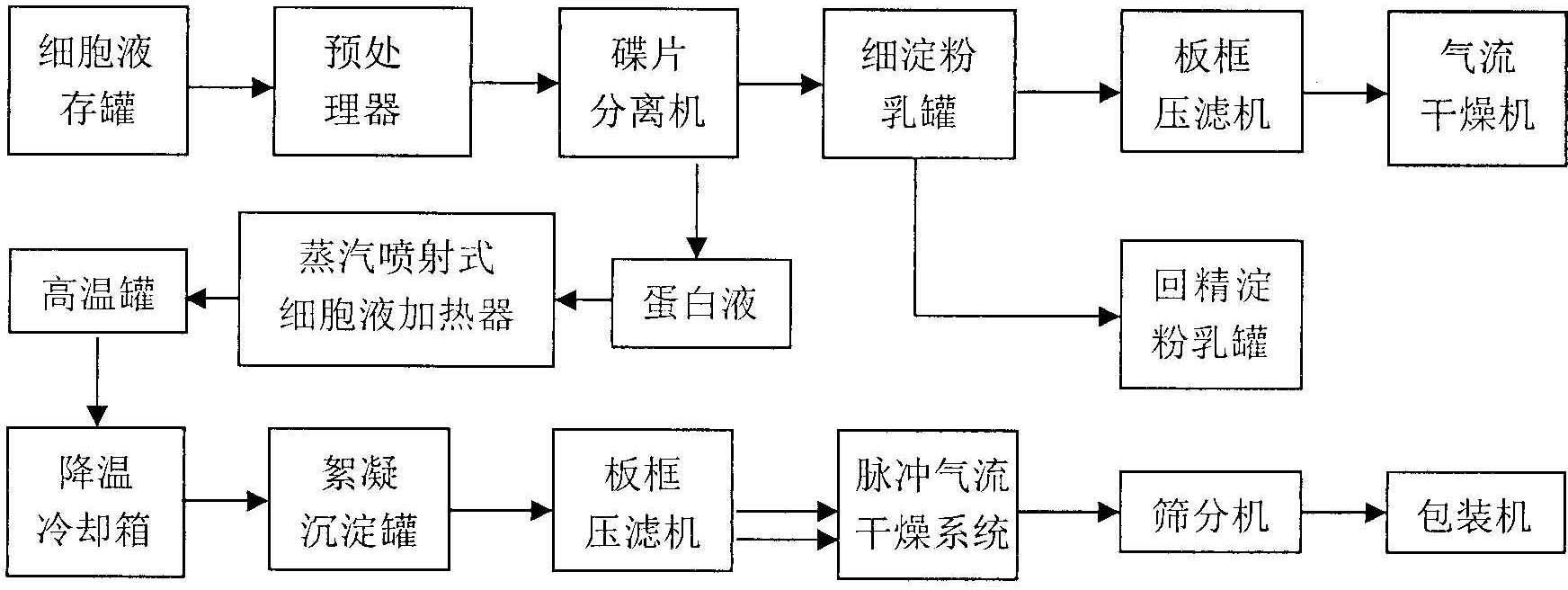

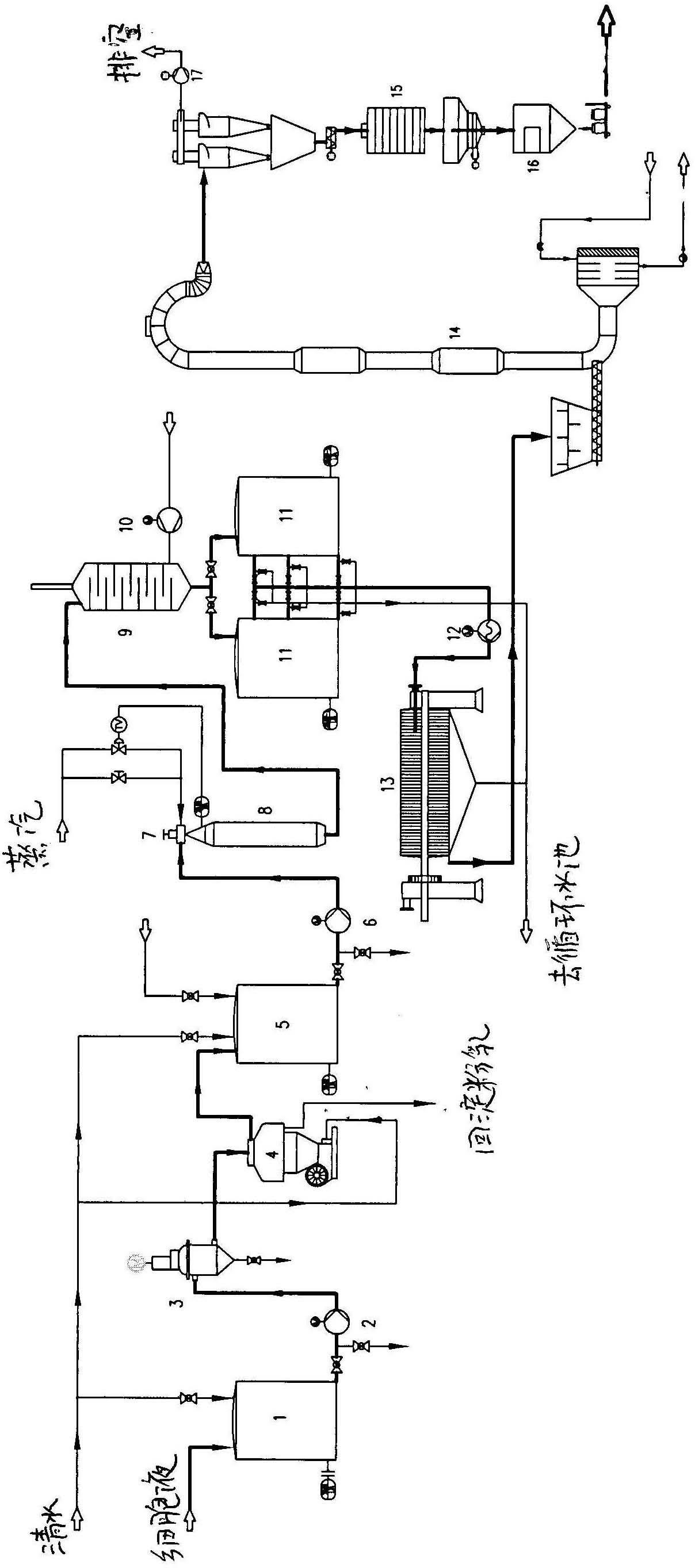

Process for extracting sweet potato protein by thermal deposition method

ActiveCN102558327ACompletely brokenEasy to separatePeptide preparation methodsPlant peptidesFiberSolubility

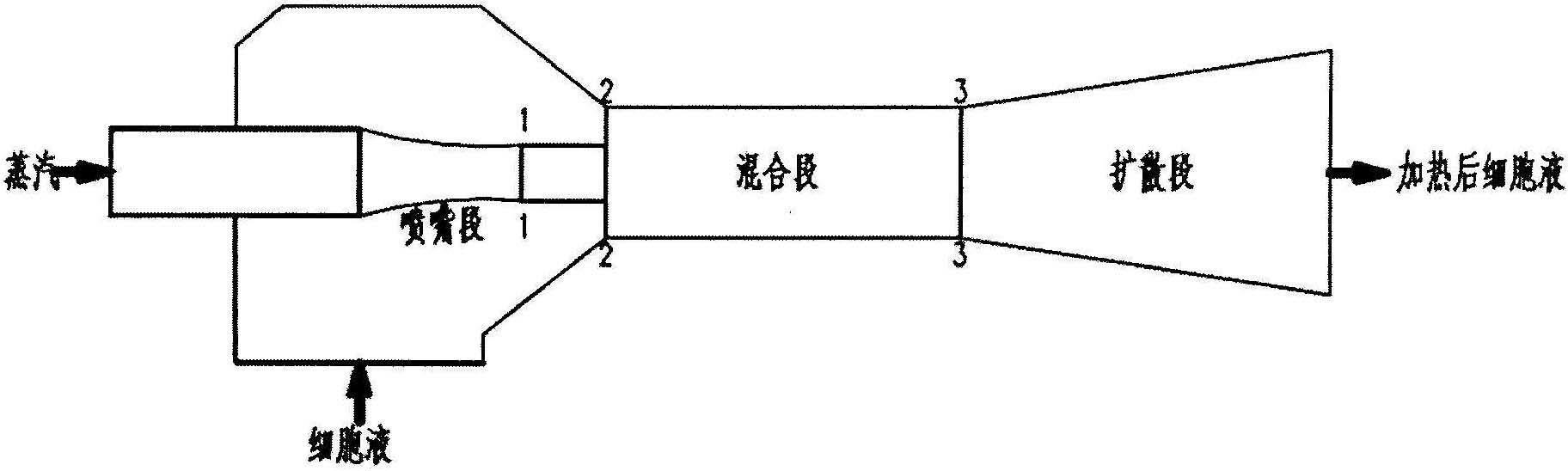

The invention relates to a process for extracting sweet potato protein by a thermal deposition method. The process is characterized by comprising the following steps of: treating cell sap to extract the sweet potato protein from the cell sap while producing sweet potato starch, separating and purifying by using a disc separator according to the difference of specific gravity of the protein and other substances such as starch and the like, removing fine fibers according to the solubility of the protein and the size of particles, and further purifying; purifying, concentrating, and degeneratingthe sweet potato protein to generate floccules according to the characteristic that the protein is degenerated at high temperature by a physical heating method; and concentrating, squeezing for dehydrating, drying, sieving, and performing aftertreatment to obtain a sweet potato protein commodity. The invention has the advantages that: (1) the sweet potato protein is degenerated by a steam jet cell sap heater, a moving part is not provided, and continuous production is ensured; (2) chemicals such as a flocculating agent and the like are not added, so that pollution is avoided, and subsequent treatment difficulty is reduced; and (3) the process is technically mature, and the industrial production capacity can be achieved.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

Methods of making and using a superabsorbent polymer product including a bioactive, growth-promoting additive

ActiveUS7423090B2Promote growthImprove usabilityBiocideStarch dervative coatingsSuperabsorbent polymerGrowth promoting

A method of and a product formed by entrapping a bioactive, growth-promoting additive in a starch matrix to form a starch-based, superabsorbent polymer product for use in agricultural applications involves (1) graft polymerizing a monomer and a starch to form a starch graft copolymer including a starch matrix; (2) isolating the starch graft copolymer; (3) forming particles of starch graft copolymer; and (4) adding a bioactive, growth-promoting additive such that at least some of the bioactive, growth-promoting additive is entrapped by the starch matrix. Following placement of the starch-based SAP including a bioactive, growth-promoting additive in proximity to a plant, root, seed, or seedling, growth of the plant, root, seed, or seedling is promoted because availability of beneficial nutrients is increased.

Owner:UPL MAURITIUS LTD

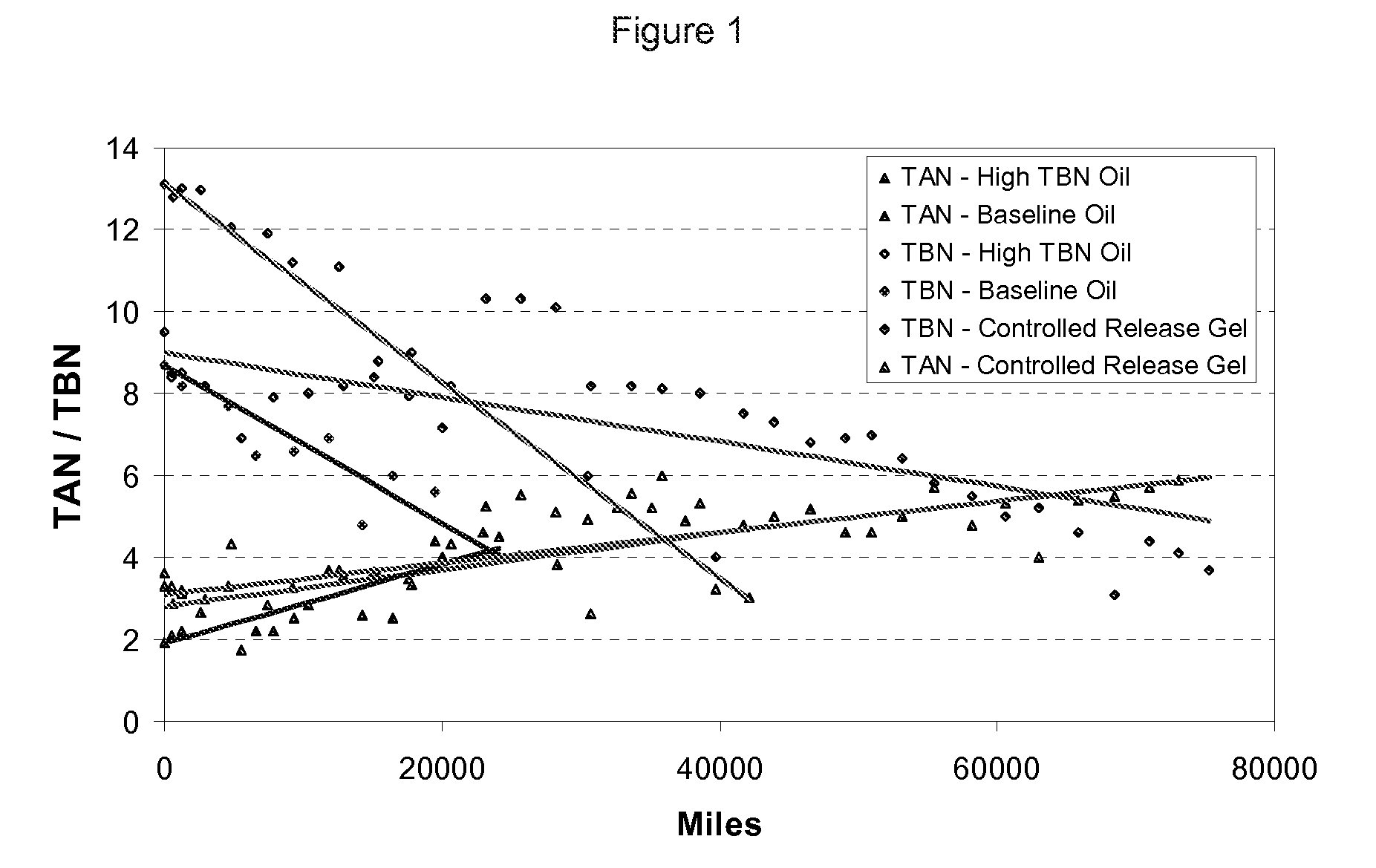

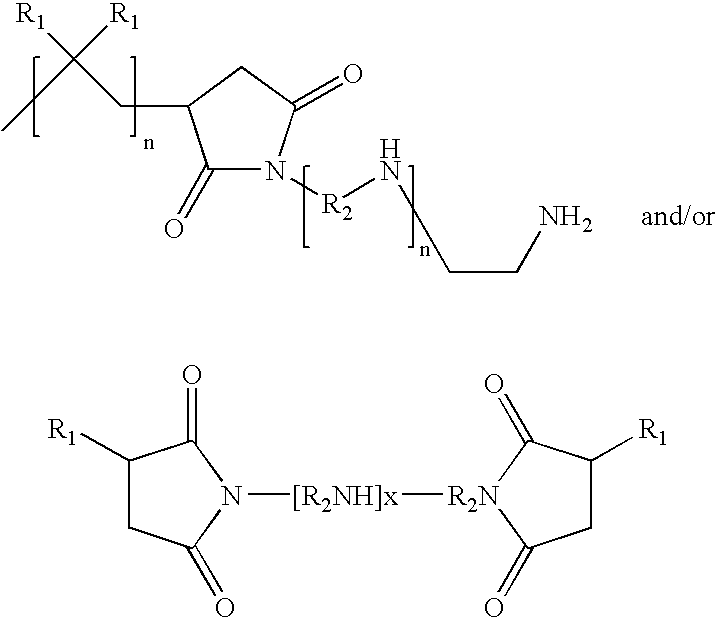

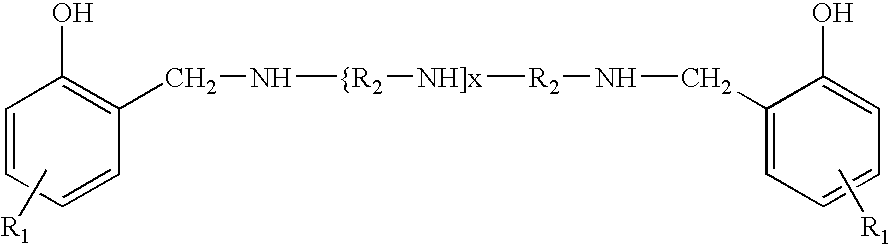

Low Ash Controlled Release Gels

InactiveUS20080188386A1Lower Level RequirementsImprove featuresTin organic compoundsGroup 5/15 element organic compoundsControlled releaseMedicine

The present invention relates to a controlled release gel with an ashless component and defined ash-producing component. Further, the invention relates to the use of a controlled release gel with a controlled level of ash-producing (i.e., metal) components for delivery of additives into lubricants wherein the gel has reduced ash and SAPS producing components.

Owner:THE LUBRIZOL CORP

Fire-extinguishing mixture

InactiveCN101874917AImprove barrier propertiesImprove water retentionFire extinguisherFoaming agentSuper absorbent

The invention relates to a fire-extinguishing mixture used for retarding fire spreading, in particular to a fire-extinguishing mixture which can form the gel barrier layer and have high viscosity. The fire-extinguishing mixture is prepared by mixing super absorbent polymer (SAP) with water-soluble thickener and water-soluble foaming agent in specific proportions so that when mixed in water, SPA absorbs moisture to form gel to be covered on the surface of a blazer and cut off oxygen supply needed by the fire source; the water-soluble thickener is used to increase the adhesion of gel and reducecracks generated in the gel barrier layer on the surface of the blazer; and water-soluble foaming agent is used to generate foam to increase the vertical adhesion of the gel barrier layer, further prolong the time that the gel barrier layer adheres to the surface of the blazer, overcome the problem that the traditional fire-extinguishing method using water or foam has poor adhesion or retarding property, and greatly improving the extinguishing effect.

Owner:林健国 +3

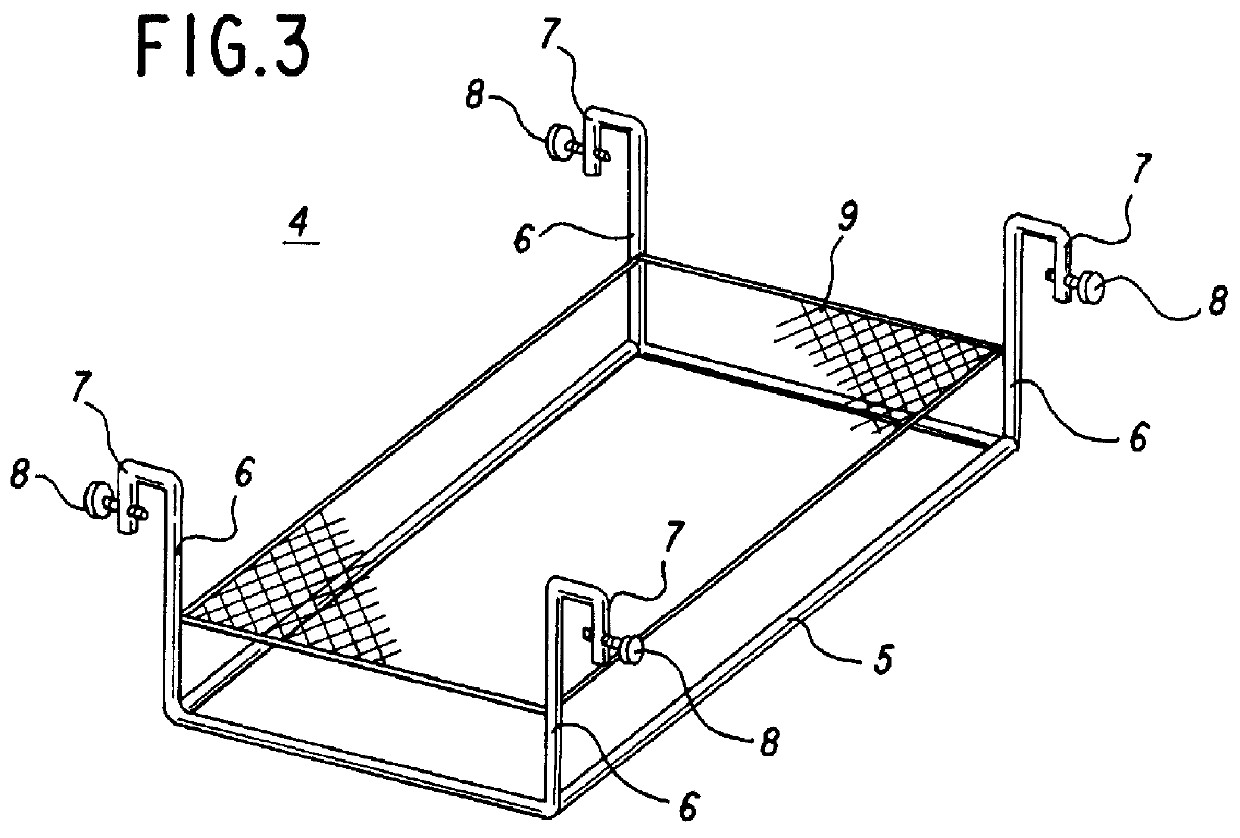

Bullet trapping medium and system

A backstop for decelerating and trapping projectiles generally includes a support structure having an inclined surface and a projectile trapping medium disposed on the inclined surface. The projectile trapping medium may be either a resilient granular ballistic medium or a combination of a ballistic medium with a hydrated super absorbent polymer (SAP) gel. Preferably, the support structure is made of a shock absorbing, foamed, fiber-reinforced concrete, such as SACON(R). In embodiments, the support structure also includes an enclosure. Additives may also be mixed into the projectile trapping medium to control alkalinity and prevent leaching of heavy metals.

Owner:ARMY UNITED STATES GOVERNMENT AS REPRESENTED BY THE SEC OF THE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com