Patents

Literature

43 results about "Chromium product" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for separating and recycling vanadium and chromium from vanadate-chromate-containing solution

InactiveCN102676810AAchieve deep separationHigh recovery rateProcess efficiency improvementIon exchangeIon-exchange resin

The invention relates to a method for separating and recycling vanadium and chromium from a vanadate-chromate-containing solution, which is characterized in that by using the difference of between anion exchange potentials formed by hexavalent chromium and quintavalent vanadium in water solutions by weak alkali and strong alkali anion exchange resins, saturation adsorption is utilized to implement deep separation of vanadium and chromium, thereby obtaining the vanadium and chromium products. The invention has the characteristics of short technological process, favorable separating effect, environment friendliness and the like, and is simple to operate. The invention can effectively shorten the technological process for separating and recycling vanadium and chromium from the vanadate-chromate-containing solution, enhance the separating effect of vanadium and chromium, lower the recycling cost of vanadium and chromium, and save the reagent consumption; and vanadium and chromium in the solution are deeply separated through ion exchange and are respectively recycled. The invention is suitable for industrialized application.

Owner:CENT SOUTH UNIV

Method for separating and recycling vanadium and chromium from vanadium and chromium-containing material

InactiveCN104388683AHigh purityHigh recovery rateProcess efficiency improvementSlagAmmonium metavanadate

The invention discloses a method for separating and recycling vanadium and chromium from a vanadium and chromium-containing material. The method comprises the following steps of performing selective oxidization reaction on the vanadium-containing material to oxidize low-valent vanadium in the vanadium-containing material into pentavalent vanadium, filtering and separating to obtain a chromium-containing solution and vanadium-containing enriched slag by adopting water leaching after oxidization is completed; regulating the pH of the chromium-containing solution to be naturalized to separate out chromium oxide hydrate precipitates, filtering and separating the chromium oxide hydrate precipitates to obtain chromium oxide hydrate, and further processing the chromium oxide hydrate obtained by filtering and separating to prepare chromium-series products; leaching the vanadium-containing enriched slag by an alkaline solution to obtain a vanadate solution; purifying the vanadate solution and removing impurities from the vanadate solution, then, precipitating and separating out ammonium metavanadate or ammonium polyorthovanadate in the presence of ammonium salts, and roasting the ammonium metavanadate or ammonium polyorthovanadate to obtain a vanadium pentoxide product. The method for separating and recycling vanadium and chromium from the vanadium-containing material is good in separating effects of vanadium and chromium and high in recovery rate. The vanadium product and the chromium product prepared are high in purity. Moreover, the method has the advantages of short process flow, simple and convenient operation, low production cost, environment friendliness and the like, and is suitable for industrial application.

Owner:CENT SOUTH UNIV

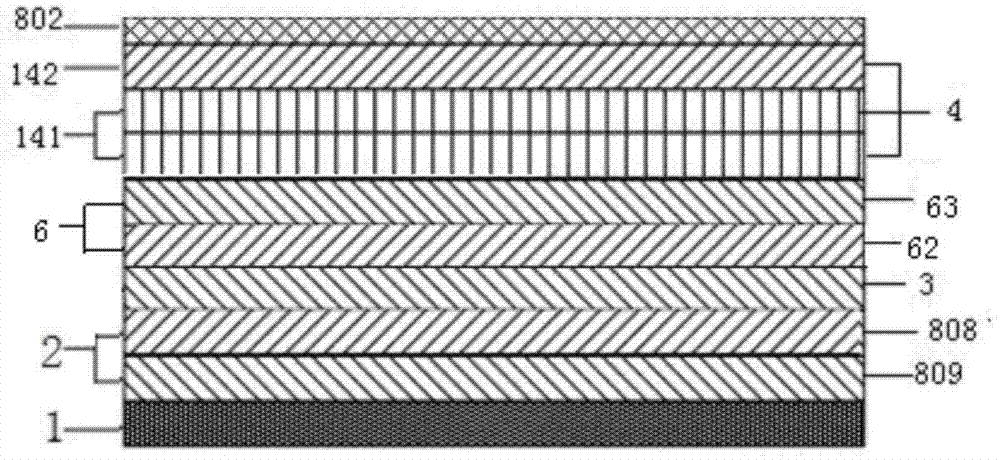

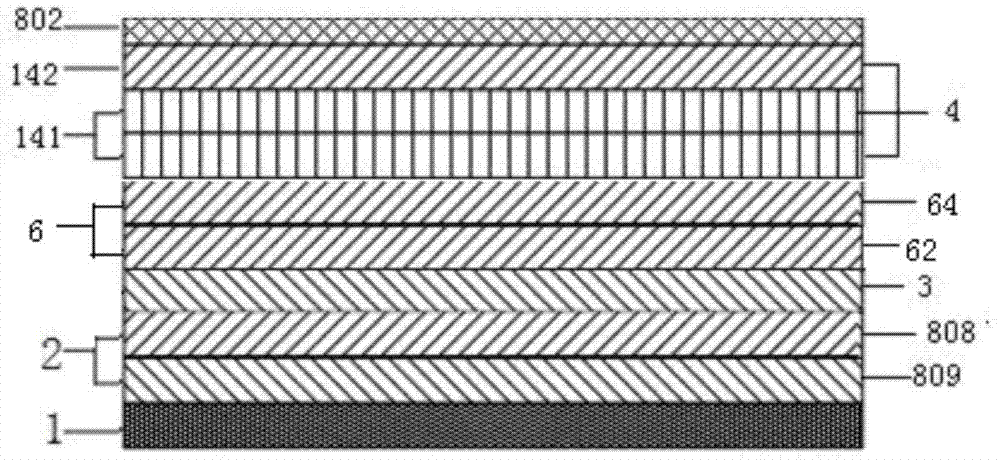

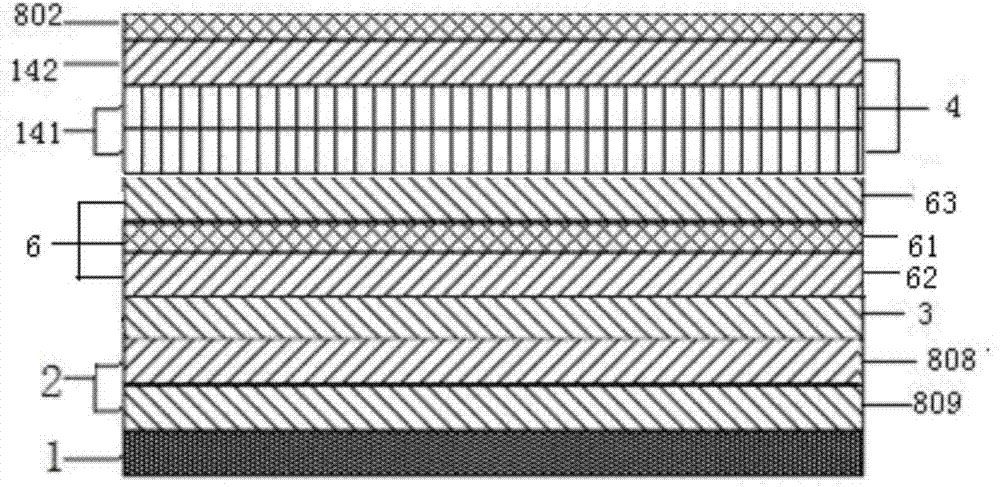

Nickel-chromium plating part and manufacturing method thereof

ActiveCN104772946AProcess stabilityCompatibility is reasonableMetal layered productsPre treatmentCopper

The invention discloses a nickel-chromium plating part and a manufacturing method thereof. The nickel-chromium plating part includes a substrate, a pretreatment coating, a base layer, a functional layer and a decorative layer. The pretreatment coating is deposited on the entire substrate, and a copper plate layer is formed on the pretreatment coating; the base layer is formed on the copper plate layer; the functional layer is formed on the base layer and includes a low potential nickel layer and a microporous nickel layer formed on the low potential nickel layer; and the decorative layer is formed on the microporous nickel layer and is a trivalent chromium coating or a hexavalent chromium coating. Based on the micropores on the part surface and chrome plating technology, the low potential nickel layer is added to improve the corrosion resistance of the product, especially the corrosion resistance of trivalent chromium plating product, so as to promote the large scale popularization and application of the trivalent chromium product, which has better environmental protection performance.

Owner:JIAXING MINHUI AUTOMOTIVE PARTS CO LTD

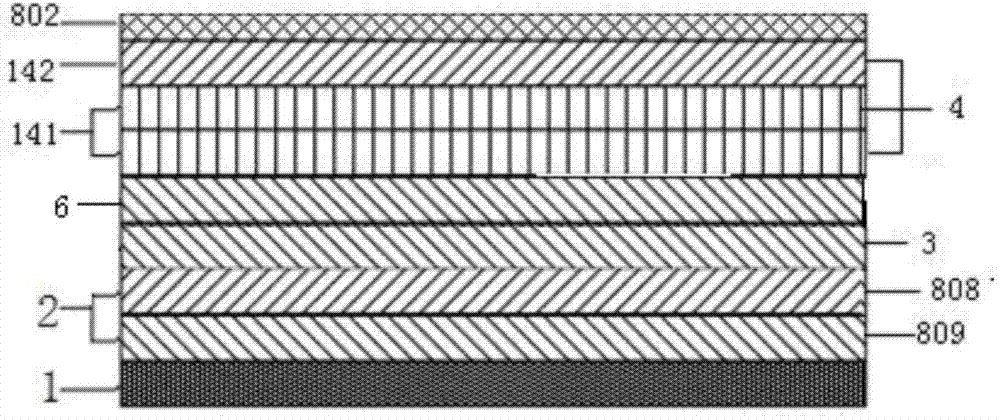

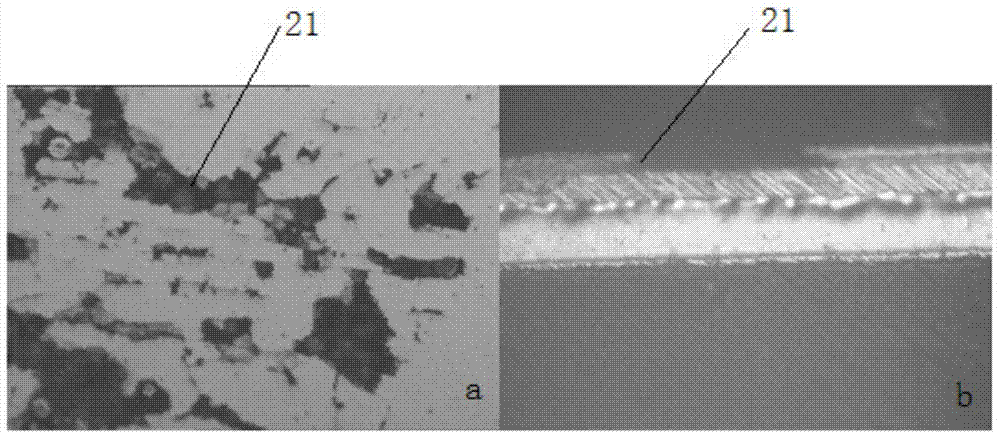

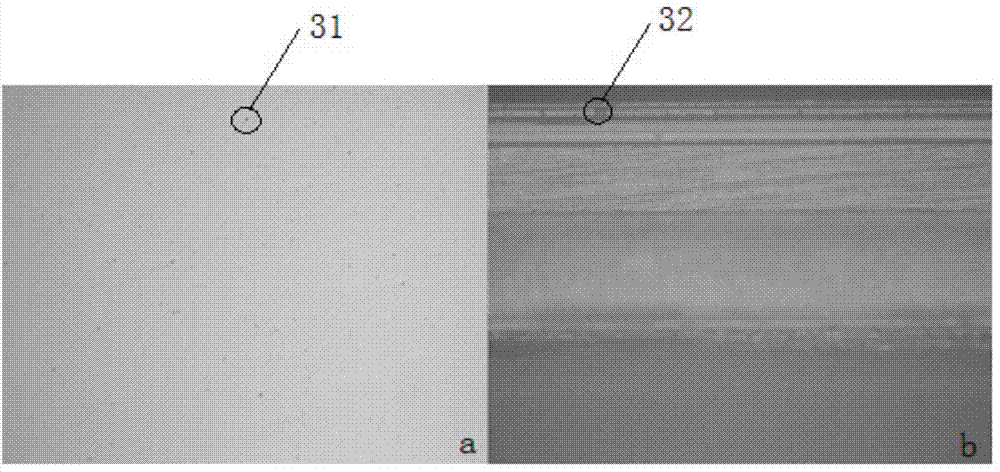

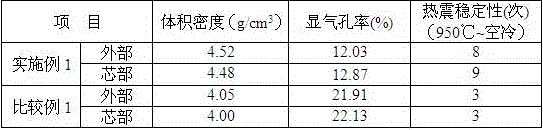

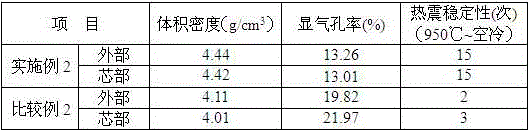

Preparation method of compact chromium oxide product with high thermal shock resistance

The invention belongs to the technical field of refractory materials, and provides a preparation method of a compact chromium oxide product with high thermal shock resistance. According to the preparation method of the compact chromium oxide product with the high thermal shock resistance, the raw material of the chromium oxide product is composite chromium oxide micro-powder with the particle size of less than or equal to 45mu m; the composite chromium oxide micro-powder is prepared from chromium oxide micro-powder, titanium oxide micro-powder and a bonding agent. The preparation method comprises the steps of adding metal Zr micro-powder into the composite chromium oxide micro-powder; homogenizing and granulating the composite chromium oxide micro-powder to obtain a chromium oxide green body; replenishing an electric furnace, which contains the chromium oxide green body, with high-purity inert gas Ar; when the temperature is 1450-1650 DEG C, carrying out heat preservation for 2-8h, and sintering to obtain the compact chromium oxide product which is high in thermal shock resistance and has the chromium oxide content of more than 86%. The preparation method of the compact chromium oxide product with the high thermal shock resistance solves the problems that the compact chromium oxide product is great in density gradient difference of an inside body and an outside body, poor in thermal shock resistance, and the like, guarantees the uniformity of an internal structure of the compact chromium oxide product, and improves the sintering properties and use performance of large compact chromium products.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

Method for recycling and preparing metal chromium

InactiveCN104099478AImprove recovery rateAchieve removalProcess efficiency improvementChromium productScrap

A method for recycling and preparing metal chromium comprises the steps of recycling chromium element from discharged waste liquid and discharged waste material, and utilizing the recycled chromium element to prepare metal chromium. The method prevents environmental pollution, realizes application of chromium resources, is simple in technology and low in cost, and can obtain metal chromium products which can meet the use requirement.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

Clean production method in atmospheric pressure leaching of limonite type laterite-nickel ore with hydrochloric acid

The invention relates to a clean production method in atmospheric pressure leaching of limonite type laterite-nickel ore with hydrochloric acid. The clean production method comprises the following steps: 1) mixing the limonite type laterite-nickel ore with hydrochloric acid for performing atmospheric pressuring leaching reaction; 2) performing calcination reaction to the pickle liquor obtained from the step 1); 3) dedusting the hydrogen chloride gas obtained from the step 2) to enter an absorption tower for producing hydrochloric acid, and collecting iron oxide powder; 4) washing and filtering the iron oxide powder, obtained from the step 3) with clean water; 5) performing liquid oxidizing reaction to solid filter cakes obtained from the step 4) to prepare corresponding chromium products, wherein the fine iron powder is obtained by slag phase; and 6) preparing the acid filtrate obtained from the step 4) into Ni and Co products. Through the clean production method, the separation of iron from nickel, cobalt and chrome in the atmospheric pressure leachate of the limonite type laterite-nickel ore can be realized, and the problem that the atmospheric pressure leachate of the limonite type laterite-nickel ore is difficultly treated can be effectively solved.

Owner:河北中科同创科技发展有限公司

Selenium-rich and chromium-rich Saccharomyces cerevisiae, selenium-rich and chromium-rich yeast product and their production process

ActiveCN101045907ALow toxicityFood safetyFungiMicroorganism based processesInorganic seleniumChromium product

The present invention relates to one kind of selenium-rich and chromium-rich Saccharomyces cerevisiae, selenium-rich and chromium-rich Saccharomyces cerevisiae product and their production process. Of the selenium-rich and chromium-rich Saccharomyces cerevisiae product, each kilogram contains selenium in 100-4000 mg and chromium in 100-4000 mg. The selenium-rich and chromium-rich Saccharomyces cerevisiae may be used as selenium and chromium replenisher added into various food products or prepared into alone preparation. The selenium-irch and chromium-rich Saccharomyces cerevisiae product has lower toxicity than inorganic selenium and chromium product and high safety, and may be used in replenishing both selenium and chromium.

Owner:ANGEL NUTRITECH CO LTD

Method for extracting and recovering chromium from cold rolling chromium sludge

InactiveCN104944719ARealize harmless treatmentHigh recovery rateSludge treatmentProcess efficiency improvementSludgeAdditional values

The invention discloses a method for extracting and recovering chromium from cold rolling chromium sludge. The method comprises the following steps: 1), soaking cold rolling chromium sludge in concentrated hydrochloric acid 20-37% in weight percentage, stirring for mixing, so as to enable Cr elements in cold rolling chromium sludge to exist in the form of chromium (iii), then leaving to stand and filtering out insoluble solid matters to obtain a solution I; 2), adding Zn powder to the solution I, fully separating out non-active metal deposition, filtering out deposition to obtain a solution II; 3), regulating the pH value of the solution II to be 7-8, introducing CO2, heating to enable Zinc (ii) and Ca (ii) to precipitate in the form of ZnCO3.3Zn(OH)2 and CaCO3, and enable Cr elements in the solution II to exist in the form of CrCl3, leaving to stand to filter out precipitate to obtain the solution III for standby application; 4), regulating the pH value of the solution III to be 8-9, heating to enable CrCl3 in the solution III to be hydrolyzed to form CrOCl precipitate, the formed CrOCl precipitate is the chromium product. According to the method for extracting and recovering chromium from cold rolling chromium sludge, the recovery rate of chromium from the cold rolling chromium sludge can reach 95% or above, the recovery rate of chromium is greatly improved, innocent treatment on cold rolling chromium sludge is fully realized, the energy consumption is reduced, and the chromium recovery additional value is increased.

Owner:武汉钢铁有限公司

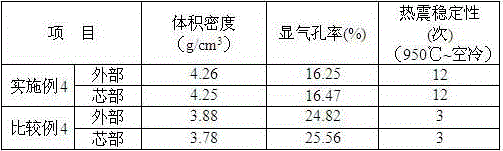

Production method of metal chromium

The invention discloses a production method of metal chromium. The production method includes the following steps that 1, chromium sesquioxide and aluminum powder are evenly mixed, and a mixed material is obtained; 2, an electrode is inserted into a smelting furnace, and then part of the mixed material is put in the smelting furnace; 3, the electrode is subjected to ohmic heating, the temperaturein the smelting furnace rapidly rises, and an aluminothermic reduction reaction is carried out; 4, after the interior of the smelting furnace reaches designated smelting temperature, the rest of the mixed material is put in the smelting furnace, the aluminothermic reduction reaction is carried out, the reaction is constant for a certain time, and it is guaranteed that the reaction is complete; 5,the electrode is powered off, heating stops, and the electrode is pulled out of the smelting furnace; and 6, the smelting furnace is cooled, subjected to slag removal, finished and broken, and the metal chromium product is obtained. Electric heating replaces a heating agent autothermal reaction, reaction conditions can be stabilized according to the aluminothermic reaction condition, the reactionuniformity is good, the consumption of an aluminum reducing agent is reduced by 20%, and the chromium yield is increased by 5% or above.

Owner:四川明宏恒正科技有限公司

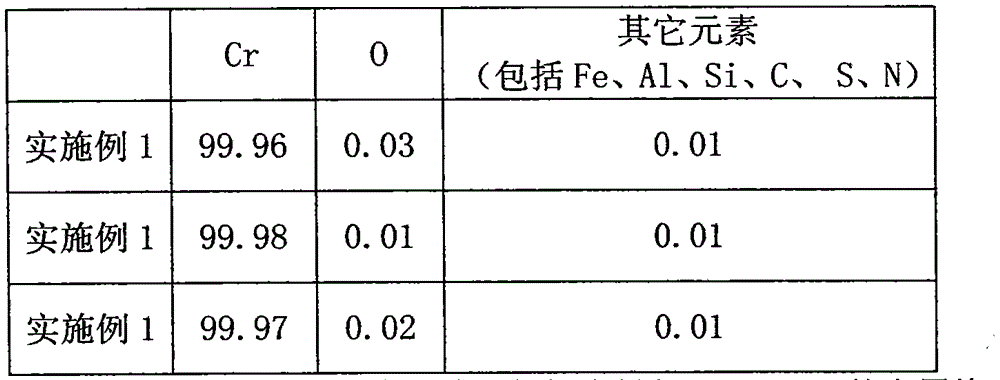

Method for selectively separating vanadium and chromium from vanadium and chromium-containing solution

ActiveCN111304466AEfficient and selective separationOvercome efficiencyProcess efficiency improvementVanadium atomChromium product

The invention discloses a method for selectively separating vanadium and chromium from a vanadium and chromium-containing solution. The method comprises the following steps of adding a pH regulator into the vanadium and chromium-containing solution to convert vanadium in the solution into polyvanadate and chromium into dichromate, then adding a selective floating extraction agent into the solutionto promote the floating extraction agent and polyvanadate to form a molecular associate, adding an associate stabilizer and a bubble dispersant, introducing air to enable bubbles to be hydrophobically mineralized to form polyvanadate-floating extraction agent-bubble micro-droplets, and finally deeply enriching and separating polyvanadate components through floating extraction; and adding a reducing agent into the chromium-rich flotation raffinate to reduce Cr<6+> into Cr<3+>, finally regulating the pH value of the solution to separate out chromium in the form of Cr(OH)3 precipitation, and drying and calcining the vanadium-rich and chromium-rich components to obtain the high-purity vanadium-chromium product. The method is good in selective separation effect on vanadium and chromium, simplein technological process, low in operation cost and particularly suitable for deep separation of vanadium and chromium.

Owner:ZHENGZHOU UNIV

Multilayer ultra corrosion resistant nickel-chromium plating part and manufacturing method thereof

ActiveCN104775143AProcess stabilityCompatibility is reasonableMetal layered productsCopperChrome plating

The invention discloses a multilayer ultra corrosion resistant nickel-chromium plating part and a manufacturing method thereof. The multilayer ultra corrosion resistant nickel-chromium plating part includes a substrate, a pretreatment coating, a base layer, a functional layer and a decorative layer. The pretreatment coating is deposited on the entire substrate, and a copper plate layer is formed on the pretreatment coating; the base layer is formed on the copper plate layer; the functional layer is formed on the base layer and includes a low potential nickel layer and a microporous nickel layer formed on the low potential nickel layer; and the decorative layer is formed on the microporous nickel layer and is a trivalent chromium coating or a hexavalent chromium coating. Based on the micropores on the part surface and chrome plating technology, the low potential nickel layer is added to improve the corrosion resistance of the product, especially the corrosion resistance of trivalent chromium plating product, so as to promote the large scale popularization and application of the trivalent chromium product, which has better environmental protection performance.

Owner:JIAXING MINHUI AUTOMOTIVE PARTS CO LTD

Application of detoxic chromium dregs as cement admixture

ActiveCN1792958AShorten the setting timeHigh rate of increase in strength valueCement productionPolymer scienceSlag

An application of detoxicated Cr slags in preparing early-strenthening low-alkali cement and its products is disclosed. Said cement is prepared through proportionally mixing said detoxicated Cr slags with clinker and natural bihydrated gypsum. Its advantages are high quality of cement and no secondary pollution.

Owner:SICHUAN YINHE CHEM

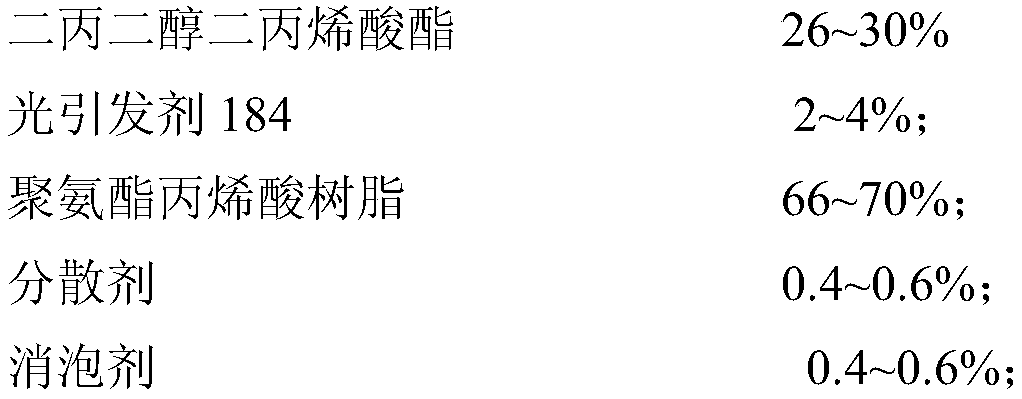

Rapid and accurate determination method of chromium and chromium extracting and manufacturing product process

InactiveCN109988914APhotography auxillary processesProcess efficiency improvementChromium CompoundsImpurity

The invention relates to a rapid and accurate determination method of chromium and a chromium extracting and manufacturing product process. Chromium-containing substances such as metal chromium, chromium alloy, chromite and chromium compounds are dissolved by adding acid, impurities in the chromium solution are removed by adding special substances to prepare a high-purity chromium solution, and then the chromium solution is subjected to chemical method and instrument analysis to quickly determine the content of chromium and extract chromium to prepare chromium products. According to the rapidand accurate determination method, metal chromium ions are firstly purified, the influence of other metal ions on chromium is fully eliminated to enable the determination of chromium to be very fast and accurate, and the extracted chromium has high purity, so that the high-quality chromium series high-end products are prepared, and the rapid and accurate determination method is widely applied to different fields of the requirements of chromium series products.

Owner:唐翔

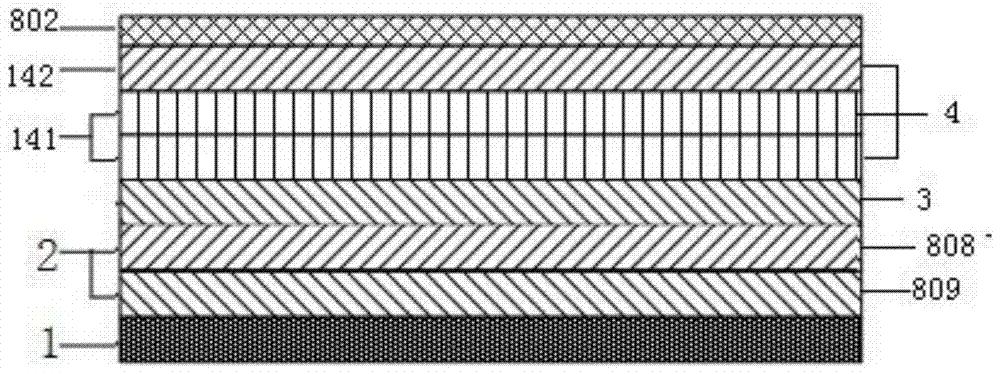

Nickel-chromium plated parts and method of manufacture

ActiveCN104772947BProcess stabilityCompatibility is reasonableMetal layered productsCopperChrome plating

The invention discloses a nickel-chromium plating part and a manufacturing method thereof. The nickel-chromium plating part includes a substrate, a pretreatment coating and a decorative layer. The pretreatment coating is deposited on the entire substrate, and a copper plate layer and a functional layer are formed on the pretreatment coating; the functional layer is formed on the copper plate layer; the functional layer includes a low potential nickel layer and a microporous nickel layer formed on the low potential nickel layer; and the decorative layer is formed on the microporous nickel layer. Based on the micropores on the part surface and chrome plating technology, the low potential nickel layer is added to improve the corrosion resistance of the product, especially the corrosion resistance of trivalent chromium plating product, so as to promote the large scale popularization and application of the trivalent chromium product, which has better environmental protection performance.

Owner:JIAXING MINHUI AUTOMOTIVE PARTS CO LTD

Method for preparing vanadium product and chromium product from double salt containing vanadium and chromium, and application thereof

InactiveCN110668497AAchieve separationRealize the purpose of synchronous recovery and preparationChromates/bichromatesVanadium oxidesAcid dissolutionHydrometallurgy

The invention discloses a method for preparing a vanadium product and a chromium product from a double salt containing vanadium and chromium, and an application thereof. The method comprises the following steps: 1) mixing the double salt containing vanadium and chromium with water, and performing heating for dissolving to obtain a mixed solution containing sodium vanadate, sodium chromate, sodiumsulfate, sodium carbonate and sodium hydroxide; 2) performing a reaction by using a calcifying agent, and converting the sodium vanadate, sodium sulfate and sodium carbonate to form a precipitate; 3)performing separation to obtain a solid phase and a liquid phase; 4) dissolving the obtained solid by using an acid, adding sulfuric acid to make the pH value be 4-5, and performing separation; and 5)preparing the vanadium product from the liquid phase obtained by separation, and preparing the chromium product from the liquid phase obtained by separation. The method is a refining and separating method for vanadium-chromium mixed crystals, is adopted to prepare the qualified vanadium and chromium products, and solves the problem that the composite salt obtained from vanadium and chromium in the hydrometallurgy process cannot be productized.

Owner:HEBEI IRON AND STEEL

Nickel-chromium plated parts and method of manufacture

ActiveCN104772946BProcess stabilityCompatibility is reasonableMetal layered productsCopper platingPre treatment

The invention discloses a nickel-chrome-plated part and a method for manufacturing the same, wherein the nickel-chrome-plated part comprises a base material; a pre-treatment coating deposited on the entire base material, and a copper-plated layer is formed on the pre-treatment coating; and a base layer , which is formed on the copper plating layer; and a functional layer, which is formed on the base layer, wherein the functional layer includes a low potential nickel layer and a microporous nickel layer formed on the low potential nickel layer; and a decorative layer, which is formed on the micro On the hole nickel layer, the decorative layer is any one of trivalent chromium plating or hexavalent chromium plating. The present invention increases the low-potential nickel coating on the basis of the micropores and chrome-plating process on the surface of the component, thereby improving the corrosion resistance of the product, especially the corrosion resistance of trivalent chromium-plated products, which can promote more environmentally friendly trivalent chromium Larger-scale promotion and application of products.

Owner:JIAXING MINHUI AUTOMOTIVE PARTS CO LTD

Magnesium alloy no-chromium passivant and use method

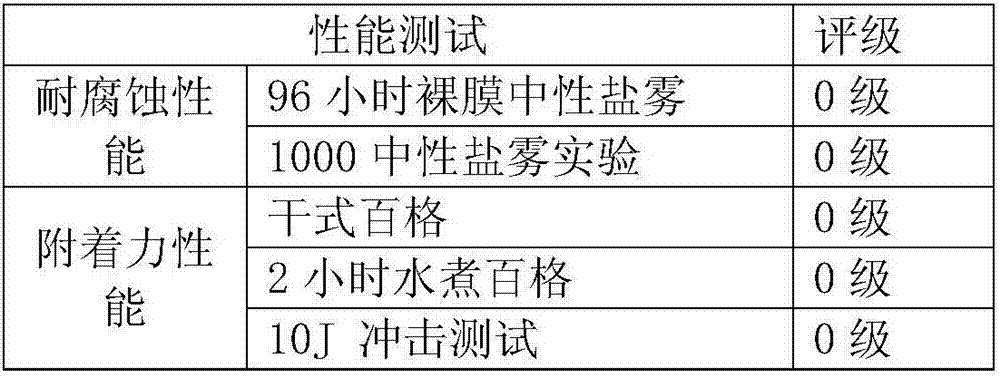

ActiveCN107201514ASolve pollutionExcellent anti-corrosion performance of bare filmMetallic material coating processesZirconateVanadate

The invention discloses a magnesium alloy no-chromium passivant and a use method. The passivant comprises a compound and derivative of titanium, a compound and derivative of zirconium, nano particles, thiocarbamide and a silane coupling agent. The compound and derivative of titanium is on or combination of diethanolamine titanate diisopropyl ester and triethanolamine titanate diisopropyl ester, and compound and derivative of zirconium is one or combination of hexafluorozirconic acid, fluotitanic acid and triethanolamine zirconium zirconate, and the silane coupling agent is one or combination of a titanate coupling agent, a zirconic acid coupling agent, a molybdate coupling agent and a vanadate coupling agent. According to the magnesium alloy no-chromium passivant and the use method, the problem that traditional chromium washing causes a large amount of wastewater pollution, and meanwhile the problem that the anti-corrosion protection performance of the no-chromium product to metal and the attaching force performance of a coating cannot achieve the chromizing product effect is solved.

Owner:安徽光铧帝业化学有限公司

Method for co-extraction-selective reverse extraction separation of vanadium and chromium from solution containing vanadium and chromium

ActiveCN113201657AAchieve separationSimple processProcess efficiency improvementPhysical chemistryVanadium atom

The invention discloses a method for co-extraction-selective reverse extraction separation of vanadium and chromium from a solution containing vanadium and chromium. The method comprises the following steps that co-extraction of vanadium and chromium is performed by the aid of an ammonium salt extraction agent, then selective reverse-extraction of vanadium is performed by the aid of an alkaline solution according to the difference of the binding capacity of vanadium and chromium with the extraction agent under specific conditions, and finally, reverse-extraction of chromium is performed by the aid of a chlorine salt or solid-phase precipitation method to realize separation of chromium. Different types of chromium products can be obtained according to different requirements; different types of organic phases can also be adopted according to system requirements. The method has the characteristics of good vanadium and chromium separation effect, short flow, simple technology and high vanadium and chromium recovery rate.

Owner:CENT SOUTH UNIV

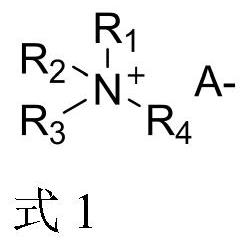

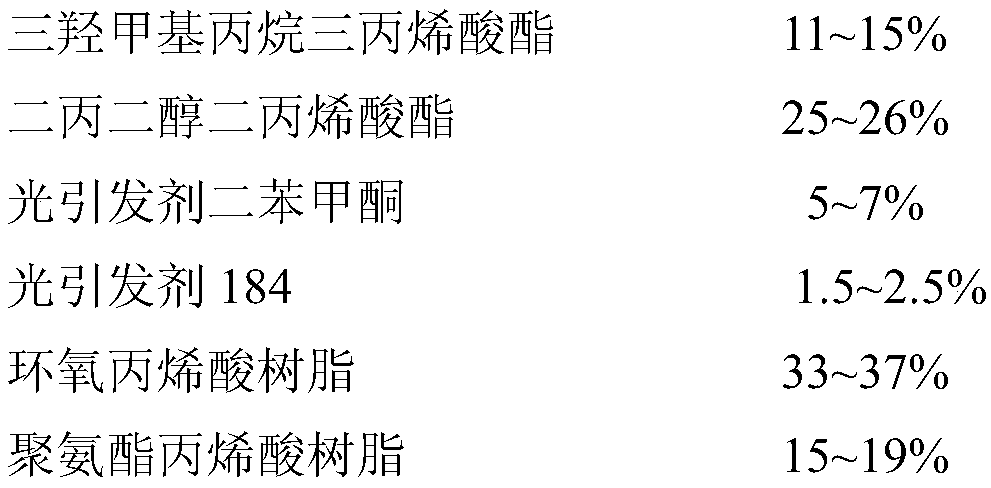

Film forming agent and application of film forming agent in aluminium profile surface treatment chromate-free passivation solution

InactiveCN110629214AGood resistance to salt sprayGood compatibilityElectrophoretic coatingsMetallic material coating processesZirconateWater quality

The invention discloses aluminium profile surface treatment chromate-free passivation solution which comprises the following components in percentage by mass: 0.1-0.5% of sodium polyacrylate, 1.5-3.0%of a film forming agent, 0.1-0.5% of zirconate, 0.1-0.5% of titanate, 1-3% of a nonionic surfactant, 0.01-2.5% of dihydric alcohol and the balance of water. The film forming agent provided by the invention is used in the aluminium profile surface treatment chromate-free passivation solution and has better compatibility with zirconate and titanate; the prepared passivation solution has excellent salt fog resistance, does not nitpick the water quality, does not generate flocculent precipitate and also improves the adhesive force of a spraying paint with a substrate after passivation; and the aluminium profile surface treatment chromate-free passivation solution is stable in formula, longer in storing time, environmentally friendly, safe and non-toxic, simple in waste water treatment, low inusing unit cost, and does not contain chromium.

Owner:常州广树化工科技有限公司

Comprehensive recovery method of vanadate-chromate-containing solution

InactiveCN103602819BEfficient separationSeparation and recycling wondersProcess efficiency improvementRecovery methodSlag

A comprehensive recovery method of a vanadate-chromate-containing solution is characterized by: firstly adding a reducing agent to respectively reduce pentavalent vanadium and hexavalent chromium in the solution into tetravalent vanadium and trivalent chromium under proper pH conditions, then adding an alkali to adjust the pH value and further to precipitate vanadium and chromium in the solution, filtering to obtain vanadium-chromium-containing slag, then adding the vanadium-chromium-containing slag into an alkaline solution to selectively leach out vanadium, and then adding acid into the leaching solution to adjust the pH value and further to precipitate vanadium, so as to realize effective separation and recovery of vanadium and chromium and directly obtain the vanadium product and the chromium product. The comprehensive recovery method has the advantages of being short in process flow, good in separation effect, simple in operation, environment-friendly and the like, the recovery rate of vanadium reaches up to 95% or more and the recovery rate of chromium reaches up to 97% or more, and the comprehensive recovery method is applicable to large-scale industrialization.

Owner:CENT SOUTH UNIV

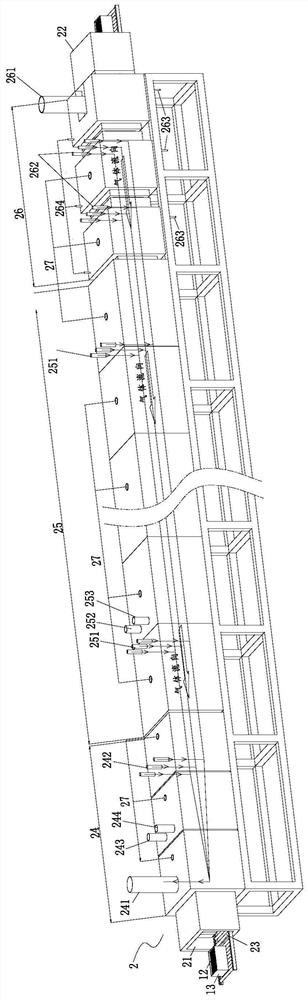

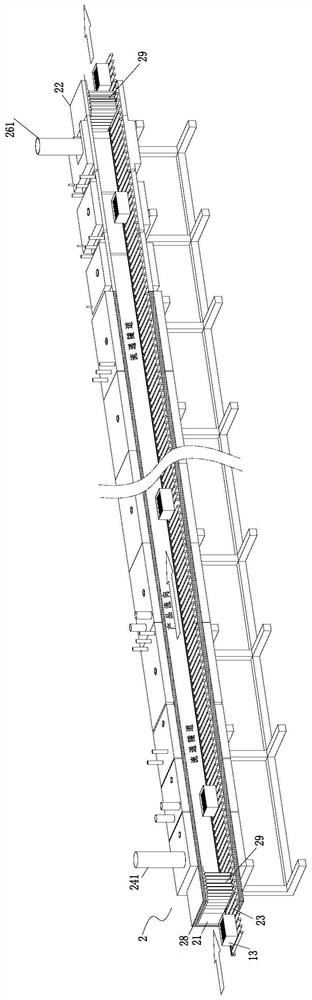

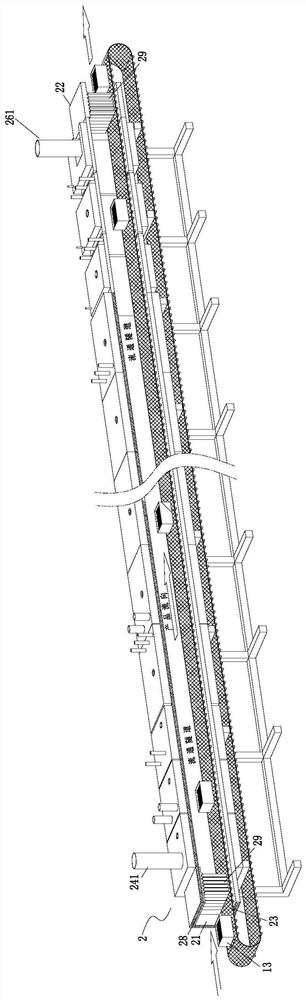

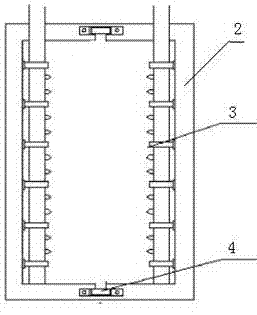

Continuous production method for solid powder chromizing

InactiveCN112011756ARealize continuous productionLow equipment requirementsSolid state diffusion coatingMetallurgyShielding gas

The invention discloses a continuous production method for solid powder chromizing. The continuous production method comprises the following steps that (1) a workpiece is pre-buried in a powdery chromizing agent and contained in a load bearing box; and (2) chromizing treatment: the load bearing box filled with the workpiece and the chromizing agent is conveyed into a high-temperature furnace froma workpiece inlet through a conveying mechanism, the load bearing box sequentially passes through a heating zone, a heat preservation zone and a cooling zone of the high-temperature furnace and then is sent out from a workpiece outlet to complete chromizing treatment, protective gas is introduced into the high-temperature furnace, the flowing direction of the protective gas is opposite to the moving direction of the workpiece, the content of oxygen in the heat preservation zone is lower than 100 PPM, and the dew point is lower than -35 DEG C. According to the continuous production method for solid powder chromizing, the chromizing process is improved for the defects of the existing process, so that continuous production of chromizing can be realized; therefore, compared with the difficultyof the existing sealed processing, the processing difficulty is greatly reduced, the equipment requirement is low, the production efficiency is improved, the high-temperature furnace does not need tobe repeatedly heated and cooled to cause a large amount of loss of heat energy, the environment is protected, energy is saved, the processing cost is about 1 / 5-1 / 8 of that of the sealed processing, and the application range of chromizing products can be greatly expanded.

Owner:佛山市智晓科技服务有限公司

Treatment method for dirt on surface of electroplated chromium product

The invention relates to a treatment method for dirt on the surface of an electroplated chromium product. The treatment method comprises the processes of oil removal, coarsening, recycling, twice reducing, palladium activating, peptizing, chemical nickel plating, copper pre-plating, copper plating, acid activating, semi-bright nickel plating, bright nickel plating, nickel sealing, chromium plating, reducing and drying, wherein the next process is performed by washing after the front process, and in the reducing process and a washing process after the reducing process, liquid level of a reducing slot and liquid level of a washing slot after the reducing process are reduced; after the reducing process, twice spraying washing processes are increased; the drying process is performed after the spraying washing processes, and a hanger hung with an electroplated chromium product is unloaded to the ground through an unloading vehicle; and meanwhile, air curtain machines at the two sides of the unloading vehicle perform gas blowing on the electroplated chromium product. The treatment method has the advantages that: a dirt phenomenon on the surface of the product can be effectively removed, the comprehensive qualification rate of the product is increased, and great cost caused by goods return as the product is dirty is reduced.

Owner:延康汽车零部件如皋有限公司

Method for extracting and recovering chromium from cold-rolled chrome sludge

InactiveCN104944719BRealize harmless treatmentHigh recovery rateSludge treatmentProcess efficiency improvementSludgeAdditional values

The invention discloses a method for extracting and recovering chromium from cold rolling chromium sludge. The method comprises the following steps: 1), soaking cold rolling chromium sludge in concentrated hydrochloric acid 20-37% in weight percentage, stirring for mixing, so as to enable Cr elements in cold rolling chromium sludge to exist in the form of chromium (iii), then leaving to stand and filtering out insoluble solid matters to obtain a solution I; 2), adding Zn powder to the solution I, fully separating out non-active metal deposition, filtering out deposition to obtain a solution II; 3), regulating the pH value of the solution II to be 7-8, introducing CO2, heating to enable Zinc (ii) and Ca (ii) to precipitate in the form of ZnCO3.3Zn(OH)2 and CaCO3, and enable Cr elements in the solution II to exist in the form of CrCl3, leaving to stand to filter out precipitate to obtain the solution III for standby application; 4), regulating the pH value of the solution III to be 8-9, heating to enable CrCl3 in the solution III to be hydrolyzed to form CrOCl precipitate, the formed CrOCl precipitate is the chromium product. According to the method for extracting and recovering chromium from cold rolling chromium sludge, the recovery rate of chromium from the cold rolling chromium sludge can reach 95% or above, the recovery rate of chromium is greatly improved, innocent treatment on cold rolling chromium sludge is fully realized, the energy consumption is reduced, and the chromium recovery additional value is increased.

Owner:武汉钢铁有限公司

A method for surface treatment of plastic parts

ActiveCN105820361BSimple processReduce energy consumptionVacuum evaporation coatingSputtering coatingVacuum evaporationPollution

The invention relates to a surface treatment method of plastic parts. The surface treatment method comprises the following steps: 1) cleaning the surface of a workpiece; 2) spraying a first organic coating; 3) putting the workpiece into an infrared furnace to carry out leveling drying; 4) putting the workpiece into an ultraviolet curing oven to carry out curing by ultraviolet radiation; 5) hanging the workpiece to a PVD (Plating Vacuum Deposition) furnace, carrying out vacuum evaporation and plating aluminum films to obtain a semi-finished product of which the surface is silver and bright; 6) spraying a second organic coating to the semi-finished product; 7) putting the workpiece into the infrared furnace to carry out pre-drying leveling; 8) putting the workpiece into the ultraviolet curing oven to obtain a finished product. According to the invention, the technological process is simple, the energy consumption is low, zero discharge of wastewater is realized in the whole process, and the pollution to the surrounding environment is avoided; furthermore, the raw materials are low in price and easy to purchase, and no obvious differences occur between the appearance and performances of the coating and the appearance and performances of an electroplating chromium product, and the coating has good corrosion resistance, excellent salt fog performances and higher level in comparison with the traditional plating SC4, so as to be especially suitable for harsh environments of bathrooms and the like.

Owner:NINGBO RUNNER INDAL CORP

A kind of method for recovering and preparing metallic chromium

InactiveCN104099478BImprove recovery rateAchieve removalProcess efficiency improvementChromium productMaterials science

A method for recycling and preparing metal chromium comprises the steps of recycling chromium element from discharged waste liquid and discharged waste material, and utilizing the recycled chromium element to prepare metal chromium. The method prevents environmental pollution, realizes application of chromium resources, is simple in technology and low in cost, and can obtain metal chromium products which can meet the use requirement.

Owner:GUANGXI SHENGLONG METALLURGICAL CO LTD

A method for co-extraction-selective stripping separation of vanadium and chromium from vanadium-chromium-containing solution

ActiveCN113201657BAchieve separationSimple processProcess efficiency improvementPhysical chemistryVanadium atom

The invention discloses a method for co-extracting-selective back-extracting and separating vanadium and chromium from a solution containing vanadium and chromium, using an ammonium salt extraction agent to carry out co-extraction of vanadium and chromium, and then utilizing the ability of vanadium and chromium to combine with the extraction agent under specific conditions The difference between vanadium and vanadium is selectively stripped by alkaline solution, and finally chromium is stripped by chloride salt or solid phase precipitation to achieve the separation of chromium. Chromium can obtain different types of chromium products according to different needs; the organic phase can also adopt different types according to system requirements. The invention has the characteristics of good vanadium-chromium separation effect, short process, simple process and high vanadium-chromium recovery rate.

Owner:CENT SOUTH UNIV

Selenium-rich and chromium-rich Saccharomyces cerevisiae, selenium-rich and chromium-rich yeast product and their production process

ActiveCN100451098CLow toxicityFood safetyFungiMicroorganism based processesInorganic seleniumChromium product

The present invention relates to one kind of selenium-rich and chromium-rich Saccharomyces cerevisiae, selenium-rich and chromium-rich Saccharomyces cerevisiae product and their production process. Of the selenium-rich and chromium-rich Saccharomyces cerevisiae product, each kilogram contains selenium in 100-4000 mg and chromium in 100-4000 mg. The selenium-rich and chromium-rich Saccharomyces cerevisiae may be used as selenium and chromium replenisher added into various food products or prepared into alone preparation. The selenium-irch and chromium-rich Saccharomyces cerevisiae product has lower toxicity than inorganic selenium and chromium product and high safety, and may be used in replenishing both selenium and chromium.

Owner:ANGEL NUTRITECH CO LTD

A kind of vanadium chromium solution separation, the method for reclaiming vanadium chromium

ActiveCN105861829BAchieve restorationComplete restorationProcess efficiency improvementVanadium dioxideRecovery method

The invention discloses a method for separating a vanadium and chromium solution and recycling vanadium and chromium. A reducing agent is added to the vanadium and chromium solution under the condition that the pH value ranges from 8 to 14, and the temperature ranges from 20 DEG C to 100 DEG C, and pentavalent vanadium and hexavalent chromium are reduced into tetravalent vanadium and trivalent chromium; the trivalent chromium forms chromic hydroxide precipitate in situ, and a chromic hydroxide filter cake and vanadium-containing filtrate are obtained through filtering; the chromic hydroxide filter cake is used for preparing chromic oxide; and the vanadium-containing filtrate is used for preparing hydration vanadium dioxide or vanadyl sulfate or vanadium pentoxide. By means of the method, efficient separation and recovery of vanadium and chromium are achieved, the vanadium recovery rate reaches 96% or higher, the chromium recovery rate reaches 98% or higher, and the purity of vanadium and chromium products reaches 98% or higher. The method has the beneficial effects that the technological processes are short, the separation efficiency is high, the cost of raw materials and auxiliary materials is low, operation is easy and convenient, and the method can be used for large-scale industrial production.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

Combined sodium salt roasting method for vanadium-containing and chromium-containing raw materials

PendingCN114703362ARealize joint production and joint promotionHigh extraction rateProcess efficiency improvementChromium CompoundsSodium salt

The invention discloses a vanadium-containing and chromium-containing raw material combined sodium salt roasting method which comprises the following steps: mixing two or more vanadium-containing and chromium-containing raw materials, and then adding a sodium salt auxiliary agent for mixing; putting the mixed raw material into a kiln for roasting to obtain roasted clinker; the obtained clinker is smashed and put into water to be soaked after being smashed, or the clinker is directly put into water without being smashed and stirred when the clinker is still hot, a water-soluble vanadium-chromium compound in the clinker is fully dissolved into water and filtered, filtrate obtained through first-time filtering is high-concentration leaching liquid and is used for producing vanadium-chromium products, filter cakes are washed with clear water again, and the vanadium-chromium product is obtained. Residual soluble vanadium and chromium compounds in the filter cake are taken away until the filter cake is cleaned up. The method is simple in process, low in roasting temperature, capable of recycling water and free of hazardous waste, the vanadium resource extraction rate can reach 95% or above, the chromium extraction rate can reach 85% or above when a high-chromium raw material is used, the chromium extraction recovery rate can reach 75% or above when a low-chromium raw material is used, and the method is suitable for efficient recovery of resources of different vanadium-containing and chromium-containing materials.

Owner:SICHUAN YINHE CHEM +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com