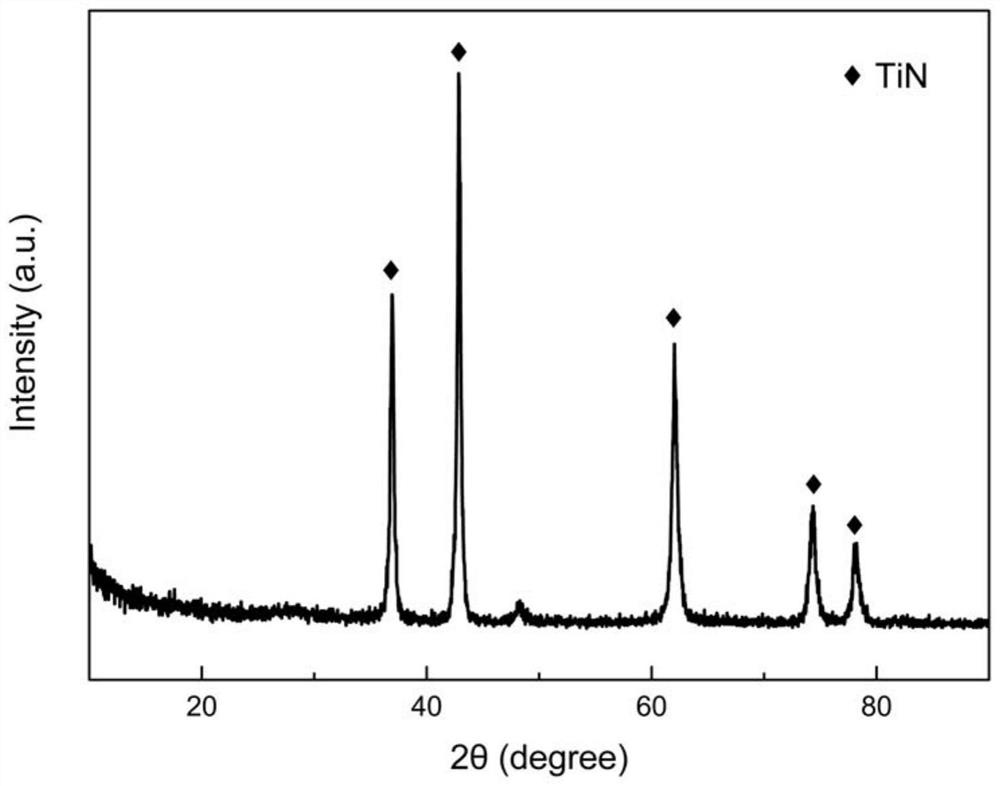

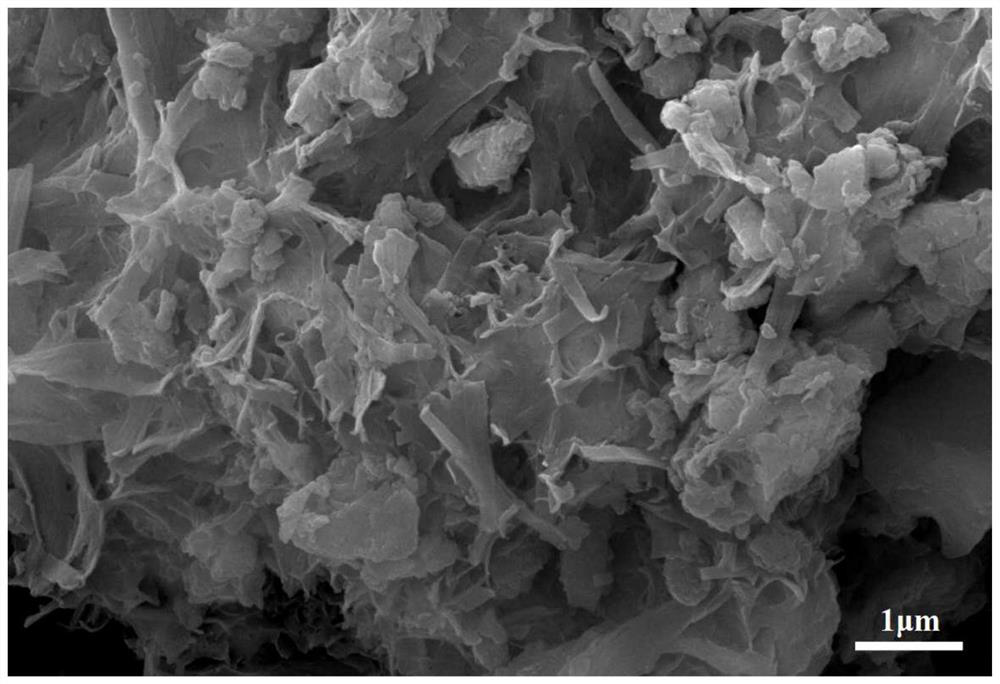

Preparation method of titanium nitride nanosheet wave-absorbing material

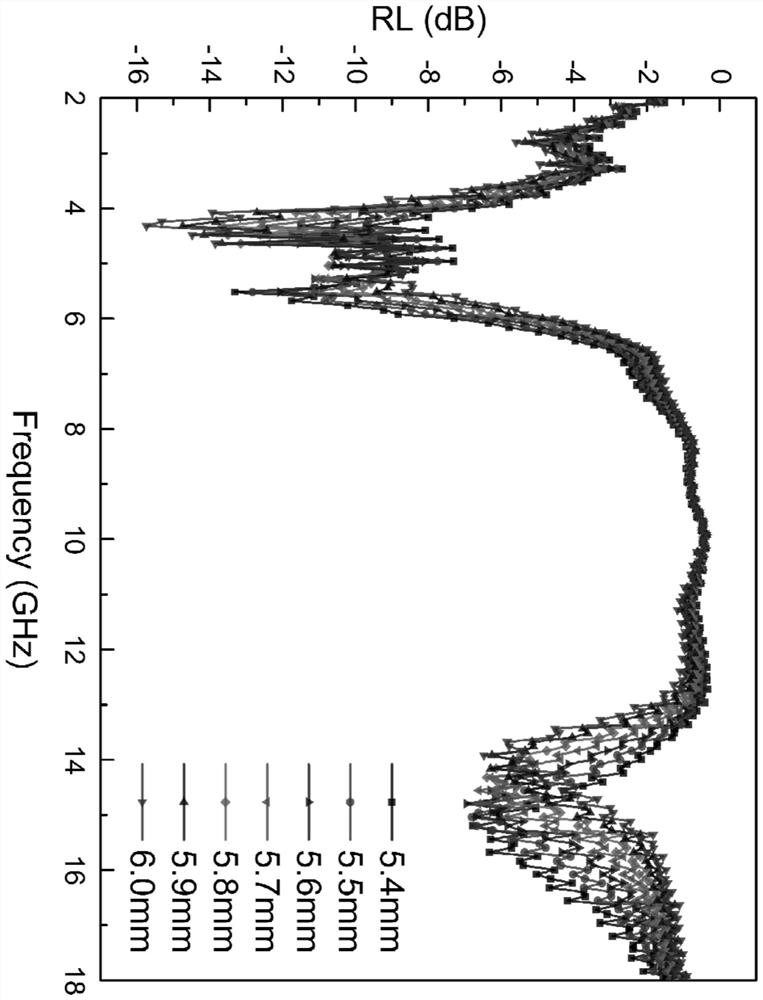

A technology of titanium nitride nanometer and wave absorbing material is applied in the field of wave absorbing material, which can solve the problems of high cost and complicated process, and achieve the effects of low price, good wave absorbing properties and green preparation process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0014] Specific embodiment 1: In this embodiment, a method for preparing a titanium nitride nanosheet wave-absorbing material is realized according to the following steps:

[0015] 1. Mix sodium hydroxide and deionized water, and carry out magnetic stirring to obtain an aqueous solution;

[0016] 2. Transfer the above aqueous solution to the reaction kettle, add titanium nitride and stir evenly, put it in an oven for reaction, wash the obtained product with deionized water and dry it in the oven to obtain titanium nitride nanosheet wave-absorbing material, and complete The preparation method.

specific Embodiment approach 2

[0017] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the concentration of the aqueous solution in step 1 is 2 to 10 mol / L, and the volume of the aqueous solution is 25 to 35 mL; the mass of the titanium nitride is 1 to 35 mL. 4g. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the magnetic stirring time in Step 1 is 5-30 minutes, and the rotation speed is 200-800 rpm. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| mass | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com