Porous glass ceramic capable of absorbing electromagnetic waves and preparation method thereof

A technology of porous glass ceramics that absorbs electromagnetic waves, applied in chemical instruments and methods, other chemical processes, etc., can solve problems such as performance degradation, and achieve the effects of low cost, good durability, and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

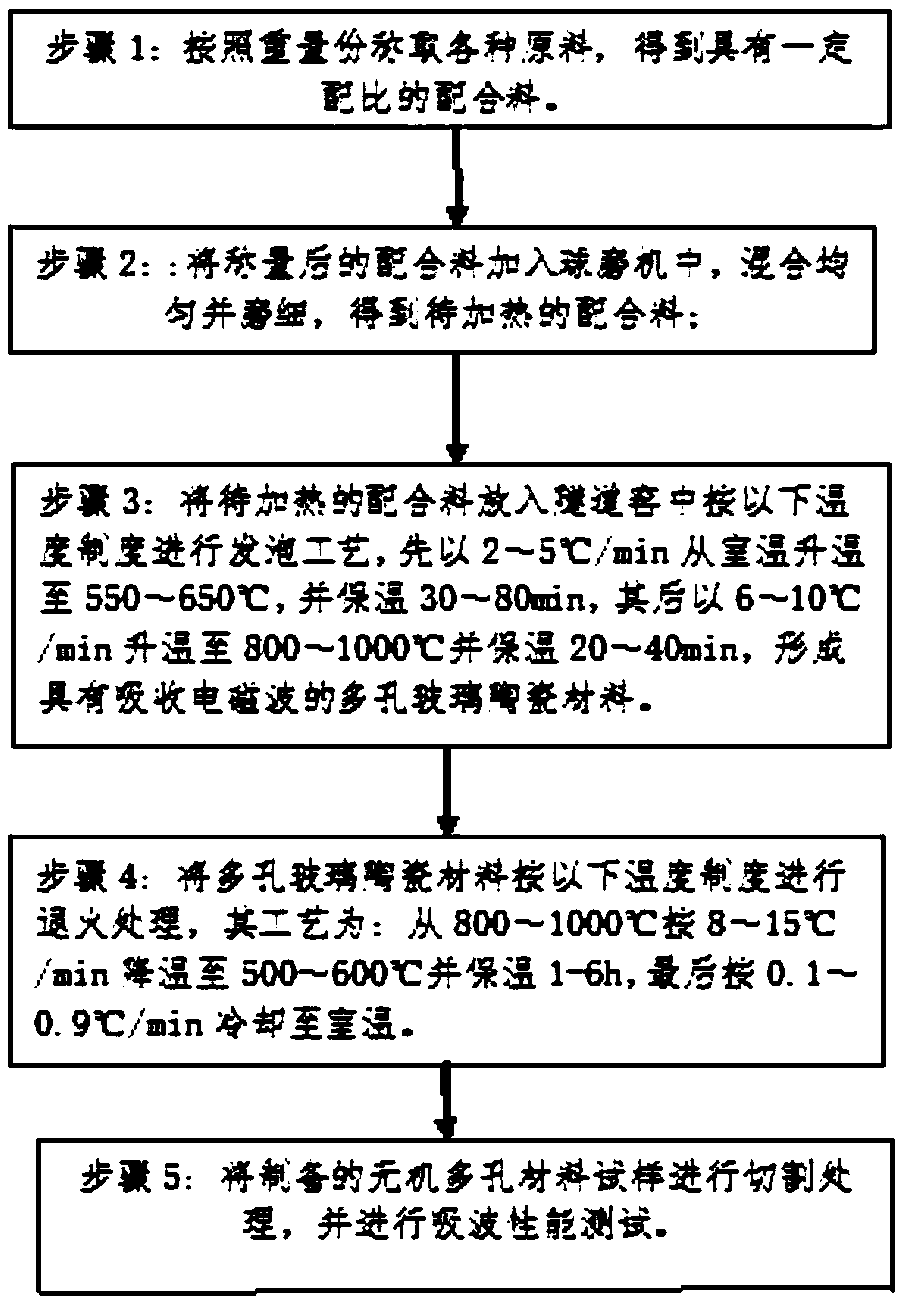

Method used

Image

Examples

Embodiment 1

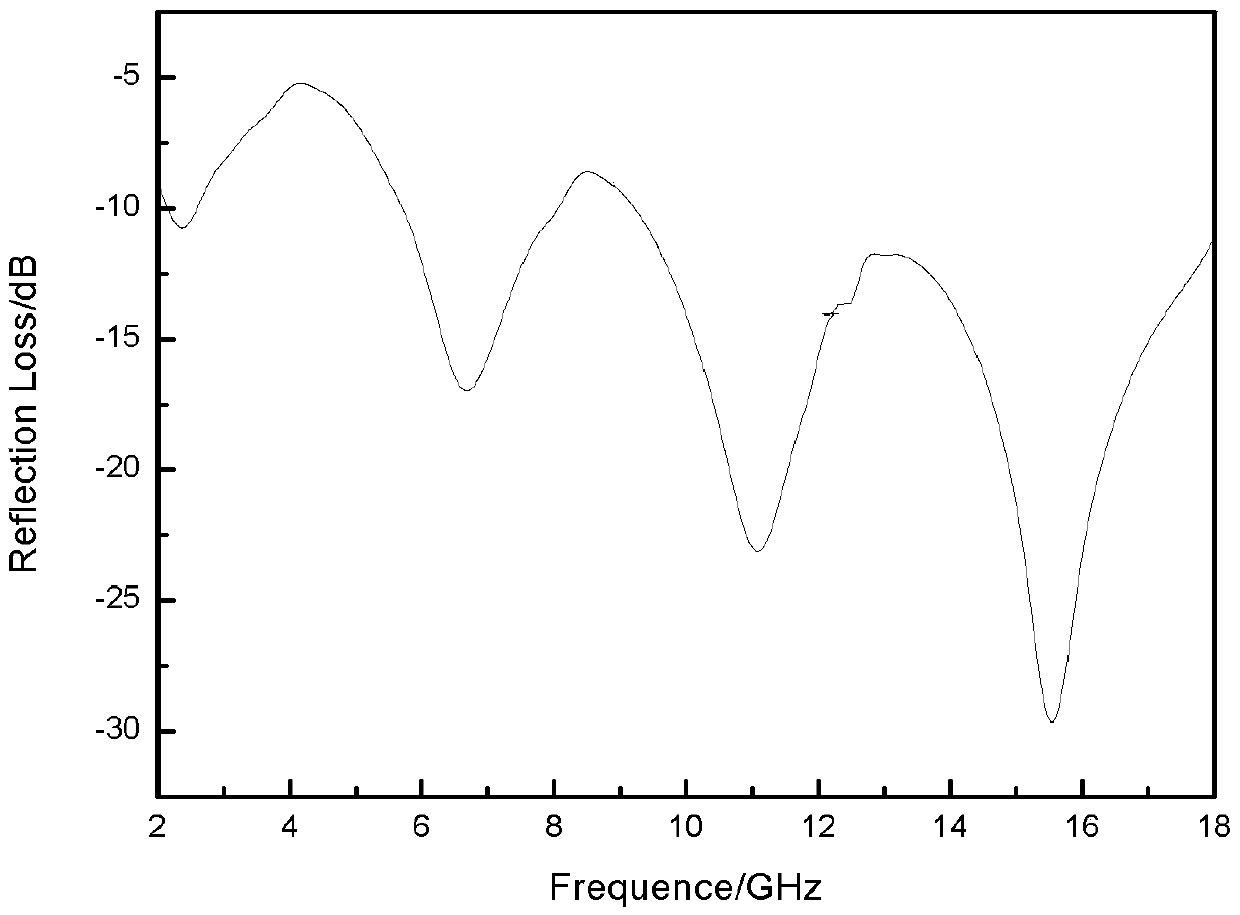

[0039] Weigh 5kg of flat glass powder, 2kg of ceramic granulation powder, 10g of silicon carbide, 10g of antimony trioxide, 3kg of ferrite, 100g of graphite, and 100g of SiC fiber, and place them in a ball mill for dry grinding for 3 hours. Materials to be fired; apply calcined kaolin evenly on a 660*660*240mm detachable mold as a release agent to prevent the foamed sample from adhering to the mold and making it difficult to take it out; pour the materials to be fired into the mold and Spread evenly so as to be able to foam evenly; adjust the temperature system of the tunnel kiln. Cool at 15°C / min to 600°C, perform annealing treatment, and keep it warm for 1h, then cool to room temperature at 0.1°C / min to obtain the required radar wave absorbing material, and cut the sample for performance testing . The compressive strength of the prepared porous glass-ceramic-based radar wave absorbing material is 2.5MPa, which is much higher than that of general foam glass materials. The h...

Embodiment 2

[0041] Weigh 7.5kg of frit glass powder, 2kg of ceramic granulation powder, 20g of silicon carbide, 30g of antimony trioxide, 300g of SiC fiber, 500g of ferrite, and 300g of graphite, and place them in a ball mill for dry grinding. The ball milling time is 3 hours. That is to get evenly mixed materials to be fired; apply calcined kaolin evenly on the removable mold of 660*660*240mm as a release agent; pour the materials to be fired into the mold and spread them evenly; adjust the temperature system of the tunnel kiln , the temperature is raised from room temperature to 650°C at a rate of 5°C / min, and kept for 80 minutes, then raised to 900°C at a rate of 6°C / min, and kept for 40 minutes, then cooled to 500°C at a rate of 8°C / min, annealed, and kept After cooling for 6 hours to room temperature at 0.5°C / min, the required radar wave absorbing material can be obtained, and the sample is cut for performance testing. The compressive strength of the prepared porous glass-ceramic-bas...

Embodiment 3

[0043] Weigh 7kg of frit glass powder, 0.5kg of ceramic granulation powder, 30g of silicon carbide, 50g of antimony trioxide, 200g of SiC fiber, 2.5kg of ferrite, and 400g of graphite in a ball mill for dry grinding. The ball milling time is 2 hours. Take out After that, the uniformly mixed materials to be fired are obtained; evenly smear calcined kaolin on the removable mold of 660*660*240mm as a release agent; pour the materials to be fired into the mold and spread them evenly; adjust the temperature of the tunnel kiln System, the temperature is raised from room temperature to 550°C at 2°C / min, and kept for 40 minutes, then raised to 900°C at 6°C / min, kept for 20 minutes, then cooled to 600°C at 10°C / min, annealed, and Keep warm for 3 hours, and then cool down to room temperature at 0.2°C / min to obtain the required radar wave absorbing material, and cut the sample for performance testing. The compressive strength of the prepared porous glass-ceramic-based radar wave absorbin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com