Patents

Literature

69results about How to "Good absorbing characteristics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

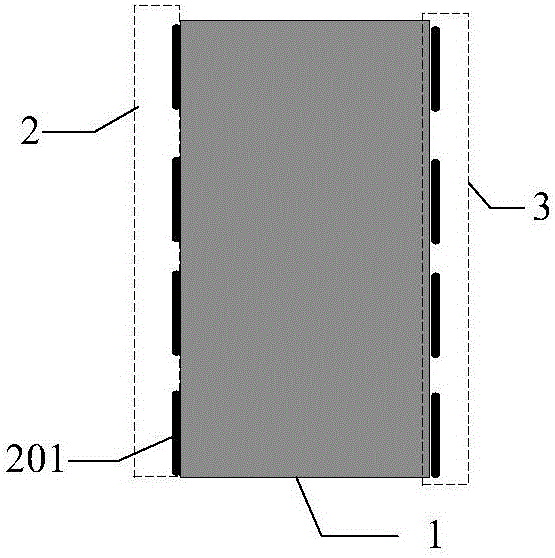

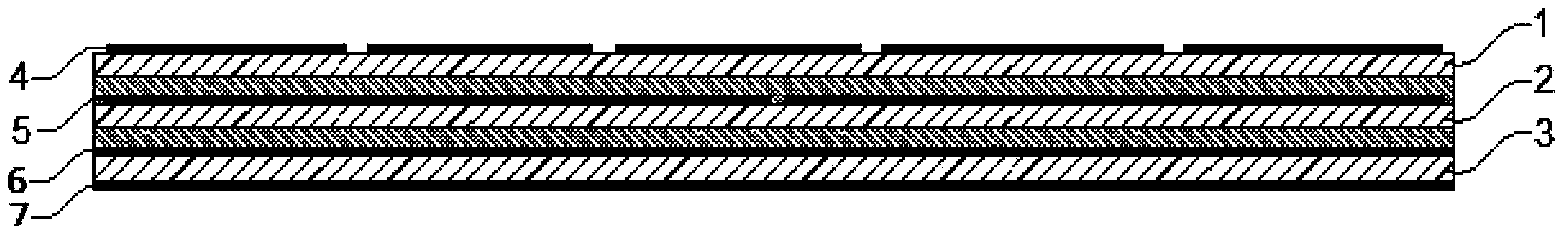

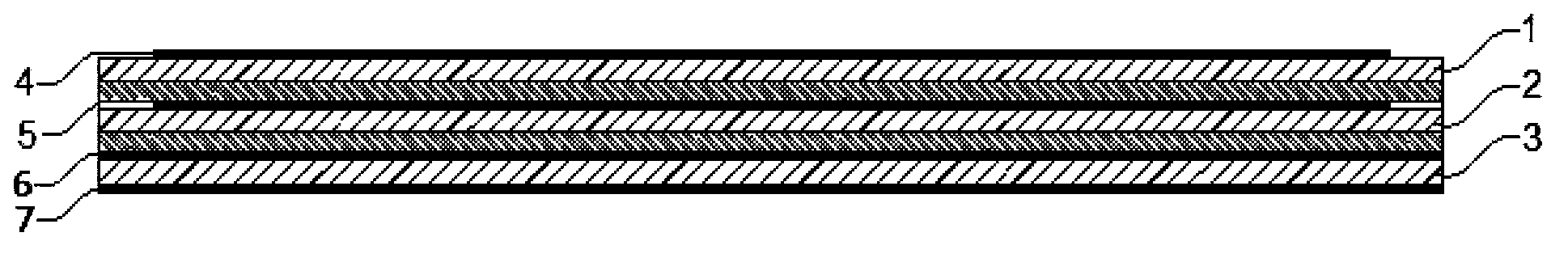

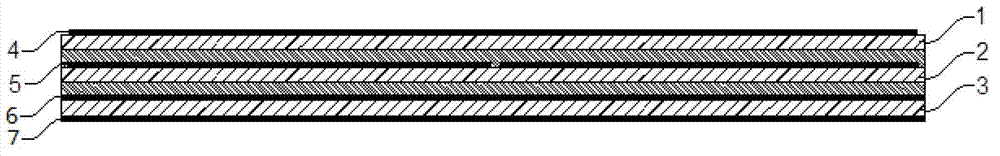

Net-shaped layered-structure electromagnetic wave absorbing metamaterial

ActiveCN105762531AGood absorbing characteristicsMagnetic/electric field screeningAntennasFilling materialsResonance

The invention relates to the field of electromagnetic stealth technology and radiation protection, and discloses a net-shaped layered-structure electromagnetic wave absorbing metamaterial. The electromagnetic wave absorbing material comprises: a first member (10) which at least includes one type of transparent flexible polymer materials and serves as an outer casing; a second member (20) which at least includes one type of flexible polymer materials and serves as a filling material between two metallic layers; a third member (3) which at least includes one type of metallic net-shaped structure and serves as a resonance net-shaped unit array. The third member (3) may adopt one type of metallic materials and may adopt plural metallic materials, and even alloy materials. The first member, the second member and the third member can all have many groups and form a multi-layered metamaterial structure. The layered-structure absorbing metamaterial of the invention increases absorbing width of electromagnetic waves and expands application range of the layered-structure absorbing metamaterial.

Owner:BEIJING JIAOTONG UNIV

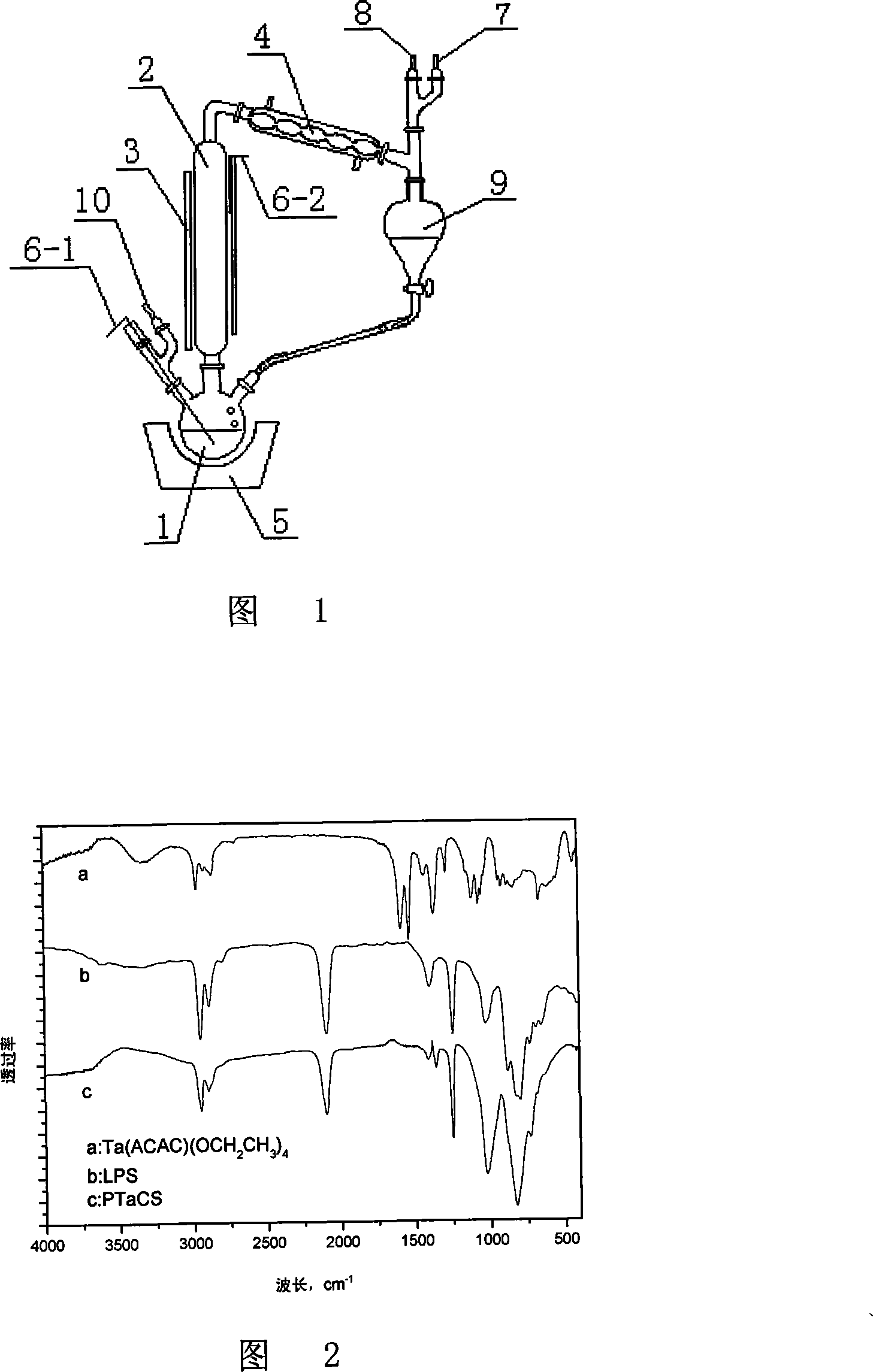

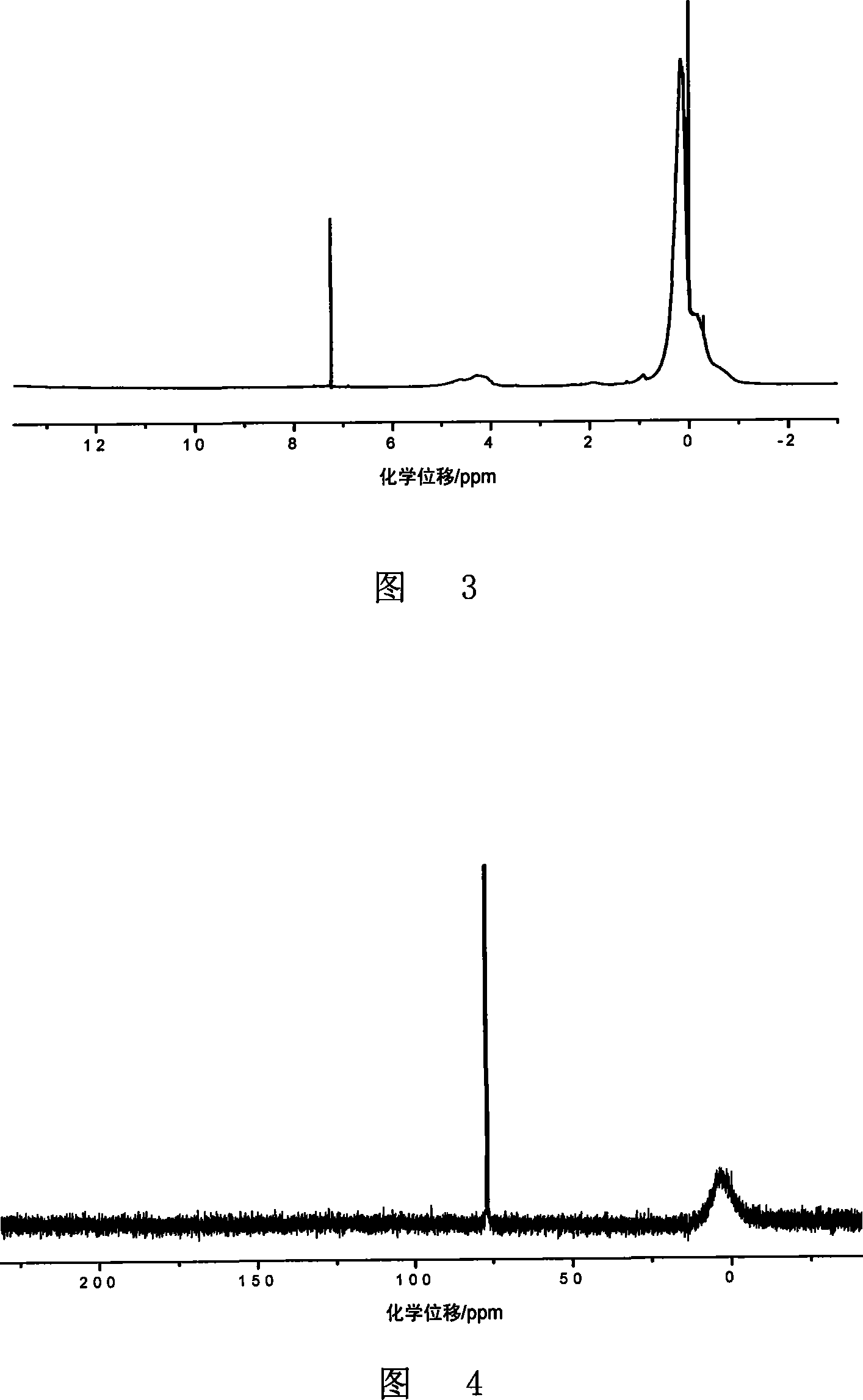

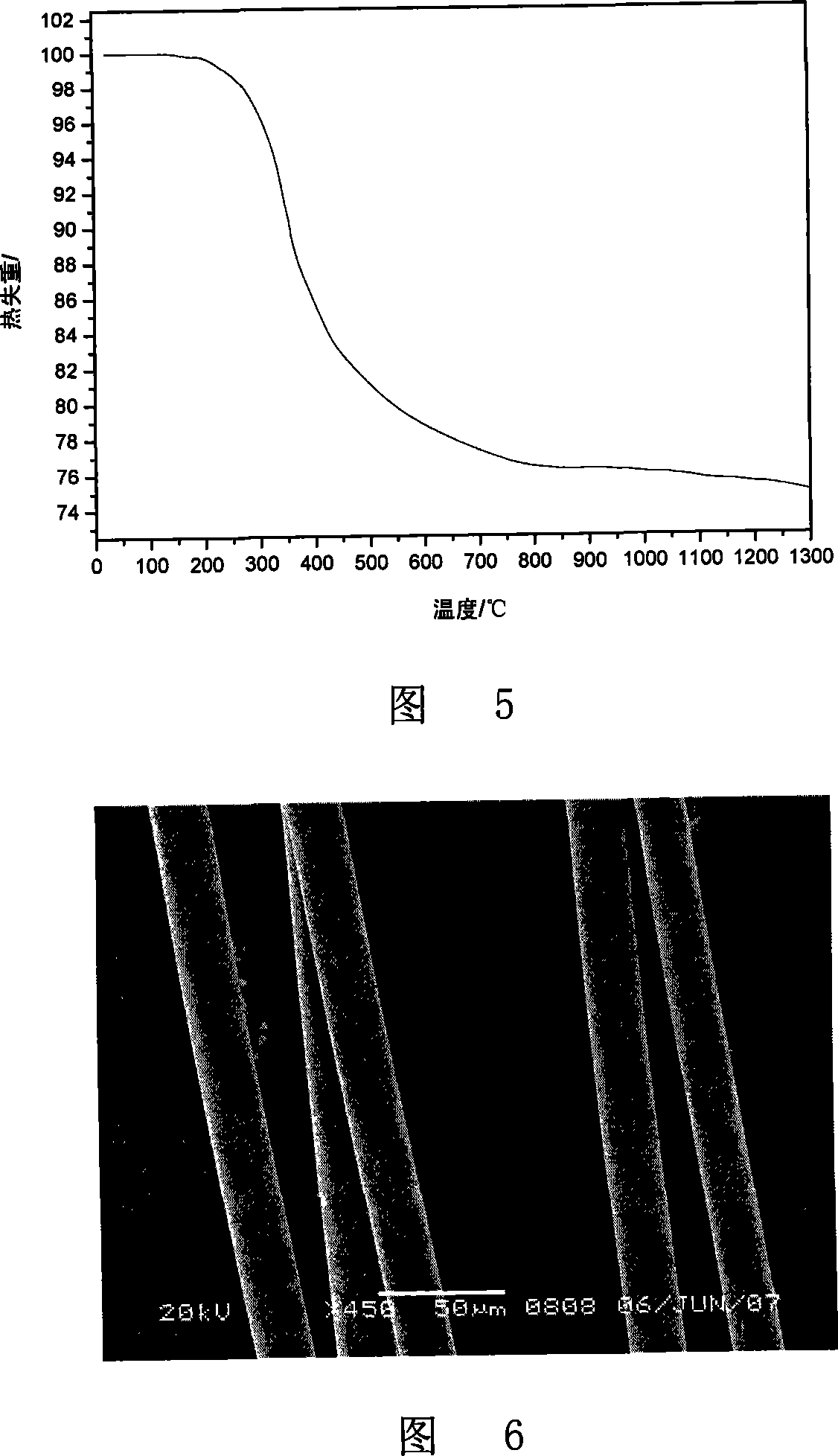

Method for synthesizing tantalum-containing SiC ceramic precursor

InactiveCN101186504AWide variety of sourcesControllable and adjustable contentFiberSynthesis methods

The invention discloses a synthesis method of an SiC-containing ceramics precursor, which comprises the steps that: 1. low molecular weight polymer with main chain containing silicon is sent into a three-mouth flask, and is added with 0.5wt% - 20wt% of tantalum organic compounds or chloride; 2. under the protection of Ar or N2 or compound of the Ar or N2, the temperature of the three-mouth flask is raised to 350 to 500 DEG C, and the temperature of a cracking column is controlled within 450 DEG C to 550 DEG C; then thermal decomposition rearrangement reaction is carried out for 0.5 to 25 hours, and then cooling is done; 3. the obtained rough product is dissolved by xylene and filtered; the filtrate solution is distilled by reducing temperature to between 250 to 390 DEG C, then the obtained material is cooled. The invention has the advantages of wide raw material source, reaction process being easy to be controlled, simple equipment, high purity of product, good formability, and good performance of super-high temperature and absorbing property; in addition, the ceramics fiber produced in the method has good oxidation resistance performance and is easy to realize large-scale industrial production.

Owner:NAT UNIV OF DEFENSE TECH

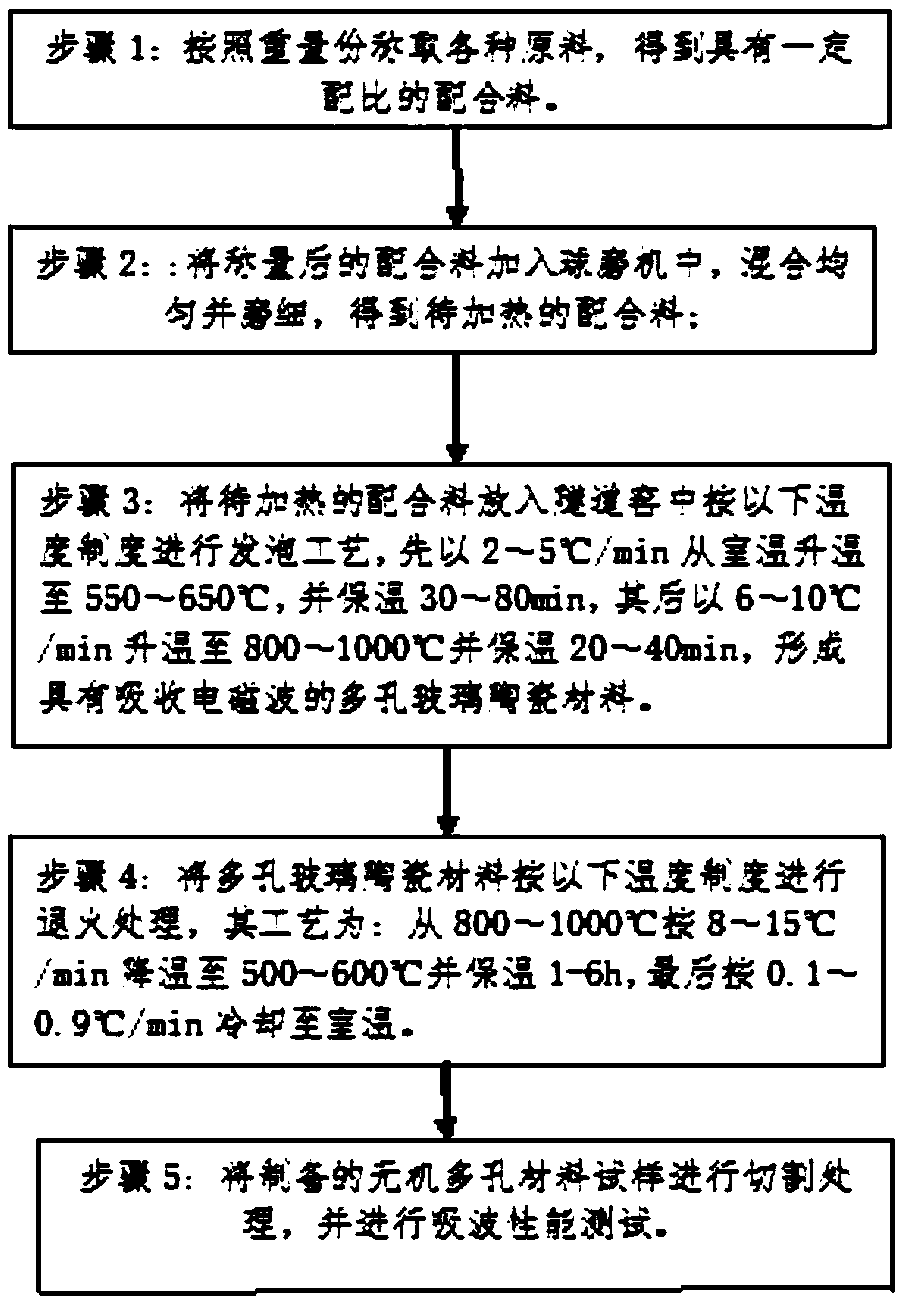

Porous glass ceramic capable of absorbing electromagnetic waves and preparation method thereof

InactiveCN105502951AHigh strengthIncreased durabilityOther chemical processesCeramicwareRadarMetallic materials

The invention provides a porous glass ceramic capable of absorbing electromagnetic waves and a preparation method thereof, and relates to the field of preparation of inorganic non-metallic materials. The porous glass ceramic is used for preventing and absorbing the electromagnetic waves. The preparation method comprises the steps that cullet, ceramic granulation powder, silicon carbide and antimonous oxide are adopted to serve as base materials of an inorganic porous material, one or more of graphite, ferrite and SiC fiber serve as media for dissipating the electromagnetic waves, ball-milling mixing is conducted on the base materials and the media for dissipating the electromagnetic waves, foaming of the base materials is achieved at certain temperature, and the inorganic porous radar wave absorbing material is formed finally. By means of the porous glass ceramic capable of absorbing the electromagnetic waves and the preparation method thereof, the plate-shaped or special-shaped machined radar wave absorbing material which is lightweight, high in strength, capable of keeping heat and insulating the heat and excellent in wave absorbing property can be obtained.

Owner:BEIJING UNIV OF TECH

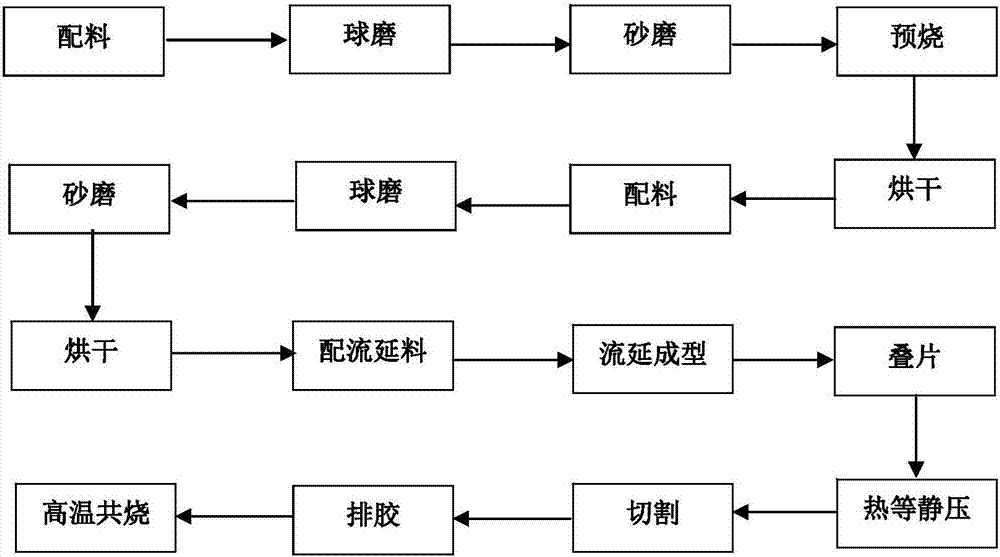

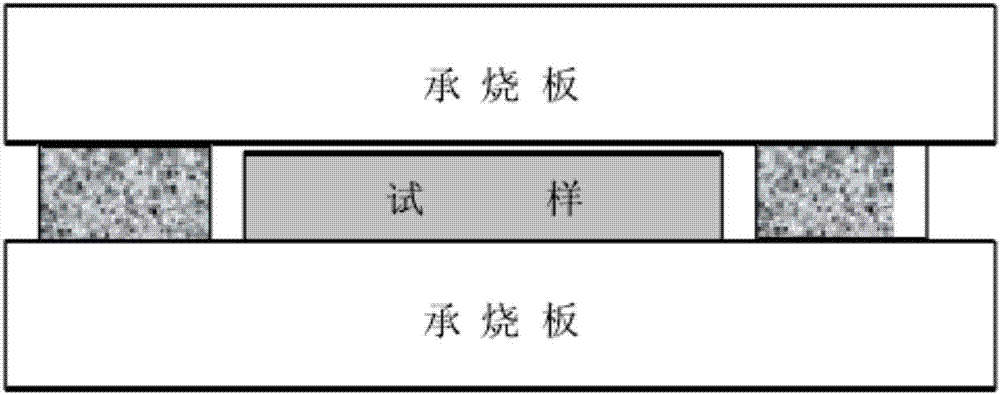

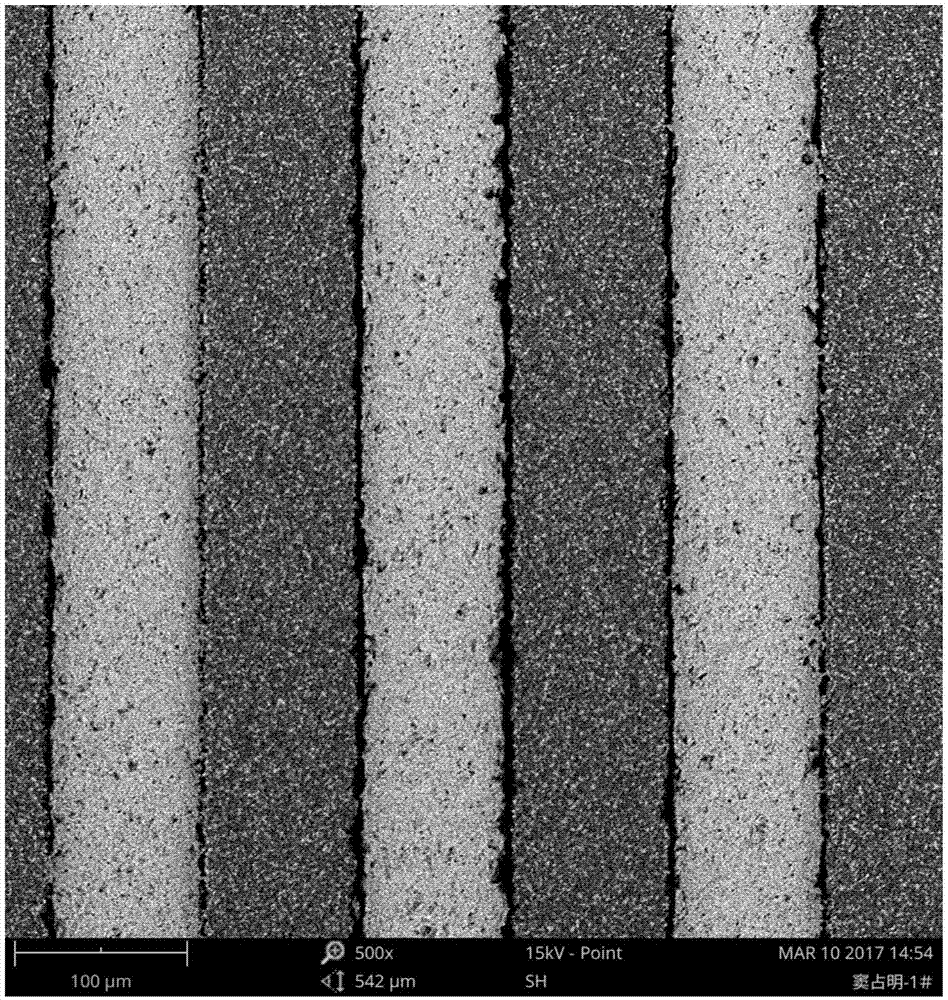

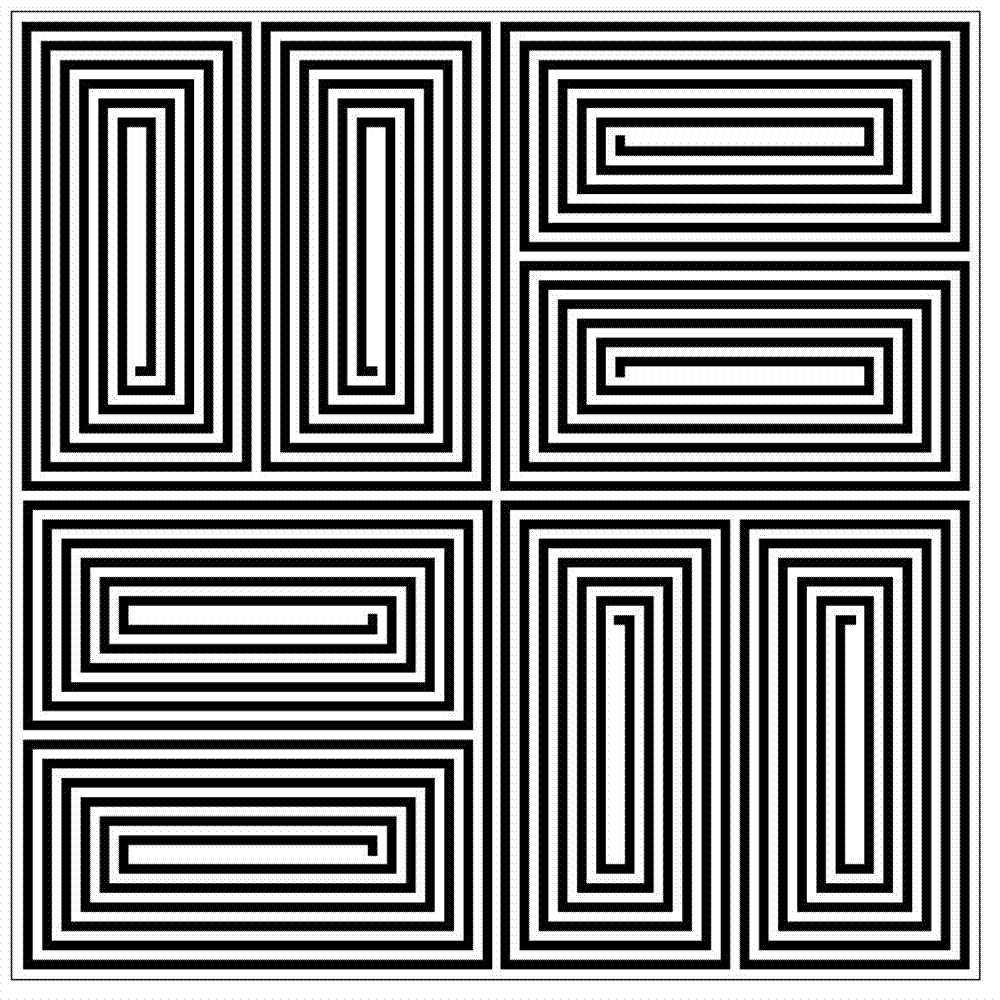

Microwave ferrite material and microwave dielectric ceramic high-temperature co-firing method

InactiveCN107021747ASolve the problem of high temperature co-firing matchingAddress reactivityMicrowaveMiniaturization

The invention provides a microwave ferrite material and microwave dielectric ceramic high-temperature co-firing method. According to the method, an auxiliary agent is added; the raw material grain diameter is regulated; a transition layer is inserted; the raw diaphragm thickness is controlled; the sintering temperature, the compacting speed rate, the sintering shrinking rate and the thermal expansion speed rate of two ceramic materials are regulated and controlled; the defects of warping, slabbing, cracks and the like caused by high-temperature co-firing are reduced; secondly, a high-quality raw porcelain belt is obtained by optimizing the tape casting formation process; finally, high-temperature co-firing is performed by a space limitation sintering method; the inner stress is ensured to be uniformly released; microdefects at the ceramic compound interface are reduced or inhibited. The method has the advantages that the problem of serious co-firing mismatching of microwave dielectric ceramic materials and microwave ferrite materials is solved; the high-temperature matched co-firing of 3 to 30 layers of microwave dielectric ceramic materials and microwave ferrite materials is realized; a material foundation is laid for further miniaturization of multilayer high-temperature and low-temperature co-firing microwave devices.

Owner:CHINA ZHENHUA GRP YUNKE ELECTRONICS

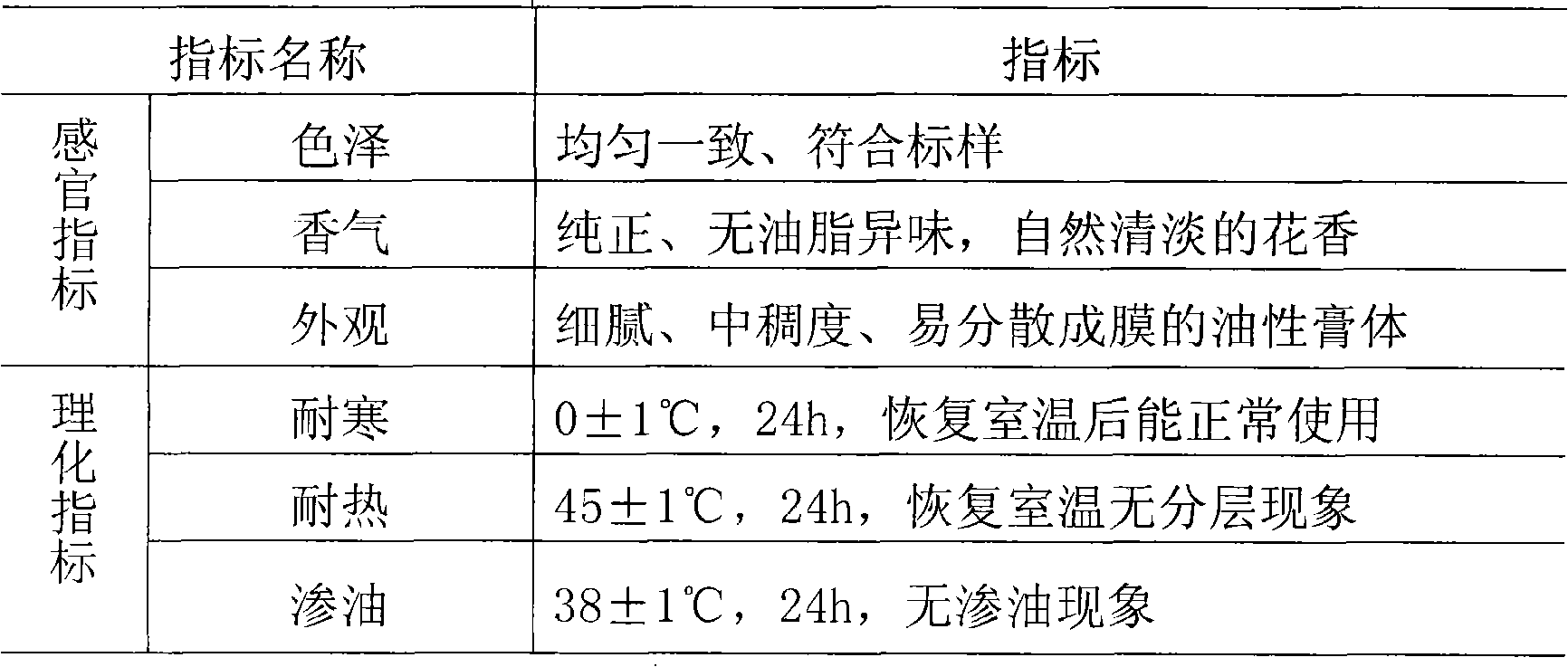

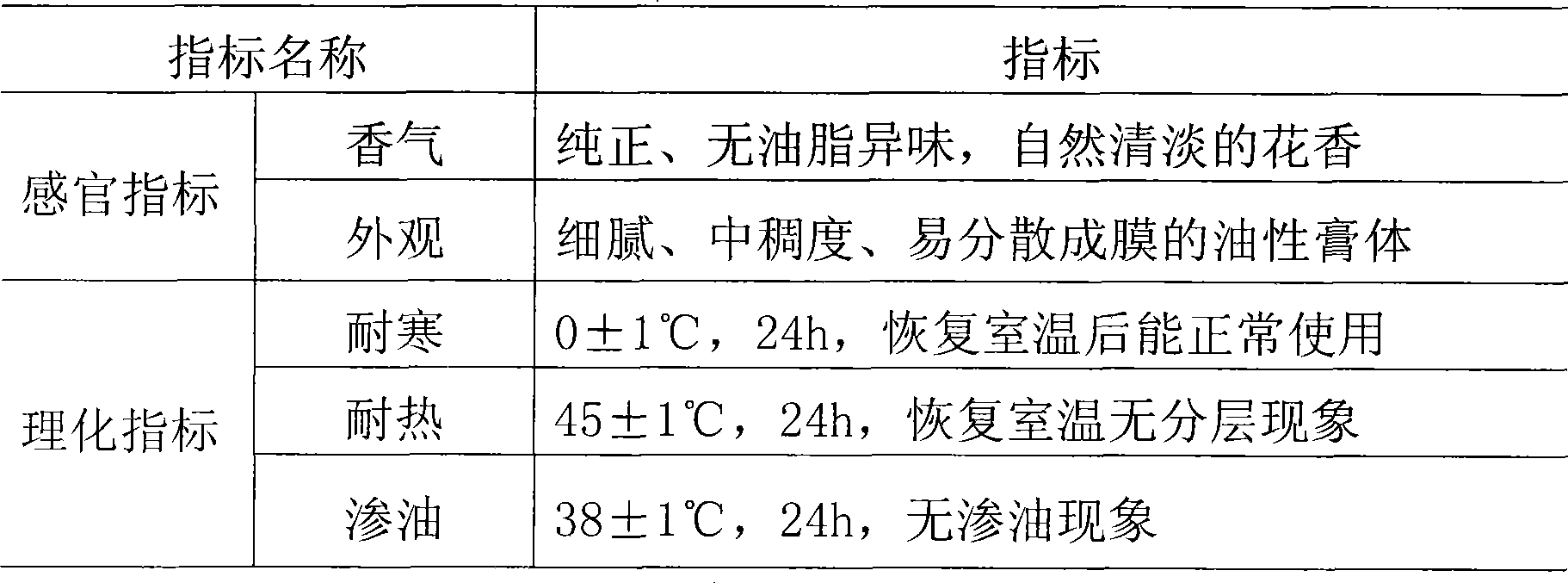

Military camouflage ointment and preparation thereof

The invention relates to a military camouflage ointment and a preparation method thereof, comprising 70 to 92 parts of matrix raw material; 1 to 8 parts of lake; 1 to 6 parts of titanium oxide; 1 to 6 parts of nano-zinc oxide; and 5 to 10 parts of DEET. Mineral oil and dimethyl silicone oil are firstly mixed and stirred, hydrogenated castor oil, ceresin and lanolin are added till the dissolution; talcum powder, the titanium oxide and the nano-zinc oxide are further added and stirred for even mixing; the lake and the DEET are added, and then the homogenization, the filling, the sealing and the preservation are carried out. The ointment of the invention can solve the technical problems that the existing military camouflage ointment can not simultaneously meet the purposes of meeting camouflage, preventing UV burns, infrared ray, visible light and mosquito bites, the ointment of the invention can prevent the UV burns, the mosquito bites and the infrared ray, thus having the advantages of safety, no allergy, no toxicity or side effects, mild aroma, good air permeability, insolubility in water, easy cleaning, high performance-price ratio, convenient carrying and good stability.

Owner:XIAN HANGJIE CHEM TECH

Wave-absorbing metamaterial and preparation method thereof

ActiveCN103788520AGood absorbing characteristicsBulk chemical productionPolystyreneInorganic materials

The invention discloses a wave-absorbing metamaterial and a preparation method thereof. The wave-absorbing metamaterial comprises the following components in percentage by volume: 30%-90% of syndiotactic polystyrene (SPS), 7%-69% of aerogels and 1%-33% of magnetic metal powder. The wave-absorbing metamaterial not only has good in wave-absorbing performance but also is relatively wide in temperature-resistant range as the aerogels in the wave-absorbing metamaterial are all inorganic materials; the SPS is crystalline and can enable the overall temperature-resistant range of a system to be expanded to be 270 DEG C, and the temperature-resistant range is greatly expanded in comparison with that of other thermoplastic resin.

Owner:KUANG CHI INST OF ADVANCED TECH

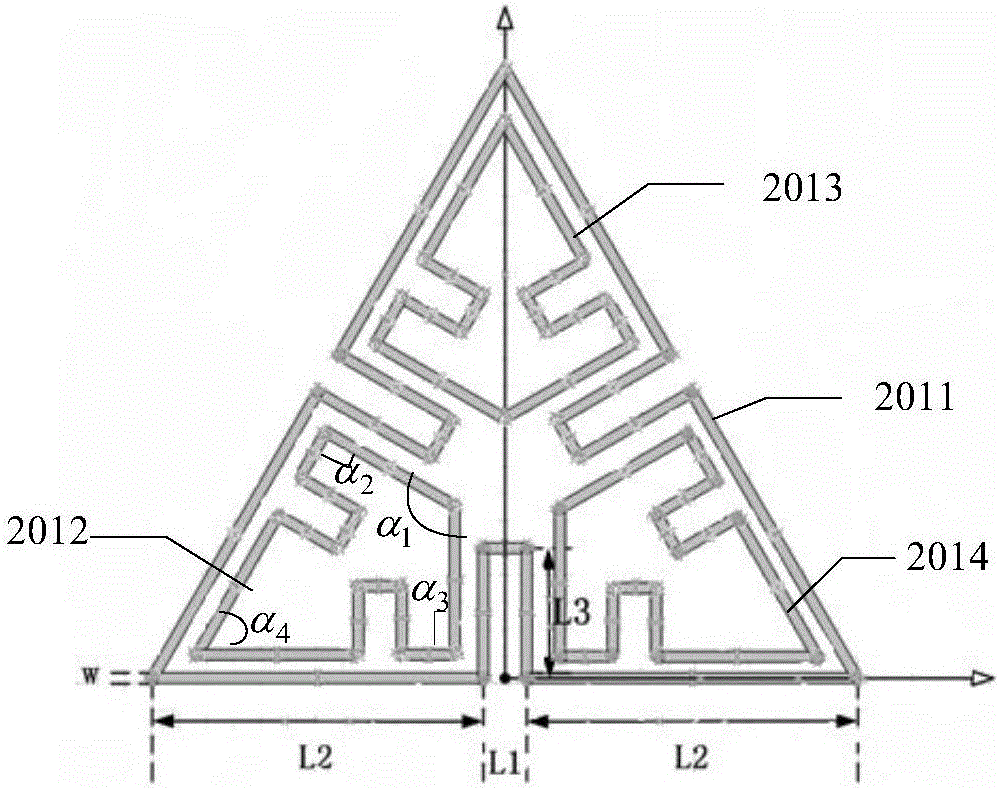

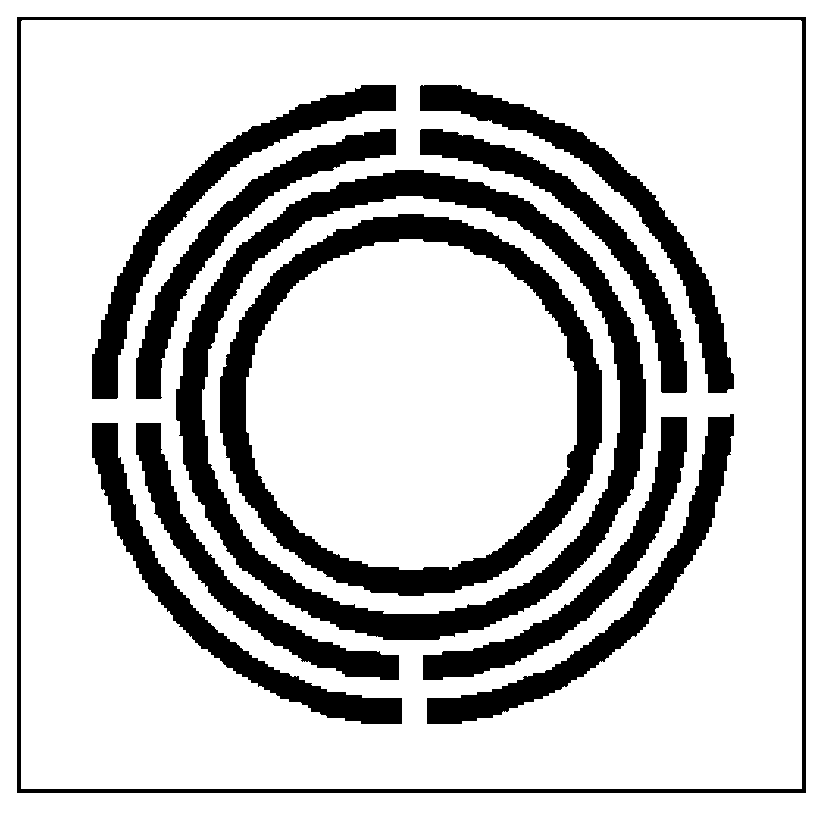

Fractal-element-based frequency selective surface structure and window absorber

ActiveCN105870638AGood absorbing characteristicsImprove feature indicatorsAntennasDielectric plateBase frequency

The invention discloses a fractal-element-based frequency selective surface structure which comprises a first frequency selective surface layer and a first dielectric plate, wherein the first frequency selective surface layer comprises a plurality of patch elements; each patch element comprises a first fractal ring, a second fractal ring, a third fractal ring and a fourth fractal ring; the first fractal ring is a regular triangle ring; each side is provided with a U-shape bending part; the second fractal ring, the third fractal ring and the fourth fractal ring are located in the regular triangle ring and are in rotational symmetry distribution about the center of the regular triangle ring; the second fractal ring, the third fractal ring and the fourth fractal ring are quadrangle rings; the first vertex angle, the second vertex angle and the third vertex angle are 120 degrees, 90 degrees and 90 degrees in sequence; the fourth vertex angle is opposite to the first vertex angle; and two sides of the fourth vertex angle are provided with the U-shaped bending parts respectively. The frequency selective surface structure disclosed by the invention has good polarization stability; and the wave-transmitting characteristic can be effectively improved on the basis of keeping the wave-absorbing characteristic. Furthermore, the invention further discloses a frequency selective surface structure-based window absorber.

Owner:BEIJING INST OF ENVIRONMENTAL FEATURES

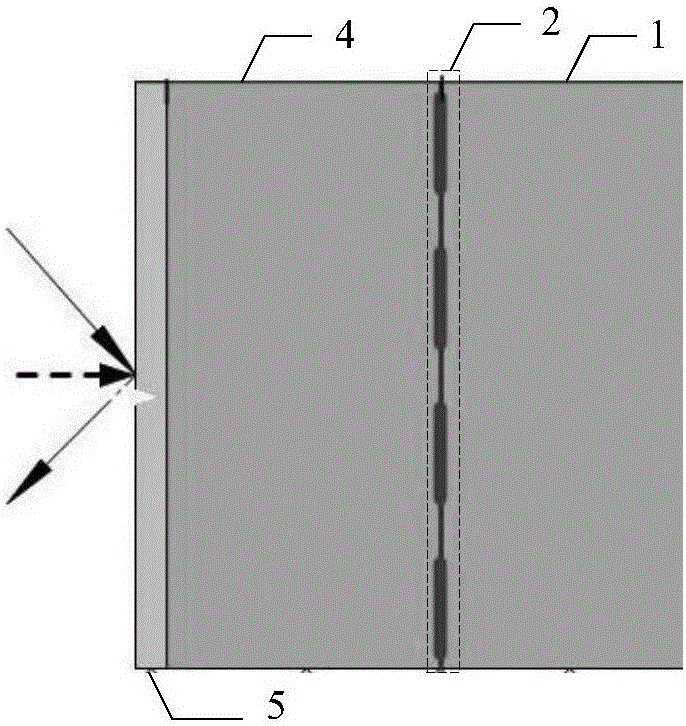

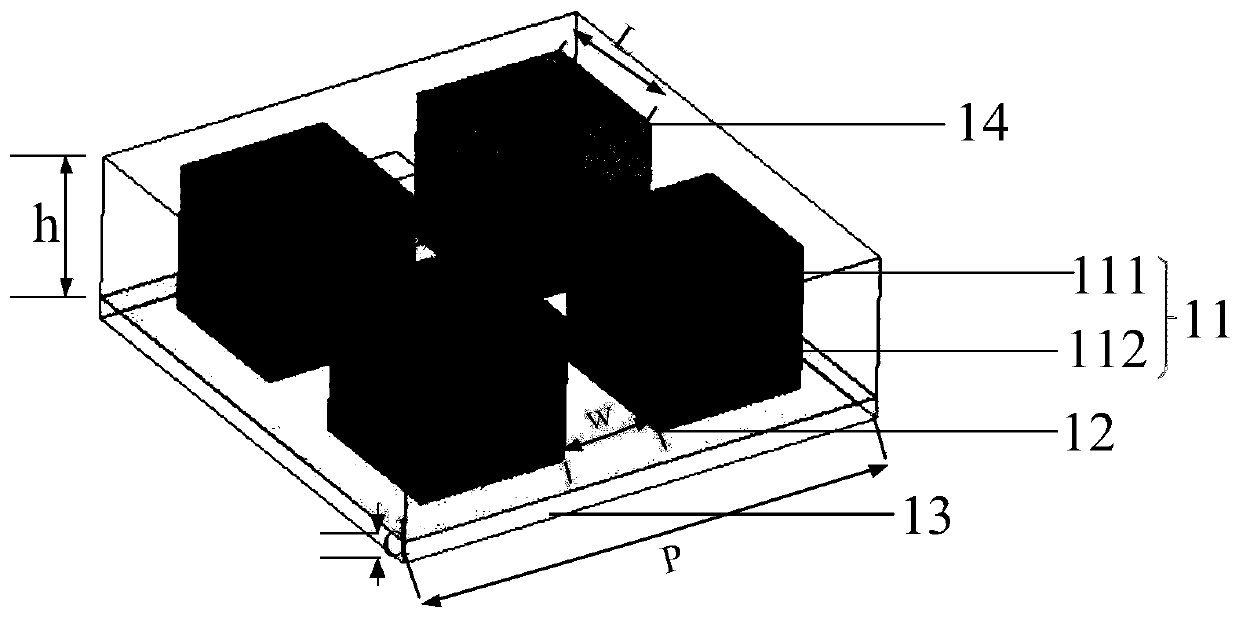

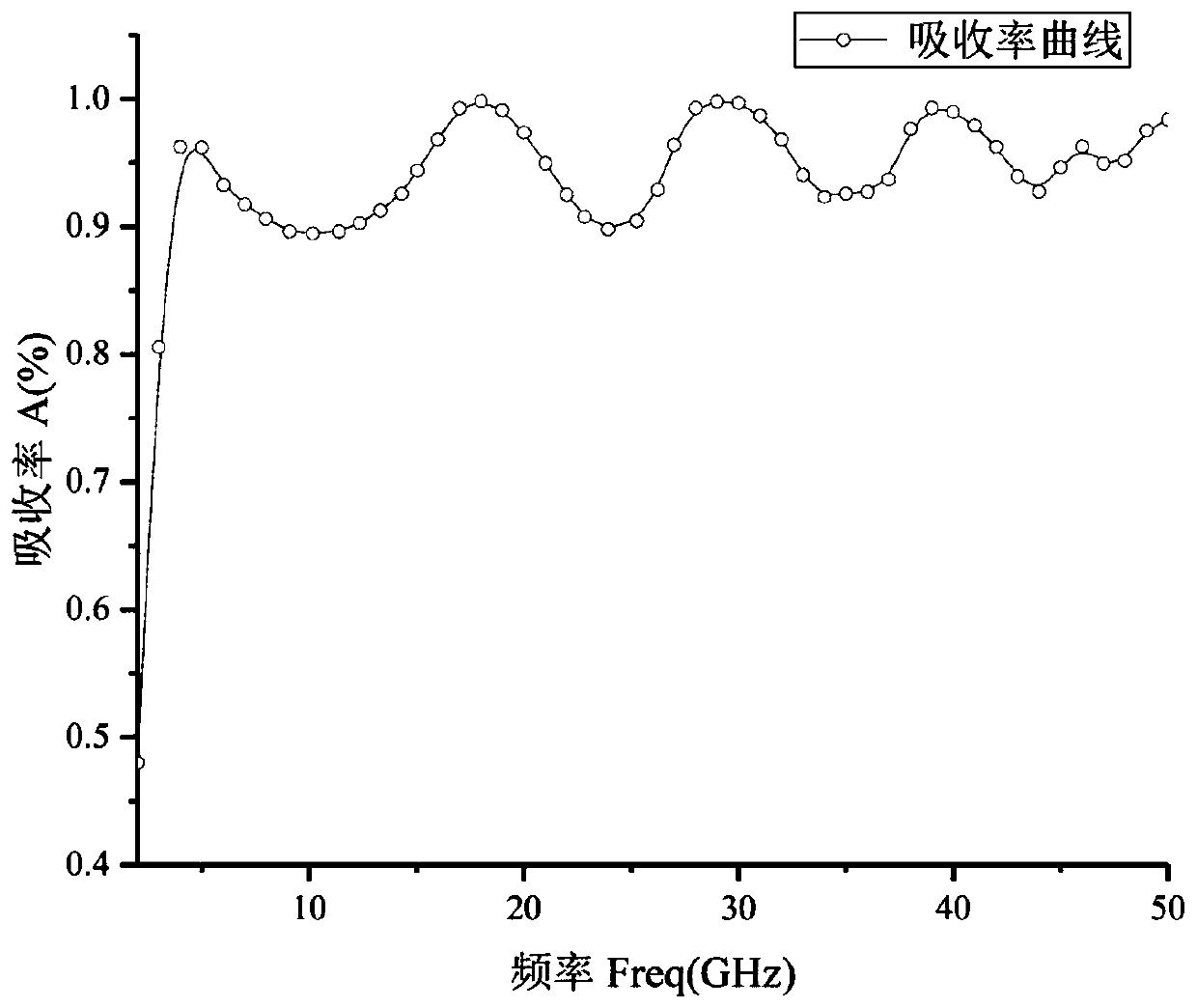

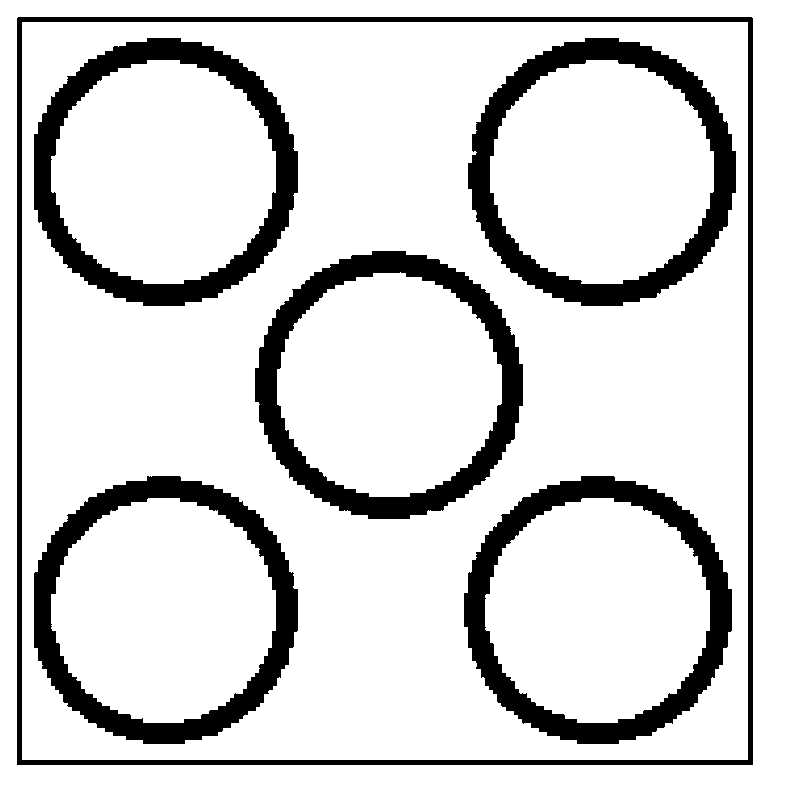

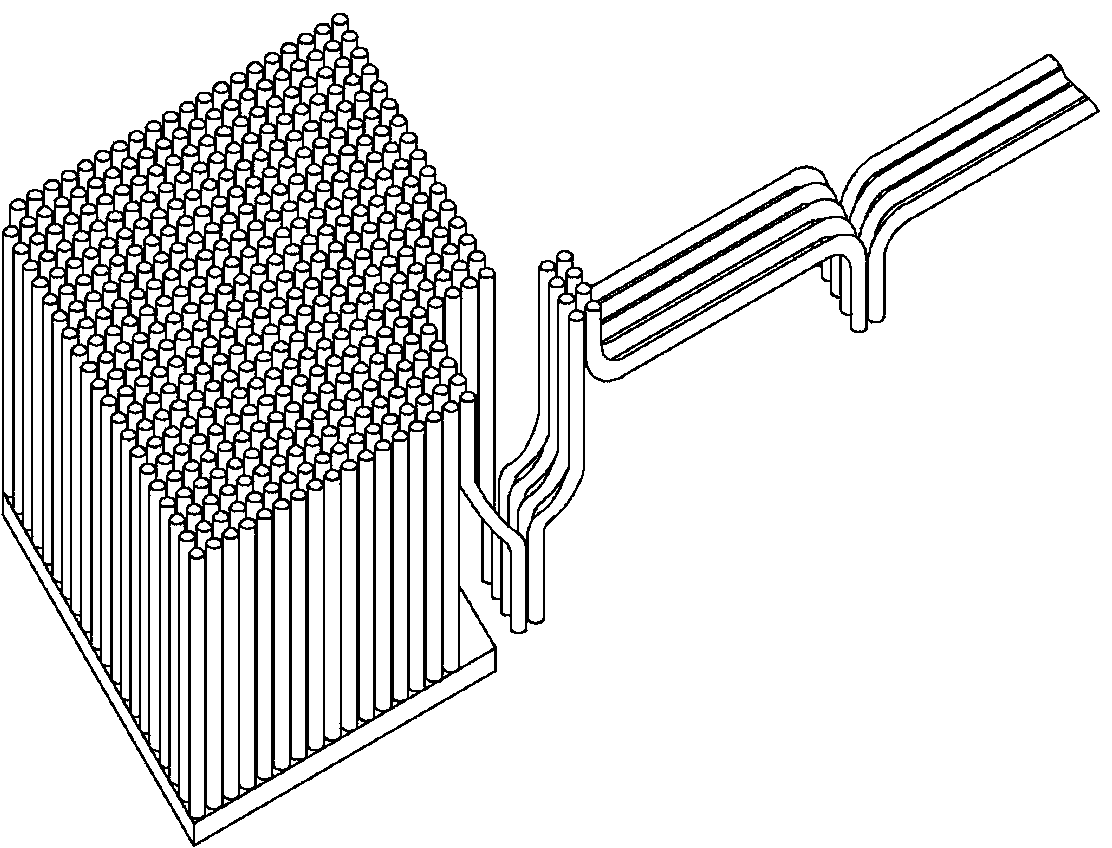

Composite three-dimensional ultra-wide-band metamaterial transparent wave absorber

InactiveCN110534908AHas low frequency absorption characteristicsGood ultra-bandwidth absorbing characteristicsAntennasTransmittanceEngineering

The invention discloses a composite three-dimensional ultra-wide-band metamaterial transparent wave absorber, which comprises a plurality of structural units. The structural units are periodically andcontinuously distributed in two dimensions; each structural unit sequentially comprises a lower-layer structure, a middle-layer structure and an upper-layer structure from bottom to top; the middle-layer structure comprises four hollow cylinder units, and the four hollow cylinder units are arranged in a rectangular array; each hollow cylinder unit is of a rotationally symmetrical regular N-polygon hollow cylinder structure; the side wall of the hollow cylinder structure serves as a supporting layer, and a conductive film layer is attached to the inner side; the upper-layer structure comprisesa frequency selection surface; the lower-layer structure comprises a substrate layer and a back plate layer; and the structural units are made of transparent materials. According to the wave absorberprovided by the invention, the problem that the existing wave absorber cannot give consideration to broadband wave absorption and high visible light transmittance is solved, and the design of novel transparent wave absorption is realized.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

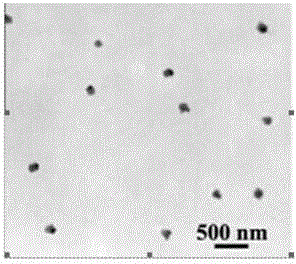

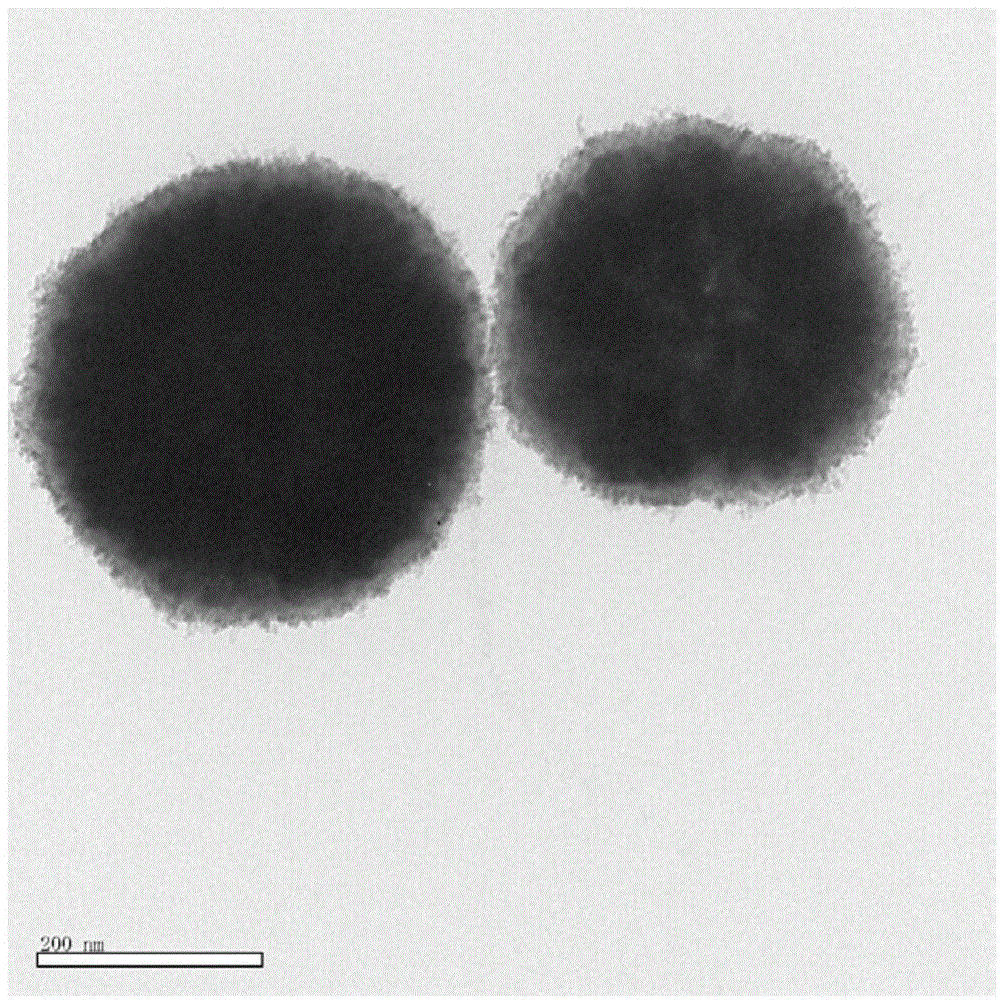

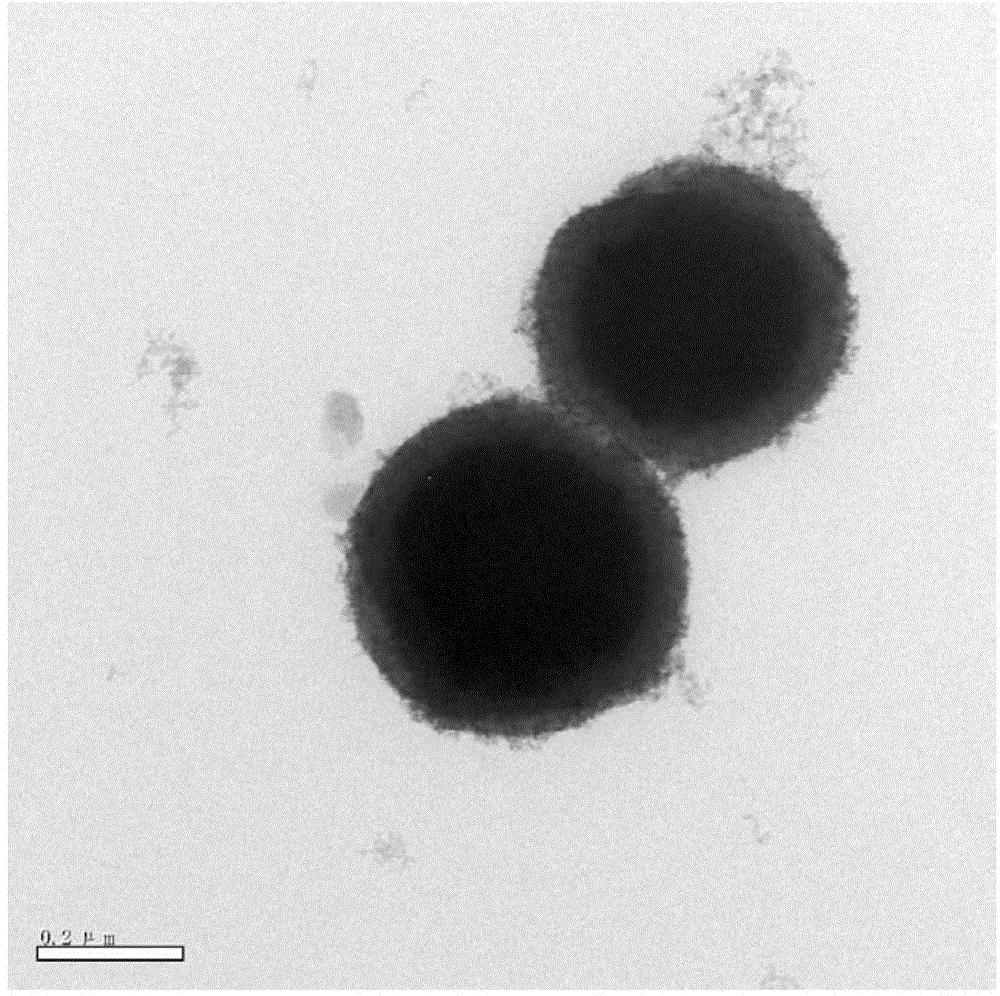

Fe3O4@SiO2@ZnO ternary heterostructure core-shell nanoparticle and preparation method therefor

InactiveCN105374491AGood dispersionAvoid inhomogeneitySilicaChloride preparationDispersityMicrosphere

The invention discloses an Fe3O4@SiO2@ ZnO ternary heterostructure core-shell nanoparticle and a preparation method therefor. The preparation method comprises the steps of obtaining an Fe3O4 nanoparticle through a conventional hydrothermal method; performing surface modification on the Fe3O4 nanoparticle through a trisodium citrate water solution; and coating the surface of the modified Fe3O4 nanoparticle with SiO2 through a Stober method to obtain an Fe3O4@SiO2 nanoparticle; and coating the surface of the Fe3O4@SiO2 nanoparticle with ZnO through thermal decomposition of zinc salt to obtain the Fe3O4@SiO2@ZnO nanoparticle. The preparation method solves the shortcomings of high probability of agglomeration, uneven coating layer, incomplete coating and the like existing in the preparation of the Fe3O4 based ternary heterostructure core-shell nanoparticle; the prepared Fe3O4@SiO2@ZnO ternary heterostructure core-shell nanoparticle is uniform in the coating layer, and extremely high in the dispersity, uniformity, magnetic responsiveness and wave absorption property; and in addition, the preparation process is environment-friendly and pollution-free.

Owner:NANJING UNIV OF SCI & TECH

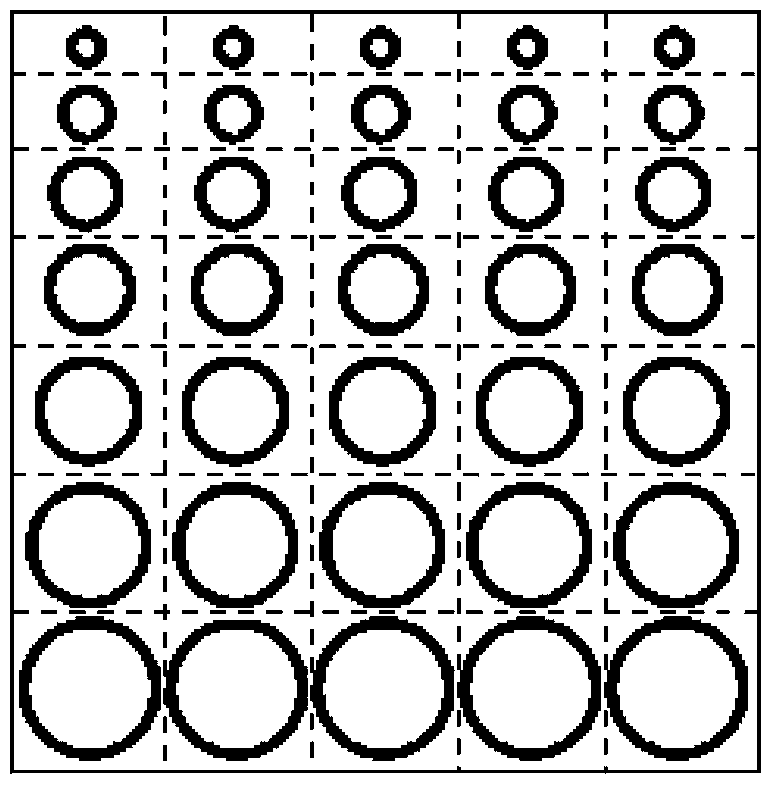

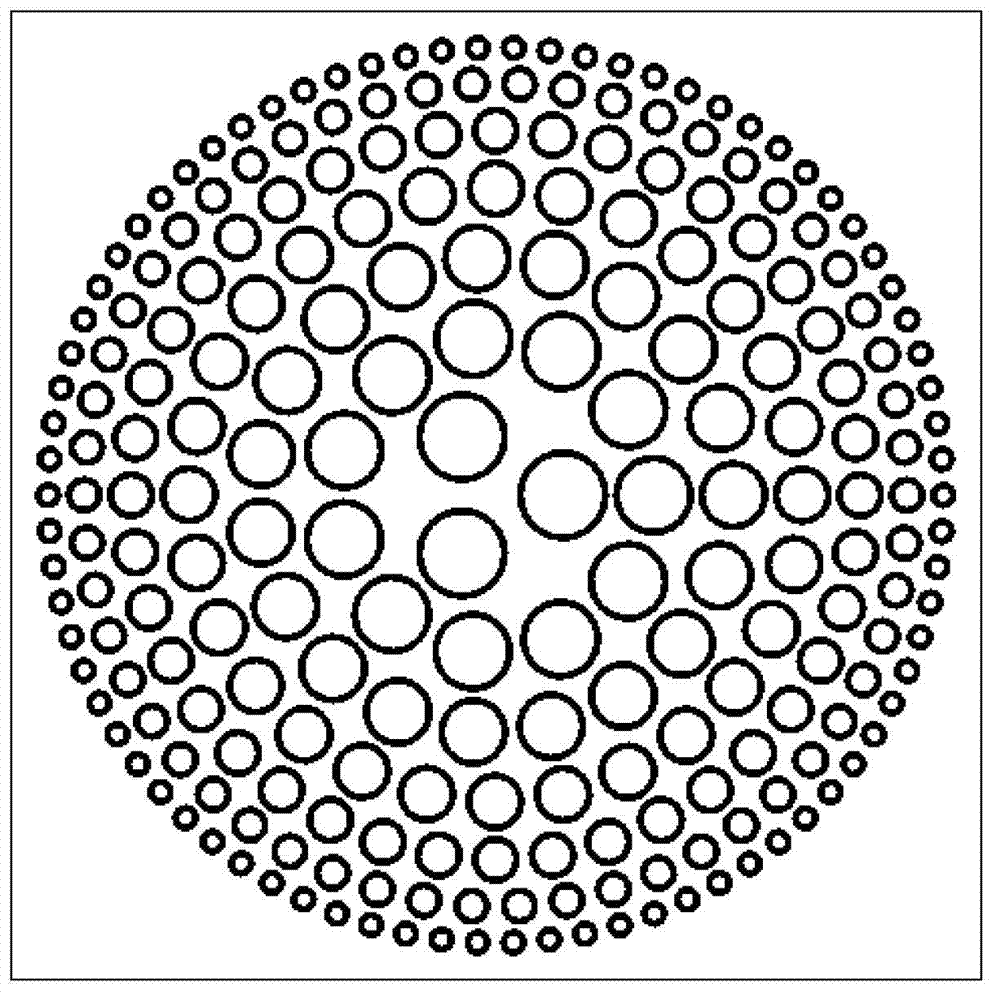

Wave absorbing material

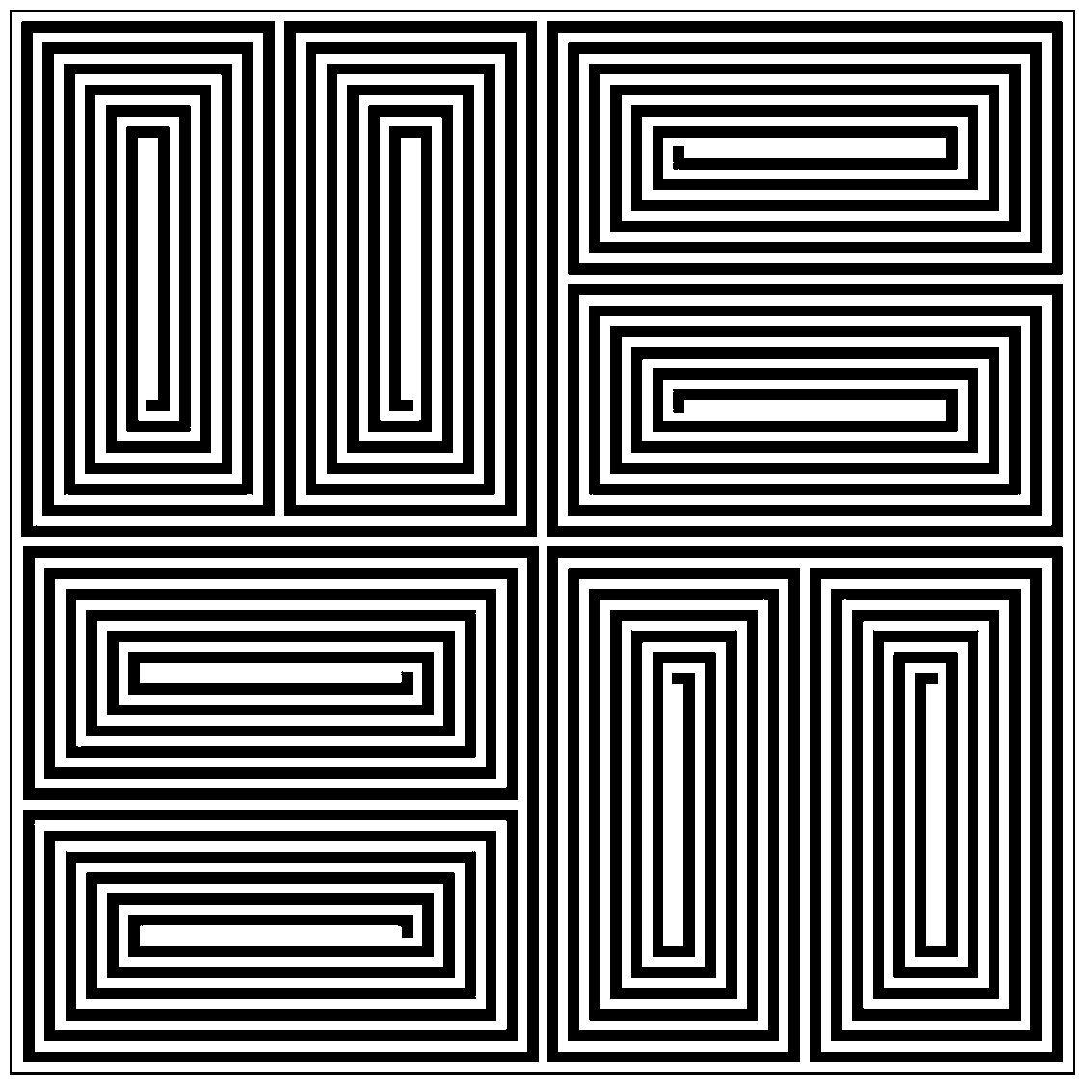

ActiveCN103582402AGood absorbing characteristicsMagnetic/electric field screeningOptoelectronicsMetal microstructure

The invention relates to a wave-absorbing material which comprises at least one material sheet layer. Each material sheet layer comprises three layers of substrates which include the first substrate, the second substrate and the third substrate from top to bottom. Each substrate comprises at least one substrate unit, and the upper surface of each substrate unit is provided with a metal microstructure in an attached mode. The size of each substrate unit and the size of the corresponding metal microstructure of the first substrate decrease gradually from one side to the other side opposite to the one side of the first substrate, and the corresponding artificial microstructure is a hollow ring structure; the metal microstructure attached to the upper surface of each substrate unit of the second substrate is of an open ring structure, and the two ends of the open ring are spirally wound inwards respectively to form two spiral structures which are not intersected with each other; the metal microstructure attached to the upper surface of each substrate unit of the third substrate is complementary to the metal microstructure attached to the upper surface of each substrate unit of the second substrate. The wave-absorbing material of the structure has good wave-absorbing performance on low-frequency stages.

Owner:KUANG CHI INST OF ADVANCED TECH

Wave absorbing material

ActiveCN103582403AGood absorbing characteristicsMagnetic/electric field screeningOptoelectronicsMetal microstructure

The invention relates to a wave absorbing material which comprises at least one material sheet layer. Each material sheet layer comprises three layers of substrates which are the first substrate, the second substrate and the third substrate from top to bottom, each substrate comprises at least one substrate unit, and the upper surface of each substrate unit is provided with a metal microstructure in an attached mode. The metal microstructures attached to the upper surfaces of the substrate units of the first substrate are the same in size, and at least one of the metal microstructures is a hollow ring structure; the metal microstructures attached to the upper surfaces of the substrate units of the second substrate are hollow rings with at least two common central points and of different sizes or are hollow rings with openings; the metal microstructures attached to the upper surfaces of the substrate units of the third substrate are complementary to metal microstructures attached to the upper surfaces of the substrate units of the second substrate. The wave-absorbing material of the structure has good wave-absorbing performance on low-frequency stages.

Owner:KUANG CHI INST OF ADVANCED TECH

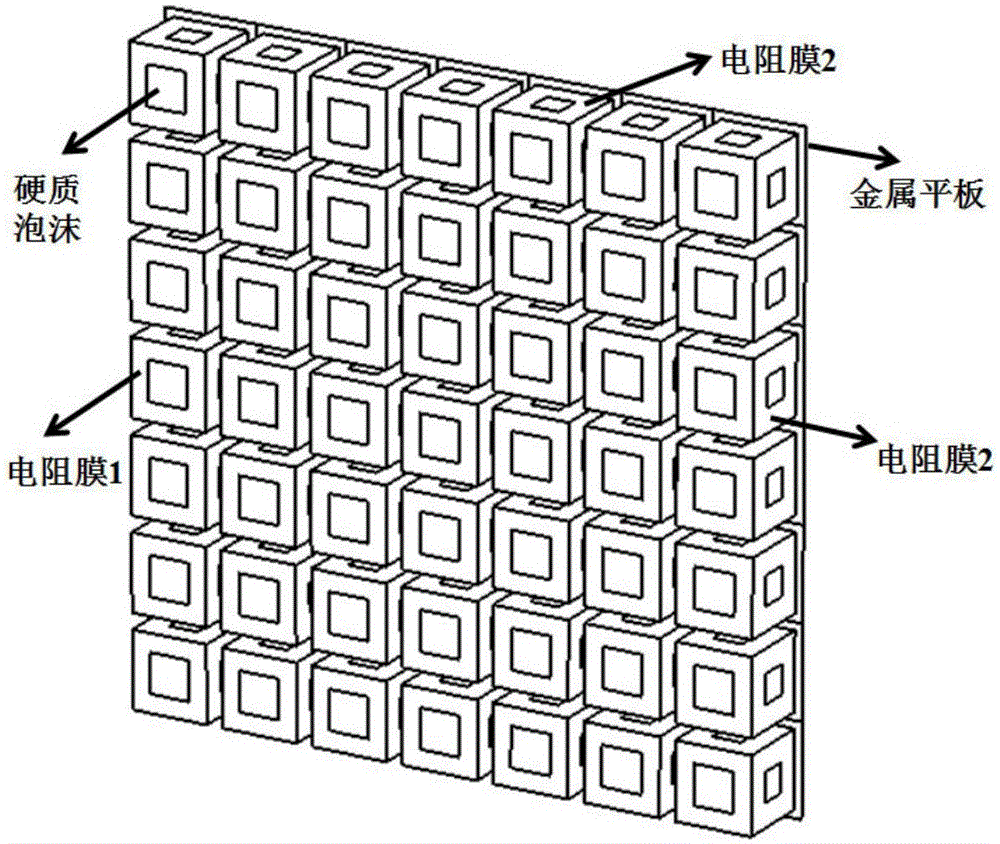

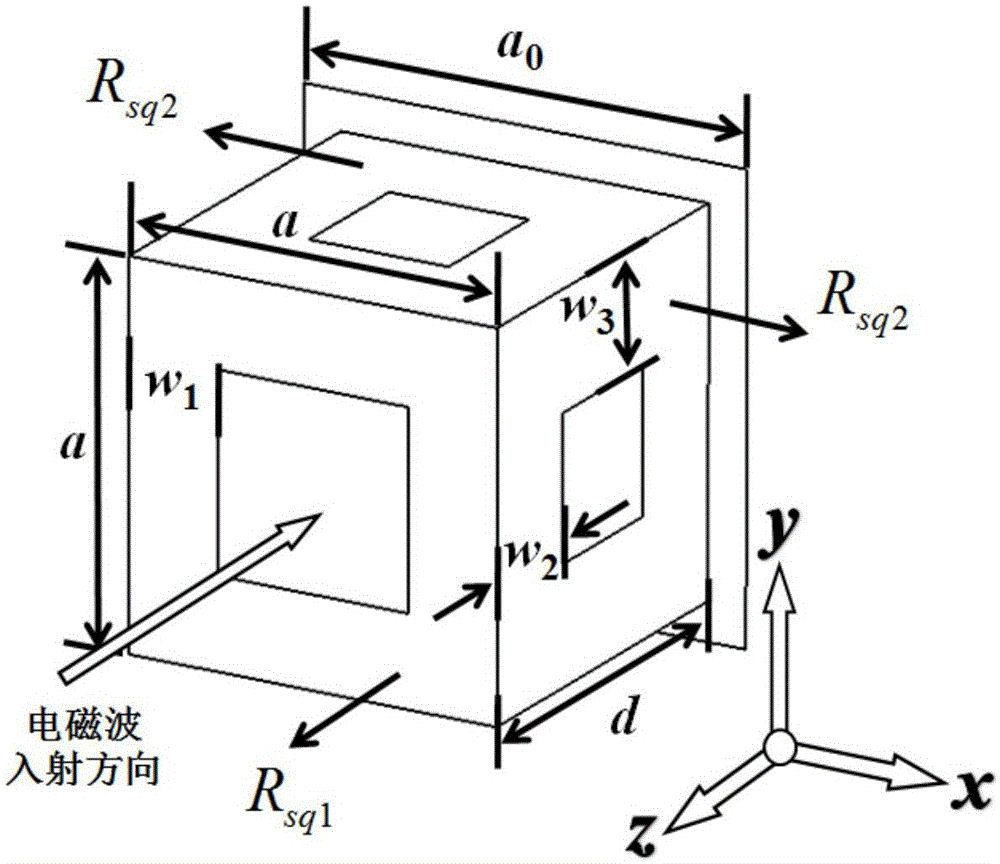

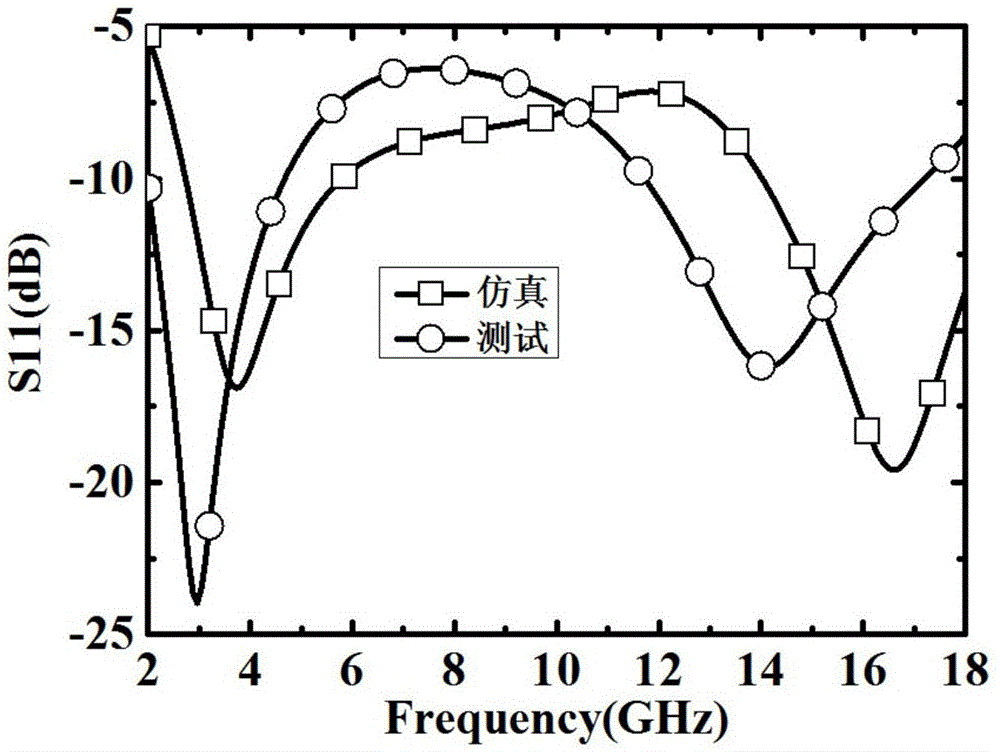

Stereo unit broadband period wave-absorbing structure

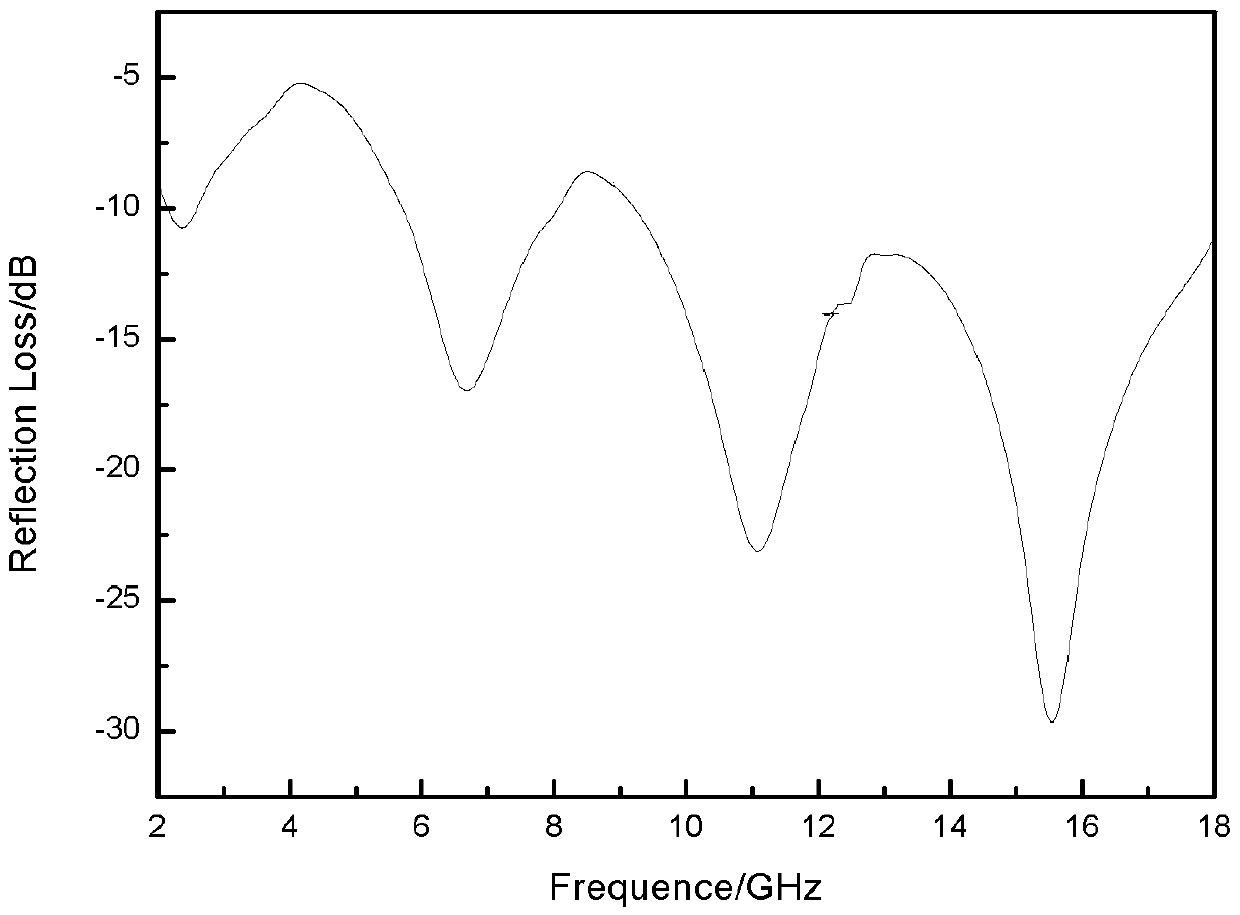

ActiveCN105101764ALight in massEliminate total reflectionMagnetic/electric field screeningUnit structureIntermediate frequency

The invention belongs to the technical field of electronic materials, especially relates to an electromagnetic wave-absorbing structure and provides a stereo unit broadband period wave-absorbing structure. The bottom layer of the stereo unit broadband period wave-absorbing structure is a metal plate. Cuboid-shaped hard foam composite unit structures printed with resistor film figures are periodically arranged above the metal plate, and the unit period is a0. Besides the surface bonded to the metal plate, the other five surfaces of each cuboid-shaped hard foam composite unit structure are also provided with the resistor films, wherein the upper surface perpendicular to an electromagnetic wave incident direction is in a square shaped and is printed with a square-annular-shaped resistor film, and the resistance is Rsq1; four side surfaces perpendicular to the upper surface are rectangular and are printed with square-annular-shaped resistor films whose resistance is the Rsq2. According to the invention, the wave-absorbing performance of the middle frequency (8-12GHz) is improved, and the incident electromagnetic waves can be absorbed by more than 80% in a 3-18GHz broadband scope.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

Electrically calcined coal-based carbon brick with high thermal conductivity and high corrosion resistance and preparation method thereof

ActiveCN108002854AImprove the degree of graphitizationReduce manufacturing costCeramicwareAir atmosphereBrick

The invention relates to an electrically calcined coal-based carbon brick with high thermal conductivity and high corrosion resistance and a preparation method thereof. According to the technical scheme, 8 to 16wt% of microwave treated electrically calcined coal fine powder, 10 to 25wt% of alpha-Al2O3 micro powder, 4 to 8wt% of silicon powder, 1 to 4wt% of aluminum titanium alloy powder and 2 to 4wt% of high temperature pitch are used as substrates, 50 to 65wt% of microwave treated electrically calcined coal particles are used as aggregate, and thermoset phenolic resin accounting for 10-20wt%of the sum of the substrates and the aggregate is additionally added. The preparation method comprises the following steps: mixing the substrates to obtain substrate fine powder; then putting the aggregate into a mixing mill and performing mixed milling, then adding the thermoset phenolic resin and performing mixed milling; finally adding the substrate fine powder and performing mixed milling; andperforming moulding and drying to obtain green bodies of carbon bricks. The surfaces of the green bodies of the carbon bricks are uniformly sprayed or brushed with a layer of slurry and dried, and the green bodies of the carbon bricks are subjected to thermal insulation in an air atmosphere at 1,150 to 1,250 DEG C for 12 to 24h, thereby obtaining the electrically calcined coal-based carbon brickwith high thermal conductivity and high corrosion resistance. The electrically calcined coal-based carbon brick has the advantage of low cost and is easy to industrially produce, and the prepared products have high strength, high thermal conductivity and excellent property of resisting corrosion of liquid iron.

Owner:WUHAN UNIV OF SCI & TECH

Wave-absorbing ceramic-based composite material with multi-scale toughening and layering structure and preparation method thereof

ActiveCN113754455AAchieve uniformityAvoid the problem of uneven distribution inside and outsideNanostructureBinding force

The invention discloses a wave-absorbing ceramic-based composite material with a multi-scale toughening and layering structure and a preparation method thereof. The preparation method comprises the following steps: deposition of an interface layer, introduction of a one-dimensional nano toughening phase, design of a layering structure preform, suction filtration and impregnation of a precursor, and cracking. A one-dimensional reinforcing phase is introduced into the continuous fiber reinforced ceramic-based composite material in situ, and multi-stage toughening of the ceramic-based composite material is achieved. The one-dimensional nano reinforced phase is introduced through in-situ growth before the fiber preform is formed, so that the nano reinforced phase is uniformly distributed in the ceramic-based composite material while relatively strong binding force between the one-dimensional nano structure and the fiber is ensured, the designability of the microstructure of the composite material is improved, and the preparation period is shortened. The nano wave-absorbing agent is in gradient distribution in the composite material by adopting a suction filtration and impregnation process, the excellent wave-absorbing performance of the material can be ensured, meanwhile, a preform is prepared by adopting a layering process, a special-shaped component can be designed and prepared, and the design requirements of aerospace hot-end components can be met.

Owner:湖北瑞宇空天高新技术有限公司

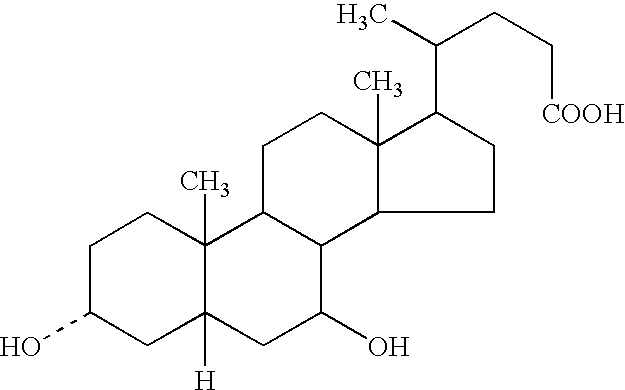

Pharmaceutical compositions of ursodiol

InactiveUS20100239661A1Promote dissolutionGood absorbing characteristicsPowder deliveryOrganic active ingredientsPharmaceutical preservativesExcipient

Owner:CADILA HEALTHCARE LTD

Sulfur and nitrogen double-doped graphene wave-absorbing material, production method and wave-absorbing performance adjusting method

PendingCN110451492AStrong absorbing characteristicsBand adjustableGrapheneDoped grapheneMaterials science

The invention relates to the field of production of wave-absorbing materials, in particular to a sulfur and nitrogen double-doped graphene wave-absorbing material, a production method and a wave-absorbing performance adjusting method. The production method of the wave-absorbing material comprises the steps of (1) producing graphite oxide by means of a hummers method, and producing a graphite oxidesolution; and (2) taking a reducing agent containing sulfur and nitrogen, adding the produced graphite oxide solution, conducting heating to elevate temperature to 80-100 DEG C, carrying out a constant temperature reaction continuously for 1-3 h, after the reaction is completed, conducting cooling to reduce the temperature to room temperature, conducting washing filtering by means of deionized water, and conducting freeze drying to obtain the black sulfur and nitrogen double-doped graphene powder. Compared with other heteroatom-doped graphene materials and most graphene composite materials, the produced sulfur and nitrogen double-doped graphene wave-absorbing material has higher wave-absorbing characteristics and an adjustable wave band; and by producing the sulfur and nitrogen double-doped graphene wave-absorbing material through a chemical wet method, the reaction condition changes from high-temperature annealing to a low-temperature reaction, and not only is energy consumption greatly reduced, but also production of a liquid-phase material which is liable to be processed into a film is achieved, so that industrial large-scale production is facilitated.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

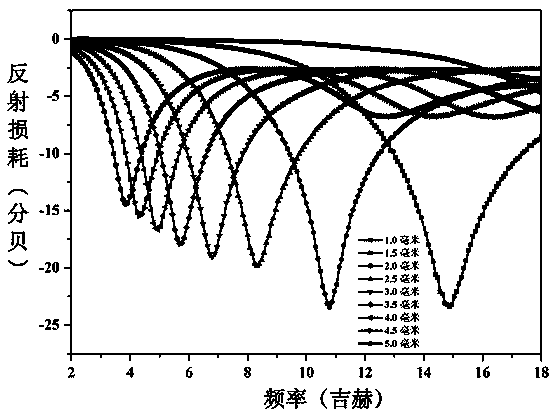

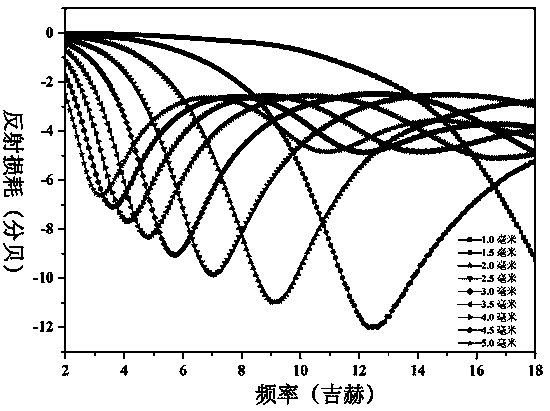

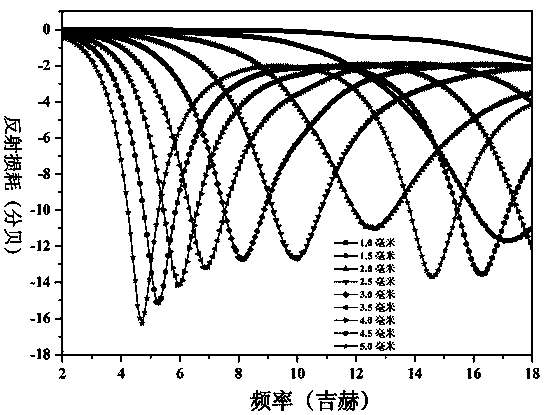

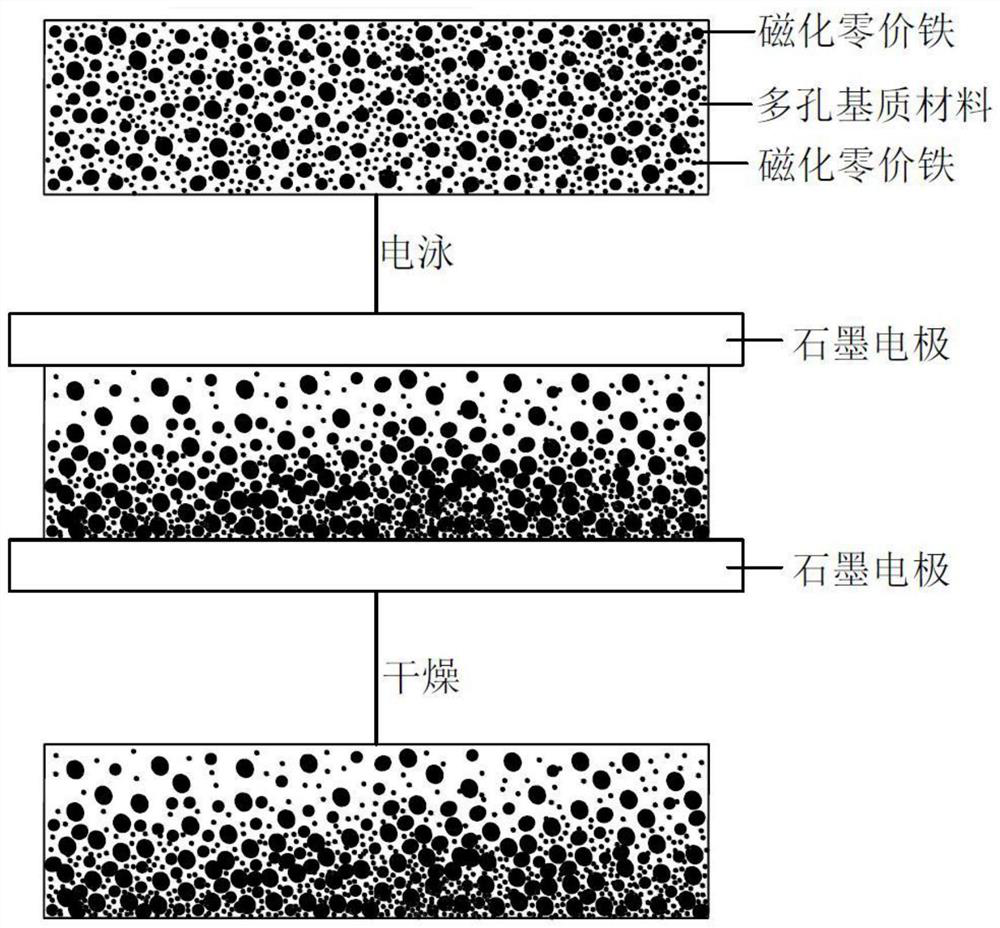

Preparation method of iron-based composite wave-absorbing material

InactiveCN112300758AImprove absorbing performanceGood absorbing characteristicsOther chemical processesElectrophoresesHost material

The invention relates to the technical field of electromagnetic wave absorbing materials, in particular to a preparation method of an iron-based composite wave-absorbing material. The reparation method comprises the following steps: S101: preparing a porous matrix material doped with ferriporphyrin; s102, preparing a mixed solution containing zinc-doped carbon quantum dots and magnetized zero-valent iron; s103, enabling the mixed solution to be fully infiltrated into the porous matrix material; s104, enabling the mixed solution to be subjected to electrophoresis in the porous matrix material through an electrophoresis device; and S105, drying the porous matrix material to obtain the iron-based composite wave-absorbing material. The zinc-doped carbon quantum dots and the magnetized zero-valent iron are compounded into the porous matrix material doped with ferriporphyrin, concentration gradient distribution of synergistic components is achieved through electrophoresis, the iron-based composite wave-absorbing material is prepared, and the material has various complex interfaces and concentration gradients so that the material has excellent wave-absorbing performance.

Owner:杭州鹿扬科技有限公司

Multilayer composite material with strong microwave absorption in GHz interval and preparation method thereof

ActiveCN112350075AGood absorbing characteristicsPromote absorptionMetallic material coating processesAntennasElectromagnetic shieldingHigh resistivity

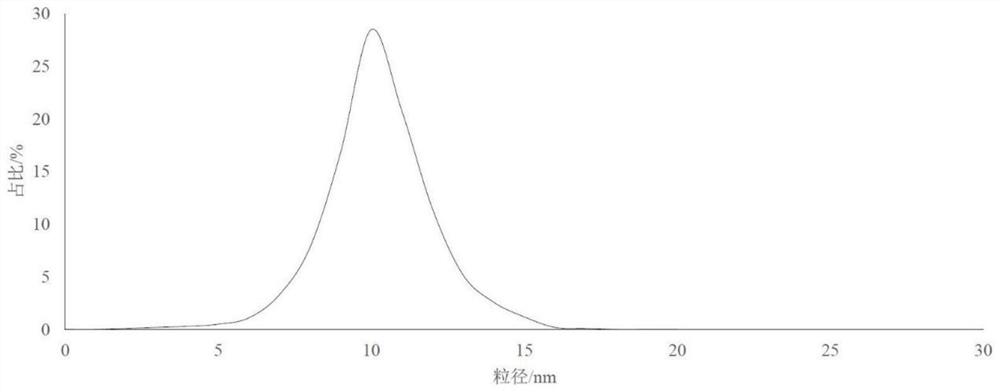

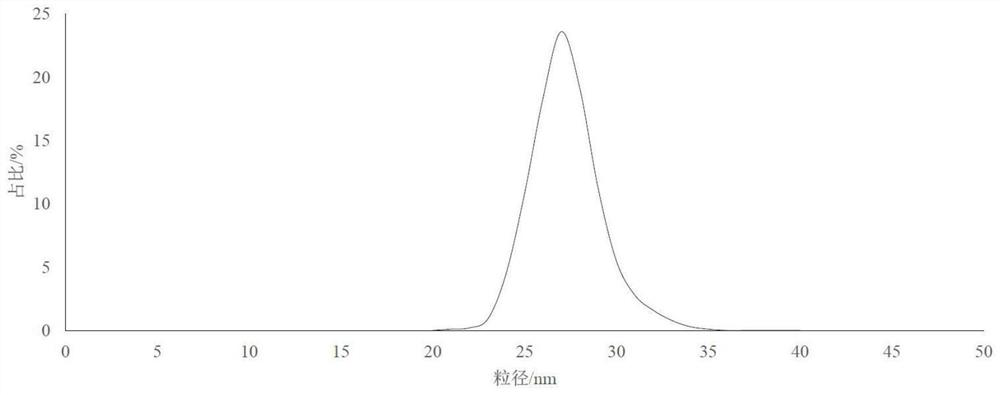

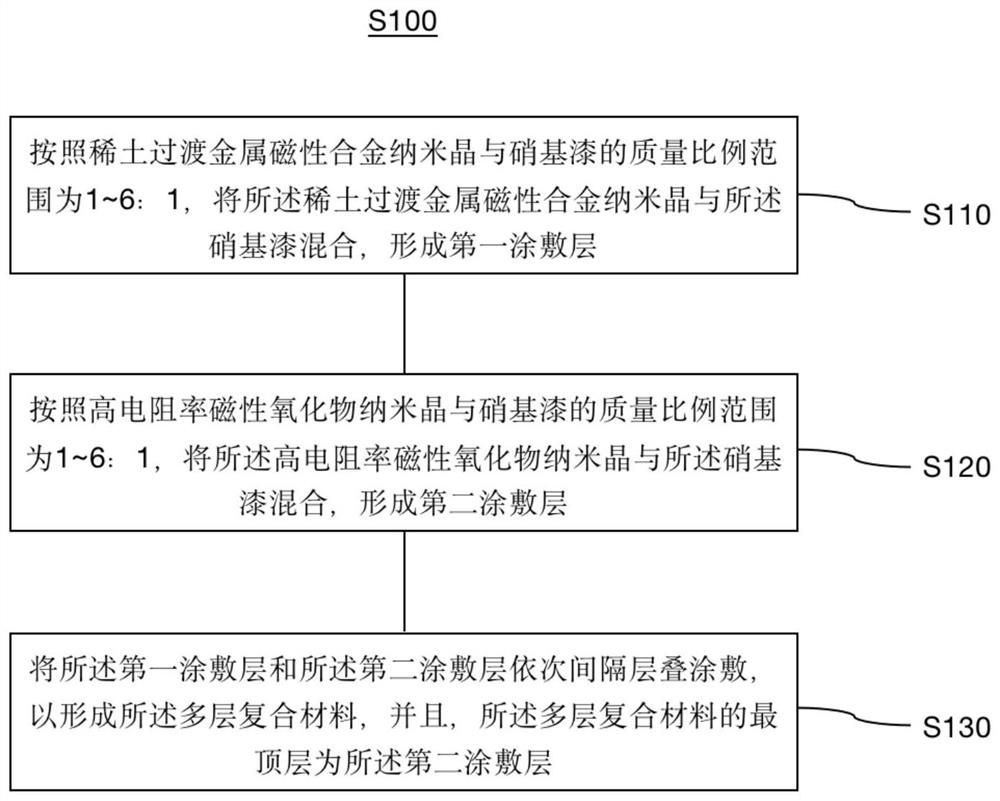

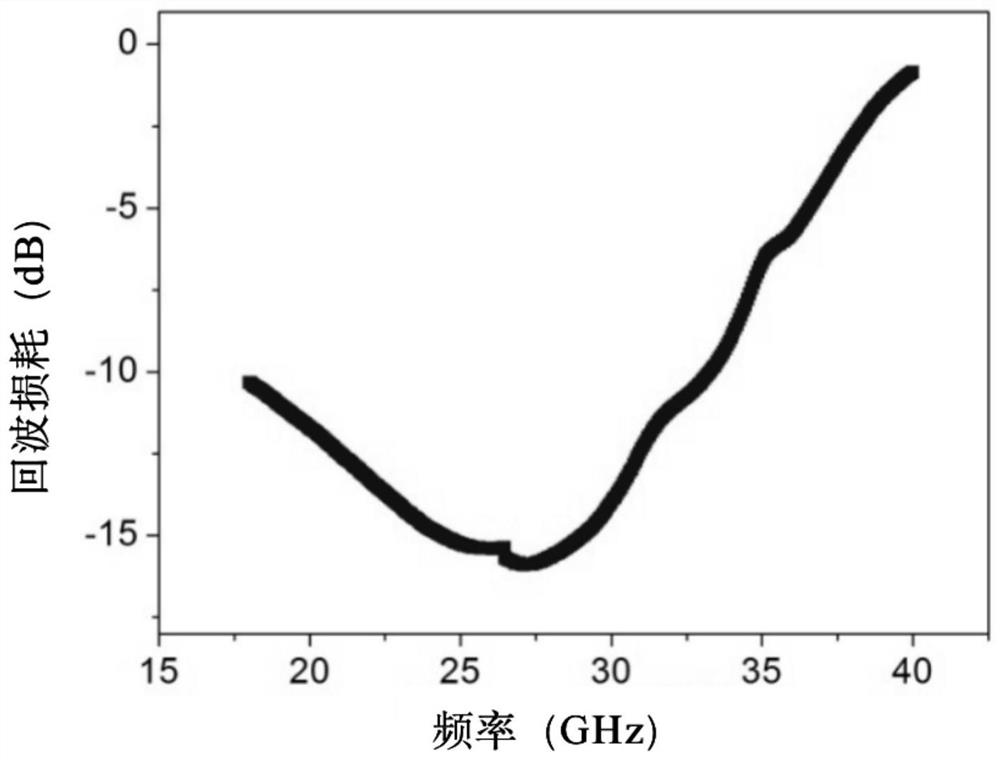

The invention provides a multilayer composite material with strong microwave absorption in a GHz interval and a preparation method thereof. The multilayer composite material comprises a plurality of first coating layers and a plurality of second coating layers which are arranged in a stacked mode. Wherein the first coating layer is formed by mixing rare earth transition metal magnetic alloy nanocrystalline and nitrolacquer, and the second coating layer is formed by mixing high-resistivity magnetic oxide nanocrystalline and nitrolacquer. The multiple first coating layers and the multiple secondcoating layers can be alternately arranged to form the second coating layers with the topmost layer being high-resistivity magnetic oxide layer nanocrystalline. Eddy current reflection electromagnetic waves of the rare earth transition metal magnetic alloy can be effectively inhibited, electromagnetic waves are enhanced to enter the wave-absorbing material, electromagnetic wave absorption is promoted, wave-absorbing efficiency is enhanced, and especially microwave absorption efficiency in a high-frequency band and a GHz range is effectively enhanced and broadened. The multilayer composite material is suitable for radar stealth, electromagnetic shielding of high-frequency equipment and the like.

Owner:INNER MONGOLIA UNIVERSITY

Calcium aluminate cement containing carbon and preparation method thereof

ActiveCN109851260AReduce energy consumptionReduce manufacturing costNitrogen atmosphereMicrowave sintering

The invention relates to calcium aluminate cement containing carbon and a preparation method thereof. The method comprises the following steps: by taking 54-62 wt% of aluminum hydroxide, 33-40 wt% ofcalcium carbonate and 1-10 wt% of graphite as raw materials, carrying out ball milling on the raw materials for 3-6 hours, and drying the raw materials to obtain premixed powder; carrying out compression molding on the premixed powder under 30-60 MPa, then putting the molded product into a microwave sintering furnace, heating the molded product to 1000-1200 DEG C under the condition of argon or nitrogen atmosphere, carrying out heat preservation for 5-30 minutes, and cooling the molded product along with the furnace to prepare the calcium aluminate cement containing carbon. The preparation method has the characteristics of low energy consumption, low production cost and suitability for industrial production. The CA content of the calcium aluminate cement containing carbon is high, and theslag resistance of the castable can be improved.

Owner:WUHAN UNIV OF SCI & TECH

Microwave strengthening method for recovering chromium from ferronickel smelting slag and preparing light heat insulation material

ActiveCN109957661ARealize full quantizationEfficient use ofProcess efficiency improvementCeramic materials productionMicrowaveWater assisted

The invention discloses a microwave strengthening method for recovering chromium from ferronickel smelting slag and preparing a light heat insulation material. The microwave strengthening method includes the two processes of selective recovery of the chromium from the ferronickel smelting slag through microwave strengthening and preparation of the light heat insulation material through leaching slag after chromium extraction. Ferronickel smelting slag powder is used as a raw material, sodium nitrite and sodium peroxide are used as additives, the mass ratio of the ferronickel smelting slag powder to the sodium nitrite to the sodium peroxide is controlled to be 1:(0.2 to 0.4):(0.3 to 1.2), after the ferronickel smelting slag powder, the sodium nitrite and the sodium peroxide are mixed well,microwave roasting is conducted, roasting materials are immersed in water assisted by microwaves, and leaching liquid and leaching slag containing the chromium are obtained after filtration; and afterthe leaching slag is evenly mixed with humic acid and water, compression moulding and drying are conducted, and the light heat insulation material can be obtained after microwave roasting. The methodcan achieve selective recovery of the chromium from the ferronickel smelting slag and efficient value-added utilization of the leaching slag, and the multiple advantages of high production efficiency, environmental protection, high added value of products and the like are achieved.

Owner:CENT SOUTH UNIV

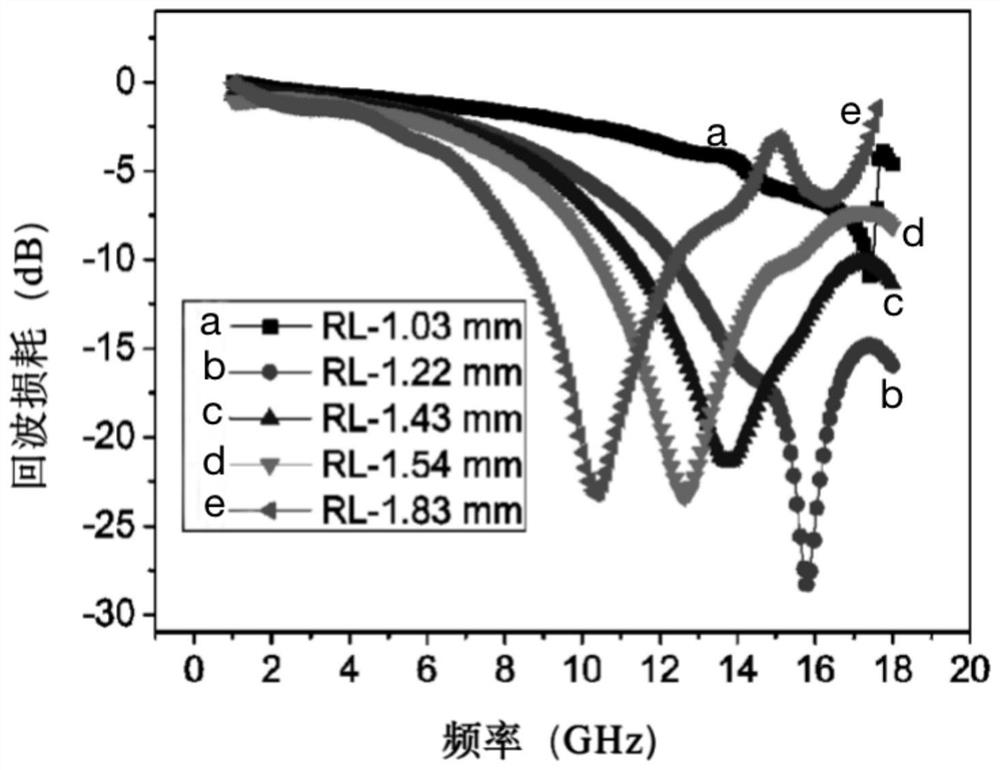

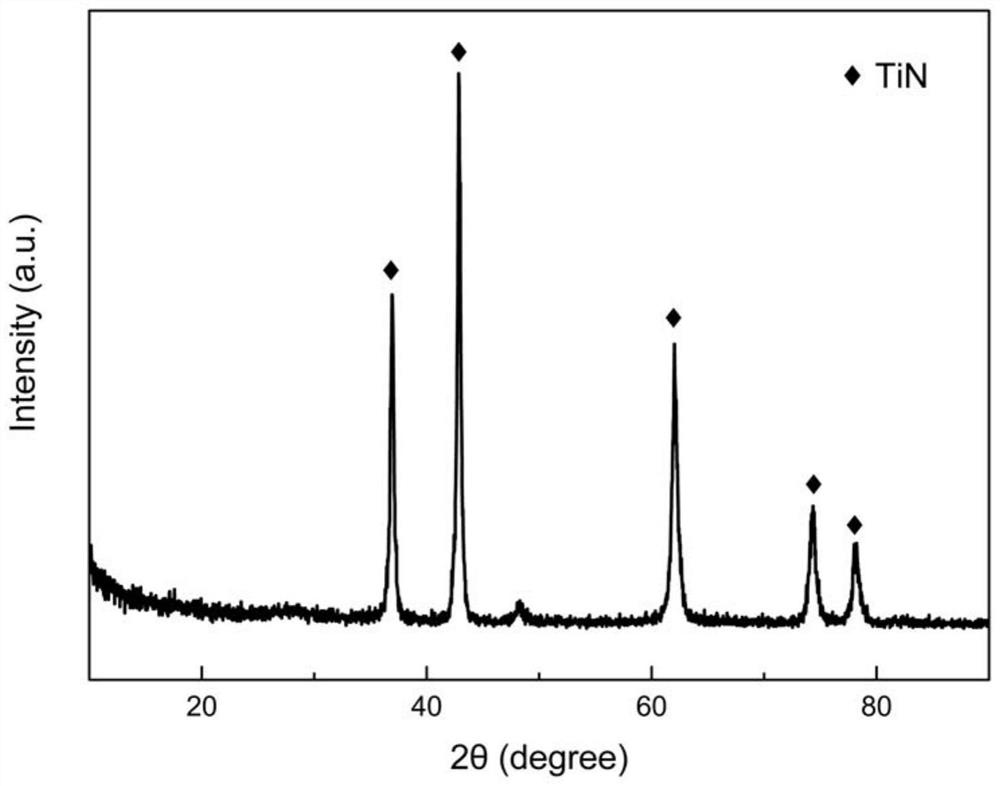

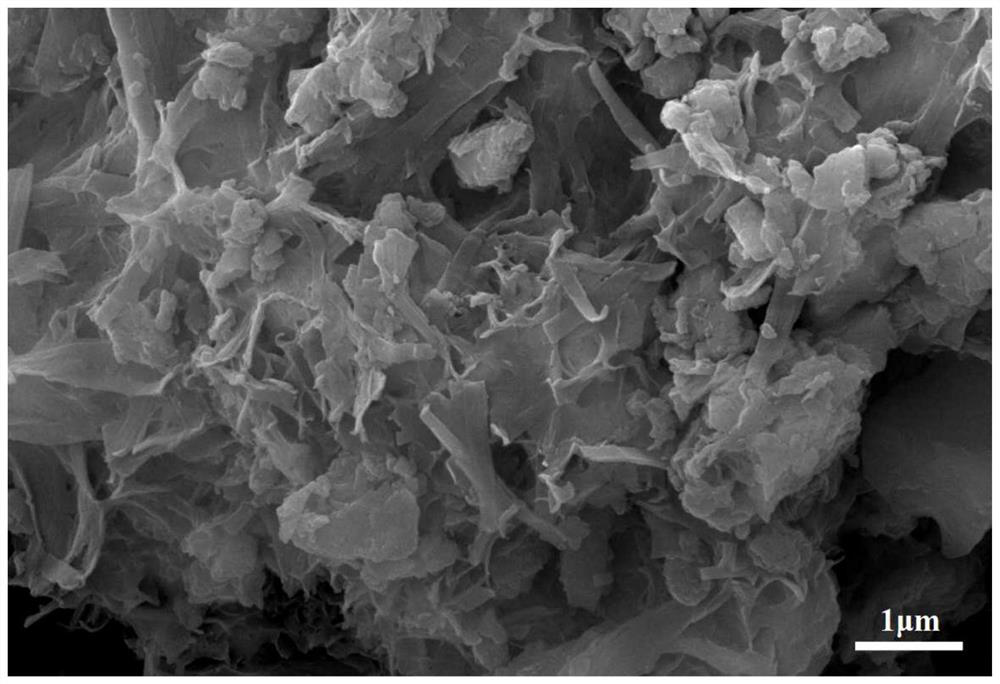

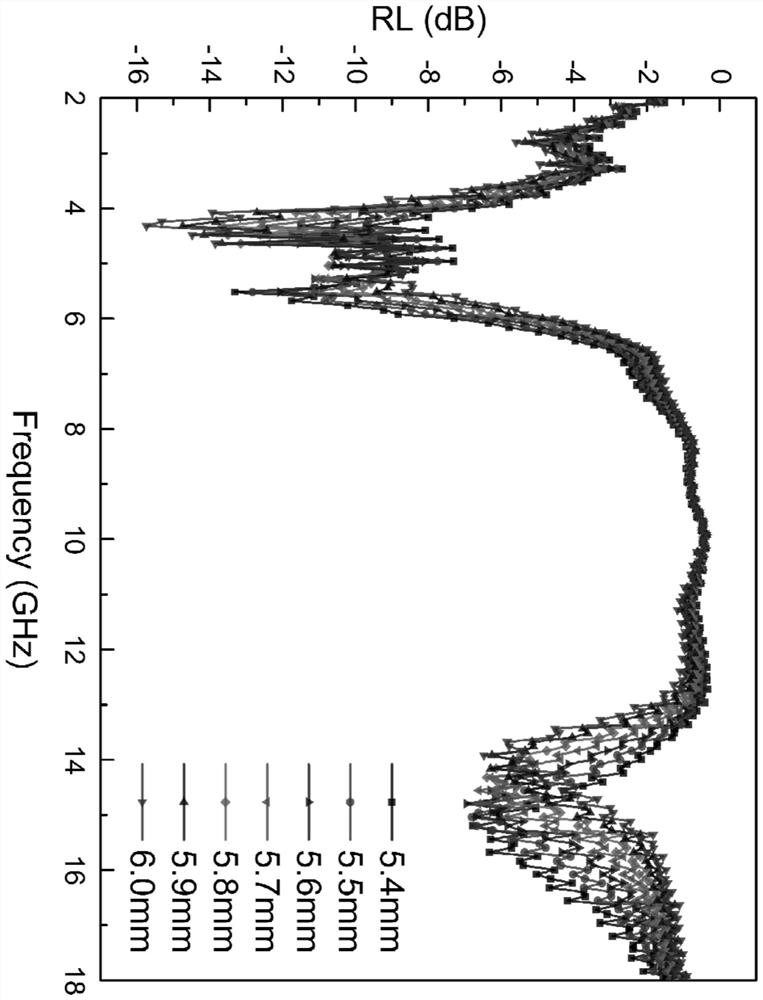

Preparation method of titanium nitride nanosheet wave-absorbing material

PendingCN113735073AGreen preparationEasy to makeNitrogen compoundsNanotechnologyAqueous sodium hydroxideTitanium nitride

The invention discloses a preparation method of a titanium nitride nanosheet wave-absorbing material, and belongs to the technical field of wave-absorbing materials. The invention aims to solve the problems of complex process and high cost of the existing method for preparing the titanium nitride wave-absorbing material. The method comprises: 1, preparing a sodium hydroxide aqueous solution; and 2, transferring the sodium hydroxide aqueous solution into a reaction kettle, adding titanium nitride for reaction, washing the obtained product, and drying to obtain the titanium nitride nanosheet wave-absorbing material. The titanium nitride nanosheet wave-absorbing material is successfully prepared, the preparation process is green, simple, low in price and suitable for large-scale mass production, the obtained titanium nitride nanomaterial has good wave-absorbing characteristics, the reflection loss value can reach-15.74 dB under the conditions of 4.32 GHz and 6 mm coating thickness, and effective absorption of electromagnetic waves of 1.04 GHz (4-5.04 GHz) is achieved. The titanium nitride nanosheet prepared by the invention is used as a wave-absorbing material.

Owner:HARBIN INST OF TECH AT WEIHAI +1

Preparation method of cobalt metal particles and cobalt oxide composite graphite nanosheet powder

ActiveCN110835123AGood absorbing characteristicsThe preparation process is simpleOther chemical processesGraphiteCobalt metalPhysical chemistry

The invention relates to the technical field of preparation of graphite nanosheet composite magnetic particles, and concretely relates to a preparation method of a magnetic composite cobalt metal particle and cobalt oxide composite graphite nanosheet powder being particularly suitable for being used as a wave-absorbing material and having the sheet-core-shell microstructure of a cobalt oxide-cobalt-graphite nanosheet. Cobalt metal particle compounded graphite nanosheet composite powder is uniformly dispersed in an aqueous solution containing an oxidizing agent, stirring is performed for dispersion to ensure sufficient contact between the composite powder and the oxidizing solution in order to generate an oxidation coating layer on the surface of metallic cobalt, so the graphite nanosheet composite cobalt and cobalt oxide composite powder is obtained. The structure of the magnetic composite cobalt metal particle and cobalt oxide composite graphite nanosheet powder has the sheet-core-shell morphology, and the preparation method has the significant advantages of simple process, easiness in operation, no environmental protection pressure, and realization of large-scale mass production.

Owner:HARBIN INST OF TECH AT WEIHAI +1

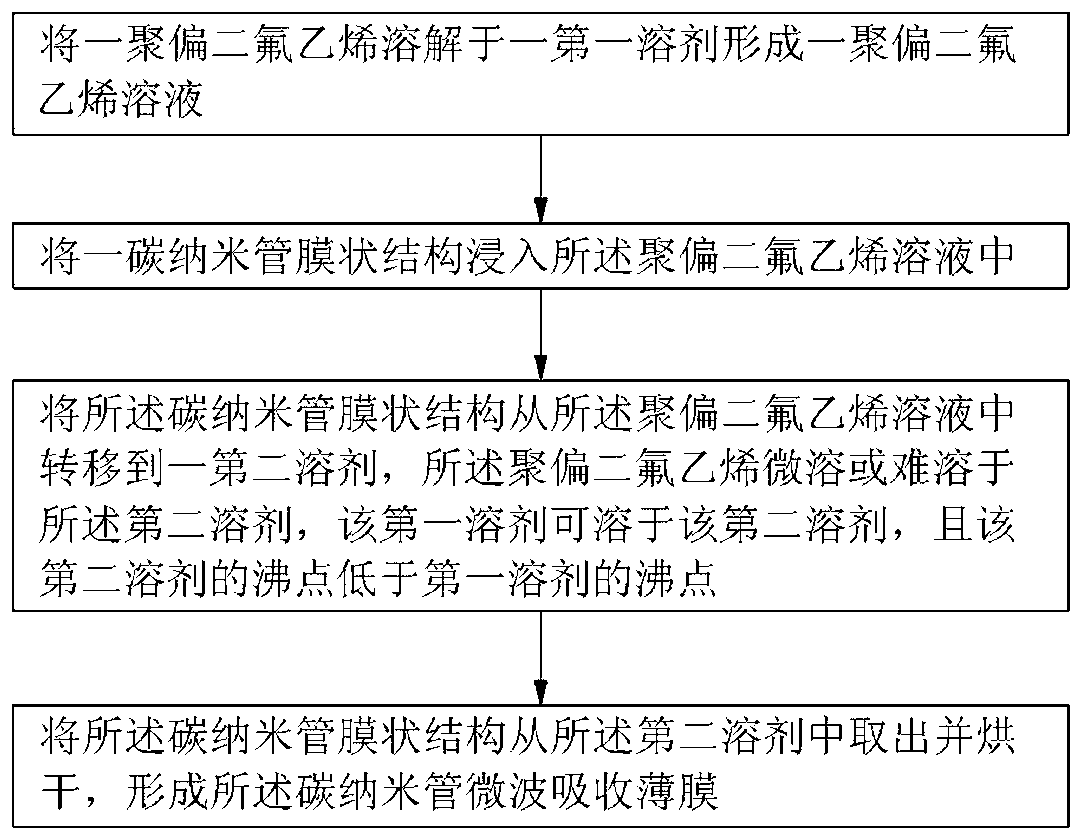

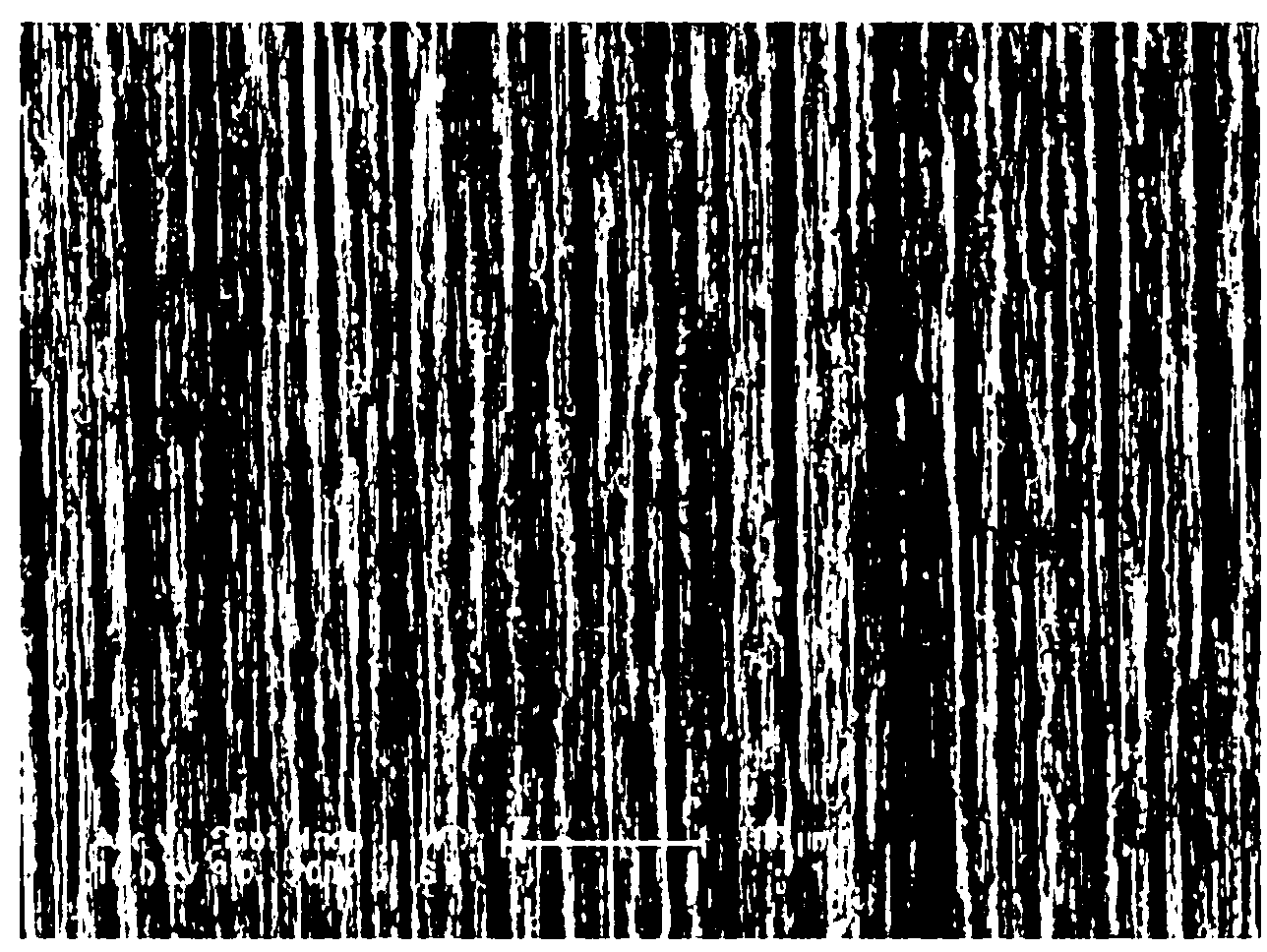

Carbon nanotube microwave absorption membrane

ActiveCN103183887AEvenly distributedGood absorbing characteristicsMaterial nanotechnologyOther chemical processesMicrowaveCarbon nanotube

The invention provides a carbon nanotube microwave absorption membrane, comprising a carbon nanotube membrane-like structure and polyvinylidene fluoride, wherein the carbon nanotube membrane-like structure comprises a plurality of uniformly distributed carbon nanotubes, and at least a part of polyvinylidene fluoride is filled in the carbon nanotube membrane-like structure.

Owner:TSINGHUA UNIV +1

Absorbing metamaterial and preparation method thereof

The invention discloses a wave-absorbing metamaterial and a preparation method thereof. The wave-absorbing metamaterial comprises the following components in percentage by volume: 30%-90% of syndiotactic polystyrene (SPS), 7%-69% of aerogels and 1%-33% of magnetic metal powder. The wave-absorbing metamaterial not only has good in wave-absorbing performance but also is relatively wide in temperature-resistant range as the aerogels in the wave-absorbing metamaterial are all inorganic materials; the SPS is crystalline and can enable the overall temperature-resistant range of a system to be expanded to be 270 DEG C, and the temperature-resistant range is greatly expanded in comparison with that of other thermoplastic resin.

Owner:KUANG CHI INST OF ADVANCED TECH

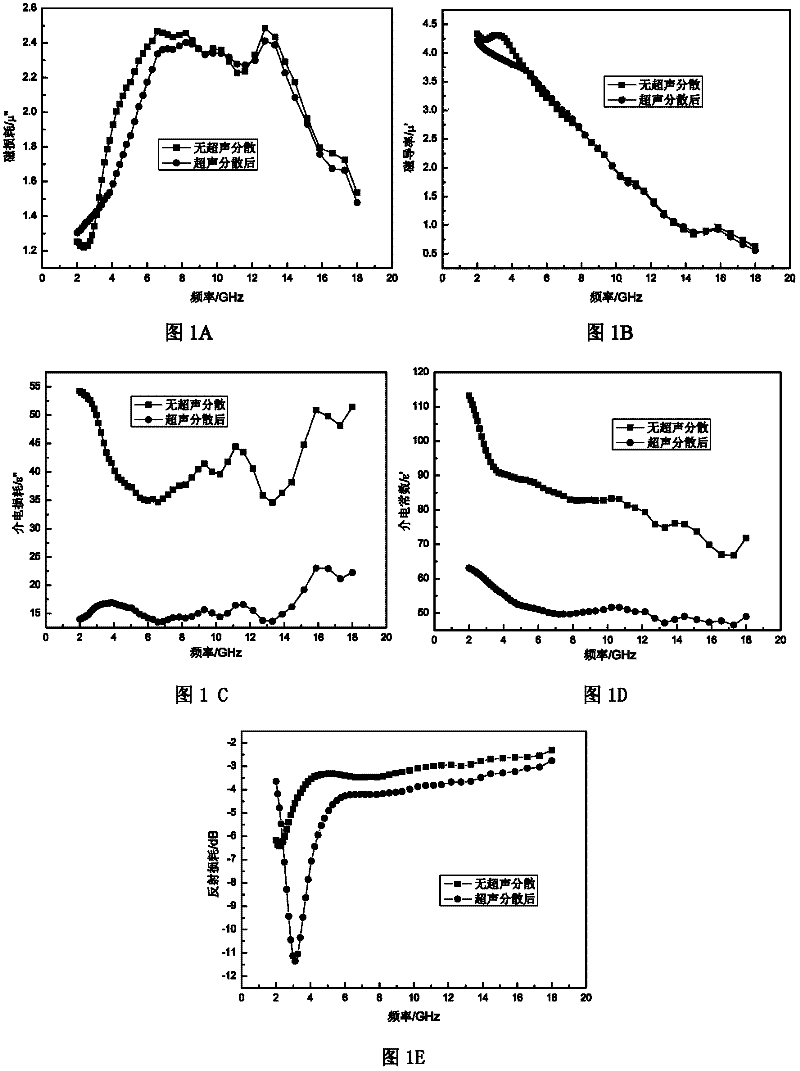

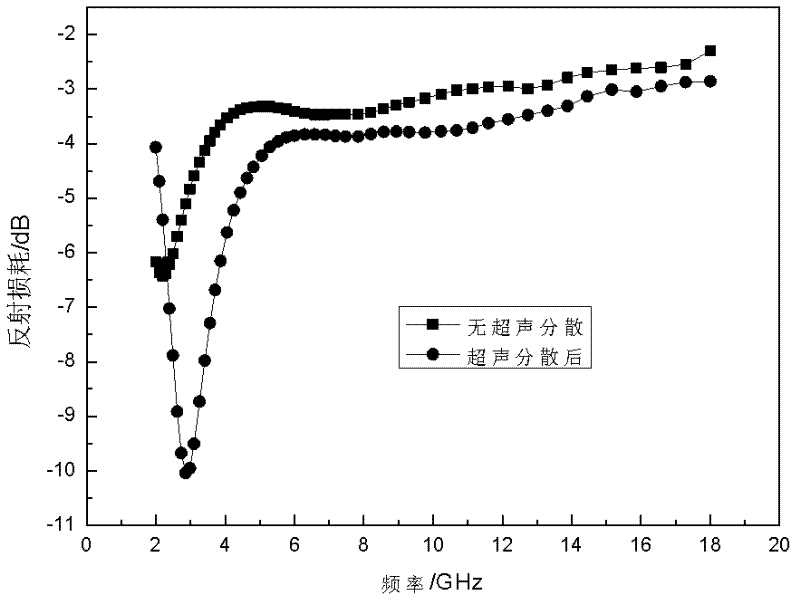

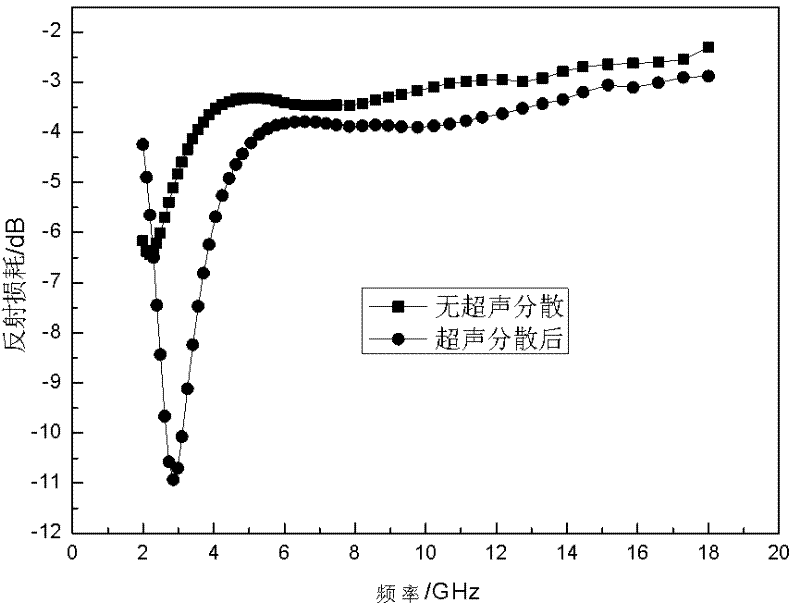

Preparation method for quickly quenched Fe-based metal grain with excellent wave absorbing property

The invention provides a preparation method for a quickly quenched Fe-based metal grain with an excellent wave absorbing property. The preparation method comprises the following steps: weighting corresponding metals according to the mass percent of each metal element in an alloy; preparing the metals into a magnetic metal alloy; and after melting, melt-spinning and ball-milling the metal alloy, performing ultrasonic dispersing treatment, thereby obtaining a material of the Fe-based metal grain with the excellent wave absorbing property, wherein the material is capable of improving an interface property and is uniformly distributed. According to the preparation method, the cavitation principle and the mechanical effect of ultrasonic wave in liquid are utilized to obtain the uniformly distributed quickly quenched Fe-based metal grain material; and when the ultrasonic wave is transmitted in a piezoelectric material and a magnetostriction material, the wave absorbing property of the material of the Fe-based metal grain is increased due to the induced polarization and the induced magnetization caused by the mechanical effect of the ultrasonic wave. The preparation method provided by the invention is correct in principle and is scientific in measures. The material of the quickly quenched Fe-based metal grain with the excellent wave absorbing property prepared according to the preparation method is high in practical value and wide in application prospect.

Owner:HOHAI UNIV

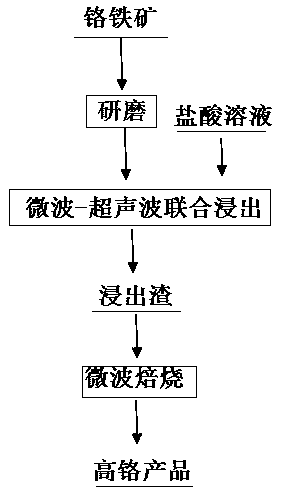

Method for preparing high-chromium product by combining micro waves and ultrasonic waves to leach chromite through hydrochloric acid

InactiveCN109022830AFast heating rateLow reduction temperatureProcess efficiency improvementChromium productChromite

The invention relates to a method for preparing a high-chromium product by combining micro waves and ultrasonic waves to leach chromite through hydrochloric acid, and belongs to the technical field ofmicrowave smelting and chromite. The method comprises the following steps of: crushing chromite into chromite powder with a grain size smaller than 200 meshes; adding the obtained chromite powder into a hydrochloric acid solution with concentration of 11.6-12.4 mol / L in a liquid-solid ratio of (2-3) to (0.5-1)mL / g, heating to 400-600 DEG C under a condition with microwave power of 1000-1500g / W, preserving heat and leaching for 20-60 minutes under conditions with ultrasonic power of 100-180W and ultrasonic frequency of 20-28 KHz, and filtering and drying to obtain leached residues after leaching is completed; crushing the obtained leached residues until the grain size is smaller than 200 meshes, adding a ferro-silicon alloy reducing agent, mass of which accounts for 75-100% of that of theleached residues, to uniformly mix, and performing constant-temperature microwave roasting for 10-40 minutes at a temperature of 1100-1450 DEG C under microwave power of 1000-1500g / W, thereby obtaining the high-chromium product. The method is simple in process, is short in process, is strong in operability and is relatively low in cost.

Owner:KUNMING UNIV OF SCI & TECH

A kind of preparation method of glass fiber cotton with wave-absorbing characteristic

Owner:SUZHOU HONGJIU AVIATION THERMAL MATERIALS TECH CO LTD

Wave absorbing material

ActiveCN102821589BGood absorbing characteristicsMagnetic/electric field screeningSplit ringOptoelectronics

The invention relates to a wave absorbing material comprising at least one material sheet layer; each material sheet layer comprises three layers of substrates; the substrates are respectively a first substrate, a second substrate and a third substrate from the upper side to the lower side; each layer of substrate comprises at least one substrate unit; a metal microstructure is attached on the upper surface of each substrate unit; the metal microstructure attached on the upper surface of the substrate unit of the first substrate is composed of a plurality of hollow-ring-shaped structures in nonidentical sizes, wherein the hollow-ring-shaped structures in the same size are arranged like a round array; the metal microstructures attached on the upper surface of the substrate unit of the second substrate is split-ring-shaped structures, wherein both ends of the a split ring respectively rotate inwards to form two mutually-disjointed spiral structures; and the metal microstructures attached on the upper surface of the substrate unit of the third substrate and the metal microstructures attached on the substrate unit of the second substrate are complementary. The wave absorbing material with the structure has better wave absorbing property at a low-frequency stage.

Owner:KUANG CHI INST OF ADVANCED TECH

Protection ointment for open country and method of producing the same

The invention relates to field protective cream and a preparation method thereof. The protective cream comprises the following steps: 70 to 92 parts of substrate raw material, 1 to 6 parts of titanium oxide and 5 to 10 parts of delphene. The preparation method comprises the following steps: firstly, blending and stirring mineral oil and dimethicone, and then adding hydrogenated castor oil, earth wax and lanolin for dissolution; secondly, adding and stirring talcum powder and titanium oxide, for uniform mixing; and thirdly, adding delphene, homogenizing, filling and storing hermetically. The cream solves the technical problem that the prior protective cream used for field can not realize ultraviolet ray burn prevention, visible light prevention and mosquito bite prevention simultaneously, can prevent ultraviolet ray burn and mosquito bite, and has the advantages of safety, no allergy, no toxic and side effect, light fragrance, good air permeability, insolubility in water, easy cleaning, high performance-to-price ratio, convenience for carrying and good stability.

Owner:中国航天科技集团公司第六研究院第一六五研究所

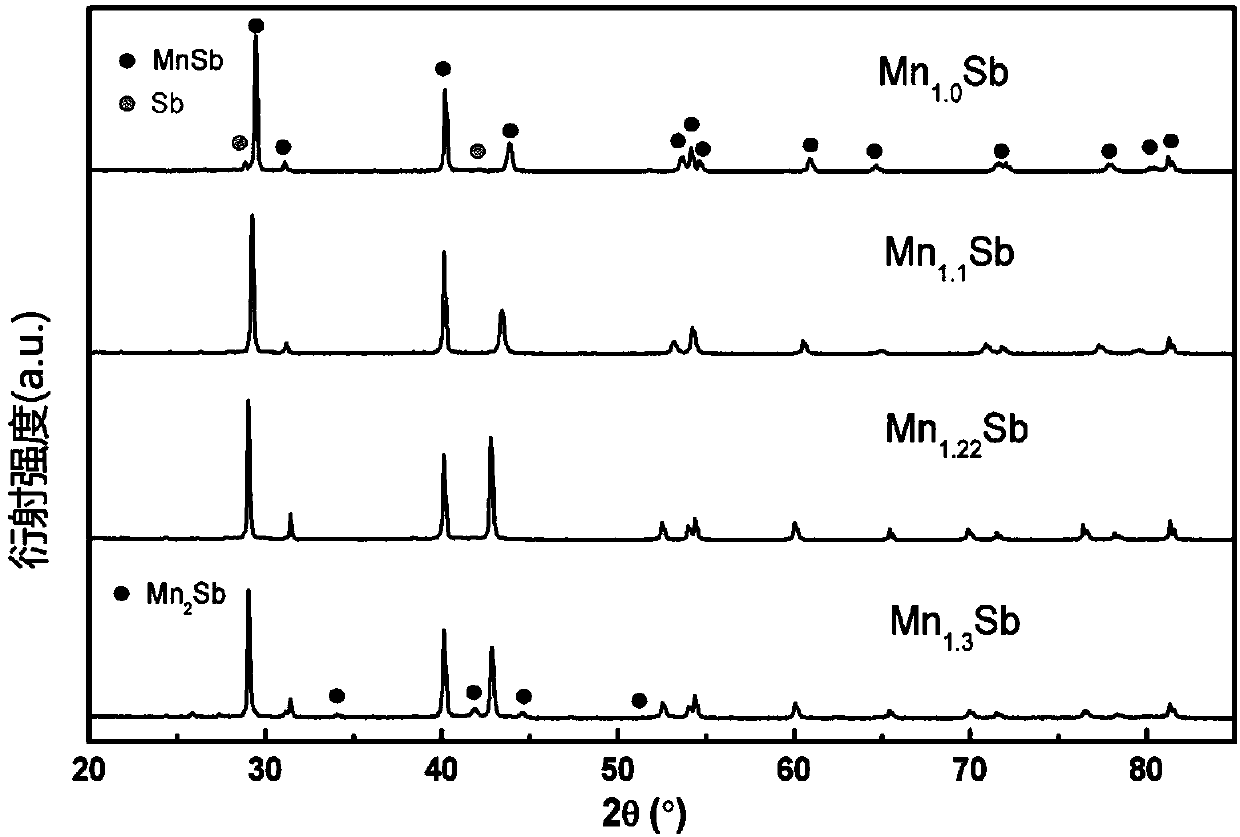

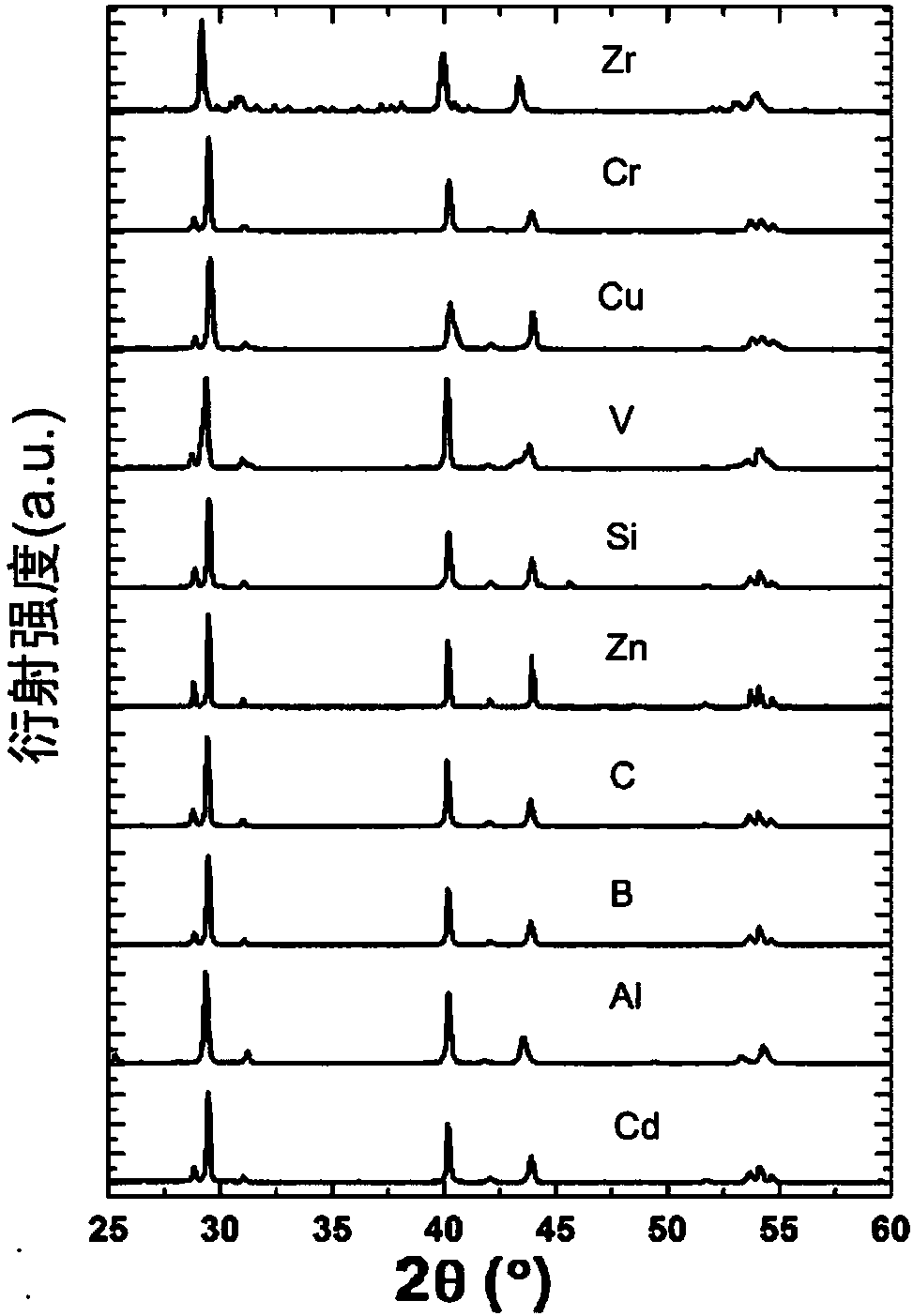

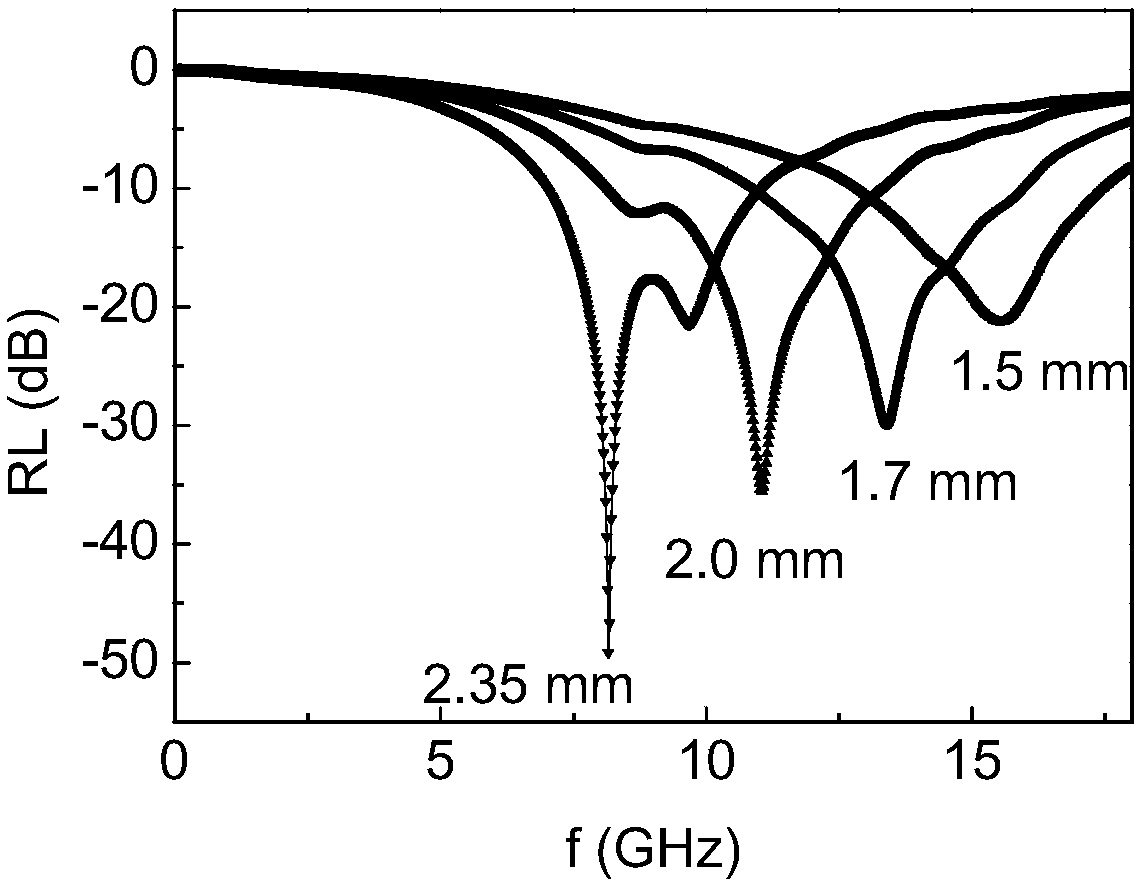

Novel electromagnetic wave absorption material and preparation method thereof

ActiveCN107760954AStrong absorption capacityImprove performanceMagnetic/electric field screeningScreening apparatusGold CompoundsFrequency band

The invention discloses a novel electromagnetic wave absorption material and a preparation method thereof. The electromagnetic wave absorption material is an Mn-Sb alloy compound, and the general chemical formula is MnxSb or (Mn, T)xSb, wherein x is larger than 0.8 and is smaller than 1.4, and T is one or an arbitrary combination of Zr, Cr, Cu, V, Si, Zn, C, B, Al and Cd. The preparation method ofthe material comprises the steps of carrying out mixed smelting or rapid-setting ingot casting on Mn and Sb elements of which the atomic proportion of Mn to Sb or (Mn, T) to Sb is 0.8 to 1.4, so as to obtain an alloy of an NiAs hexagonal structure; and then, crushing the alloy into submicron particles capable of being utilized as an electromagnetic wave absorbent. The novel electromagnetic wave absorption material has an excellent absorption capacity for electromagnetic waves of which the frequency band is from 1 G to 100 G, the absorption capacity is high, and the working frequency band is wide; and besides, the frequency band position can be adjusted according to the utilization condition, and the electromagnetic wave absorption requirement in civil and military fields can be effectively met.

Owner:PEKING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com