Flexible, highly absorbent material

a flexible, highly absorbent material technology, applied in the field of multi-layer absorbing structure, can solve the problems of reducing the capacity for absorbing additional liquid, affecting wearing comfort, and affecting wear comfort, so as to avoid such impairments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

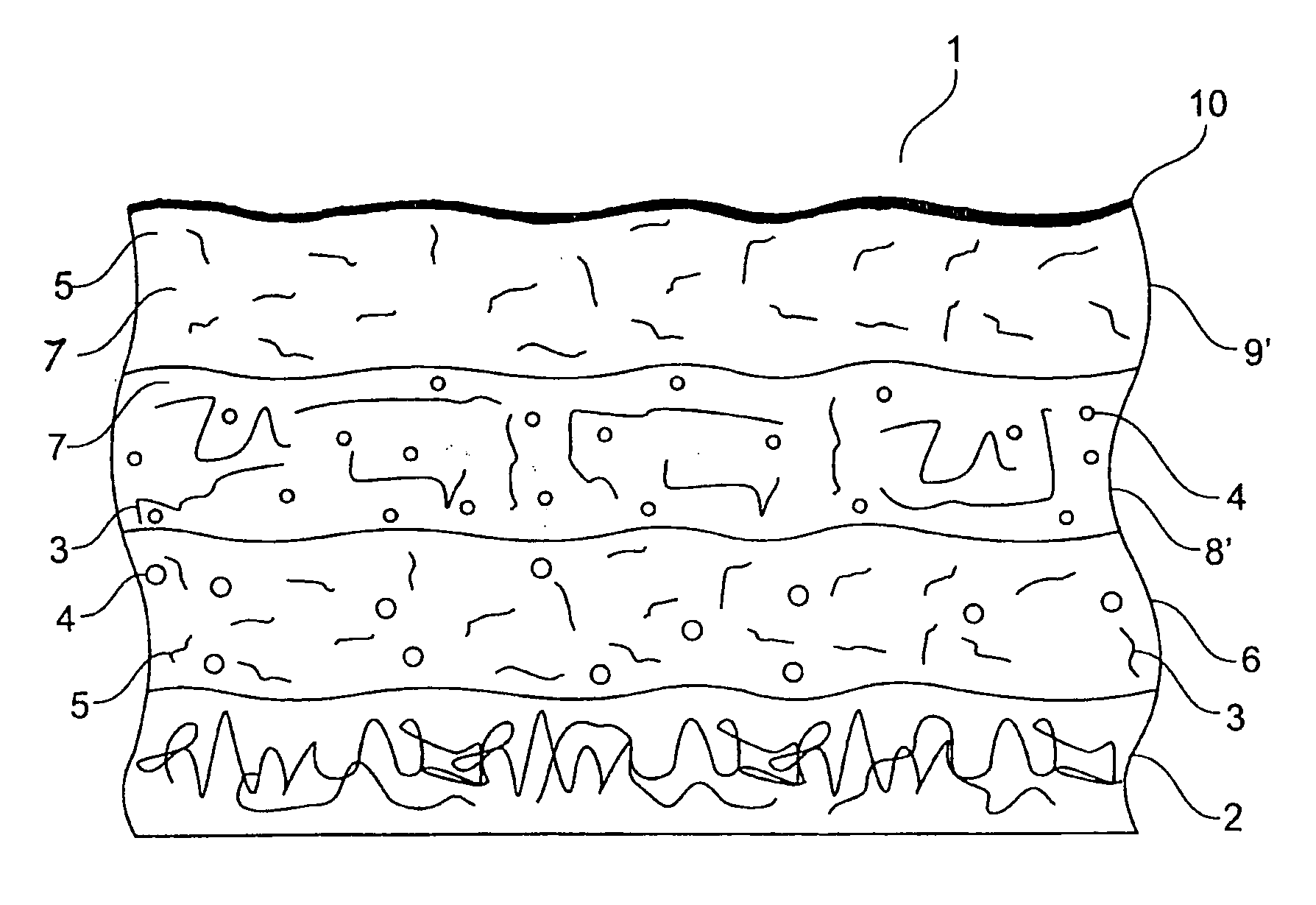

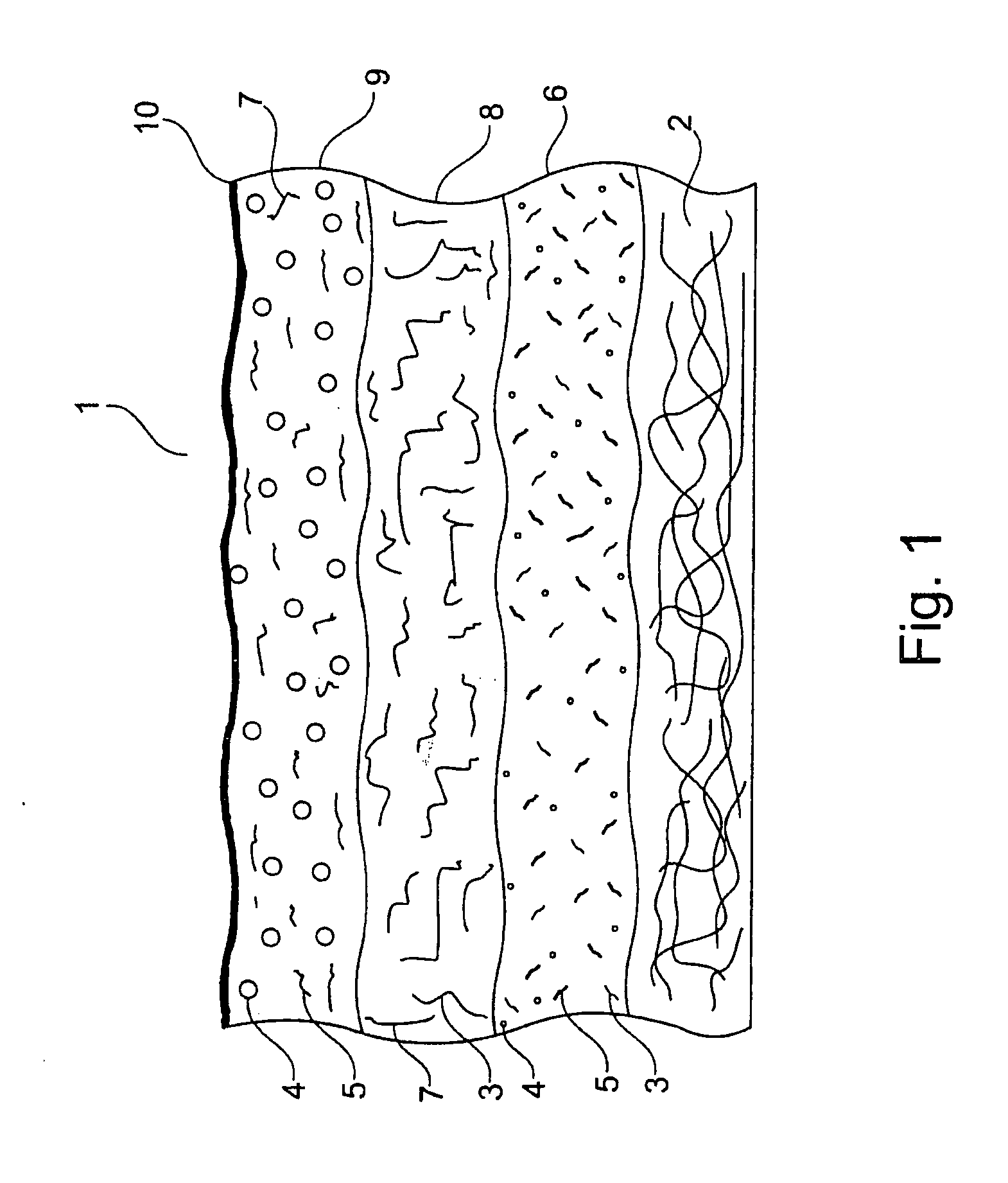

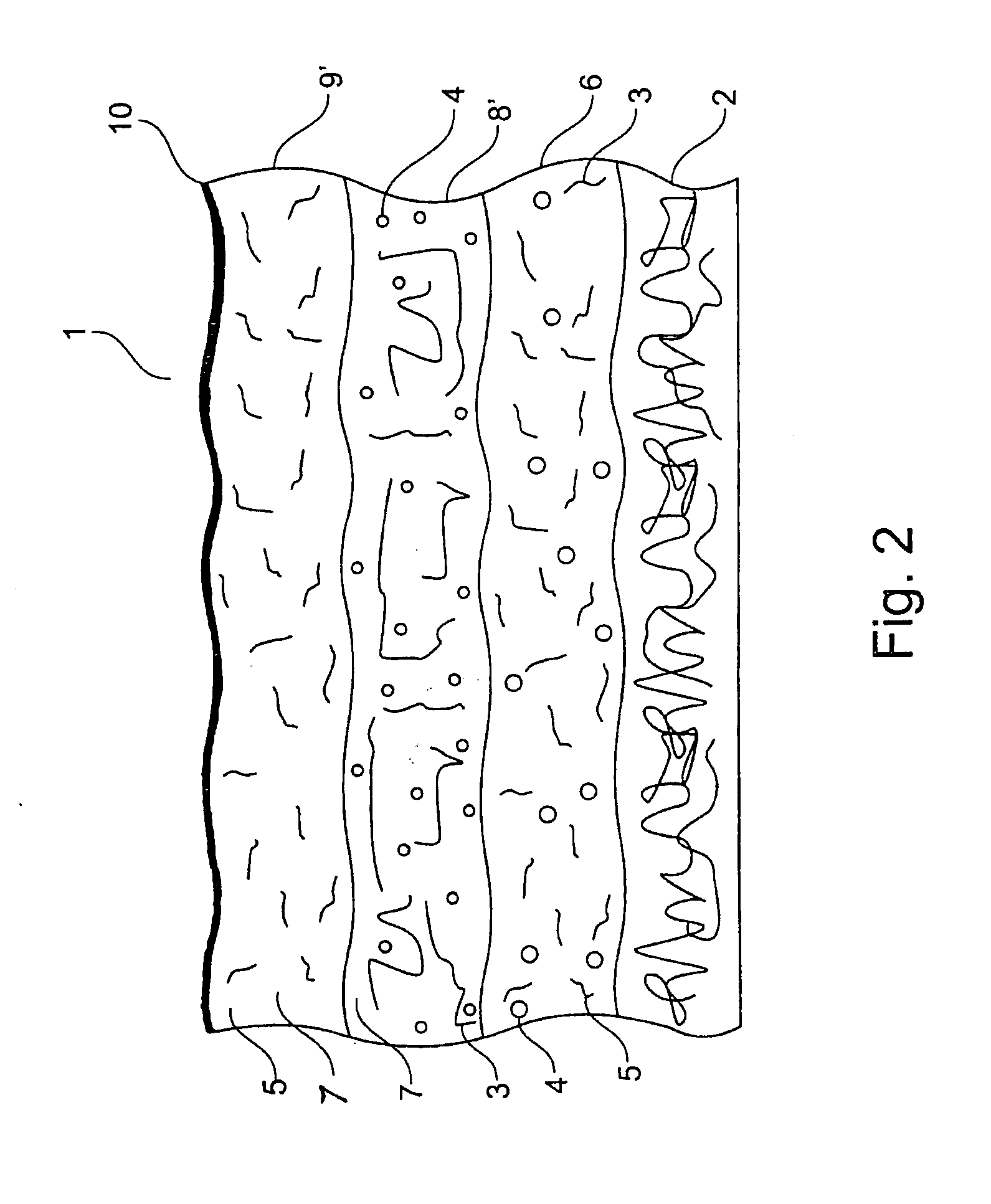

[0145]The absorbing ply structure 1 illustrated in FIG. 1 includes the following layers:[0146]a support layer 2 which includes a tissue and forms the first ply of the ply structure;[0147]a second ply 6 made of cellulose fluff pulp 3, SAP particles 4 and bonding fibers 5, e.g. bi-component fibers;[0148]a third ply 8 made of cellulose pulp 7 and cellulose fluff pulp 3;[0149]a fourth ply 9 made of cellulose pulp 7, preferably SAP particles 4, which, however, can also be omitted, and bonding fibers 5; and[0150]a layer made of a binding material 10, e.g. a latex binder.

[0151]The plies of the ply structure are disposed on top of one another and connected with one another in a subsequent calendering process using heat and pressure. Thus, the outer plies of the structure are compressed more than the center plies. The ply material 1 can also be configured without the support layer 2. The second ply 6 alone or in combination with the support layer 2 assumes the function of a liquid acquisitio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com