Continuous production method for solid powder chromizing

A technology of solid powder and production method, applied in solid diffusion coating, metal material coating process, coating and other directions, can solve the problems of limited chromizing treatment, high equipment requirements, long time, etc., to reduce processing difficulty and expand Scope of application, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (2) Embedded workpiece: such as Figure 4 As shown, the workpiece 11 is directly pre-embedded in the powdery chromizing agent 12 and contained in the setter 13, and the powdery chromizing agent 12 covers and wraps the surface of each workpiece 11 as uniformly as possible. At the same time, the workpiece 11 in this embodiment is a hollow product, so the inside of the workpiece 11 is also filled with powdery chromizing agent 12 at the same time.

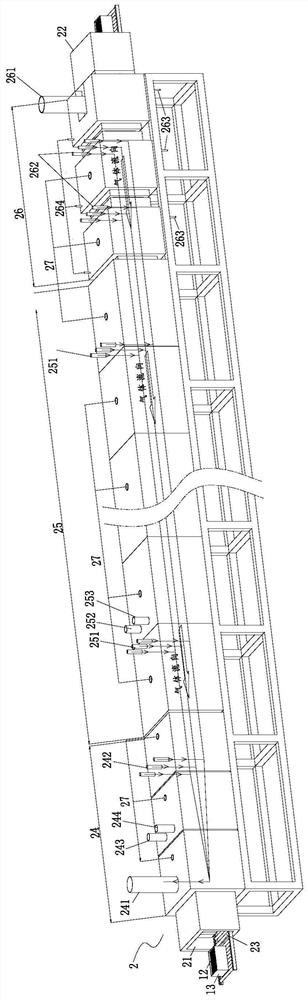

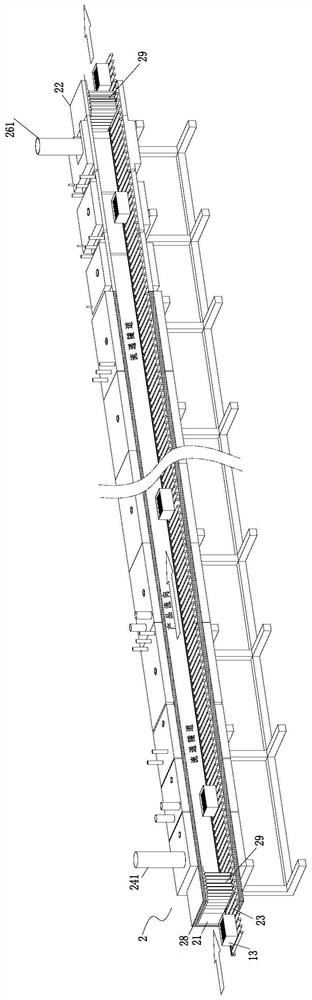

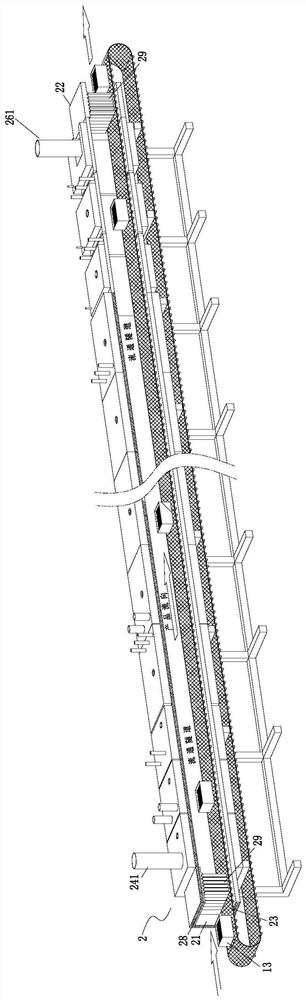

[0037] (2) Chromizing treatment: such as Figure 1-Figure 2 As shown, adopt a high-temperature furnace 2 that one end has a workpiece inlet 21 and the other end has a workpiece outlet 22, and the setter 13 with a workpiece 11 and a chromizing agent 12 is sent into the high-temperature furnace 2 from the workpiece inlet 21 by a conveying mechanism 23. After successively passing through the heating zone 24, heat preservation zone 25 and cooling zone 26 of the high temperature furnace 2, it is sent out from the workpiece outlet 22...

Embodiment 2

[0046] In this embodiment, the conveying mechanism 23 is a conveying crawler belt.

[0047] The temperature curve of present embodiment chromizing treatment is as follows Figure 5 As shown: the area from the temperature at the workpiece entrance 21 to the heat preservation zone temperature of 980°C is the temperature rise zone 24, and the time for the setter 13 to pass through the heat rise zone 24 is 90 minutes; the temperature of the heat preservation zone 25 is within the range of 980°C, and the setter box passes through the temperature rise zone 24 for 90 minutes; 13 crossing time is 16 hours; From the temperature of heat preservation zone 25 to the zone below 300 ℃ is cooling zone 26, and setter 13 passes through cooling zone 26 time and is 4 hours.

[0048] The powdery chromizing agent includes 40% by weight of chromium powder. The chromium powder is 250 mesh, selected from CrCl 2 powder. The powdered chromizing agent also includes 60% alumina as an inert filler.

...

Embodiment 3

[0051] The powdery chromizing agent includes 55% by weight of chromium powder. The chromium powder is 250 mesh, selected from Cr-Fe powder. The powdered chromizing agent also includes 44% inert filler magnesium oxide, 1% rare earth metal oxide CeO 2 . Others are the same as embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com