Method for preparing high-chromium product by combining micro waves and ultrasonic waves to leach chromite through hydrochloric acid

A hydrochloric acid leaching and chromite technology, applied in the direction of improving process efficiency, can solve the problems of many reagents, complicated process, long process, etc., and achieve the effect of low cost, short process and low reduction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

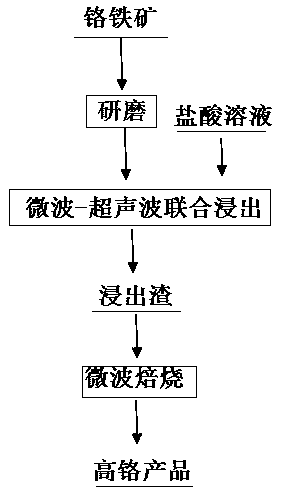

[0028] Such as figure 1 Shown, this microwave-ultrasonic combination uses hydrochloric acid leaching chromite to prepare the method for high chromium product, and its concrete steps are as follows:

[0029] Step 1, crushing the chromite ore until the particle size is below 200 mesh to obtain chromite ore powder; the chromite ore includes the following mass percentage components: Cr 2 o 3 40.82%, SiO 2 5.02%, Al 2 o 3 13.04%, CaO2.4%, MgO10.83%, TFe19.85%, Cr 2 o 3 / FeO1.69;

[0030] Step 2. Add the chromite powder obtained in step 1 into a hydrochloric acid solution with a concentration of 11.6mol / L according to the liquid-solid ratio of 2:0.5mL / g, heat up to 600°C under the condition of microwave power of 1500g / W, and The power is 100W, the ultrasonic frequency is 20KHz, and the insulation is leached for 60 minutes. After the leaching is completed, filter and dry to obtain the leaching residue;

[0031] Step 3. Powder the leaching slag obtained in step 2 until the par...

Embodiment 2

[0034] Such as figure 1Shown, this microwave-ultrasonic combination uses hydrochloric acid leaching chromite to prepare the method for high chromium product, and its concrete steps are as follows:

[0035] Step 1, crushing the chromite ore until the particle size is below 200 mesh to obtain chromite ore powder; the chromite ore includes the following mass percentage components: Cr 2 o 3 40.82%, SiO 2 5.02%, Al 2 o 3 13.04%, CaO2.4%, MgO10.83%, TFe19.85%, Cr 2 o 3 / FeO1.69;

[0036] Step 2. Add the chromite powder obtained in step 1 into a hydrochloric acid solution with a concentration of 12.4mol / L according to the liquid-solid ratio of 3:1mL / g, and heat up to 400°C under the condition of microwave power of 1000g / W. Heat preservation and leaching for 20 minutes under the conditions of 180W and ultrasonic frequency of 28KHz. After the leaching is completed, filter and dry to obtain the leaching residue;

[0037] Step 3. Powder the leach slag obtained in step 2 until the...

Embodiment 3

[0040] Such as figure 1 Shown, this microwave-ultrasonic combination uses hydrochloric acid leaching chromite to prepare the method for high chromium product, and its concrete steps are as follows:

[0041] Step 1, crushing the chromite ore until the particle size is below 200 mesh to obtain chromite ore powder; the chromite ore includes the following mass percentage components: Cr 2 o 3 40.82%, SiO 2 5.02%, Al 2 o 3 13.04%, CaO2.4%, MgO10.83%, TFe19.85%, Cr 2 o 3 / FeO1.69;

[0042] Step 2. Add the chromite powder obtained in step 1 into a hydrochloric acid solution with a concentration of 12.0mol / L according to a liquid-solid ratio of 3:1mL / g, and heat up to 500°C under the condition of a microwave power of 1300g / W. Heat preservation and leaching for 40 minutes under the conditions of 120W and ultrasonic frequency of 24KHz. After the leaching is completed, filter and dry to obtain the leaching residue;

[0043] Step 3. Powder the leaching slag obtained in step 2 until...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com