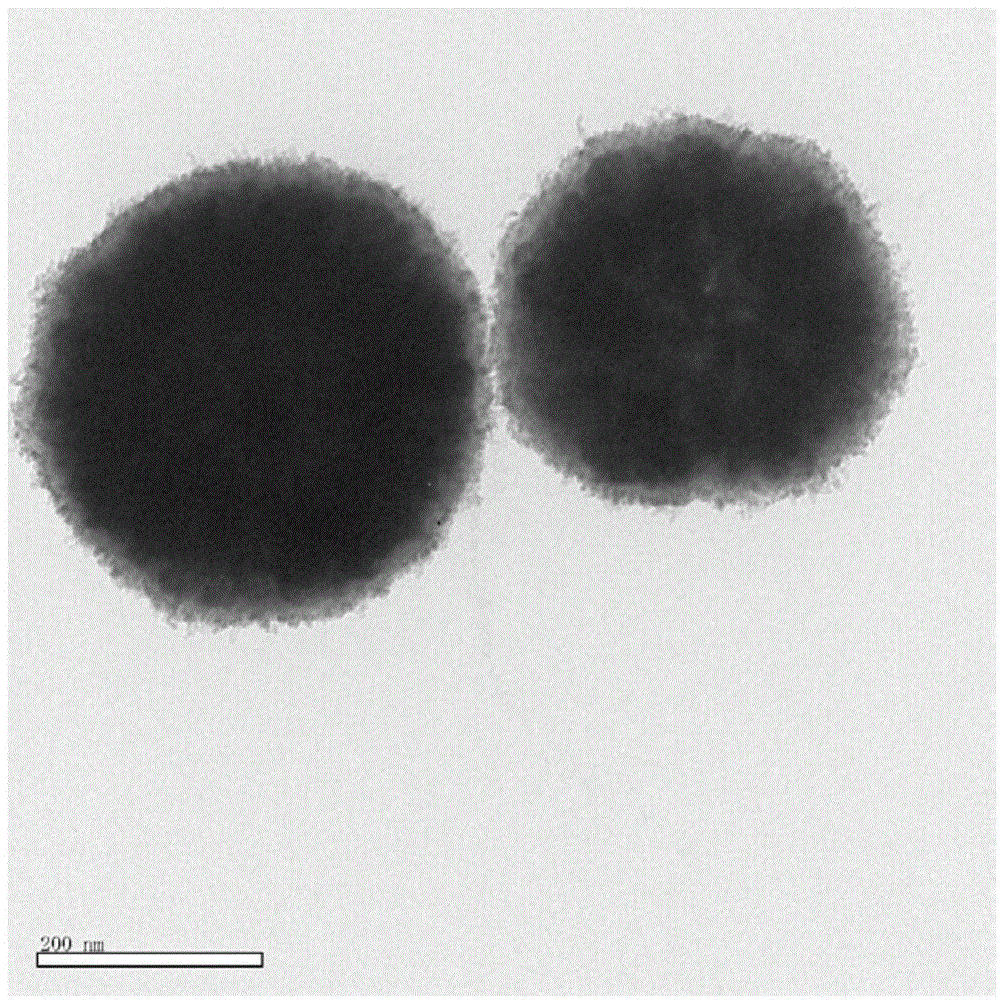

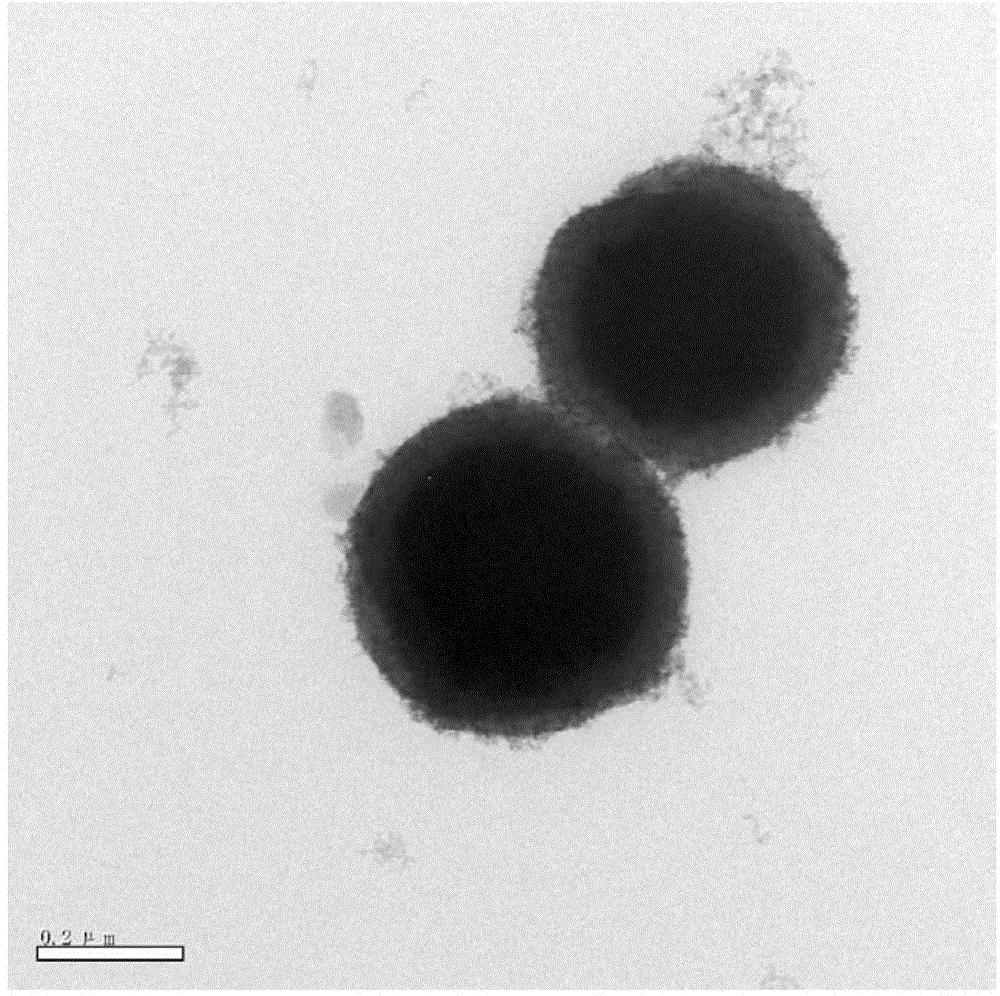

Fe3O4@SiO2@ZnO ternary heterostructure core-shell nanoparticle and preparation method therefor

A nano-microsphere, core-shell technology, which is applied in the field of Fe3O4@SiO2@ZnO ternary heterogeneous core-shell nano-microspheres and its preparation, can solve the problem of non-coated, uneven coating layer, ternary heterogeneous core-shell The structural nano-microspheres are easy to agglomerate and other problems, so as to achieve the effects of low cost, good dispersibility, and avoiding uneven coating layer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] (1) Take 0.1g of Fe with a particle size of about 300nm 3 o 4 Nanospheres (for the preparation method, see the document ActaMater.61(2013) 5829-5834), dispersed in 100mL of 0.15M trisodium citrate aqueous solution by ultrasonic and stirred for 4h;

[0029] (2) After the stirring is completed, the Fe which has been modified by trisodium citrate 3 o 4 Nanospheres dispersed in 20mLH 2 O / 80mL ethanol mixed solution, and add 1mLNH 3 .H 2 O, then the mixed solution was transferred to a three-necked flask, and under continuous stirring, 20ml of ethanol solution containing 0.3mL tetraethyl orthosilicate was added dropwise, and after the addition was completed, stirring was continued at room temperature for 12h to obtain Fe 3 o 4 @SiO 2 Binary heterogeneous core-shell nanospheres;

[0030] (3) Fe 3 o 4 @SiO 2 Nanospheres dispersed in 100mL0.03MZn(Ac) 2 .2H 2 O in ethanol solution, then transfer the mixed solution to a three-necked flask, and add 25mL of 0.125M NaOH ...

Embodiment 2

[0034] (1) Take 0.1g of Fe with a particle size of about 300nm 3 o 4 Nanospheres, dispersed in 100mL 0.15M trisodium citrate aqueous solution by ultrasonic and stirred for 4h;

[0035] (2) After the stirring is completed, the Fe which has been modified by trisodium citrate 3 o 4 Nanospheres dispersed in 20mLH 2 O / 80mL ethanol mixed solution, and add 1.5mLNH 3 .H 2 O, then the mixed solution was transferred to a three-necked flask, and under continuous stirring, 30ml of ethanol solution containing 0.45mL tetraethyl orthosilicate was added dropwise, and after the addition was completed, stirring was continued at room temperature for 16h to obtain Fe 3 o 4 @SiO 2 Binary heterogeneous core-shell nanospheres;

[0036] (3) Fe 3 o 4 @SiO 2 Nanospheres dispersed in 100mL0.03MZn(Ac) 2 .2H 2 O in ethanol solution, then transfer the mixed solution to a three-necked flask, and add 25mL of 0.125M NaOH ethanol solution dropwise under the condition of 60°C water bath, and contin...

Embodiment 3

[0038] (1) Take 0.1g of Fe with a particle size of about 300nm 3 o 4 Nanospheres, dispersed in 100mL 0.225M trisodium citrate aqueous solution by ultrasonic and stirred for 6h;

[0039] (2) After the stirring is completed, the Fe which has been modified by trisodium citrate 3 o 4 Nanospheres dispersed in 20mLH 2 O / 80mL ethanol mixed solution, and add 1.5mLNH 3 .H 2 O, then the mixed solution was transferred to a three-necked flask, and under continuous stirring, 30ml of ethanol solution containing 0.45mL tetraethyl orthosilicate was added dropwise, and after the addition was completed, stirring was continued at room temperature for 16h to obtain Fe 3 o 4 @SiO 2 Binary heterogeneous core-shell nanospheres;

[0040] (3) Fe 3 o 4 @SiO 2 Nanospheres dispersed in 100mL0.04MZn(Ac) 2 .2H 2 O in ethanol solution, then transfer the mixed solution to a three-necked flask, and add 25mL of 0.1875M NaOH ethanol solution dropwise in a water bath at 70°C, and continue to stir fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com