Microwave ferrite material and microwave dielectric ceramic high-temperature co-firing method

A technology of microwave dielectric ceramics and ferrite materials is applied in the field of high temperature co-firing of microwave ferrite materials and microwave dielectric ceramics, and can solve the problem of mismatching sintering characteristics, difficult application of high temperature co-firing materials, cracking of ceramic bodies and microcracks and other problems, to achieve the effect of reducing volume, reducing manufacturing cost and increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

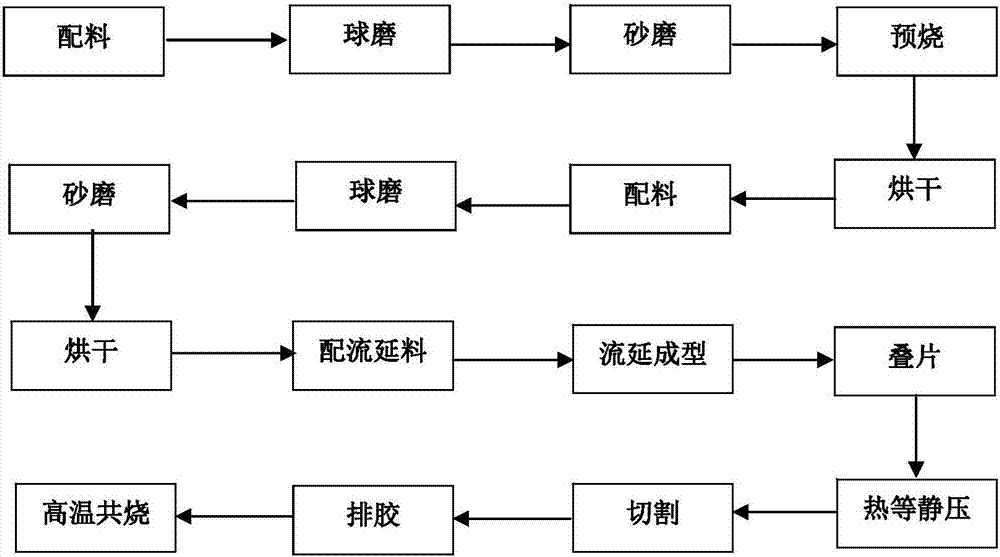

Method used

Image

Examples

Embodiment 1

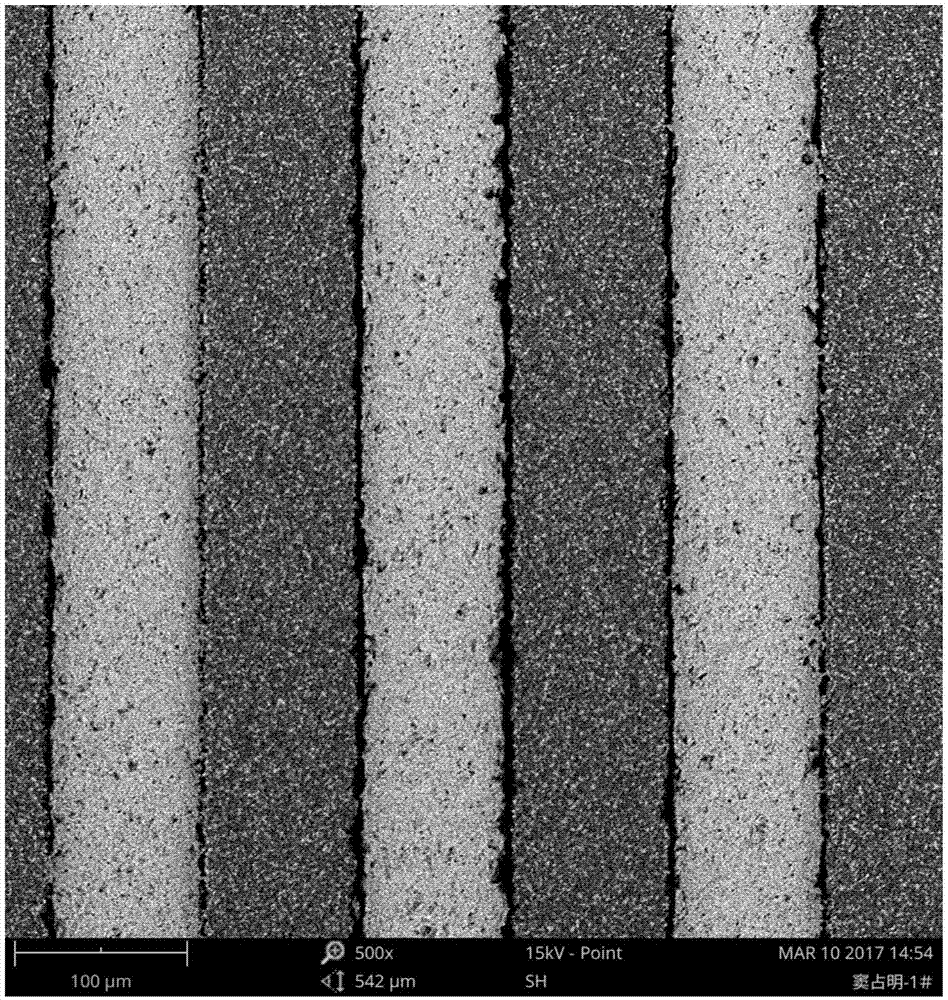

[0057] Embodiment 1: Multilayer high temperature co-fired ceramics of magnesium calcium titanate-based microwave dielectric ceramics (K25) and Ni-Zn-Fe ferrite materials with a dielectric constant of 25

[0058] (a) Powder preparation:

[0059] (1) Preparation of K25 dielectric ceramic powder: The K25 microwave dielectric ceramic material is prepared by the traditional solid-state method, and the A / B site atoms of magnesium calcium titanate microwave ceramics are replaced by doping, and the main formula Ca x Mg y La 2z / 3 TiO 3 A microwave dielectric ceramic powder with a dielectric constant of 25 is prepared, wherein x+y+z=1, x ranges from 0.07 to 0.15, y ranges from 0.81 to 0.95, and z ranges from 0.02 to 0.15.

[0060] Then, add 0.1-0.5wt% of silicon dioxide as a liquid-phase sintering aid, sand the mixed powder (35Hz, 20min-40min) to change the average particle size of the raw material, and obtain K25 dielectric ceramics with an average particle size of 0.5-1 μm Powder,...

Embodiment 2

[0073] Embodiment 2: Multilayer high-temperature co-fired ceramics of barium-titanium-based microwave dielectric ceramics (K38) and Ni-Zn-Fe-Cu ferrite materials with a dielectric constant of 38

[0074] (a) Powder preparation

[0075] (1) Preparation of K38 dielectric ceramic powder: The K38 microwave dielectric ceramic material was prepared by the traditional solid-state method, and the main formula Ba x Ti y o 3 A microwave dielectric ceramic powder with a dielectric constant of 38 is prepared, wherein y / x=4-4.5. Then, add liquid phase sintering aid ZnO 5~20wt% and Nb 2 o 5 1-6wt%, sanding the mixed powder (35Hz, 30min-60min) to change the average particle size of the raw materials, and the average particle size reaches 0.4-0.9μm K38 dielectric ceramic powder, so that the sintering temperature is 1140-1180°C.

[0076] (2) Preparation of Ni-Zn-Fe-Cu ferrite powder: The Ni-Zn-Fe-Cu ferrite material is prepared by the traditional solid-state method, and the Ni / Zn / Fe / Cu m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com