Method for synthesizing tantalum-containing SiC ceramic precursor

A technology of ceramic precursor and synthesis method, which is applied in the field of preparation of SiC ceramic precursor, can solve the problems of poor oxidation resistance, poor ultra-high temperature resistance, and single function of fibers, and achieves easy control of the reaction process and re-formability. Good, wide-ranging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

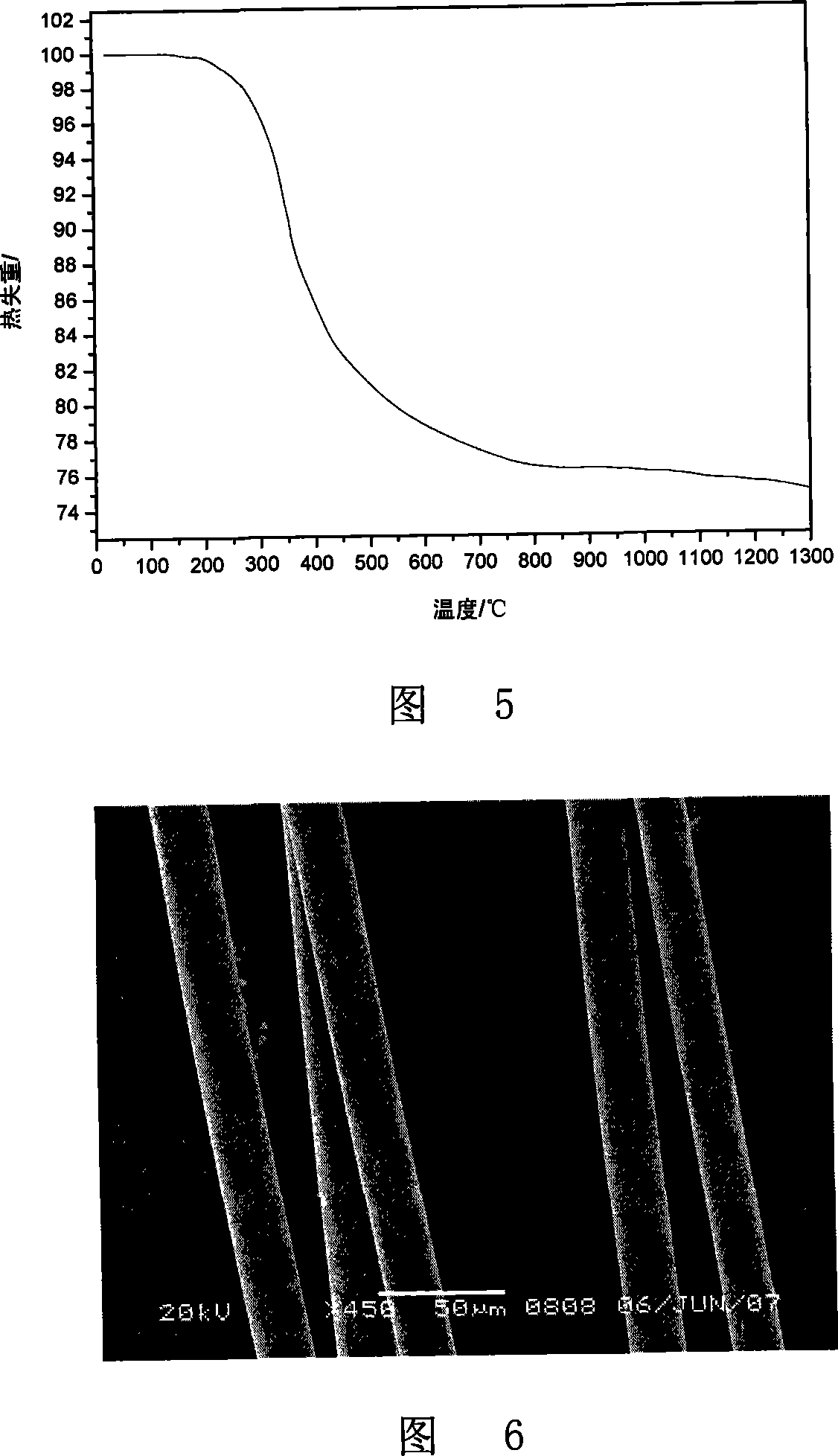

[0030] Using PSCS and tantalum tetraethoxy acetylacetonate as raw materials, the mass ratio of the two (the proportions described below are all mass ratios) is: tantalum tetraethoxy acetylacetonate: PSCS = 8: 100, and the reaction temperature is 450°C , pyrolysis temperature 500°C, heat preservation reaction for 6 hours, dissolved in xylene, filtered, and the filtrate was distilled under reduced pressure at 390°C to obtain PTCS with a softening point of 215°C and tantalum content of 4.11wt%, with a precursor yield of 70.9%. N 2 Heat preservation at 1200°C for 1 hour under the atmosphere, and the ceramic yield is 75.3%.

[0031] The tantalum-containing SiC ceramic fiber is prepared by using the PTCS precursor through melt spinning, non-melting in air and firing at high temperature. The fiber diameter is 20μm, and the tensile strength is 1.9GPa. The fiber has good ultra-high temperature resistance. After treatment at 1450°C and 1600°C, the fiber strength retention rate is 47% ...

Embodiment 2

[0034] Using PCS and tetraethoxy tantalum as raw materials, tetraethoxy tantalum: PCS = 1: 100, the reaction temperature is 400 ° C, the cracking temperature is 450 ° C, and after the reaction time of 2 hours, it is dissolved in xylene and filtered, and the filtrate is at 350 °C for vacuum distillation to obtain PTCS with a softening point of 210 °C and a tantalum content of 0.72 wt%, with a precursor yield of 78.2%. N 2 The temperature was kept at 1200° C. for 1 hour under the atmosphere, and the ceramic yield was 76.5%.

[0035] The tantalum-containing SiC ceramic fiber is prepared by using the PTCS precursor through melt spinning, non-melting in air and firing at high temperature. The fiber diameter is 18μm, and the tensile strength is 2.1GPa. The fiber has good ultra-high temperature resistance. After treatment at 1450°C and 1600°C, the fiber strength retention rate is 51% and 36% respectively; the fiber has good oxidation resistance. After heat treatment at 1000°C in ai...

Embodiment 3

[0037] Using PSCS and tantalum pentachloride as raw materials, the mass ratio of the two is: tantalum pentachloride:PSCS=20:100, the reaction temperature is 420°C, the cracking temperature is 500°C, and after 4 hours of heat preservation reaction, it is dissolved in xylene and filtered. The filtrate was distilled under reduced pressure at 350° C. to obtain PTCS with a softening point of 179° C. and a tantalum content of 9.26 wt%, with a precursor yield of 52.9%. N 2 The temperature was kept at 1200° C. for 1 hour under the atmosphere, and the ceramic yield was 72.2%.

[0038] The tantalum-containing SiC ceramic fiber is prepared by using the PTCS precursor through melt spinning, non-melting in air and firing at high temperature. The fiber diameter is 21μm, and the tensile strength is 1.8GPa. The fiber has good ultra-high temperature resistance. After treatment at 1450°C and 1600°C, the fiber strength retention rate is 45% and 35% respectively; the fiber has good oxidation re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fiber diameter | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com