Novel electromagnetic wave absorption material and preparation method thereof

A technology of absorbing materials and absorbing composite materials, applied in the field of electromagnetic wave absorbing materials, can solve the problems of difficult to reach working frequency, low absorption rate, small bandwidth range, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

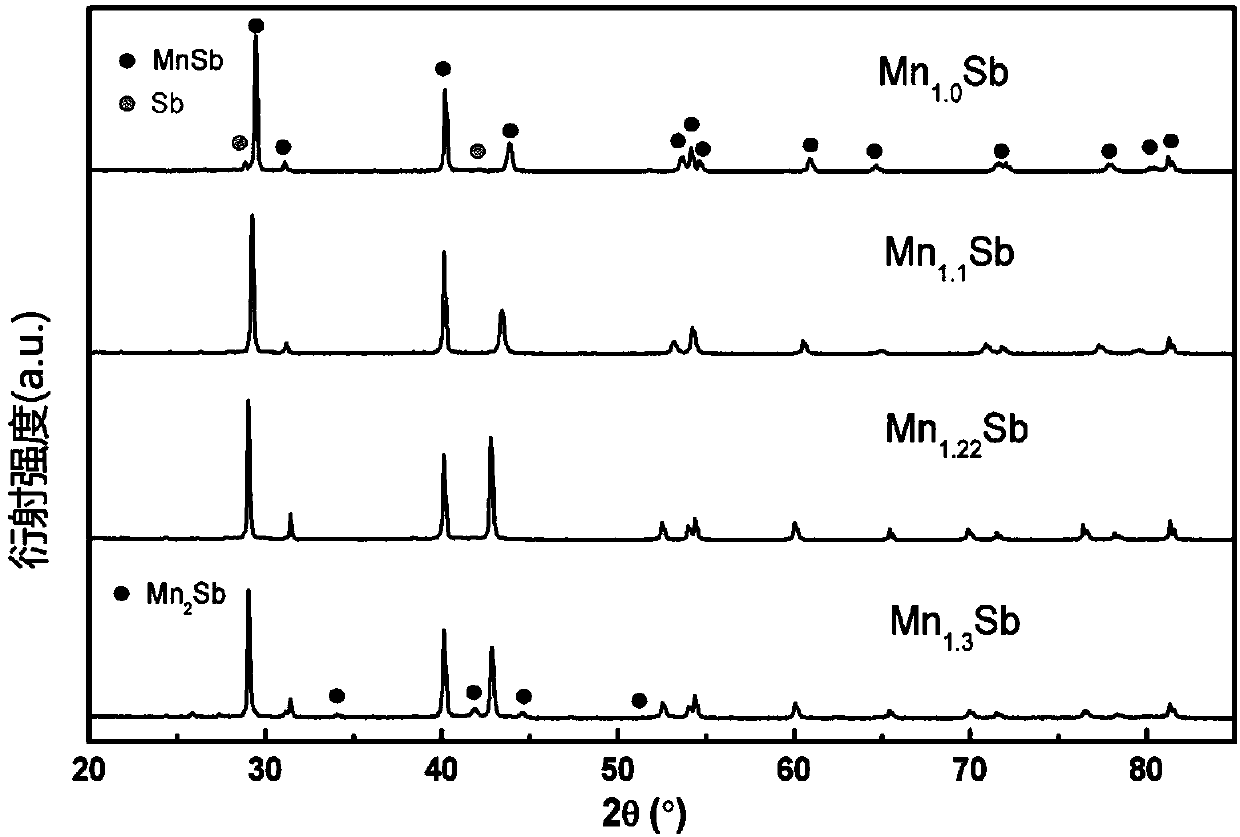

[0028] Weigh an appropriate proportion of manganese and antimony (atomic ratio Mn:Sb=x:1), prepare a master alloy by smelting, or rapidly solidify into alloy strips (1-2cm wide, 0.2-0.4mm thick) by smelting, and then Break into 50-100 micron coarse powder, and measure its diffraction spectrum by X-ray diffractometer. figure 1 for different Mn x In the XRD pattern of the Sb alloy, the main phase of the alloy shows a NiAs hexagonal structure, where the values of x are 1.0, 1.1, 1.22, and 1.3, respectively.

Embodiment 2

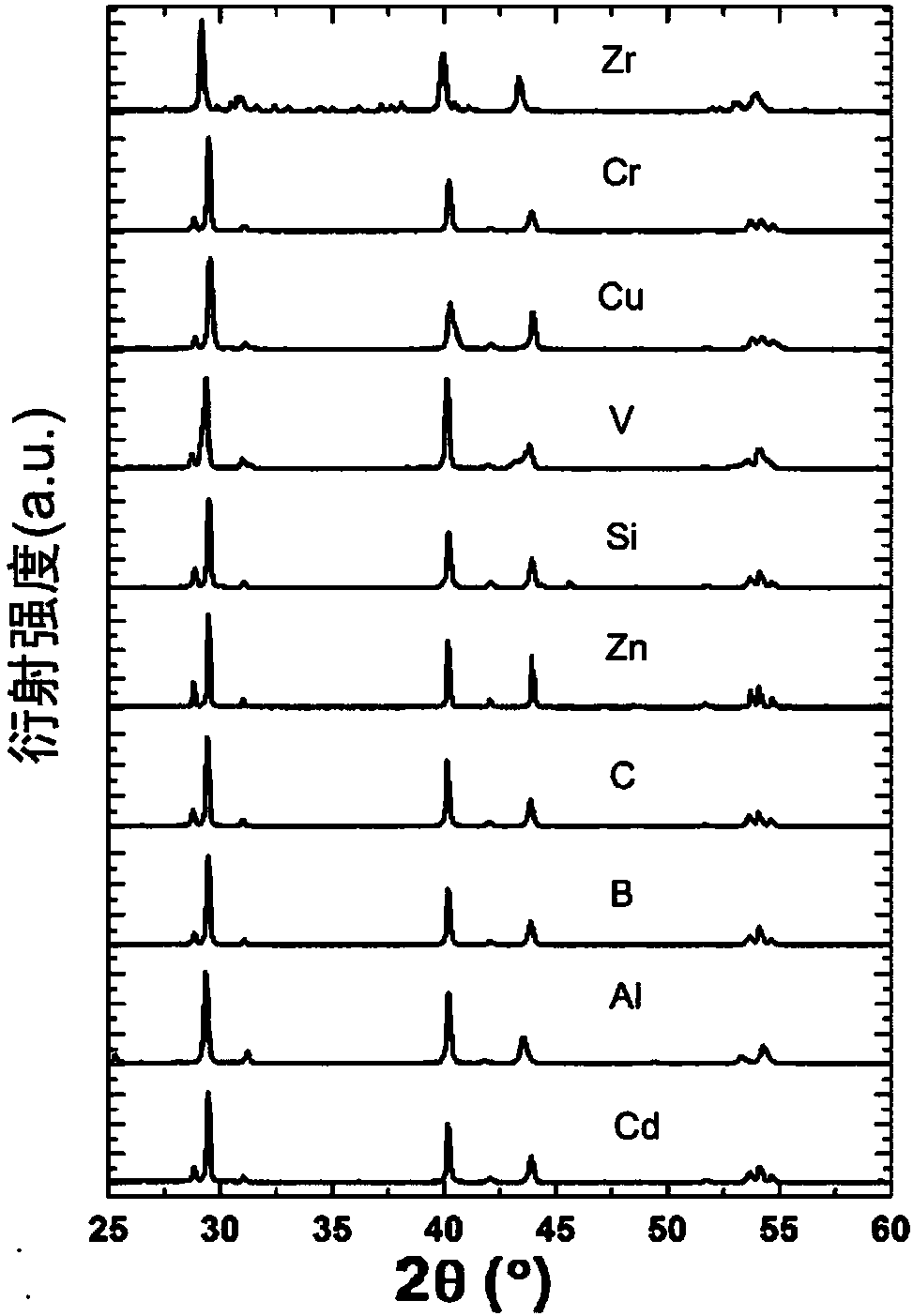

[0030] Weigh an appropriate proportion of manganese, antimony and the third element T (atomic ratio Mn:T:Sb=0.9:0.1:1), prepare a master alloy by smelting, or rapidly solidify into an alloy strip (1-2cm wide, 0.2-0.4mm thick), and then crushed into 50-100 micron coarse powder, the X-ray diffractometer was used to measure its diffraction spectrum. figure 2 Mn for adding different T elements 0.9 T 0.1 In the XRD pattern of Sb alloy, the main phase of the alloy is NiAs hexagonal structure, where T is Zr, Cr, Cu, V, Si, Zn, C, B, Al, Cd respectively. The effect of adding the third element T is to improve the stability of the material, improve the magnetization and Curie temperature of the material, and obtain excellent wave-absorbing characteristics.

Embodiment 3

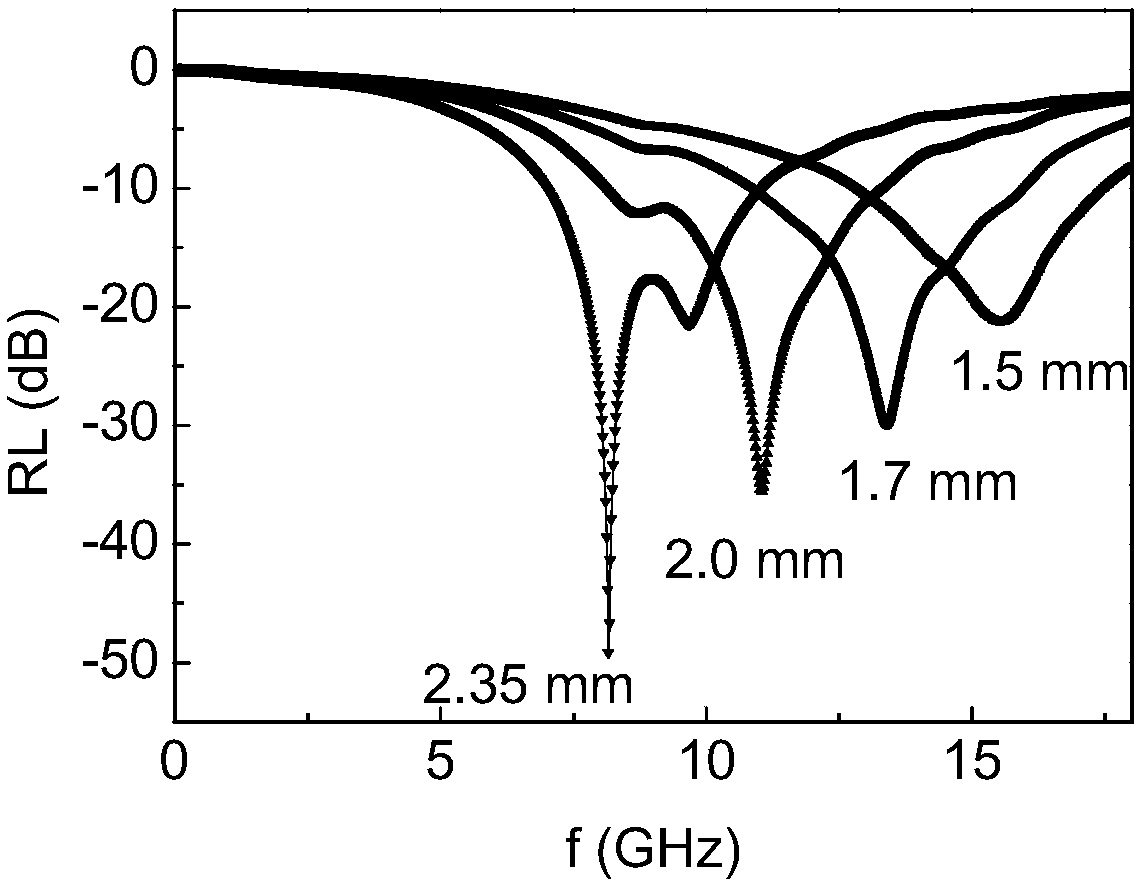

[0032] Weigh 73g of Mn and 147g of Sb, rapidly solidify into alloy ingots or alloy strips by smelting, then mechanically crush into 50-100 micron coarse powder, and ball mill the powder in gasoline and grinding aid solution for 15 hours. Drain the liquid after the ball mill is discharged, dry the magnetic powder, and make a composite bonded compression mold with paraffin wax (cylindrical ring with an inner diameter of 3.04 mm and an outer diameter of 7.00 mm). Electromagnetic properties were measured on an Agilent vector network analyzer. According to the measured electromagnetic parameters, it can be known by calculation that the absorption peak intensity of the material within the matching thickness range of 1.4-2.35mm exceeds -20dB, and the bandwidth less than -10dB is as high as 5.3GHz. The absorption strength reaches -50dB when the frequency is 8.2GHz (matching thickness is only 2.35mm). Absorption curve such as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Absorption strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com