Preparation method of polymer microsphere with liquid carbon dioxide as medium

A liquid carbon dioxide and polymer technology, which is applied in the field of polymer microsphere preparation, can solve the problems of restricted carbon dioxide fluid and high reaction pressure in the reaction process, and achieve the effects of good hydrophobicity and low surface energy, lower pressure and shorter time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] 1. Synthesis of stable dispersant

[0038] Azobisisobutyronitrile (AIBN for short) thermal initiator (0.04g, 0.00025mol), BPTTC (0.24g, 0.0010mol) and HFPMA (13.6g, 0.034mol) were dissolved in 10ml of trifluorotoluene, under nitrogen atmosphere , heated to 60°C, and reacted for 48 hours. The polymer was precipitated from solution with methanol, filtered, and dried in a vacuum oven at 45°C for 24 hours. The molecular weight of the obtained stable dispersant was 16200 g / mol.

[0039] 2. Preparation of polymer microspheres

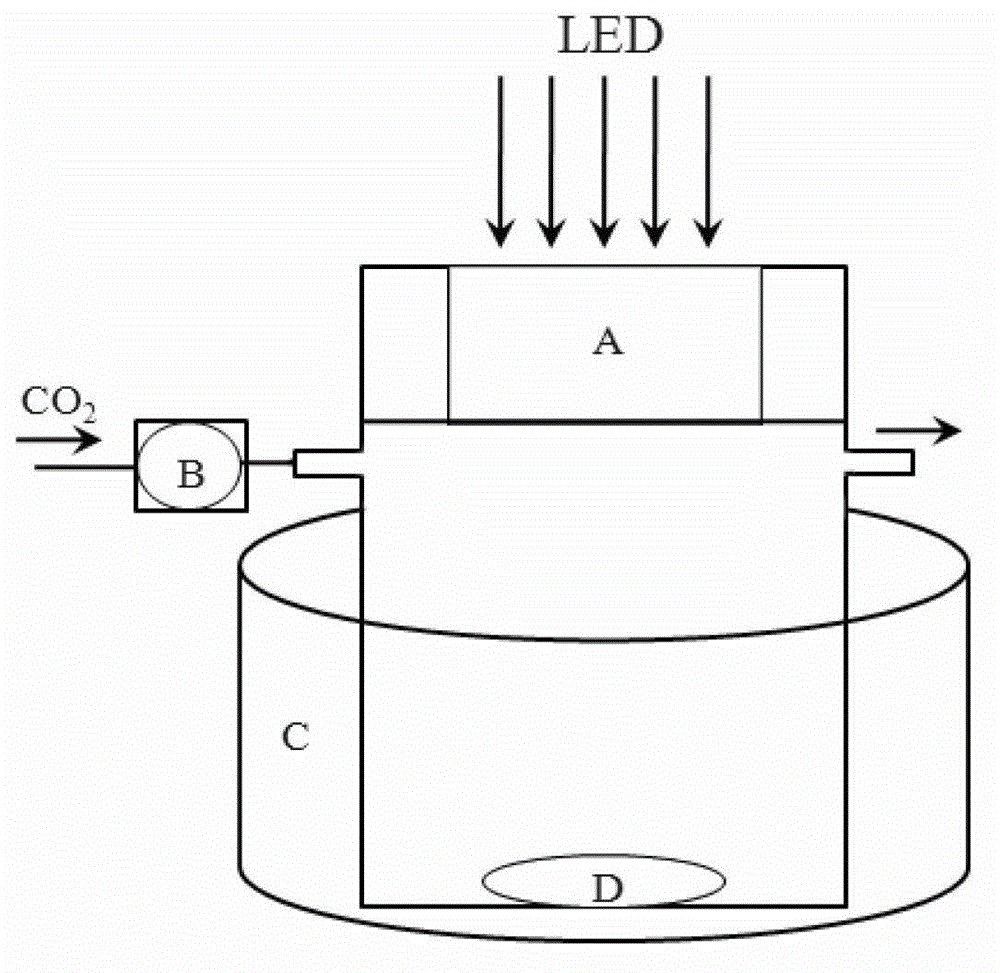

[0040] In the preparation of polymer microspheres with liquid carbon dioxide as the medium of the present embodiment, the light-induced dispersion polymerization is carried out in a 40ml autoclave (such as figure 1 As shown), the quartz glass A above the autoclave is used as a light-transmitting window, and a 3W LED is used as a light source. The reaction kettle was placed in an ice-water bath C with a magnetic stirrer D underneath. The polymerize...

Embodiment 2

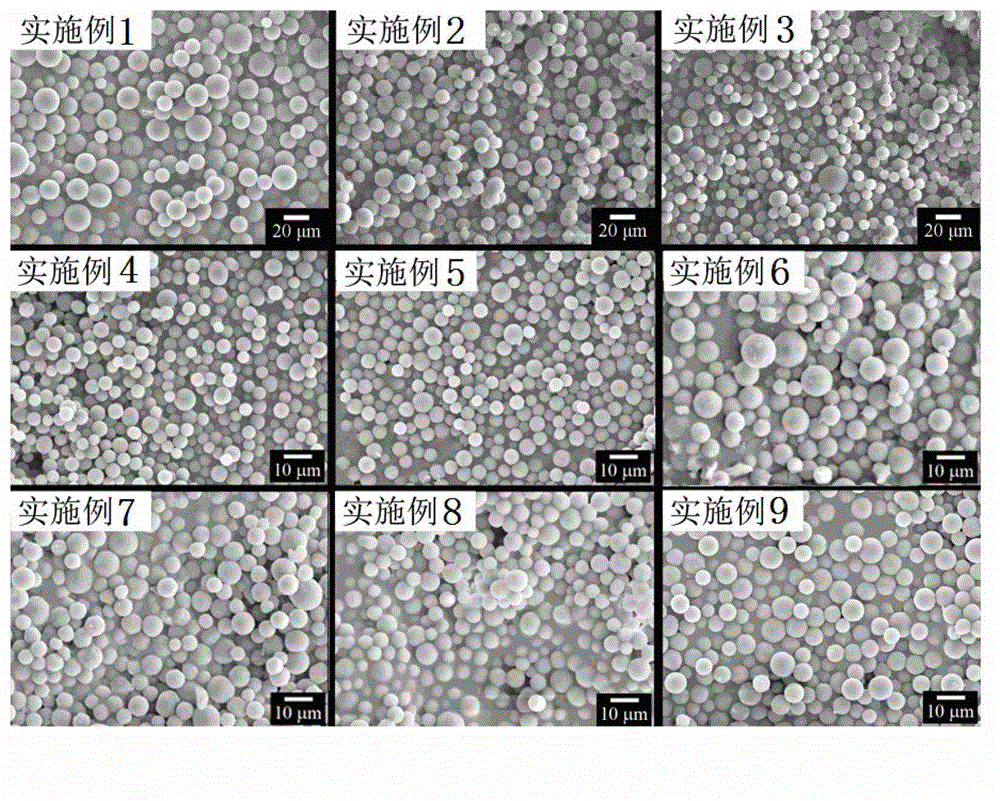

[0042] Compared with Example 1, in this example, the amount of the stabilizing dispersant is increased to 10wt%, and the types and amounts of the remaining reagents and the implementation process are the same as in Example 1. The scanning electron micrograph (SEM) of the obtained product is shown in figure 2 ,Depend on figure 2 It can be seen that the obtained polymer product is a regular spherical shape, there is no obvious adhesion between the microspheres, and the particle size of the microspheres is basically 1-10 microns, which is suitable as an additive for coating products.

Embodiment 3

[0044] Compared with Example 1, in this example, the amount of stabilizing dispersant is increased to 15wt%, and the types and amounts of other reagents and the implementation process are the same as in Example 1. The scanning electron micrograph (SEM) of the obtained product is shown in figure 2 ,Depend on figure 2 It can be seen that the obtained polymer product is a regular spherical shape, there is no obvious adhesion between the microspheres, and the particle size of the microspheres is basically 1-10 microns, which is suitable as an additive for coating products.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface energy | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com