Environment-friendly temperature-resistant salt-resistant plugging filtrate loss reducer applied to low-solid-phase saltwater drilling fluid and preparation method of plugging filtrate loss reducer

A technology of brine drilling fluid and fluid loss reducer, applied in chemical instruments and methods, drilling compositions and other directions, can solve the problems of insufficient environmental friendliness, insufficient resistance to high temperature and salt resistance, large fluid loss, etc. The effect of improving the stability against high temperature degradation, good plugging and filtration reduction performance, and good plugging and filtration reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

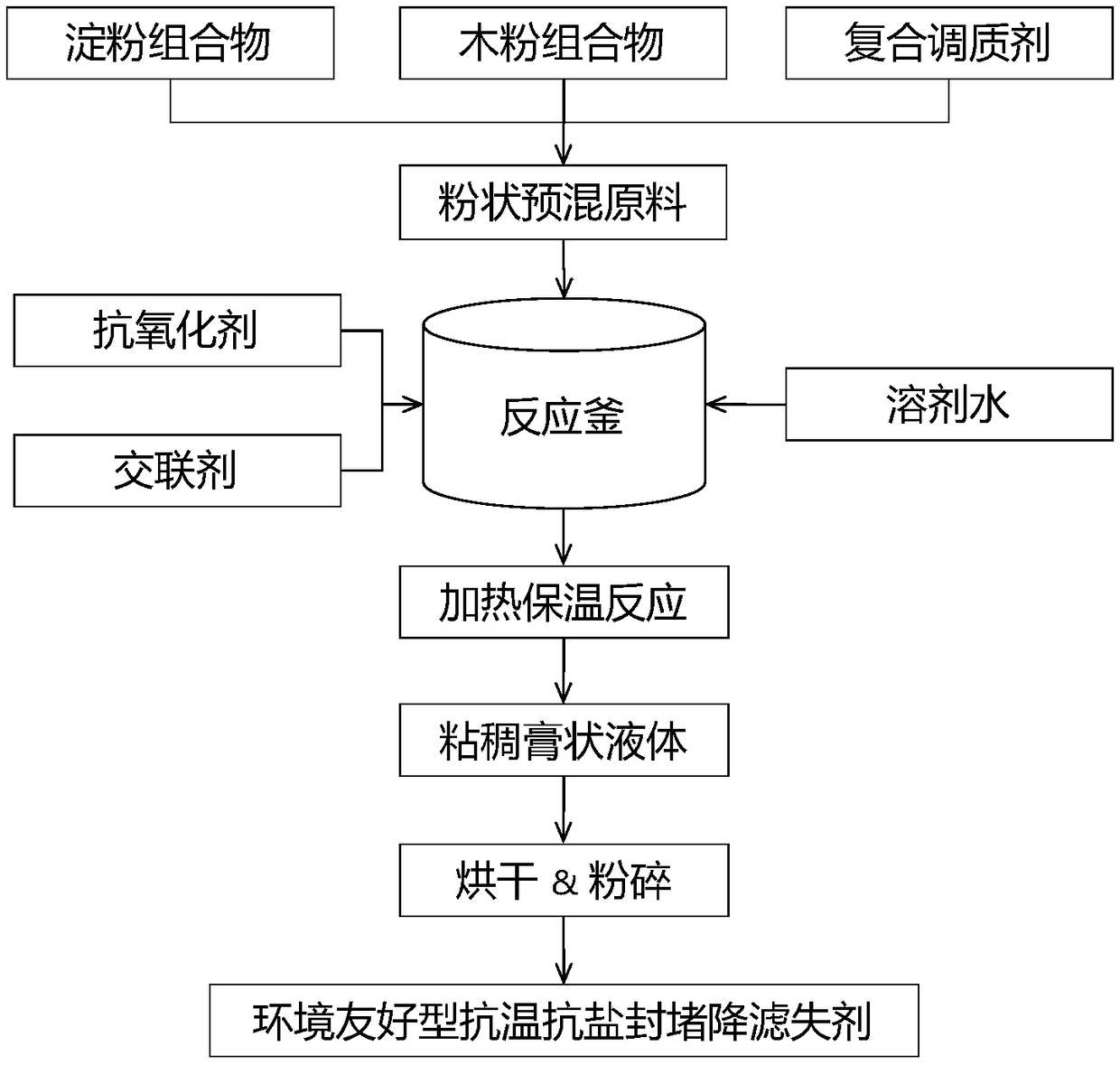

[0065] In the second aspect, the present invention also provides a method for preparing a plugging fluid loss reducer for oilfield low-solid brine drilling fluid, which is preferably used to prepare the plugging fluid loss reducer described above, and specifically includes the following steps:

[0066] Step 1: Part of the raw materials are crushed and premixed;

[0067] Step 2: Prepare a solution of crosslinking agent;

[0068] Step 3: Add the pretreated raw materials in step 1 to the solution in step 2, stir, heat up and keep warm for reaction;

[0069] Step 4: Post-treatment to obtain the final product.

[0070] among them,

[0071] In step 1,

[0072] The part of the raw materials includes natural polymer polysaccharides, wood flour, and modifiers;

[0073] The natural polymer polysaccharide is a combination of one or more of corn starch, potato starch, sweet potato starch, tapioca starch, etc., and / or

[0074] The wood powder is a combination of one or more of elm powder, phoebe phoebe ...

Embodiment 1

[0125] Pretreat sweet potato starch and elm powder by sieving, crushing and sieving, and weigh 35.00g of pretreated sweet potato starch, 25.00g of elm powder and 15.00g of modifier T-51 compounding agent and mix well;

[0126] Weigh 3.00 g of antioxidant sodium sulfite and 12.00 g of cross-linking agent hexamethylene diamine and dissolve them in 200 mL of water, and obtain a uniform solution after dissolving and cooling to obtain a cross-linking agent solution;

[0127] Add the above mixed sweet potato starch, elm powder and modifier T-51 compound to the cross-linking agent solution, stir and mix evenly, stir at medium speed and heat up to 90℃, react at 90℃ for 4h , The viscous liquid obtained;

[0128] Place the obtained viscous liquid at 100°C, dry, and crush to obtain a sample.

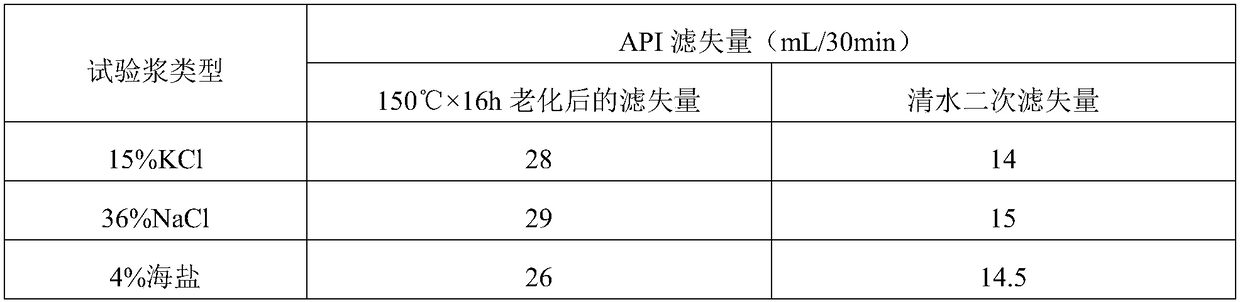

[0129] Table 1 Test results of plugging and fluid loss reduction performance of Example 1

[0130]

Embodiment 2

[0132] Pretreat sweet potato starch, elm powder and modifier by sieving, crushing and sieving, and weigh 35.00g of pretreated sweet potato starch, 25.00g elm powder and 15.00g modifier T-51 compound agent and mix well ;

[0133] Weigh 12.00 g of the cross-linking agent hexamethylene diamine and dissolve it in 200 mL of water, and obtain a uniform solution after dissolving and cooling to obtain a cross-linking agent solution;

[0134] Add the above-mentioned mixed sweet potato starch, elm powder and modifier T-51 compound to the above-mentioned cross-linking agent solution, stir and mix well, stir at medium speed and raise the temperature to 90℃, and react at 90℃ for 4h After, the viscous liquid obtained;

[0135] Place the obtained viscous liquid at 100°C, dry, and crush to obtain a sample.

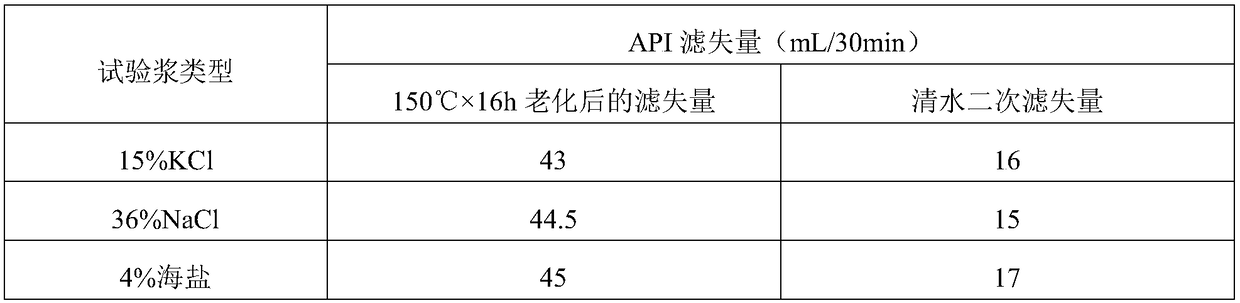

[0136] Table 2 Test results of plugging and fluid loss reduction performance of Example 2

[0137]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com