Preparation method of multilayer heterogeneous ceramic high temperature co-fired LC filter

A LC filter, high temperature co-firing technology, applied in the field of filter manufacturing, can solve the problems of material co-firing mismatch, affecting device performance and reliability, holes, etc. The effect of electric constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] Embodiment 1: the dielectric constant is 25 microwave dielectric ceramics (K25) and Ni-Zn-Fe ferrite multi-layer high temperature co-fired LC filter preparation

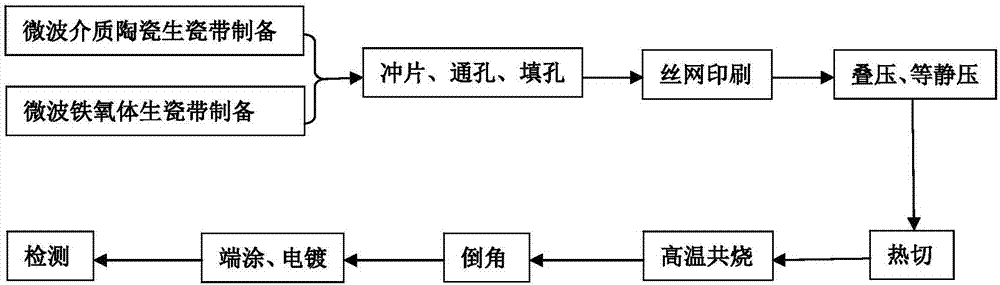

[0074] according to figure 1 The process shown prepares K25 microwave dielectric ceramics and Ni-Zn-Fe ferrite multilayer high-temperature co-fired LC filter. The technical specifications are as follows: passband frequency (GHz): (3.94-5.5); insertion loss (dB): ≤4.5; In-band fluctuation (dB): ≤1.5; Out-of-band suppression: ≥45dB@(f≤2.75GHz&f≥6.34GHz); Input and output standing waves: ≤1.5. The final filter size is 1608 (metric system, 1.6×0.8mm), and the specific preparation steps are as follows:

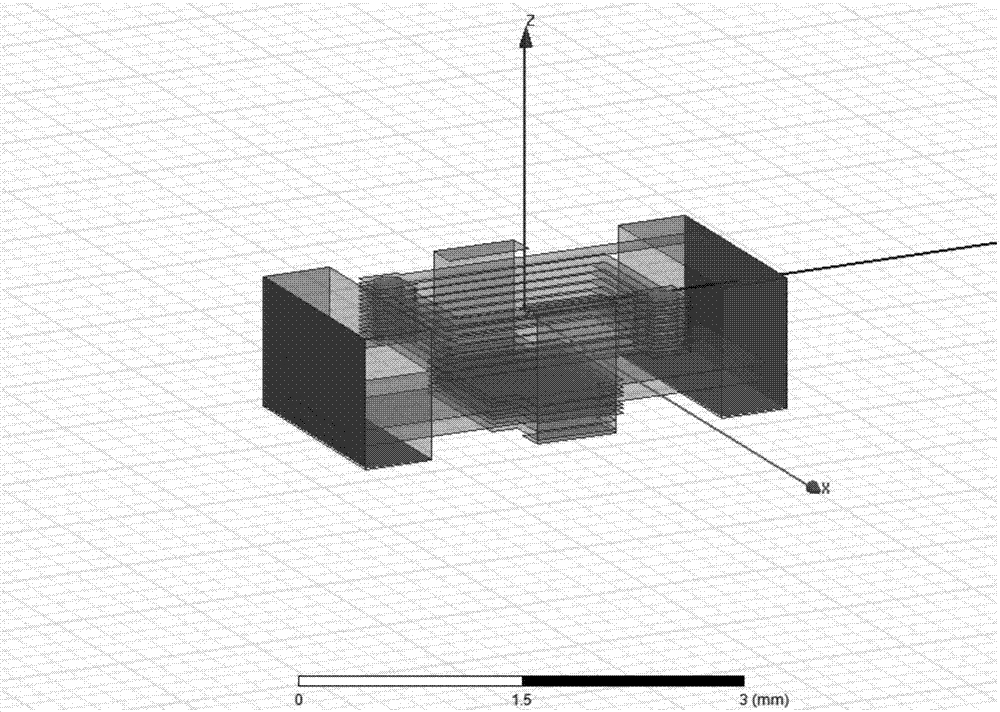

[0075] (a) Simulation design of a multilayer heterogeneous ceramic LC filter: a sandwich structure in which the upper and lower layers are microwave dielectric layers and the middle is a microwave ferrite layer. Among them, the inductance layer is made of Ni-Zn-Fe ferrite magnetic material with a permeability of ...

Embodiment 2

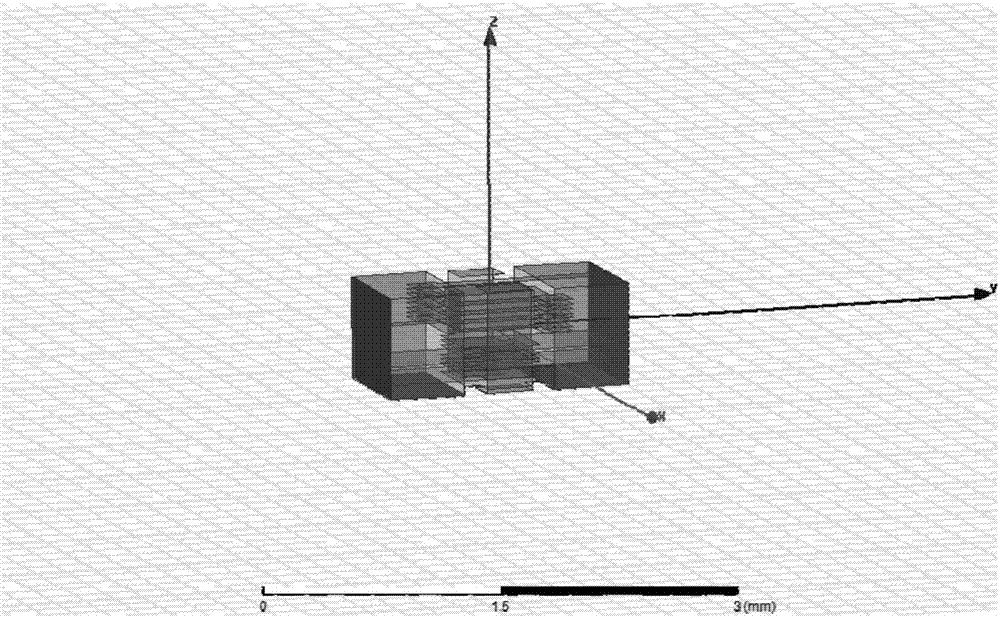

[0092] Example 2: Preparation of a multilayer high temperature co-fired LC filter with a dielectric constant of 38 microwave dielectric ceramics (K38) and ferrite

[0093] The index of the filter in Embodiment 2 is the same as that of the LC filter in Embodiment 1. However, due to the replacement of K25 with a barium-titanium-based microwave dielectric ceramic layer (K38), the dielectric constant increases and the sintering temperature decreases. In order to make heterogeneous ceramics high-temperature matching co-firing, the microwave ferrite material is adjusted to Ni-Zn -Fe-Cu system. The size of the final filter can be further reduced to 1005 (1×0.5mm). The specific preparation steps are as follows:

[0094] (a) The simulation design of the multilayer heterogeneous ceramic LC filter: also adopts the sandwich structure of microwave dielectric ceramic sandwiched by microwave ferrite on both sides. Among them, the inductance layer is made of Ni-Zn-Fe-Cu ferrite magnetic mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com