Patents

Literature

39results about How to "Efficient and selective separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

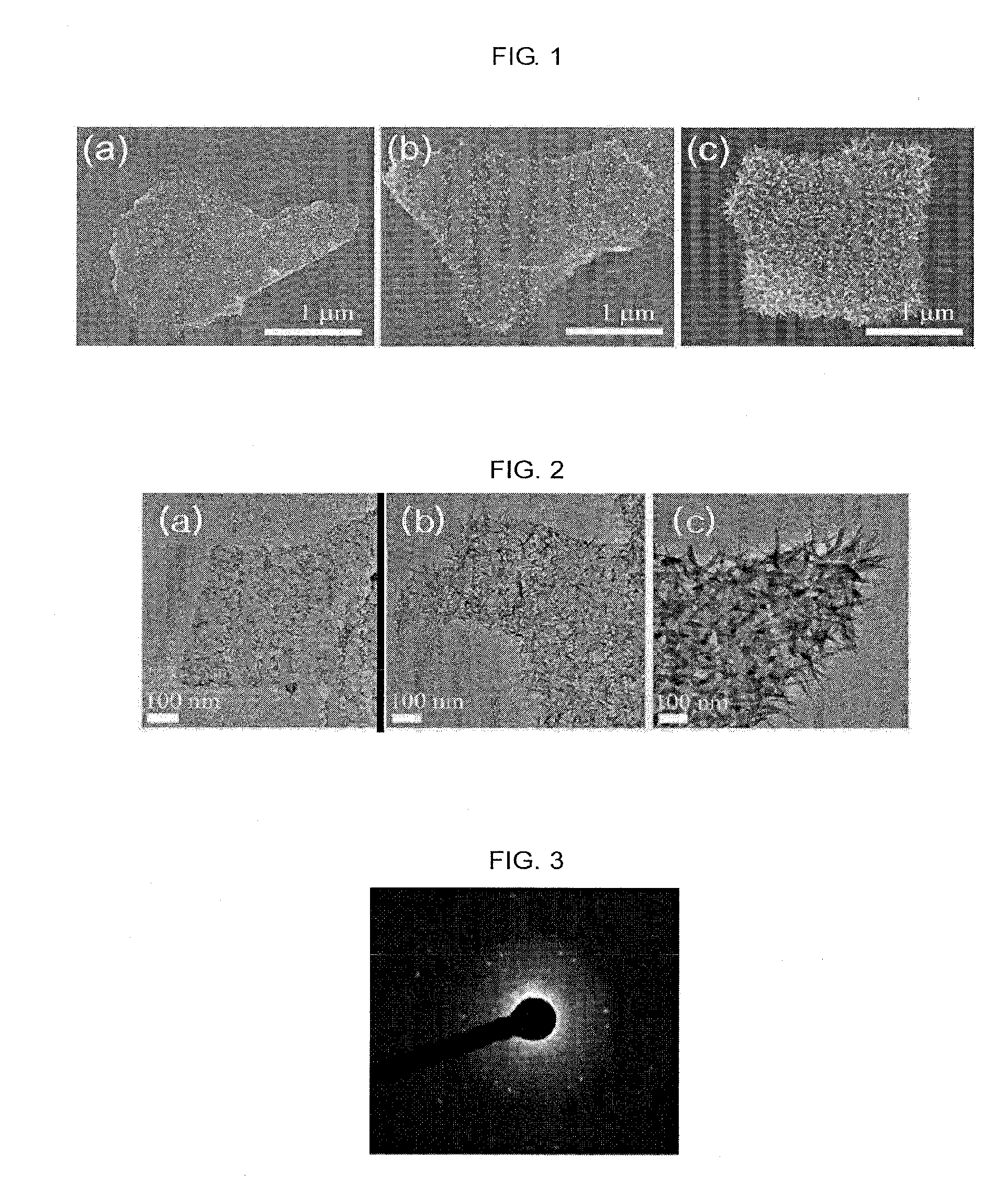

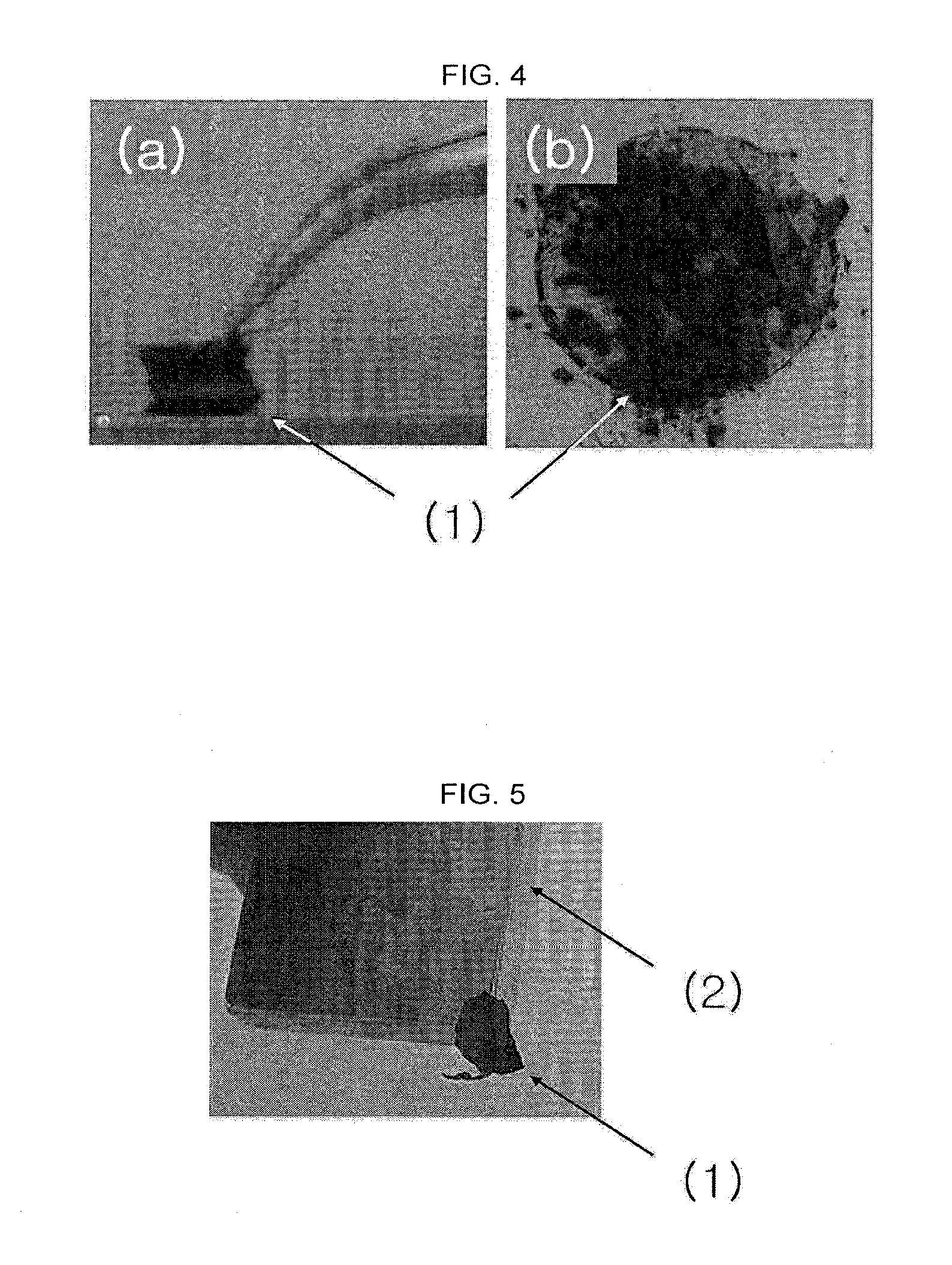

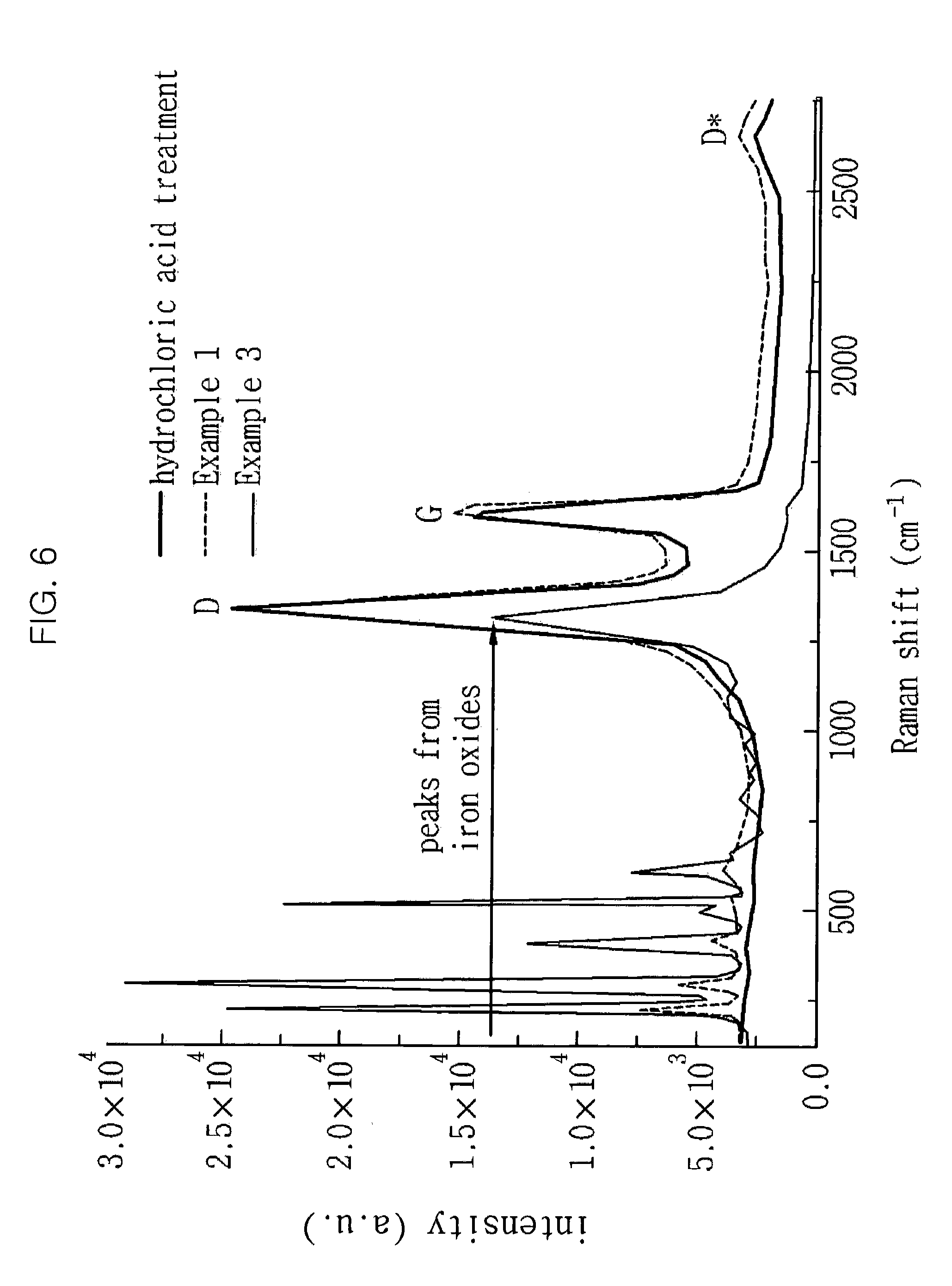

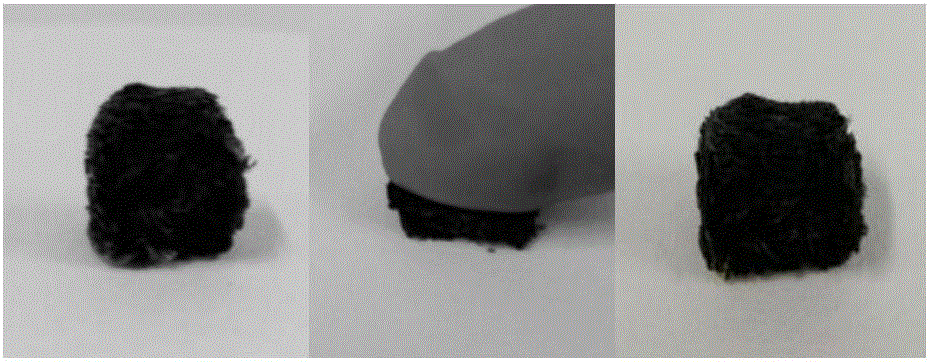

Graphene-iron oxide complex and fabrication method thereof

InactiveUS20120168383A1Efficient and selective separationImprove adsorption capacityMaterial nanotechnologyGraphiteIron nanoparticleCvd graphene

A graphene-iron oxide complex consists of graphene and needle-like iron oxide nanoparticles grown on a surface of the graphene, and a fabricating method thereof includes (A) preparing a reduced graphene dispersed solution, (B) mixing the dispersed solution with a solution containing iron oxide precursors to prepare a mixture, (C) stirring the mixture to prepare a graphene-iron oxide dispersed solution containing the graphene-iron oxide complex that needle-like iron oxide nanoparticles are grown on the surface of the graphene, and (D) separating the graphene-iron oxide complex from the graphene-iron oxide complex dispersed solution.

Owner:KOREA BASIC SCI INST

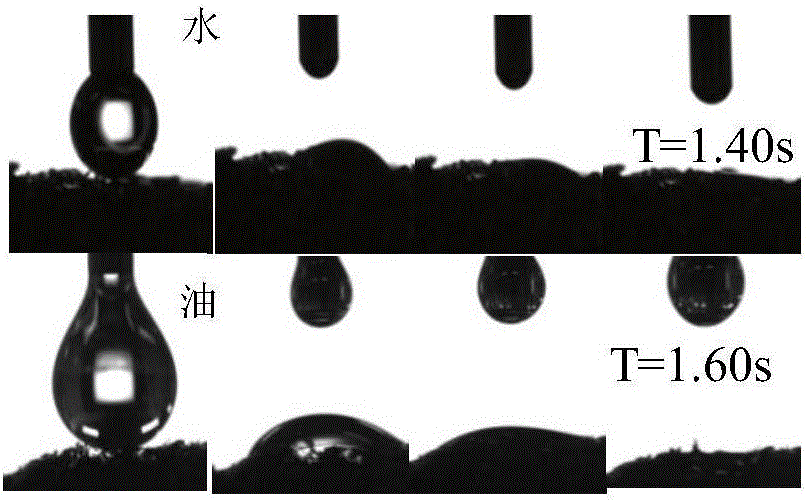

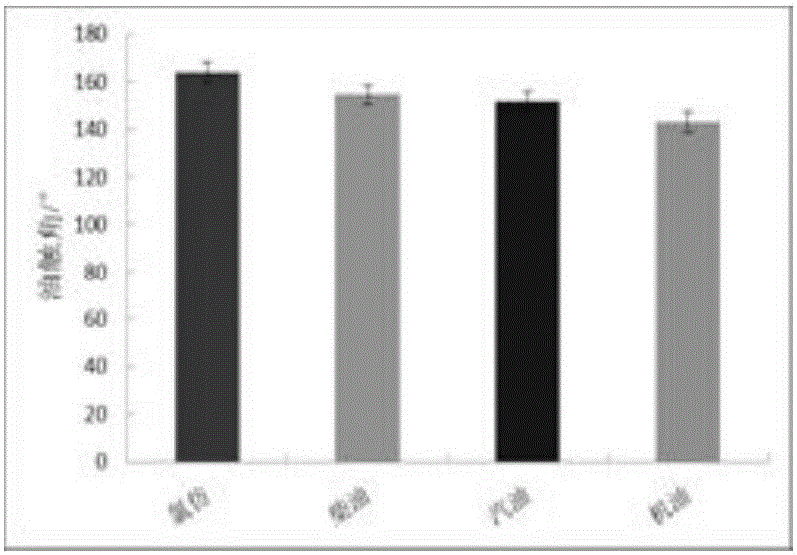

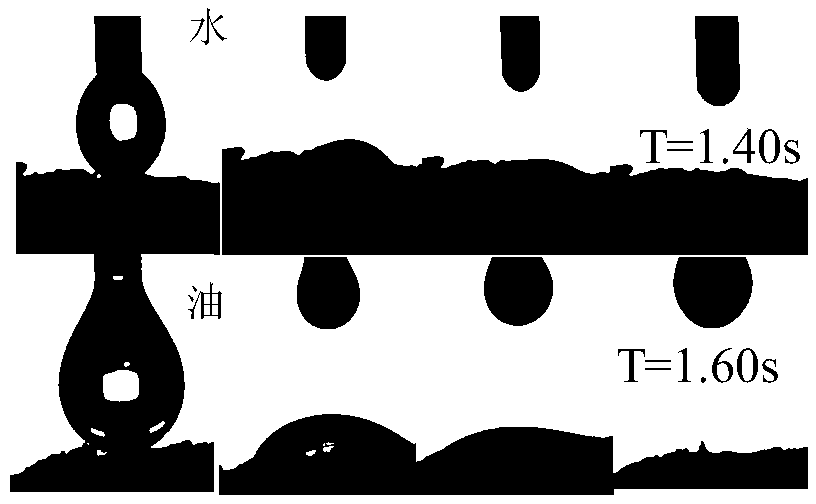

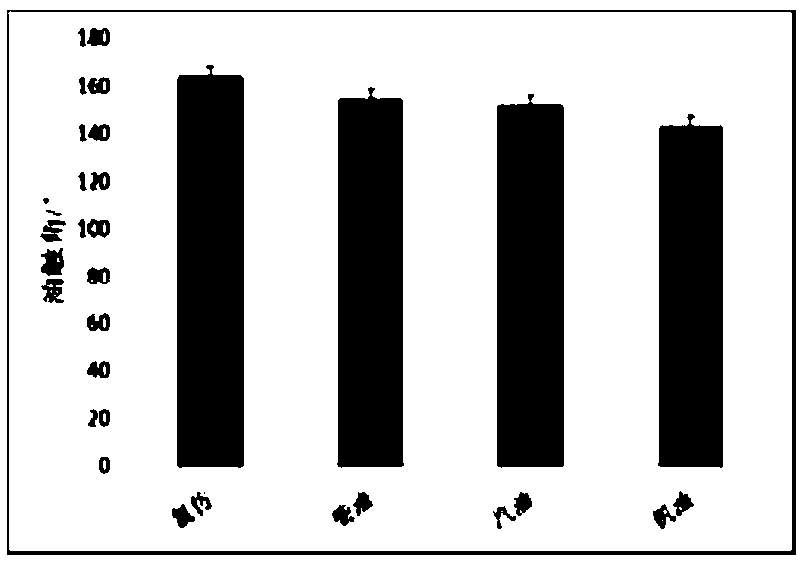

Preparation method of graphene composite foam for oil-water separation

ActiveCN106732422AAchieve separationWith underwater super oleophobic propertiesIon-exchange process apparatusFatty/oily/floating substances removal devicesFreeze-dryingAnti bacteria

The invention relates to the field of polymer materials, in particular to a preparation method of graphene composite foam for oil-water separation. The preparation method comprises the steps that reduction and crosslinking are conducted on oxidized graphene by dopamine, a hydrothermal method is used to make the oxidized graphene form a three-dimensional structure in self-assembly mode, chitosan / graphene composite foam is prepared by soaking and freeze-drying with a chitosan solution, and finally the chitosan / graphene composite foam is fluoridized to prepare the fluoridized graphene composite foam. The obtained chitosan / graphene composite foam has super amphipathicity in the air and underwater super lipophobicity, after the fluoridation, the chitosan / graphene composite foam has super hydrophobicity, and chitosan and raphene have the advantages of good flexibility, high selective separation efficiency and long cycle service life; the foam can exist stably in a corrosive medium; water takes use of gravity to go through the chitosan / graphene composite foam and does not need to be driven by external force; non-toxic biological materials such as the dopamine and the chitosan are used, the foam is green and environmentally friendly, an anti-bacteria effect of the chitosan serves as a function of purifying a water body during the oil-water separation.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

A kind of preparation method of low-density lipoprotein affinity adsorption hemodialysis membrane material

ActiveCN102258946ADoes not affect the performance of the bodyPerformance is not affectedSemi-permeable membranesOther chemical processesVery low-density lipoproteinEnvironmental resistance

The invention belongs to the fields of membrane surface engineering and bioseparation engineering and aims at providing a method for preparing a low-density lipoprotein affinity adsorption hemodialysis membrane material. The method provided by the invention comprises the following steps: prewashing the hemodialysis membrane material; placing the prewashed hemodialysis membrane material into a plasma processor cavity; introducing inert gas and activated gas until atmosphere ingredients are constant and then carrying out plasma processing; immersing into a heparin solution; adding a coupling agent to carry out an oscillation reaction; carrying out oscillation washing by utilizing a PBS (Phosphate Buffer Solution); and repeatedly washing with clean water and perform filter drying to obtain the low-density lipoprotein affinity adsorption hemodialysis membrane material. In the method provided by the invention, active reaction groups are introduced into by utilizing a constant-pressure and low-temperature plasma activation modification processing method; the reaction is only carried out on the surface of the material, the body performance of the material is not influenced, and simultaneously the method has the characteristics of high efficiency, low cost, low energy consumption, environmental friendliness and the like; the hydrophilia and blood compatibility of the surface of a macromolecule separation membrane material can be greatly improved; and the blockage effect caused by membrane pollution in the hemodialysis course can be effectively reduced.

Owner:江苏巨之澜科技有限公司

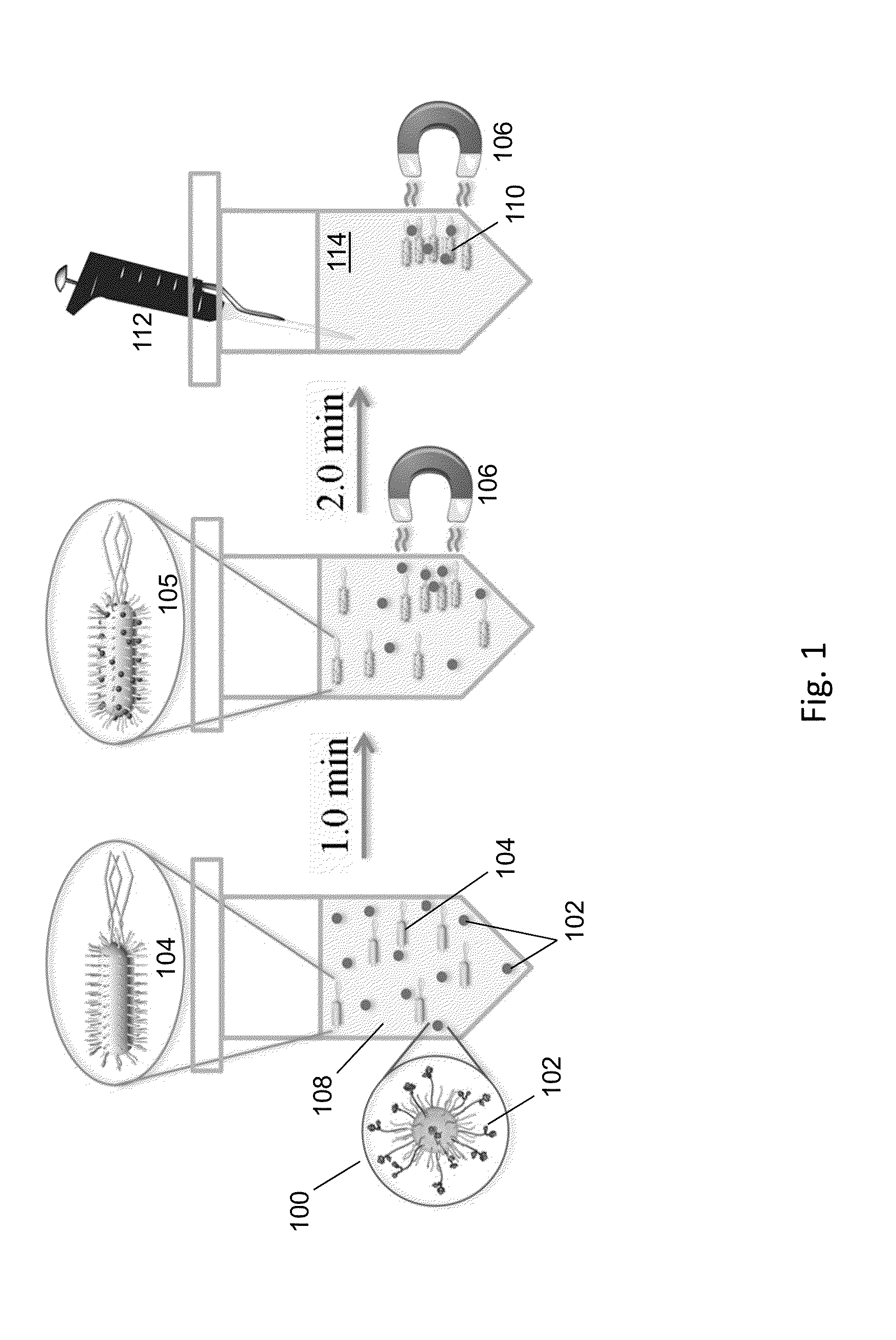

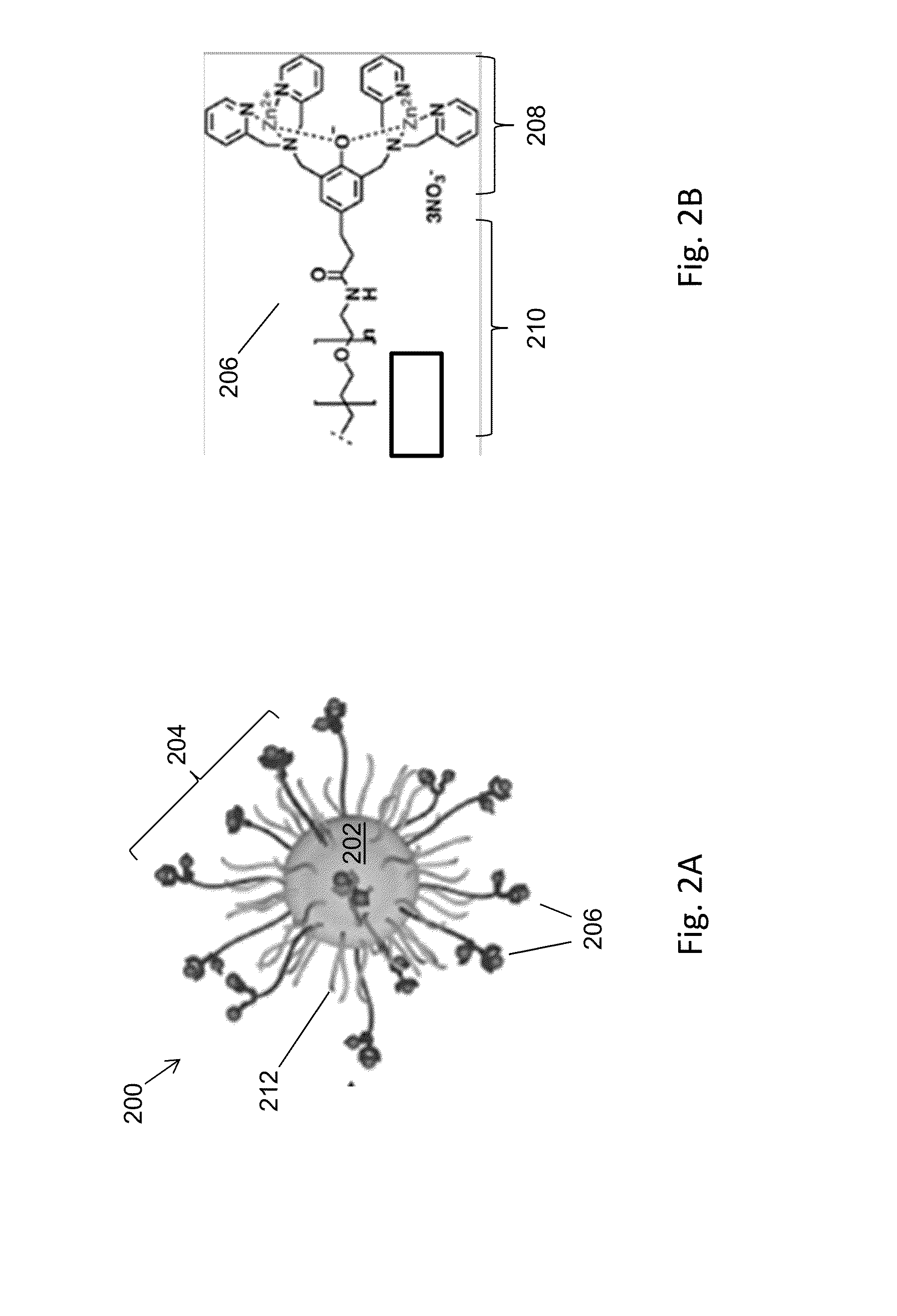

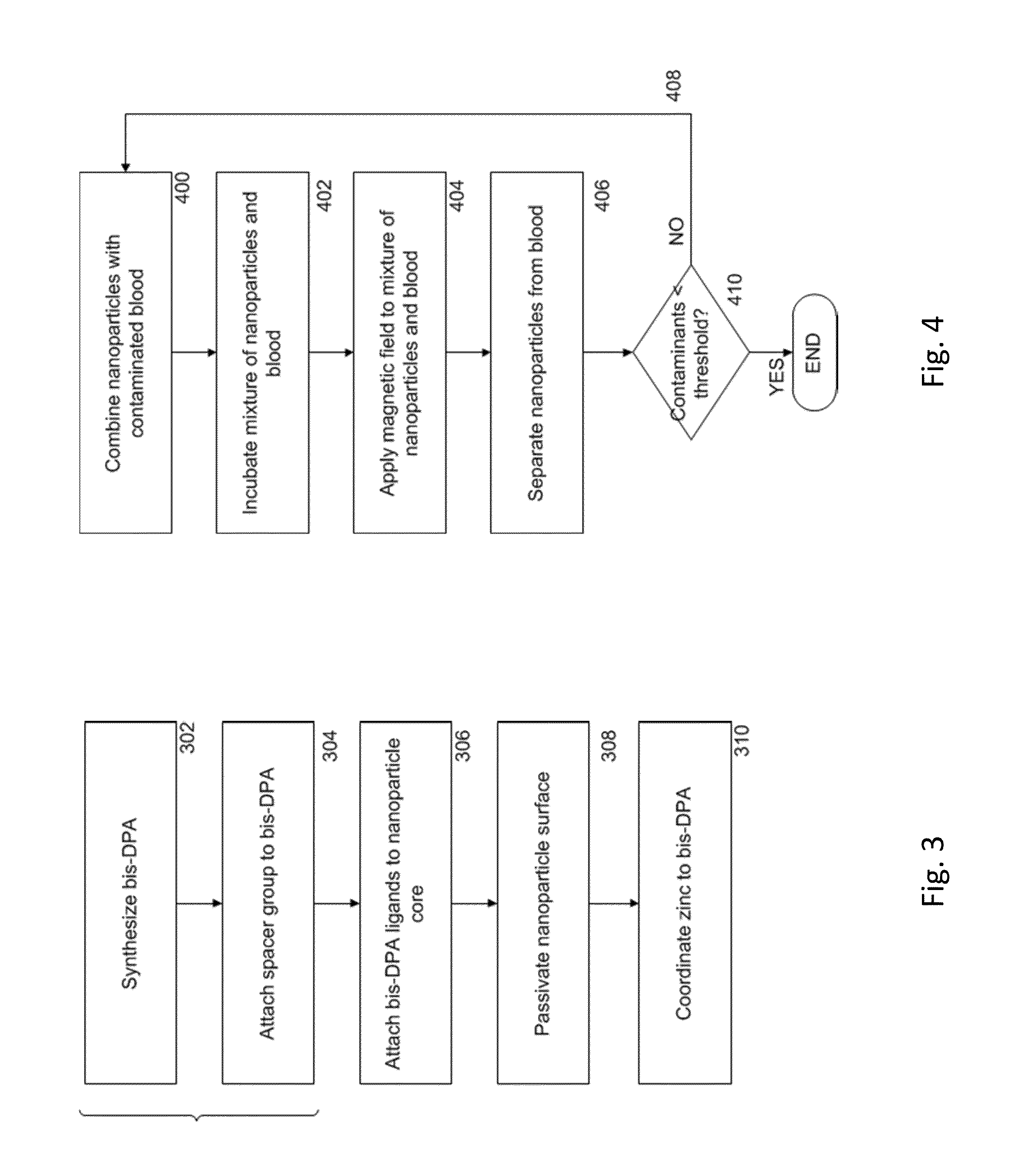

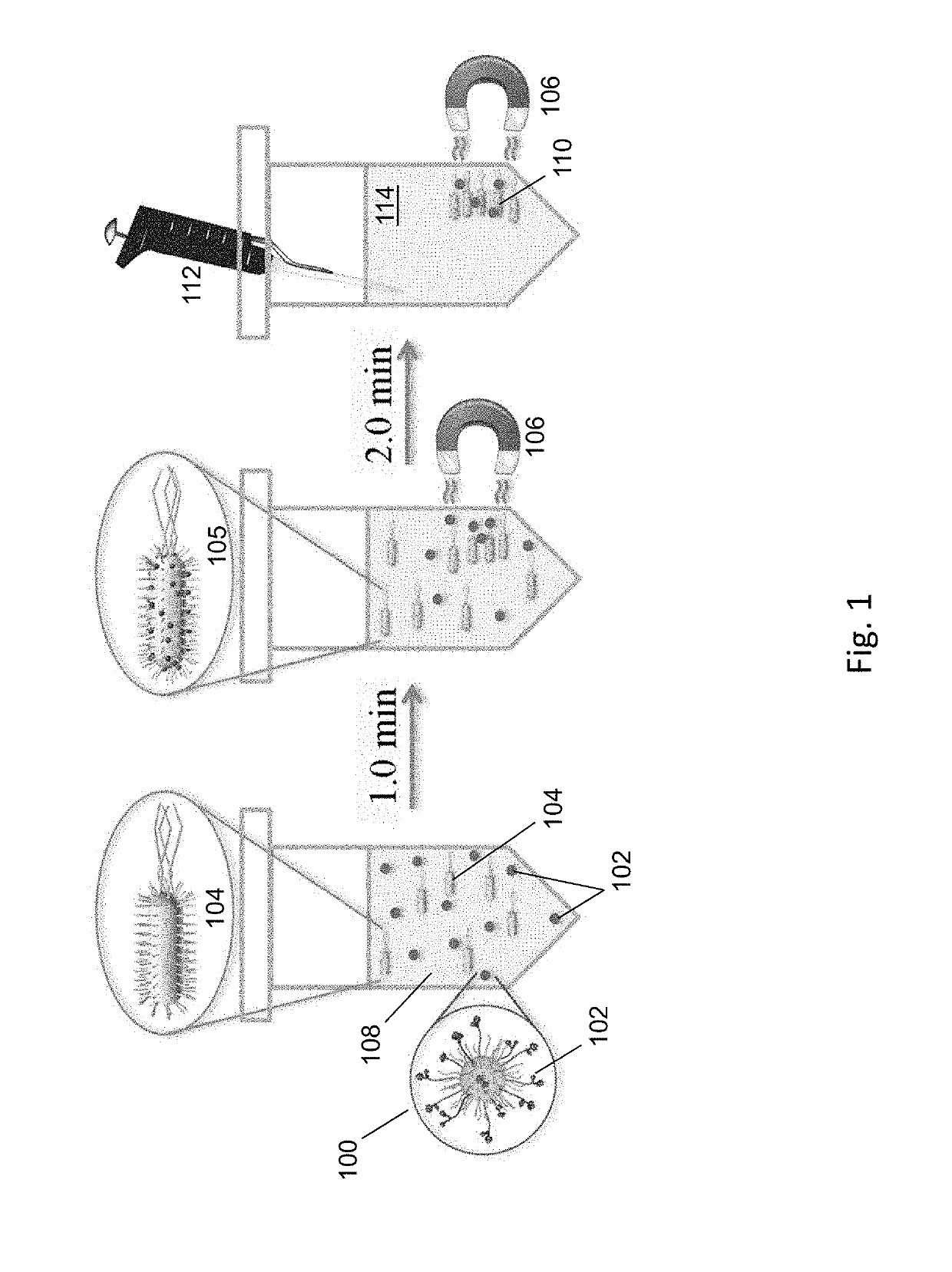

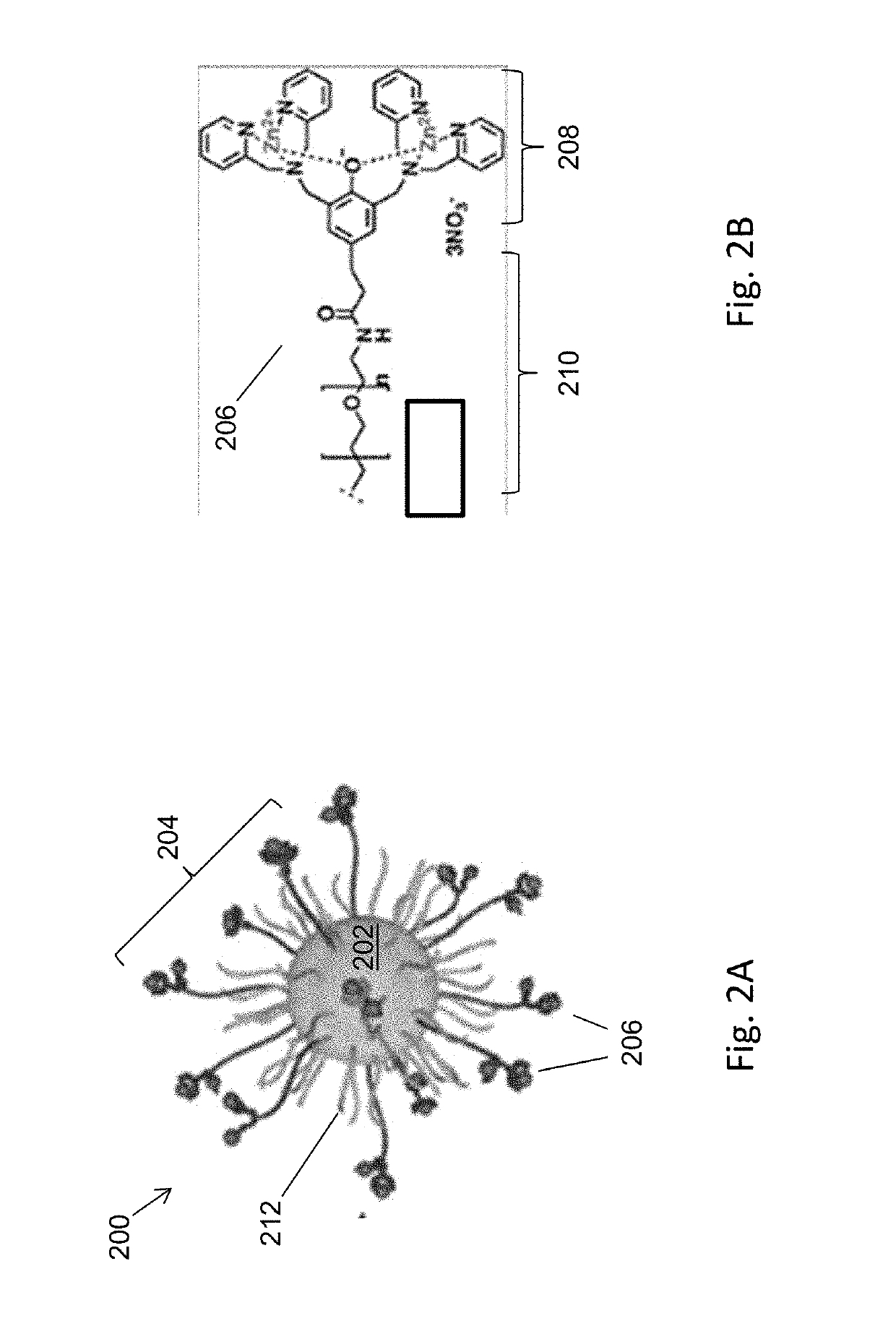

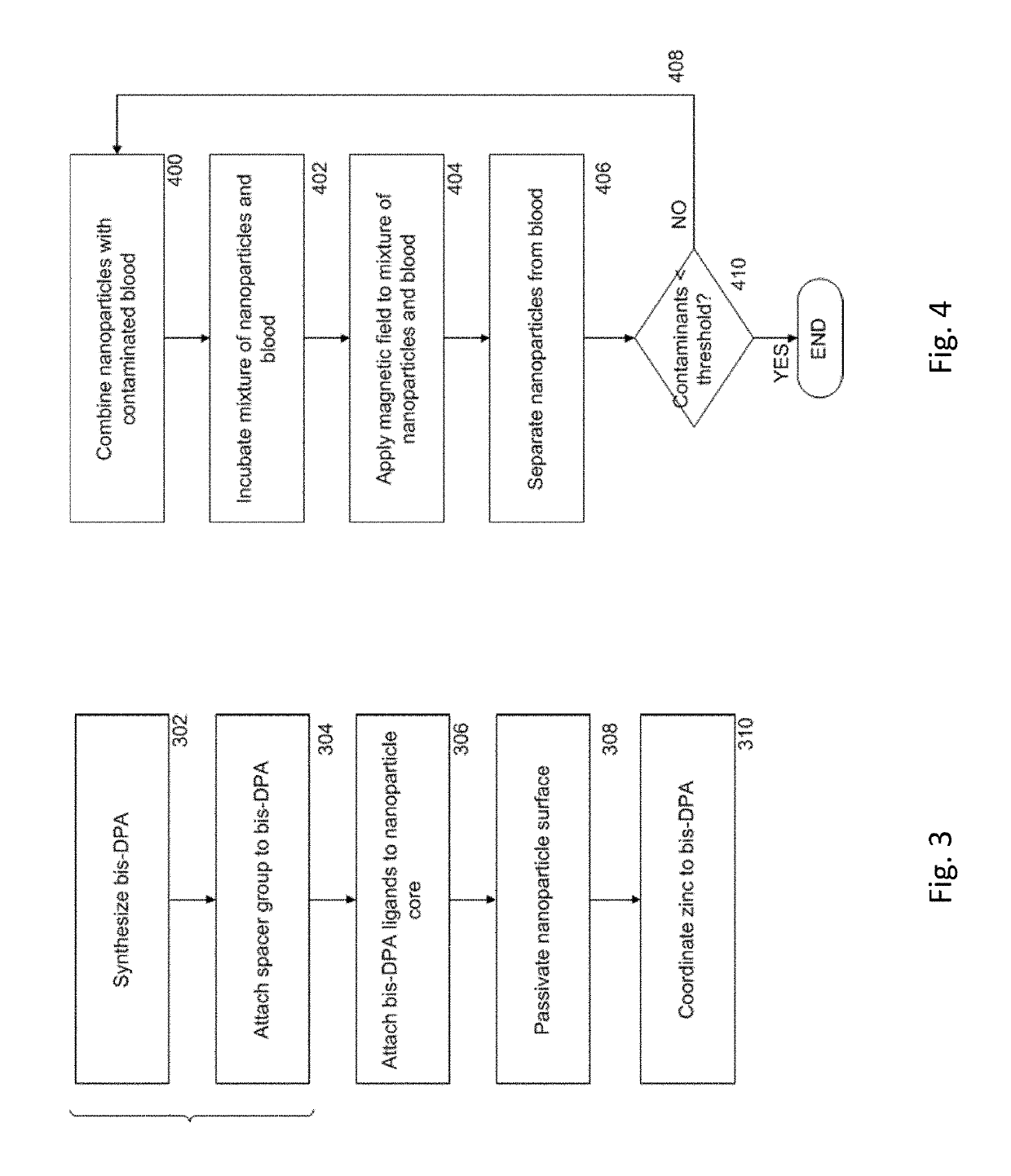

Magnetic separation using nanoparticles

ActiveUS20140212335A1Efficient and selective separationFast bindingGaseous chemical processesLiquid-gas reaction of thin-film typeNanoparticleAlbumin solution

Nanoparticles as described herein are configured to bind to bacterial contaminants, such as Gram positive bacteria, Gram negative bacteria, and endotoxins. The nanoparticles include a core comprising a magnetic material; and a plurality of ligands attached to the core. The ligands include, for example, bis(dipicolylamine) (“DPA”) coordinated with a metal ion, e.g., Zn2+ or Cu2+, to form, e.g., bis-Zn-DPA or bis-Cu-DPA, which can bind to the bacterial contaminants. The nanoparticles can be included in compositions for use in methods and systems to separate bacterial contaminants from liquids, such as liquids, such as blood, e.g., whole or diluted blood, buffer solutions, albumin solutions, beverages for human and / or animal consumption, e.g., drinking water, liquid medications for humans and / or animals, or other liquids.

Owner:MASSACHUSETTS INST OF TECH +1

Method for separating polysaccharide and protein by using choline ionic liquid two-phase aqueous system

ActiveCN104861082ASelective separation greenEfficient and selective separationPeptide preparation methodsSporocarp (fungi)Freeze-drying

The invention relates to a method for separating polysaccharide and protein by using a choline ionic liquid two-phase aqueous system, belongs to the technical field of bioactive substance separation and purification, and particularly relates to application of the ionic liquid two-phase aqueous system composed of choline chloride [Ch]Cl and inorganic phosphate K3PO4 in selective separation of fungal polysaccharide and protein. The method is mainly characterized by comprising the following steps: after degreasing crushed fungi mycelium or sporocarp with petroleum ether, using hot water with the temperature of 95 DEG C for reflux extraction for 8 hours, centrifuging, concentrating, dialyzing, and freeze-drying, so as to obtain a fungus aqueous extract; carrying out extraction separation by using the ionic liquid two-phase aqueous system composed of choline chloride[Ch]C1 and inorganic phosphate K3P04; carrying out lower-layer inorganic salt phase dialysis, ethanol precipitation and freeze-drying so as to obtain fungal polysaccharide; carrying out extraction on an upper-layer ionic liquid phase by using dichloromethane, concentrating and recycling an ionic liquid. The ionic liquid two-phase aqueous system provided by the invention is suitable for industrial production of active polysaccharides, has the effects of being green, quick and efficient, the ionic liquid can be recycled for use, the production cost is lowered, and the ionic liquid two-phase aqueous system can be commonly used for the selective separation of various fungal polysaccharide and protein.

Owner:东台海滨科技创业园管理有限公司

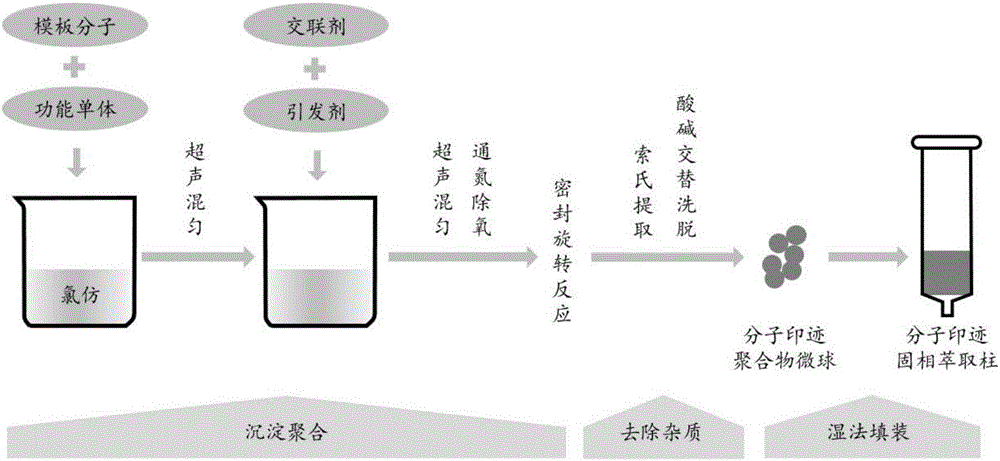

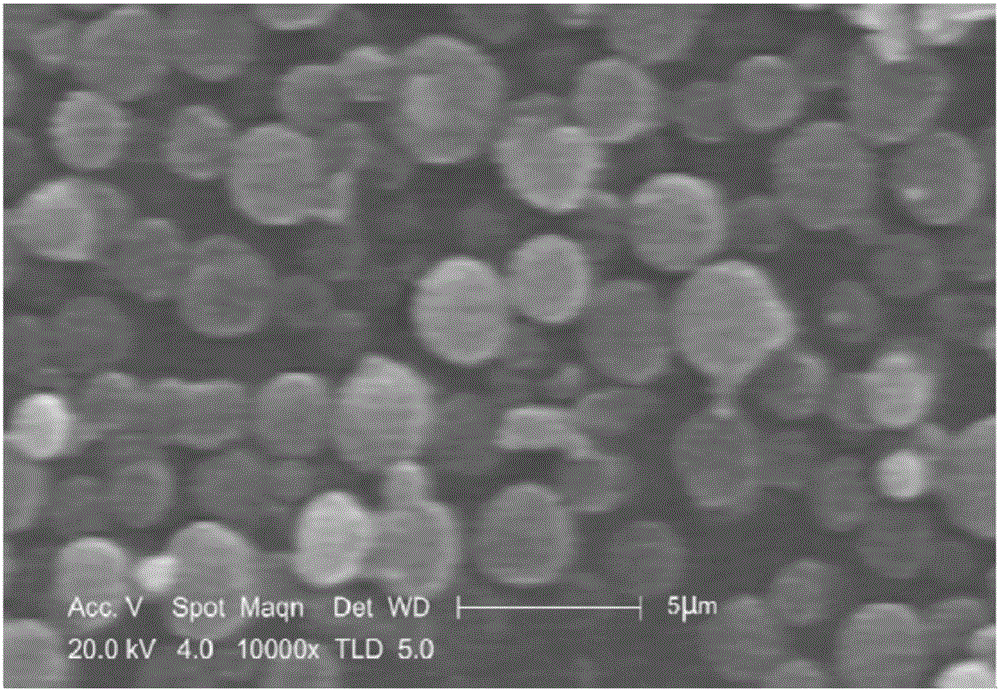

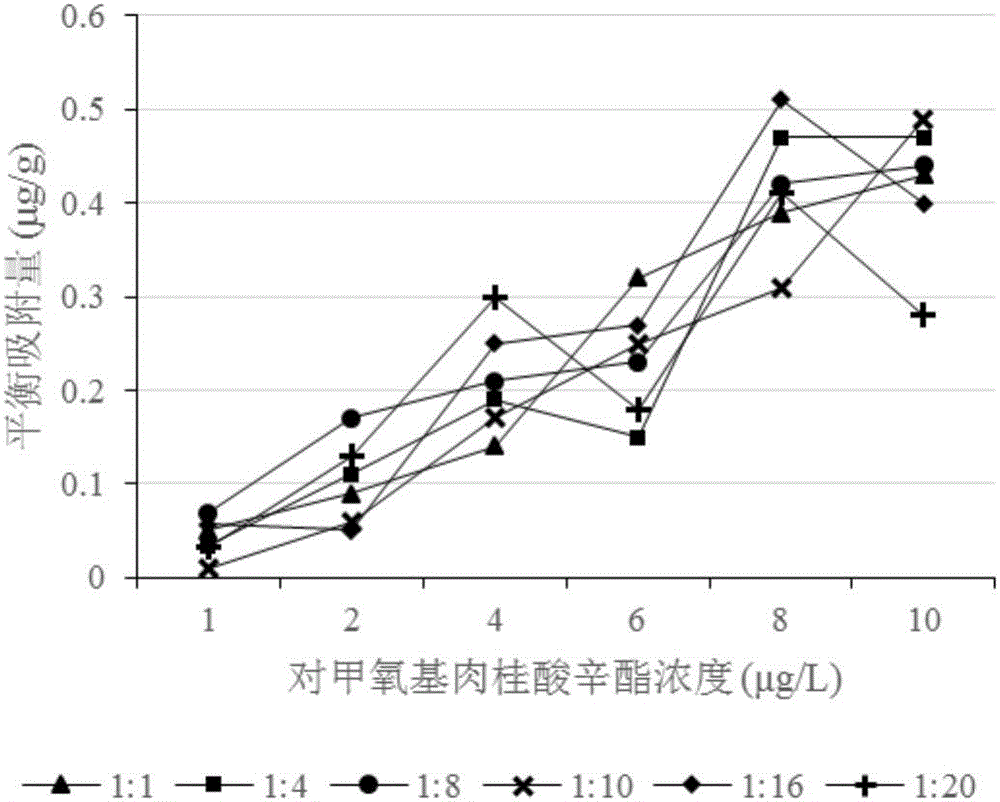

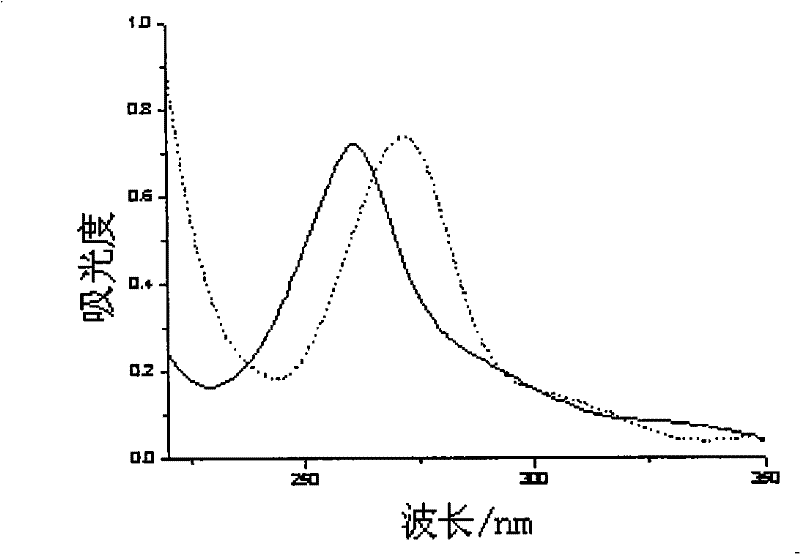

Cinnamate type ultraviolet sun-screening agent molecular engram solid-phase extraction column as well as preparation and application thereof

InactiveCN106582066AWith molecular recognition functionPredeterminedOther chemical processesComponent separationFunctional monomerMicrosphere

The invention relates to a cinnamate type ultraviolet sun-screening agent molecular engram solid-phase extraction column as well as preparation and application thereof, and belongs to the technical field of solid-phase extraction of detection analysis. According to the invention, iso-octyl p-methoxycinnamate is adopted as a template molecule, methacrylic acid is adopted as a functional monomer, ethylene glycol dimethyl acrylic ester is adopted as a crosslinking agent, azodiisobutyronitrile is adopted as an initiating agent, cinnamate type ultraviolet sun-screening agent molecular engram polymer microspheres are obtained by virtue of a precipitation polymerization method, and the obtained polymer microspheres are filled into a solid-phase extraction column through a wet method. The molecular engram polymer solid-phase extraction column provided by the invention can selectively adsorb a cinnamate type ultraviolet sun-screening agent, and compared with a conventional solid-phase extraction column, the molecular engram polymer solid-phase extraction column overcomes the defect of poor selectivity of a conventional solid-phase extraction filler, is strong in adsorptivity, high in extraction recovery rate, and achieves efficient selective separation, enrichment and purification of a trace amount of the cinnamate type ultraviolet sun-screening agent in various environments and biological samples.

Owner:SHANGHAI JIAO TONG UNIV

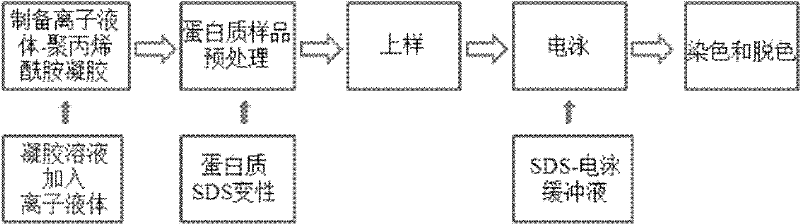

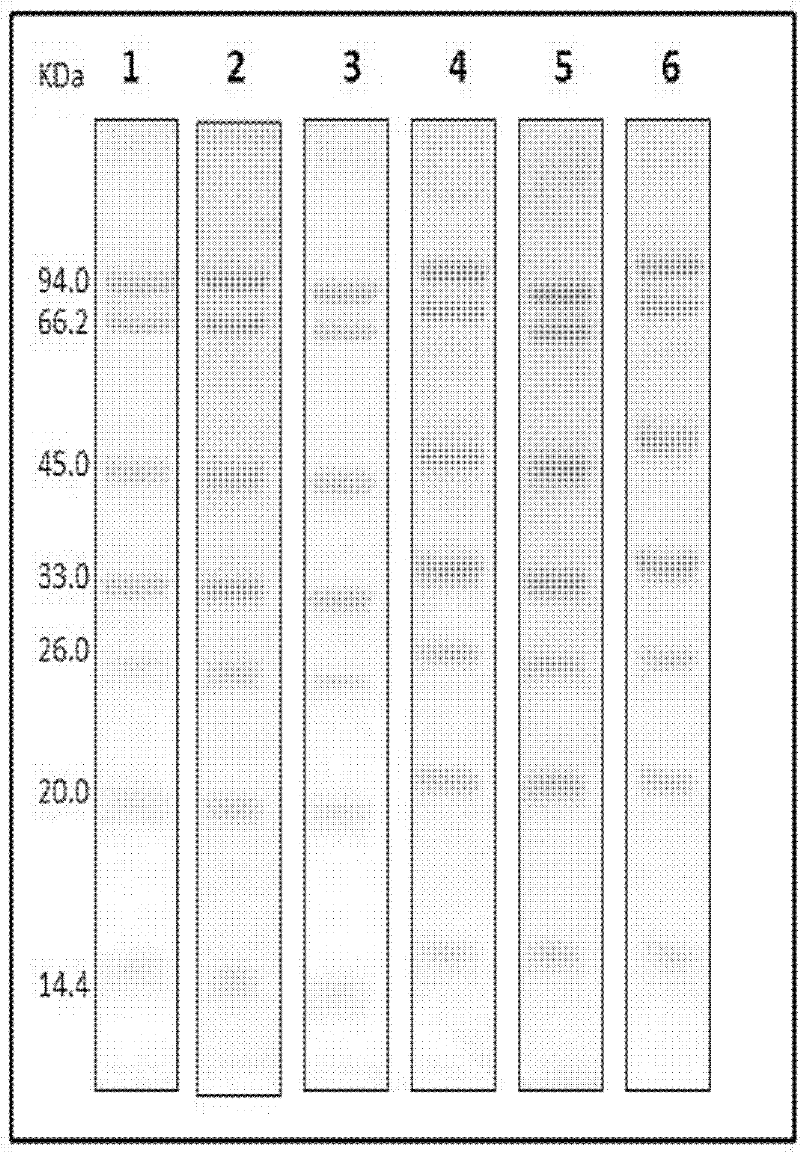

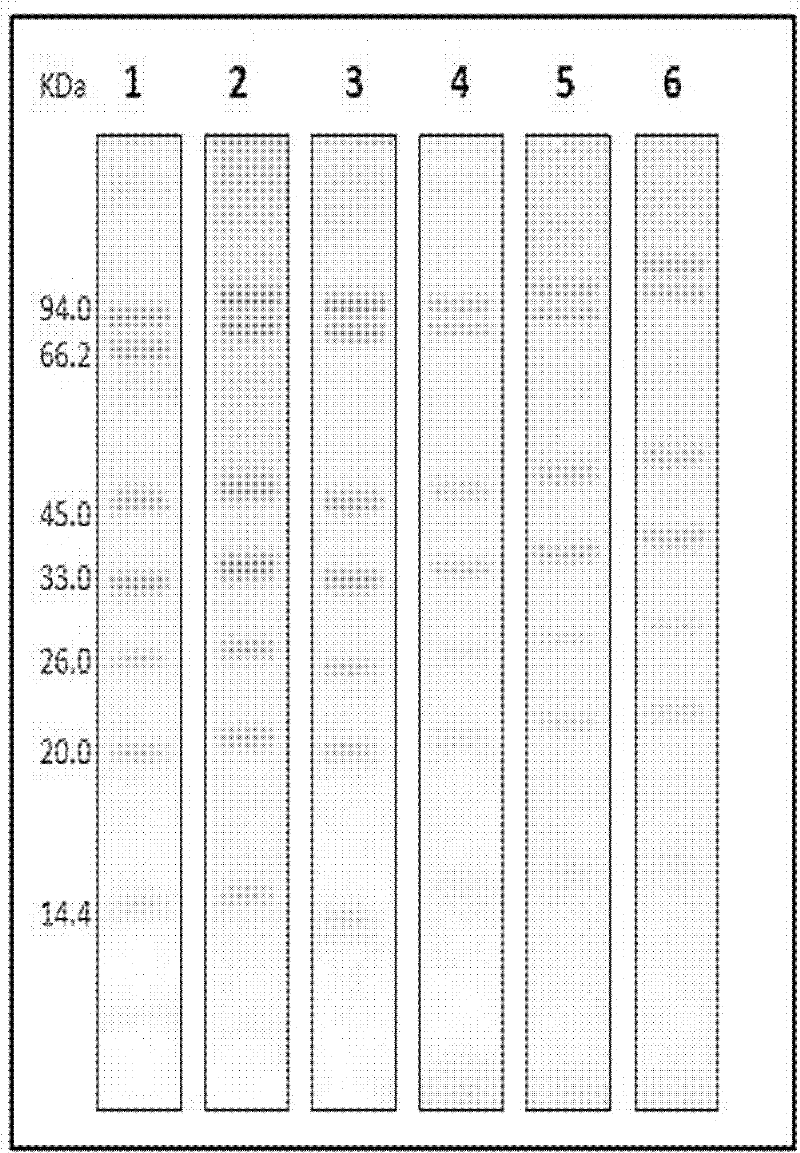

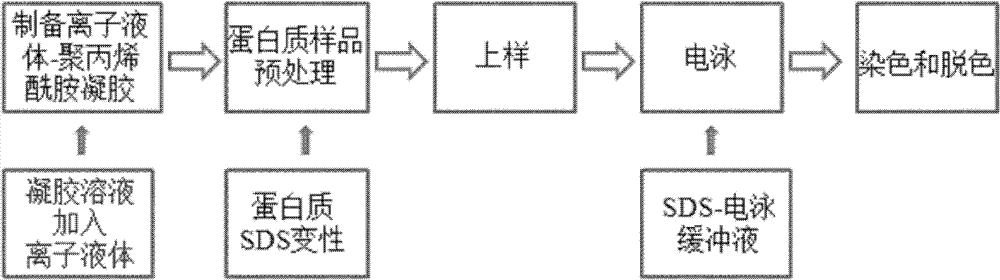

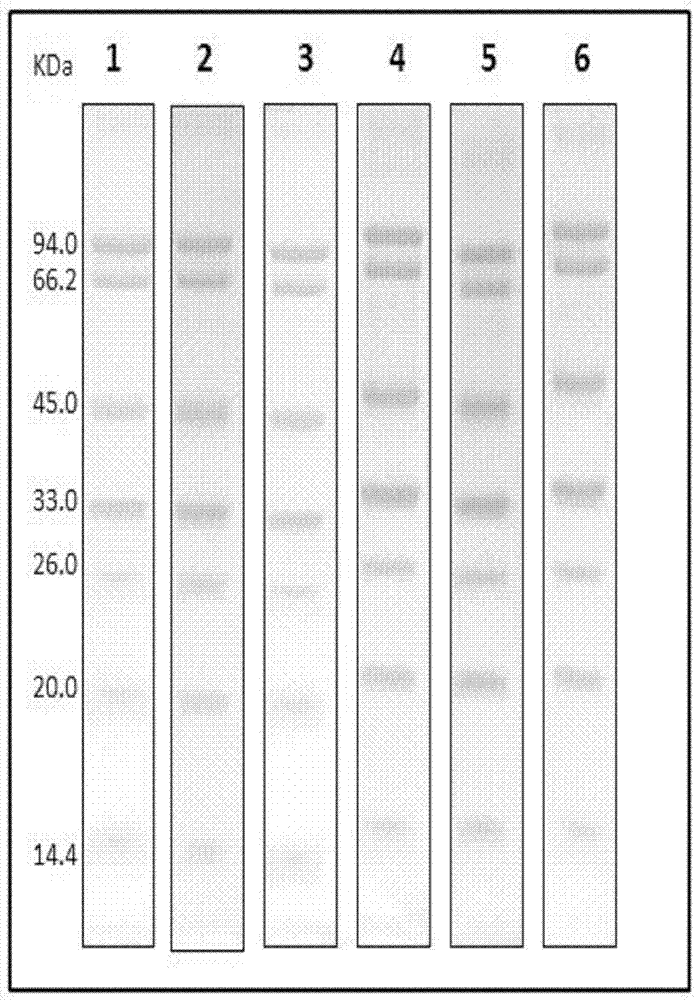

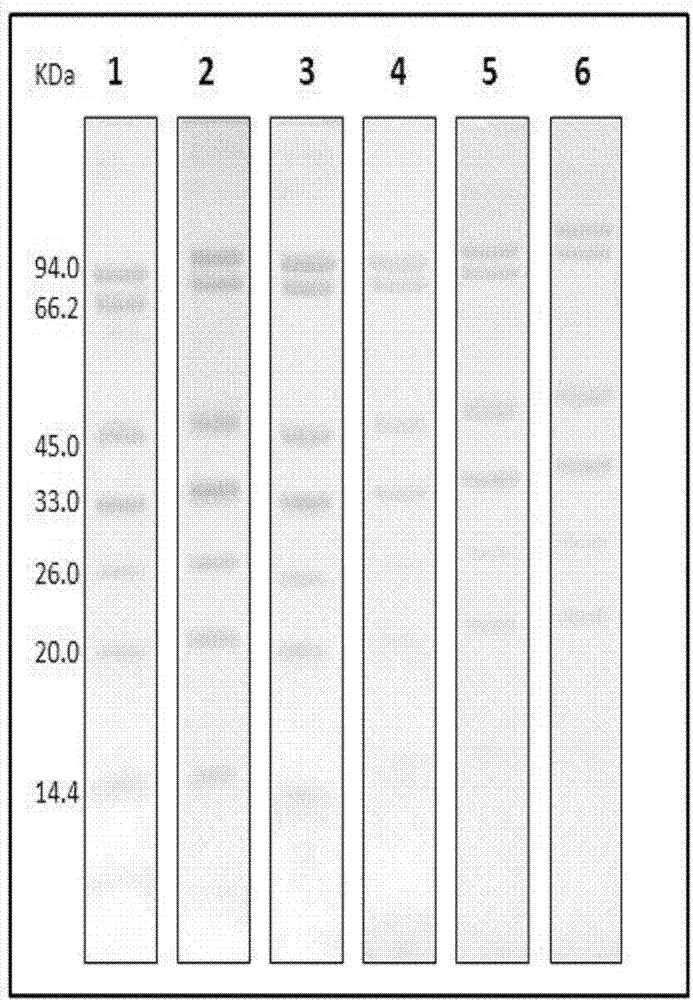

Ionic liquid- polyacrylamide gel, preparation method and purpose thereof

InactiveCN102229688AImprove efficiencyGood reproducibilityMaterial analysis by electric/magnetic meansCross-linkElectrophoresis

The invention relates to an ionic liquid-polyacrylamide gel, a preparation method and a purpose thereof, and belongs to the technical field of protein separation and analysis. The ionic liquid-polyacrylamide gel comprises a monomer, a cross-linking agent, a gel buffer system, a catalyst, an accelerator and an ionic liquid, wherein the ionic liquid has cations having no more than 4 carbon atoms onan alkyl carbon chain, and has a mass concentration of 0.05-1.0%(w / v). The ionic liquid, the monomer, the cross-linking agent and the gel buffer system are mixed together, and added with the catalystand the accelerator to be mixed uniformly; and the mixture is solidified to obtain the ionic liquid-polyacrylamide gel. The ionic liquid-polyacrylamide gel can be applied to protein electrophoretic separation, namely, an ionic liquid-sodium dodecyl sulfate-polyacrylamide gel is used for electrophoresis separation of an SDS treated protein. Especially, for different proteins having a same or a similar molecular weight, a rapid, simple, green and efficient separation thereof can be realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

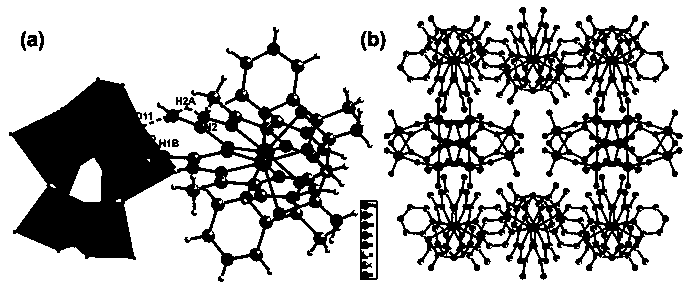

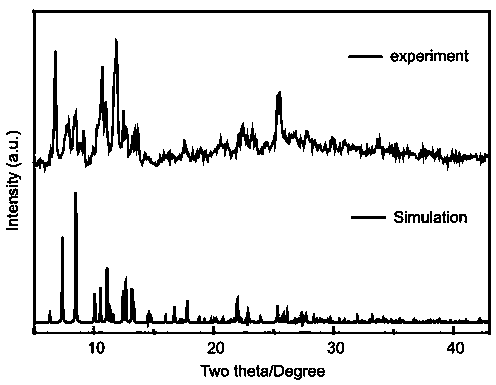

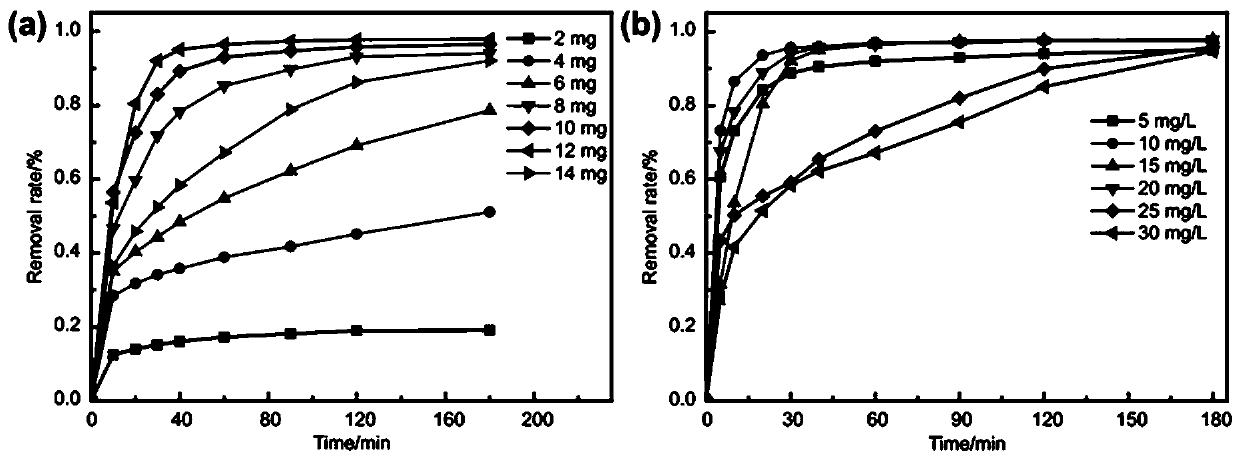

Polyacid complex, nanocomposite material containing same, and application of nanocomposite material in dye adsorption

InactiveCN110201640AAccurate understanding of structural featuresImprove adsorption capacityOther chemical processesWater contaminantsNanometreCell parameter

The invention relates to a polyacid complex. The chemical formula of the polyacid complex is [Ni(HL)2]2H2[P2Mo5O23].2H2O, wherein HL is 2-acetylpyrazine thiosemicarbazone. The polyacid complex belongsto the monoclinic crystal system, and has a C2 / c space group, and cell parameters are as follows: a = 3.0575(7) nm, b = 1.3276(3) nm, c = 1.7009(4) nm, alpha = 90 DEG, beta = 113.837 (5) DEG, and gamma = 90 DEG. The invention also provides a nanocomposite material containing the polyacid complex. The polyacid complex POMs with a good adsorption function is combined with magnetic Fe3O4 nanoparticles to form the magnetic nanocomposite material. The combination of the POMs and Fe3O4 nanoparticles makes the material have an increased adsorption efficiency and well achieve recycling under the action of an external magnetic field.

Owner:HENAN UNIVERSITY

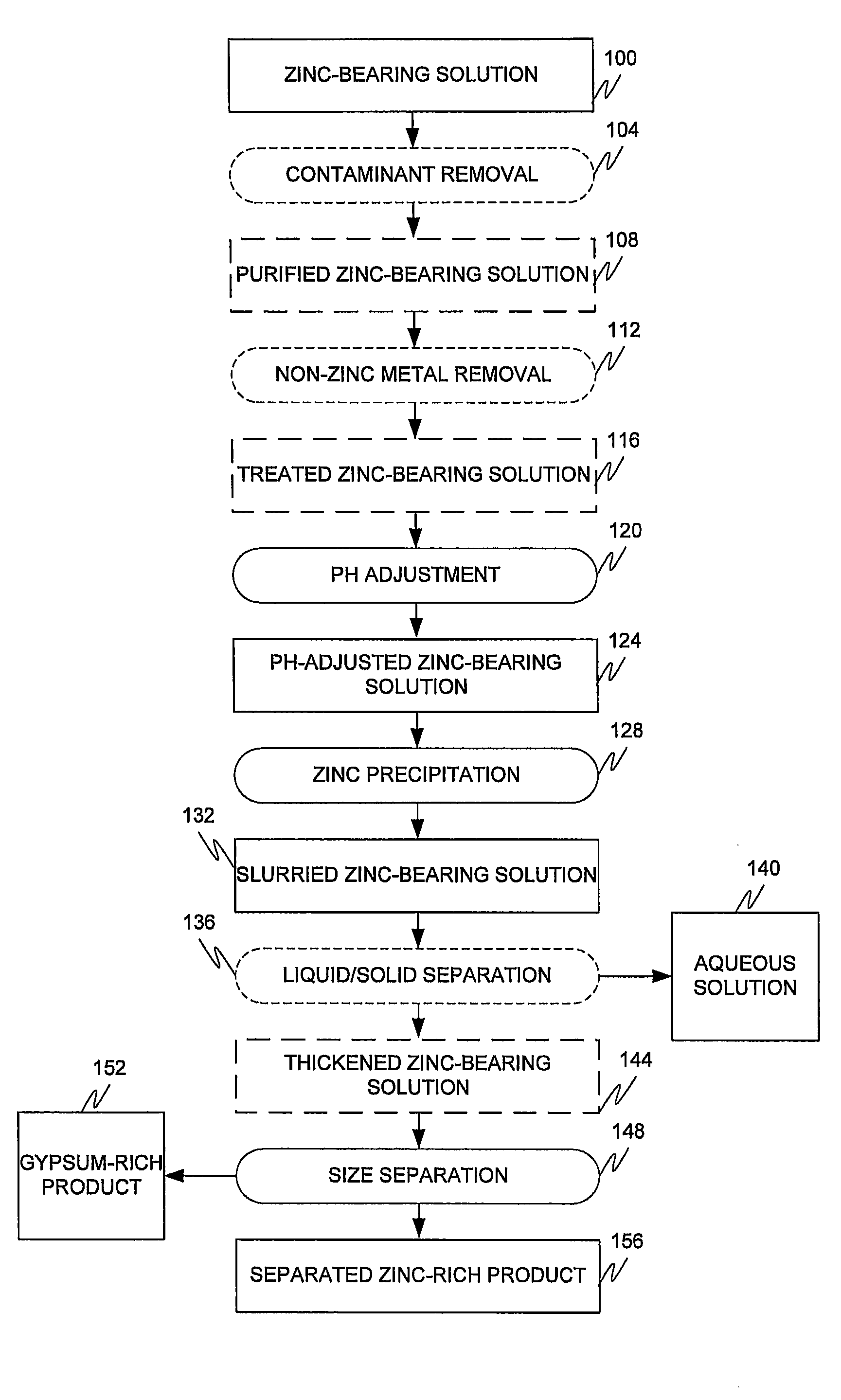

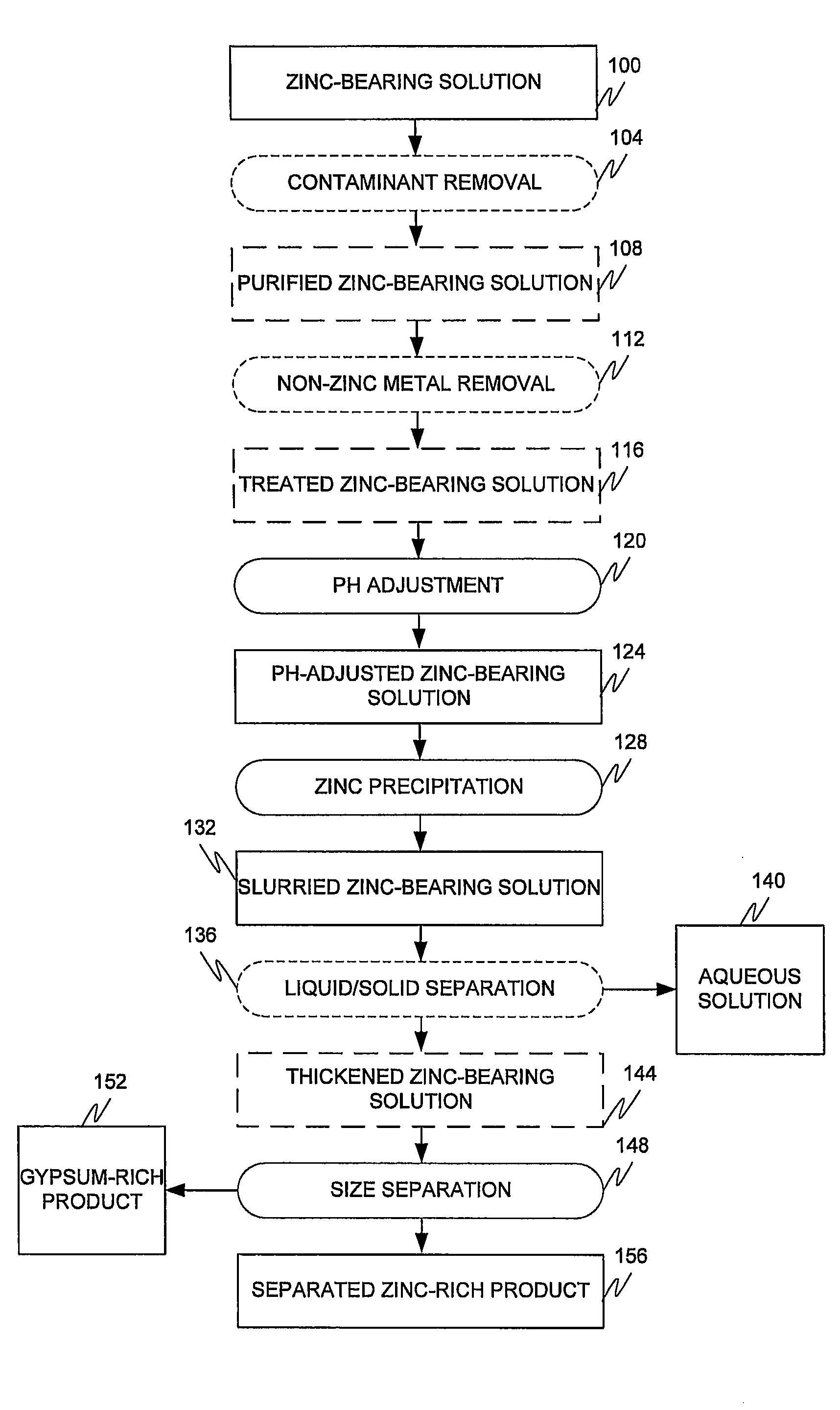

Production of zinc sulphate concentrates from a dilute zinc sulphate solution

ActiveUS8900535B2Efficient and selective separationWithout costZinc sulatesZinc oxides/hydroxidesSulfate zincSulphate Ion

In an embodiment, the present invention relates to an apparatus and a process for producing a concentrated form of basic zinc sulphate from a, typically dilute, acidic zinc sulphate-bearing solution. The process embodiment comprises the steps of precipitating the zinc, preferably primarily as basic zinc sulphate, from the acidic zinc sulphate solution, preferably using calcium oxide, in such a way as to promote the formation of separate gypsum crystals and basic zinc sulphate particles, and upgrading the zinc content in the precipitates by separating the basic zinc sulphate from the gypsum using size separation techniques.

Owner:BARRICK GOLD

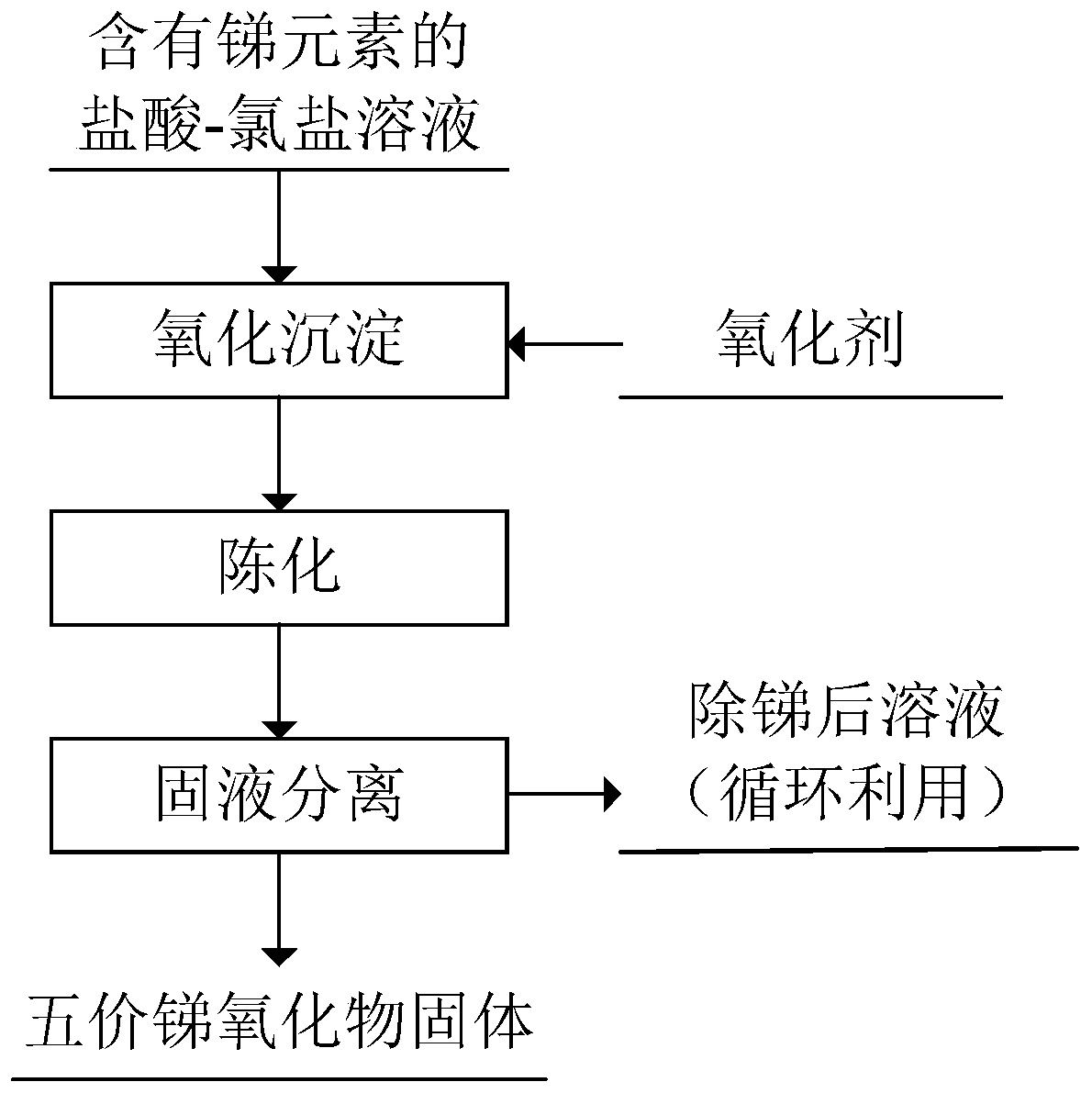

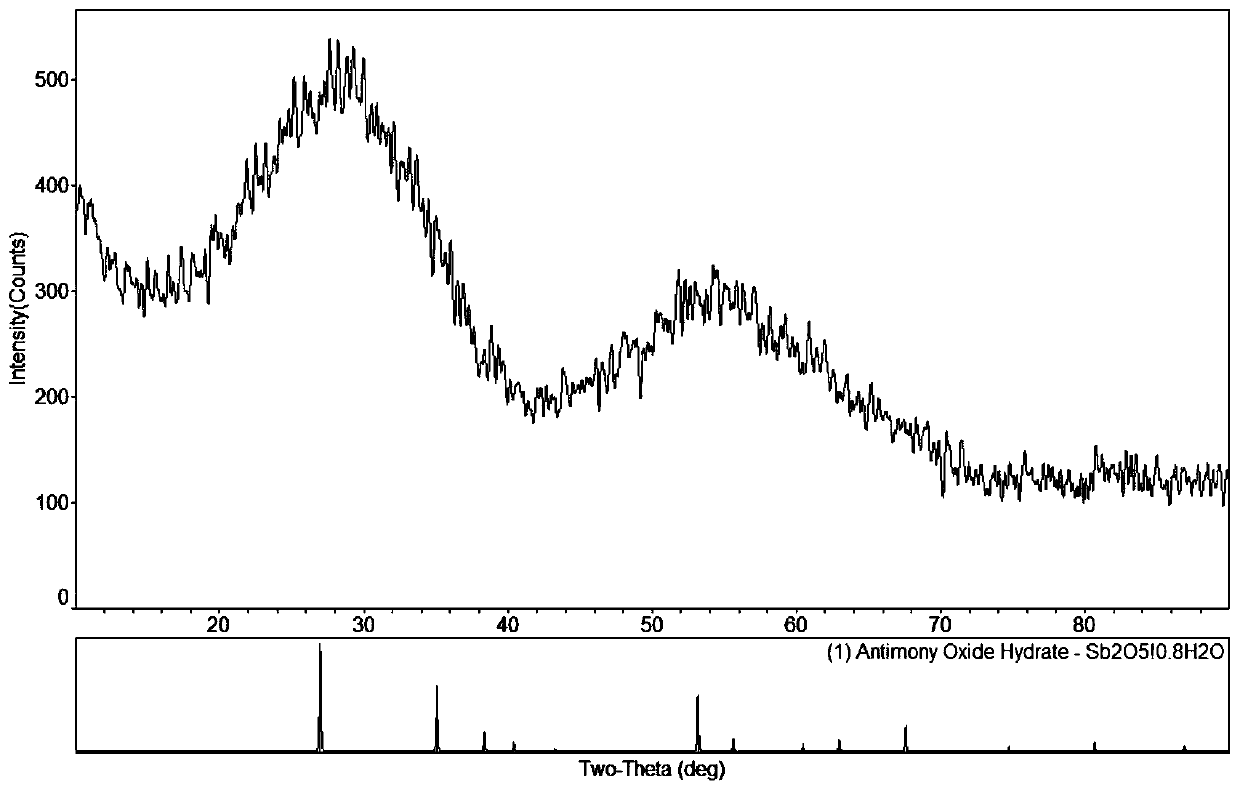

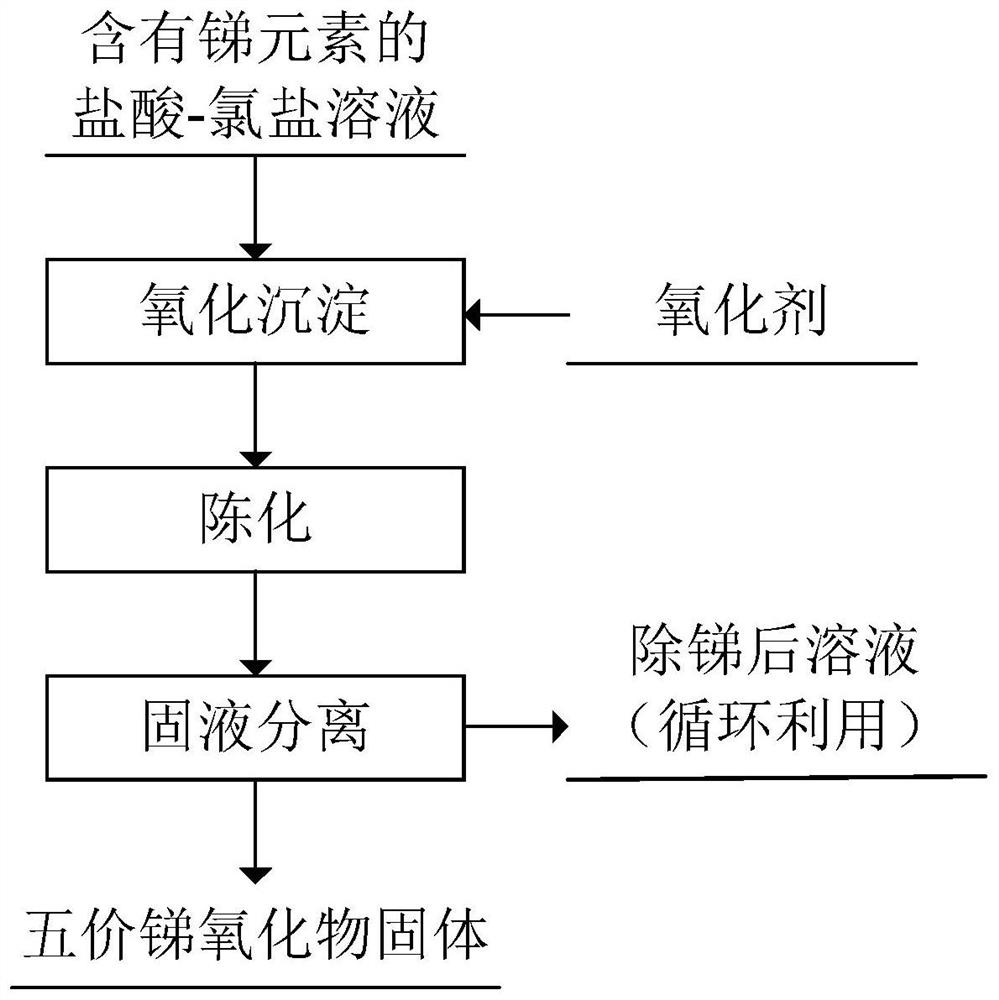

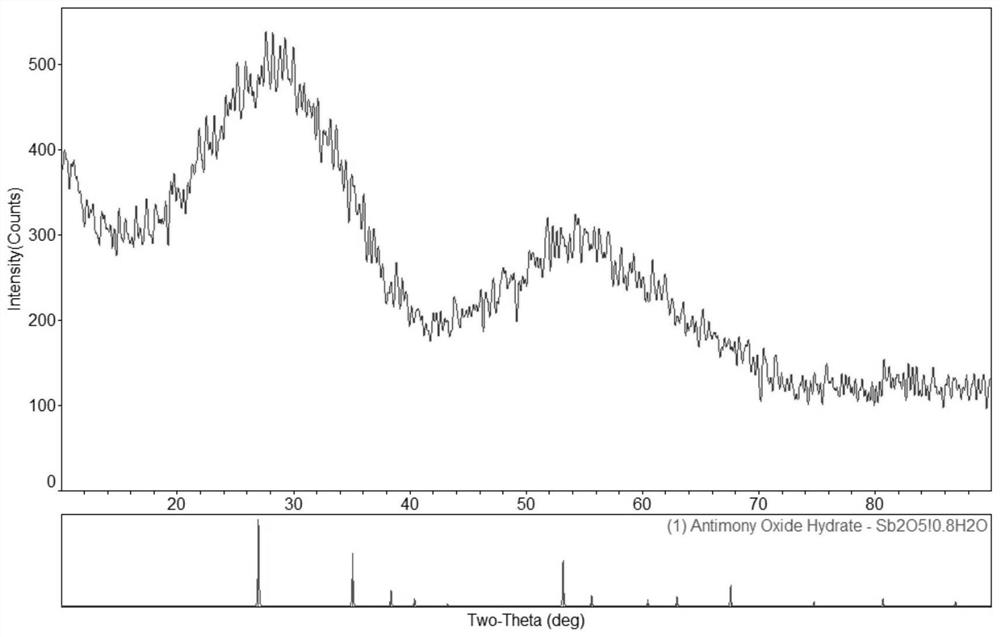

Method for separating antimony from hydrochloric acid-chloride salt solution

The invention discloses a method for separating antimony from a hydrochloric acid-chloride salt solution. The method comprises the steps of adding an oxidizing agent into the hydrochloric acid-chloride salt solution, controlling reaction conditions, oxidizing trivalent antimony in the solution into pentavalent antimony, and precipitating the pentavalent antimony to separate out pentavalent antimony oxide to obtain pentavalent antimony oxide precipitation slurry; and aging the pentavalent antimony oxide precipitation slurry, crystallizing and growing the pentavalent antimony oxide in the pentavalent antimony oxide precipitation slurry, and then carrying out solid-liquid separation to obtain a pentavalent antimony oxide solid and an antimony-removed solution, thereby achieving separation ofthe antimony. According to the method, the antimony can be efficiently and selectively separated out, the recovery rate of the antimony is high, the process flow is simple, and the operation is easy.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

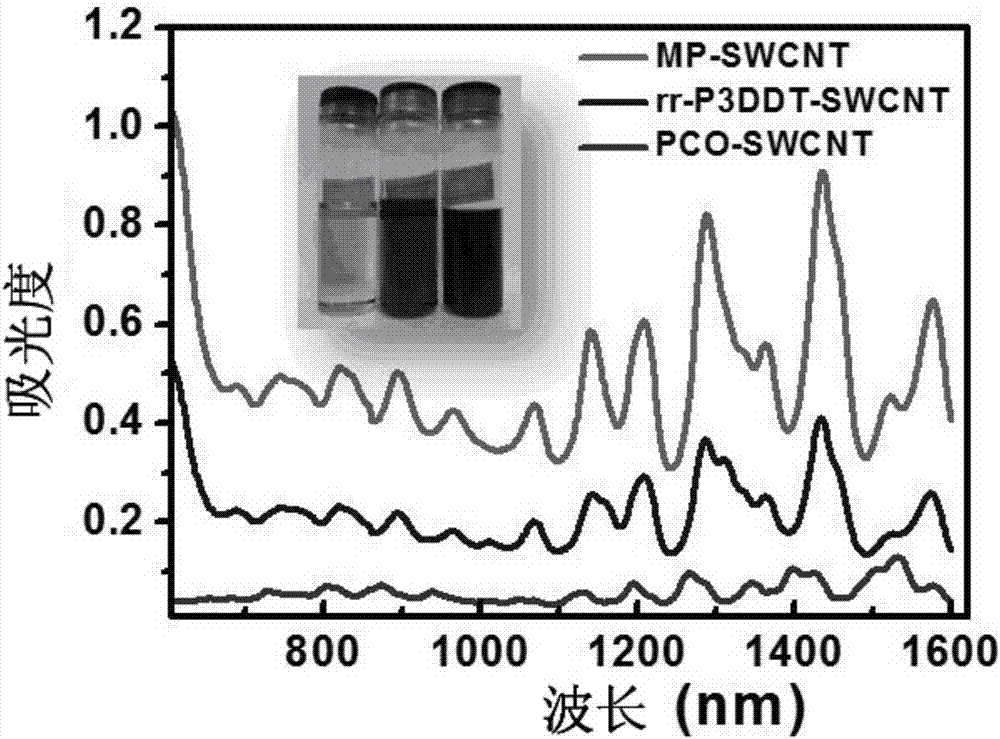

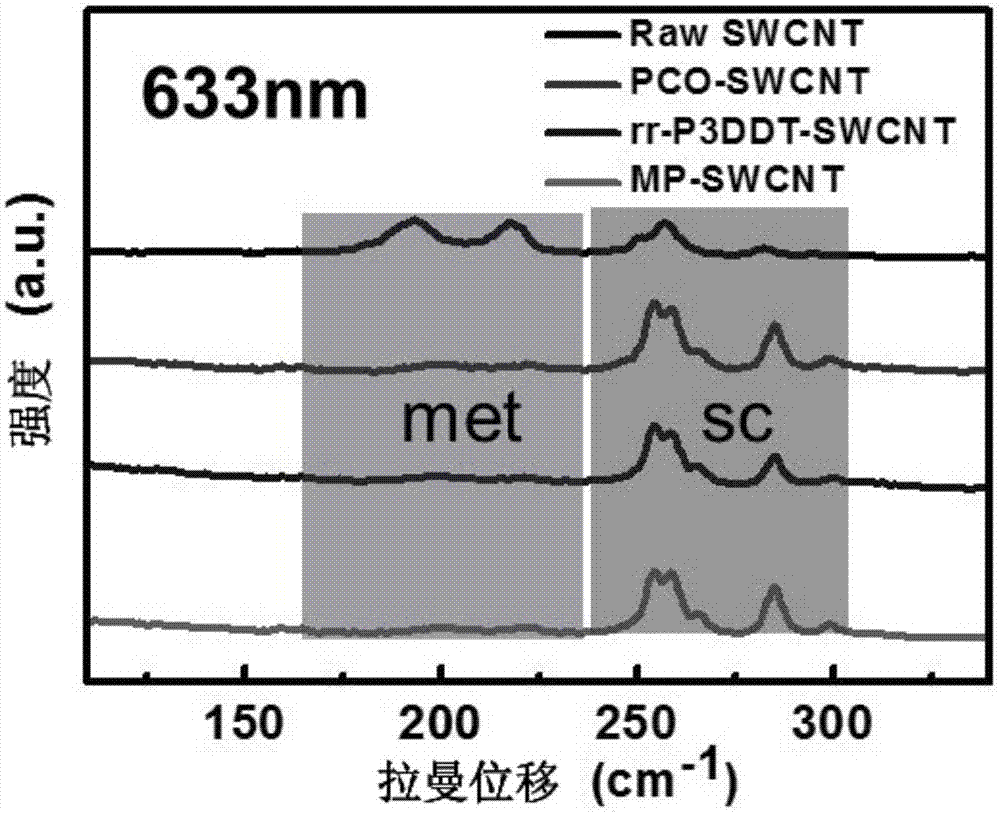

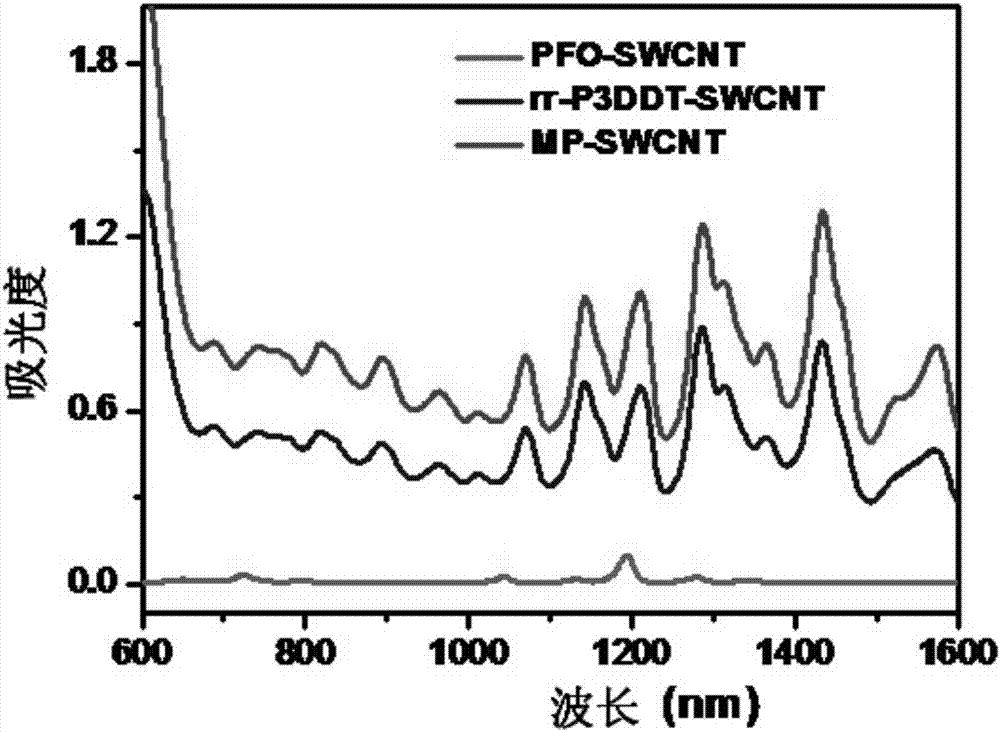

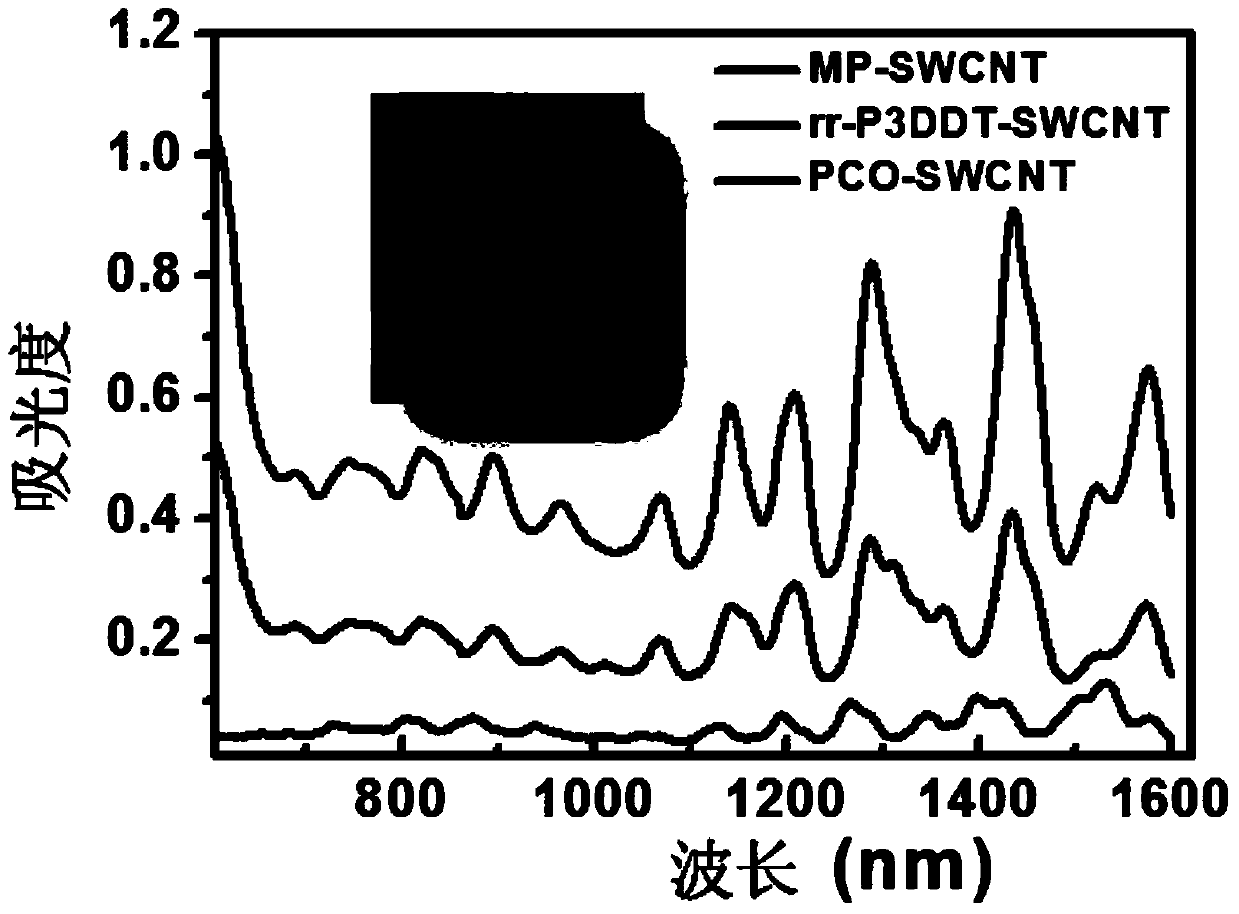

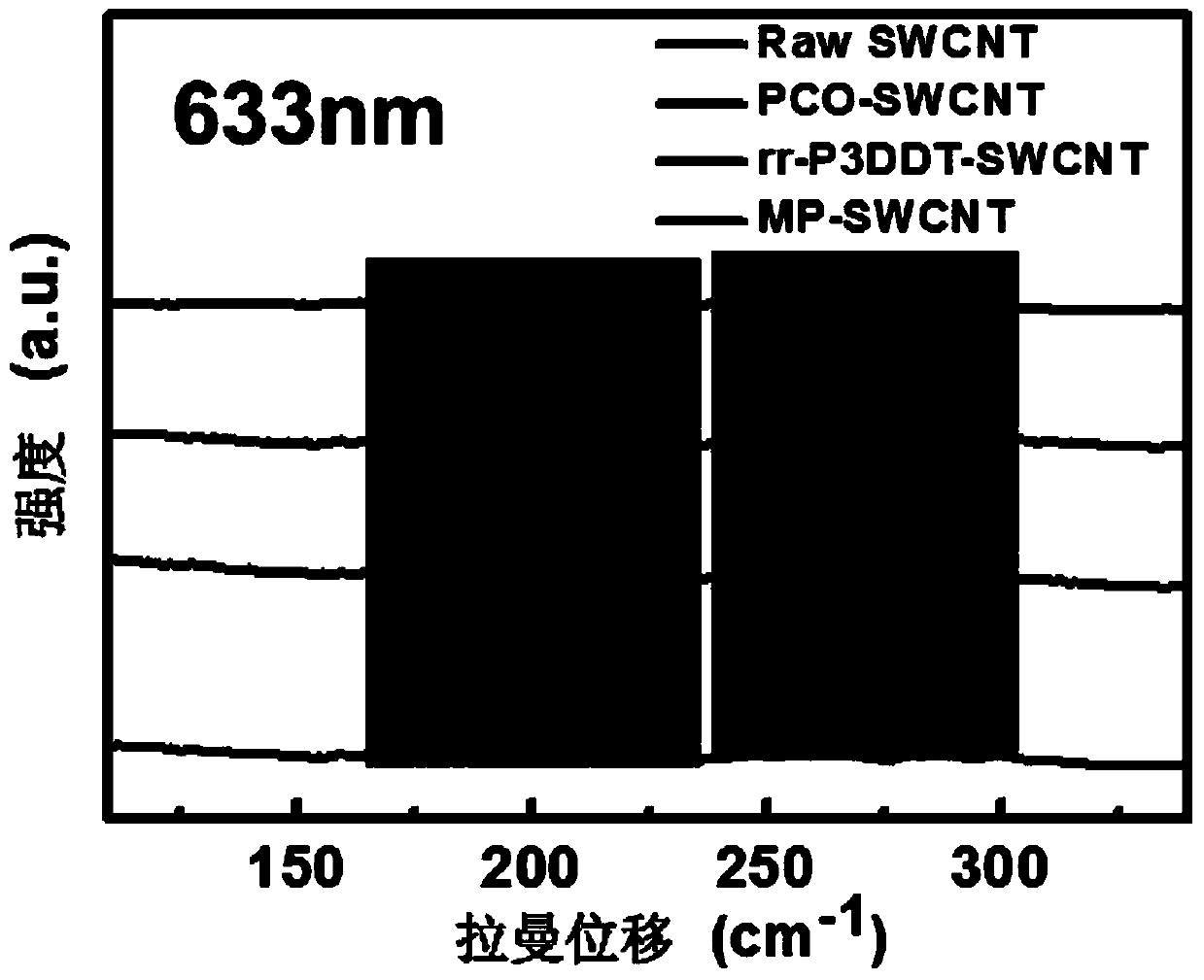

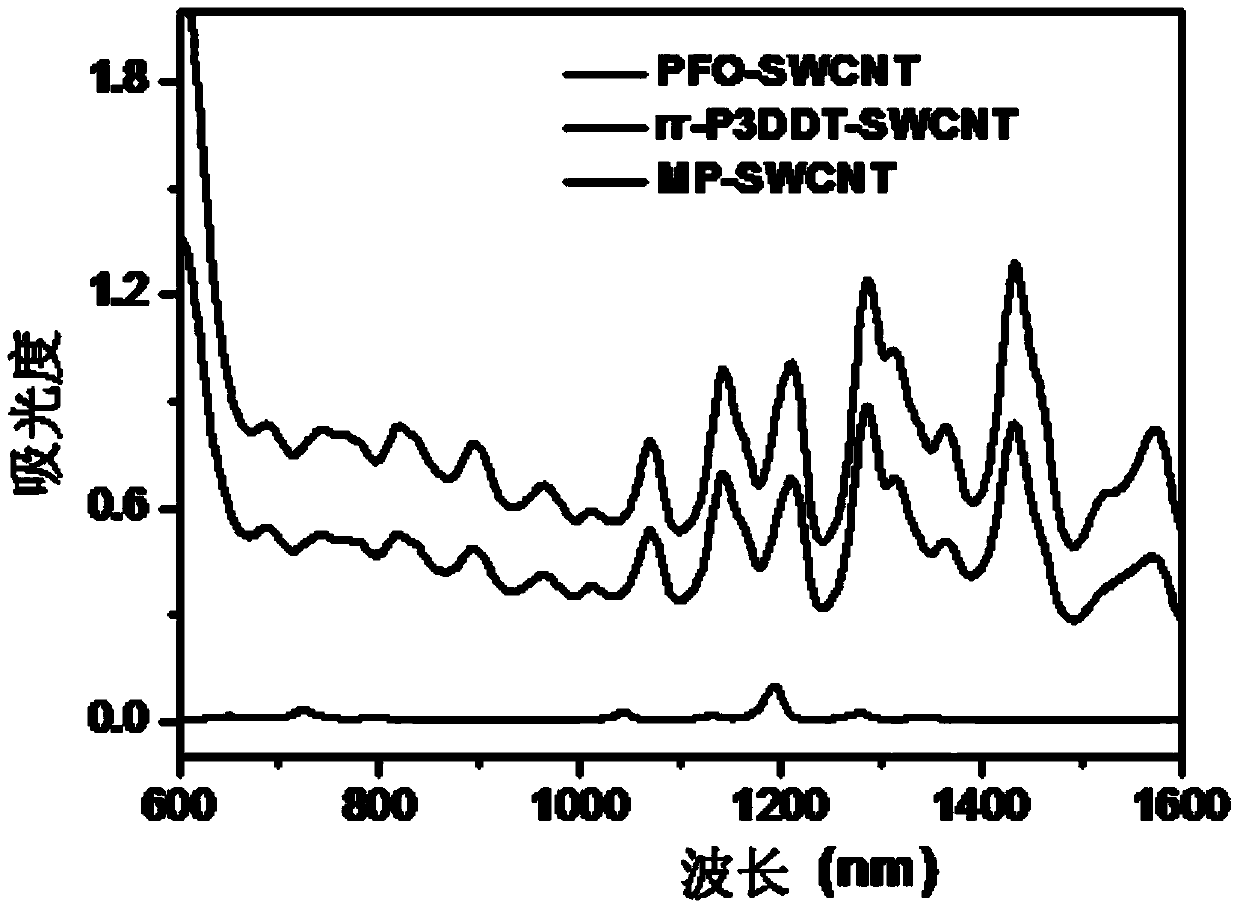

Method and reagent for improving yield of selective dispersion of semiconducting carbon nanotubes

The invention discloses a method and reagent for improving the yield of selective dispersion of semiconducting carbon nanotubes. The method comprises the following steps: uniformly mixing a single-walled carbon nanotube sample, a first polymer and a second polymer in a solvent to form a liquid-phase mixed system, and allowing the single-walled carbon nanotube sample to be sufficiently dispersed in the liquid-phase mixed system; then subjecting the liquid-phase mixed system to centrifugation; and separating out a supernatant so as to realize selective separation of the semiconducting single-walled carbon nanotubes. Both the first polymer and the second polymer can specifically bind to the semiconducting single-walled carbon nanotubes; the binding speed of the first polymer and the semiconducting single-walled carbon nanotubes is greater than the binding speed of the second polymer and the semiconducting single-walled carbon nanotubes; and the binding strength of the first polymer and the semiconducting single-walled carbon nanotubes is lower than the binding strength of the second polymer and the semiconducting single-walled carbon nanotubes. The method and reagent provided by the invention can realize selective separation of high-yield, high-purity and high-dispersity semiconductoring single-walled carbon nanotubes, is reduced in cost and improves the repeatability and stability of separation.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Polymer containing membrane for hydrometallurgical separation of precious metals, base metals and rare elements

ActiveCN112813261AGood choiceEfficient and selective separationProcess efficiency improvementEthyl groupPhysical chemistry

The invention discloses a polymer containing membrane for hydrometallurgy separation of precious metals, base metals and rare elements, and belongs to the technical field of metallurgy. The polymer containing membrane is prepared from the raw materials of PVC, an extracting agent and NPOE, and the extracting agent is tris(2-methylpropyl)phosphorus sulfide and tris(2-ethylhexyl)amine at the mass ratio of (1.36-1.56): 1. A preparation method comprises the steps of dissolving the PVC, the NPOE and the extracting agent in a volatile polar solvent, stirring for reaction to obtain a solution, pouring the solution into a container after the reaction is completed, and standing at 24-26 DEG C until the volatile polar solvent is completely volatilized so as to obtain the polymer containing membrane. The polymer containing membrane is capable of efficiently and selectively separating the precious metals and rare metals contained in base metal ore deposits, excellent in mechanical property and recycling performance and flexible in separation method, and has important popularization value in the field of hydrometallurgy.

Owner:LIUPANSHUI NORMAL UNIV

Method for selective flotation separation of molybdenum and rhenium acid radicals in alkaline leaching liquid

The invention discloses a method for selective flotation separation of molybdenum and rhenium acid radicals in an alkaline leaching liquid. The method comprises the following steps that a pH value ofthe alkaline leaching liquid containing molybdate acid radicals and rhenium acid radicals is adjusted to 7.1-12, then an organic matter modified activated carbon collecting agent composed of triethylenetetramine, tetraethylenepentamine, methyl violet 10B and cocamidopropyl betaine and a surface active agent are added into the alkaline leaching liquid, pneumatic flotation is carried out, a foam product is a rhenium-rich component, and a liquid core is a molybdenum-rich solution. The method has the advantages that the selective separation effect is good on molybdenum and rhenium, the technological process is simple, and the cost is low, and is especially suitable for separation between the rhenium and the molybdenum in the alkaline leaching liquid with low rhenium content and high molybdenumcontent.

Owner:ZHENGZHOU UNIV

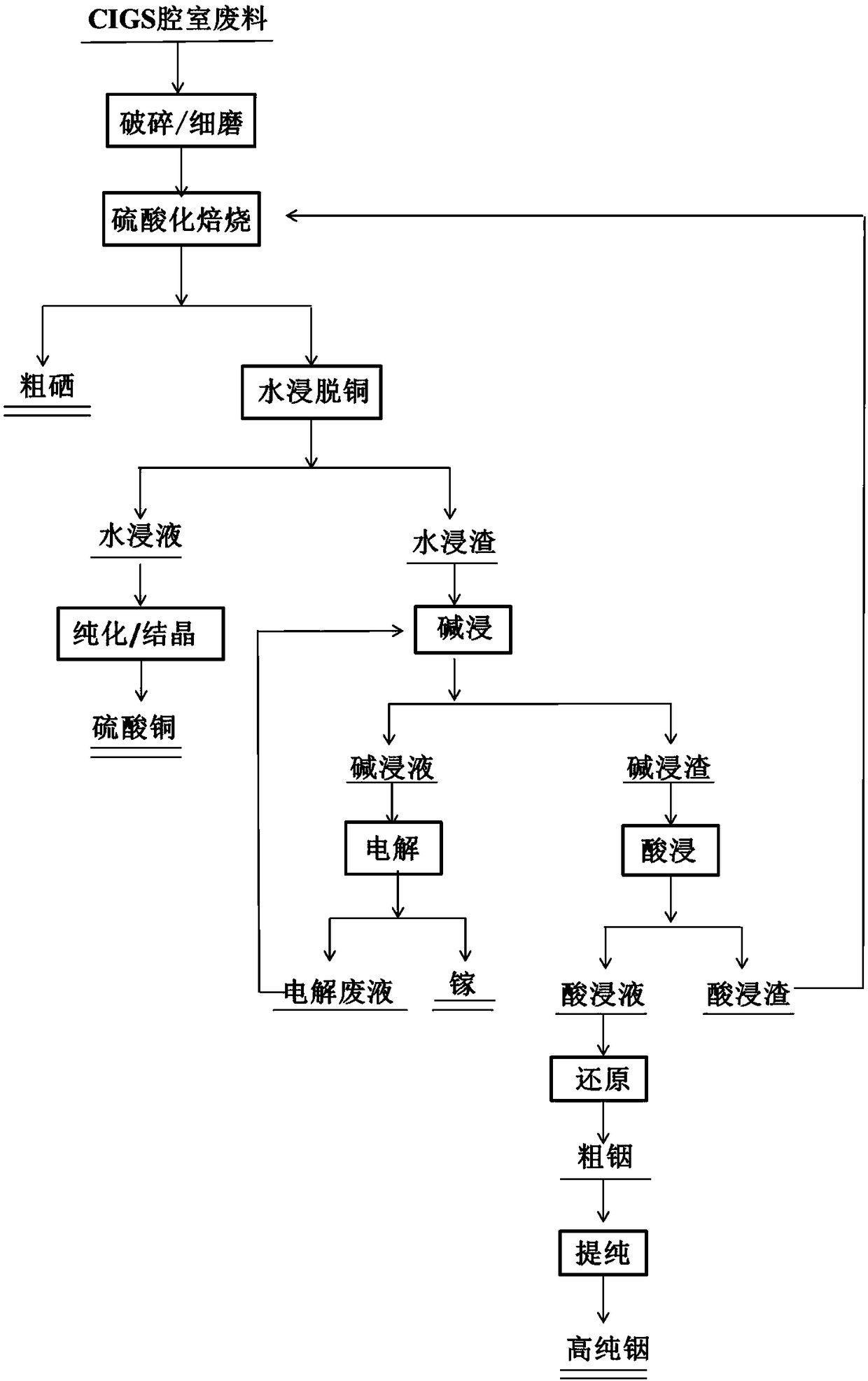

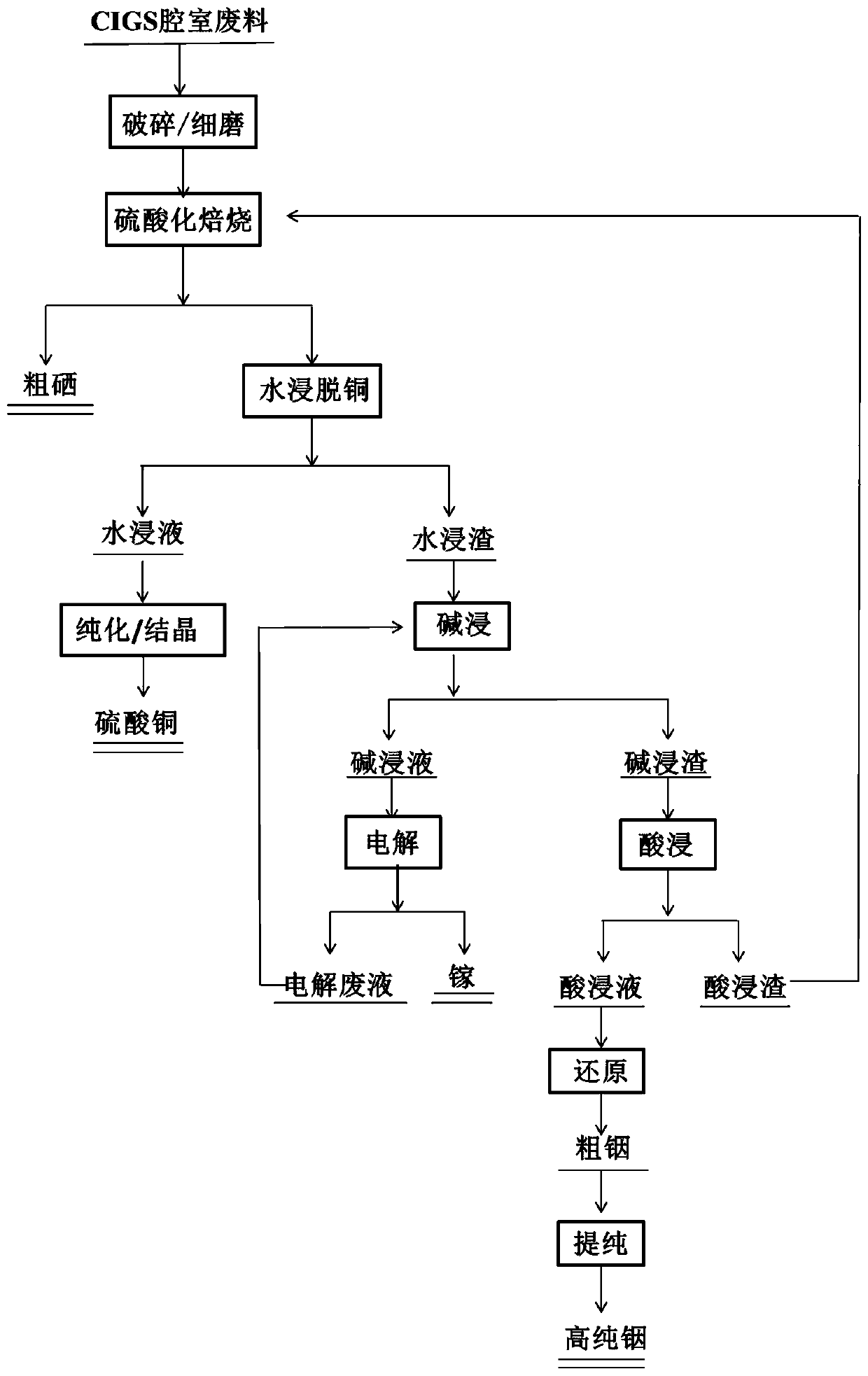

Method for recovering copper indium gallium selenium from waste of copper indium gallium selenium solar thin film cell

ActiveCN108359802AEfficient and selective separationEfficient recyclingPhotography auxillary processesEnergy inputIndiumCopper indium gallium selenide solar cells

The invention provides a method for recovering copper indium gallium selenium from waste of a copper indium gallium selenium solar thin film cell, and belongs to the technical field of resource secondary utilization. The method comprises the steps that the waste in a copper indium gallium selenium (CIGS) solar thin film cell chamber is smashed and milled, then is subjected to sulfatizing roastingto obtain crude selenium and roasting materials, the roasting materials are leached by adding water, and a copper sulfate product is obtained by purifying and crystallizing a water leaching solution;water leaching slag is subjected to alkaline leaching, then an alkali leaching solution is electrolyzed, and gallium metal is obtained; inorganic acid is added to alkali leaching slag for acid leaching, and metal indium powder is obtained by reducing and purifying an acidic leaching solution by formaldehyde, hydrazine hydrate, and iron powder or a mixture of two or three of the formaldehyde, the hydrazine hydrate, and the iron powder in any proportion; and acidic leaching slag is returned for sulfatizing roasting. The purity of the obtained crude selenium is larger than 98%, the purity of theobtained metal indium powder is less than 99%, and the purity of the obtained metal gallium is larger than 99%. The recovery rates of four valuable elements are all above 95%. The method for recovering the copper indium gallium selenium from the waste of the copper indium gallium selenium solar thin film cell is simple to operate, high in safety, high in reliability, and low in cost, scale production is easy to achieve, the environmental protection requirements are met, and the application prospects are broad.

Owner:UNIV OF SCI & TECH BEIJING

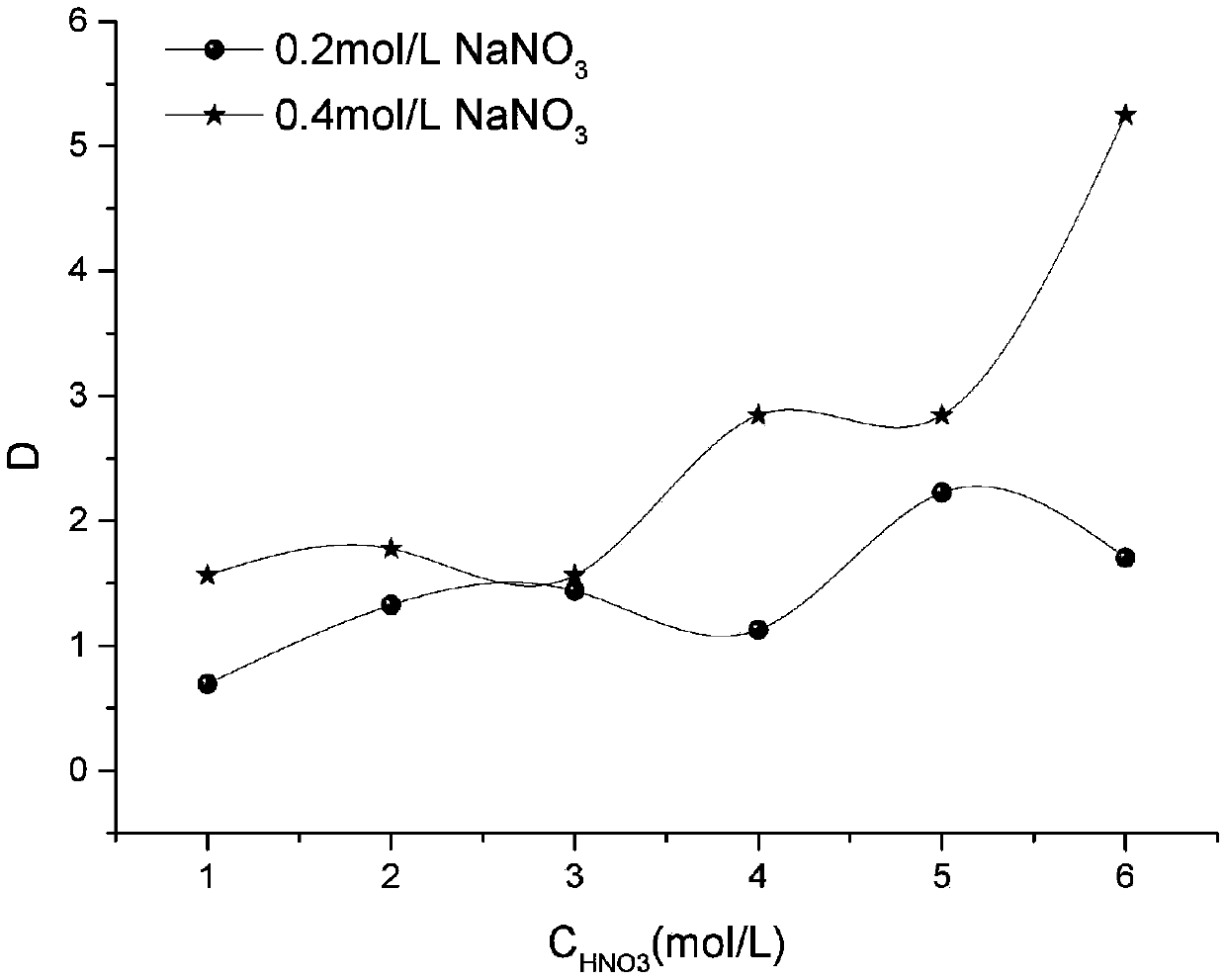

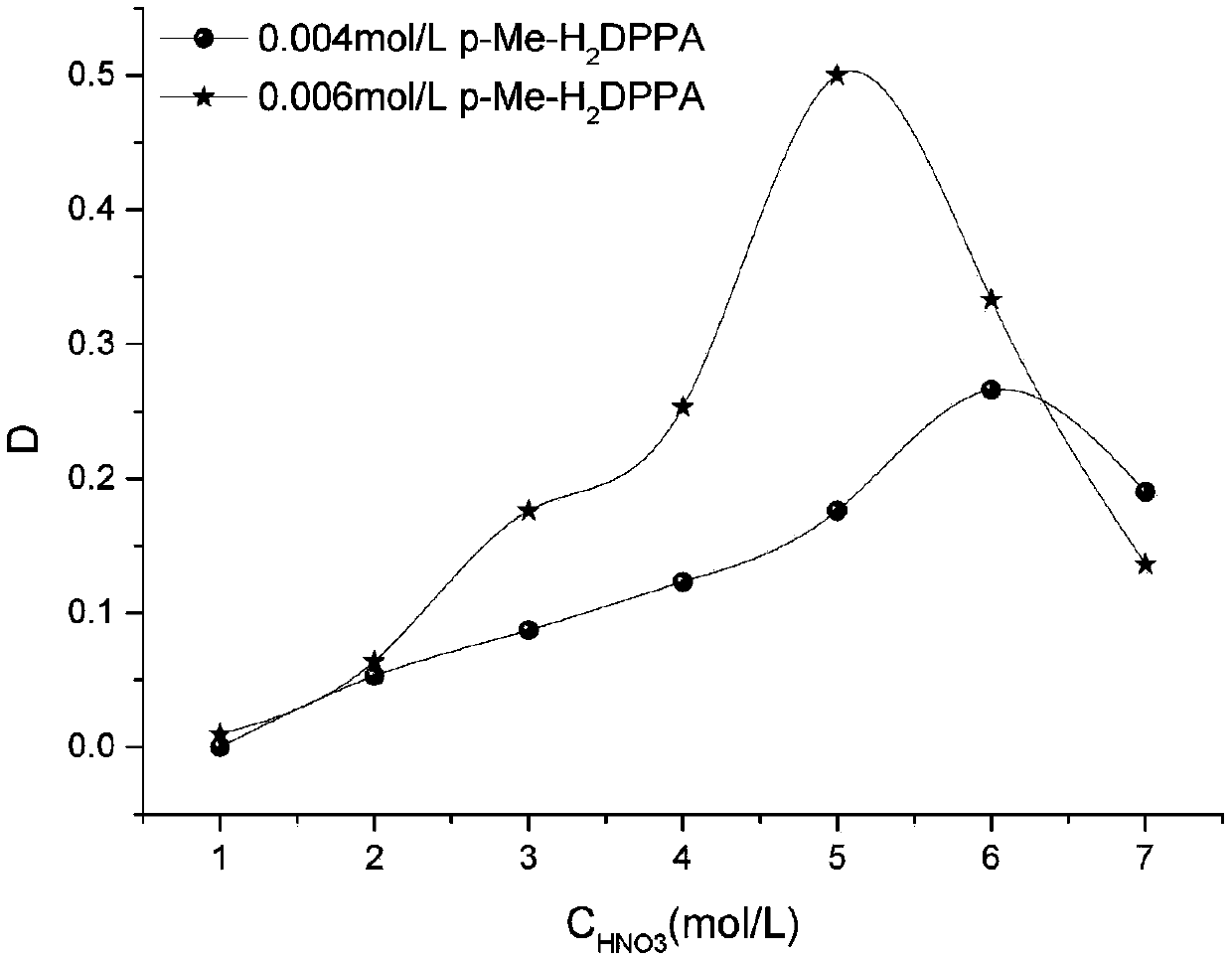

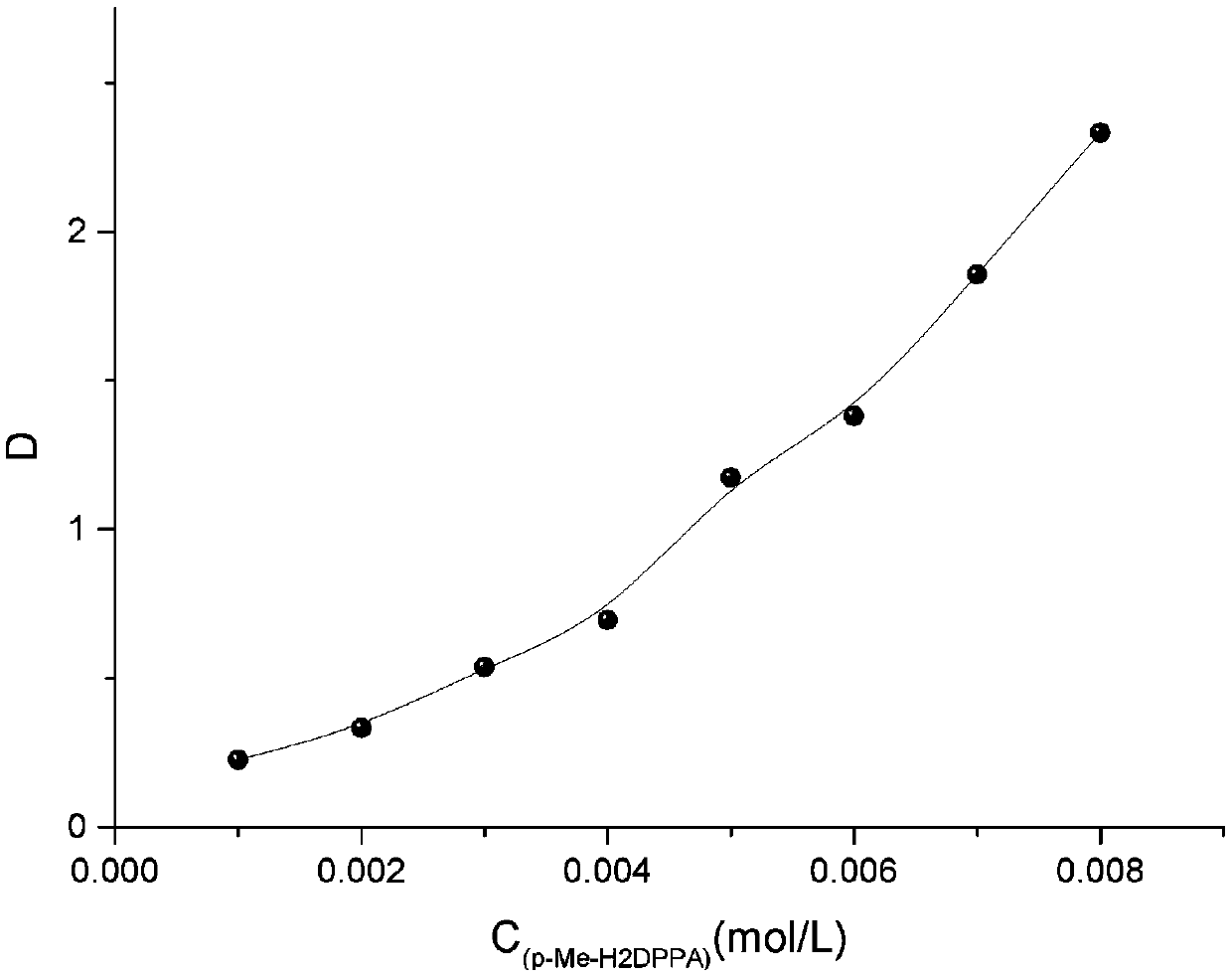

Strontium extracting method

InactiveCN109628759AFast selective separationEfficient and selective separationProcess efficiency improvementStrontiumRadiochemistry

The invention relates to a strontium extracting method. N,N'-di-p-tolylpyridine-2,6-dicarboxamide is synthesized to be used as an extraction agent to extract the strontium in a solution, and an organic phase is extracted. The strontium extracting method is characterized in that in the back extraction process of the strontium in the organic phase, water is used as a back extraction agent, the waterphase is extracted finally, and then the strontium is obtained. On one hand, the extraction agent prepared in the strontium extracting method is pure, free of phosphorus and other secondary pollutants, good in extraction effect and mature in synthesis technology; on the other hand, since deionized water is used as the back extraction agent, the raw material is easy to obtain, operation is easy, cost is low, the back extraction effect is good, and simple, rapid, efficient selective separation of the target Sr ions can be achieved.

Owner:LANZHOU UNIVERSITY

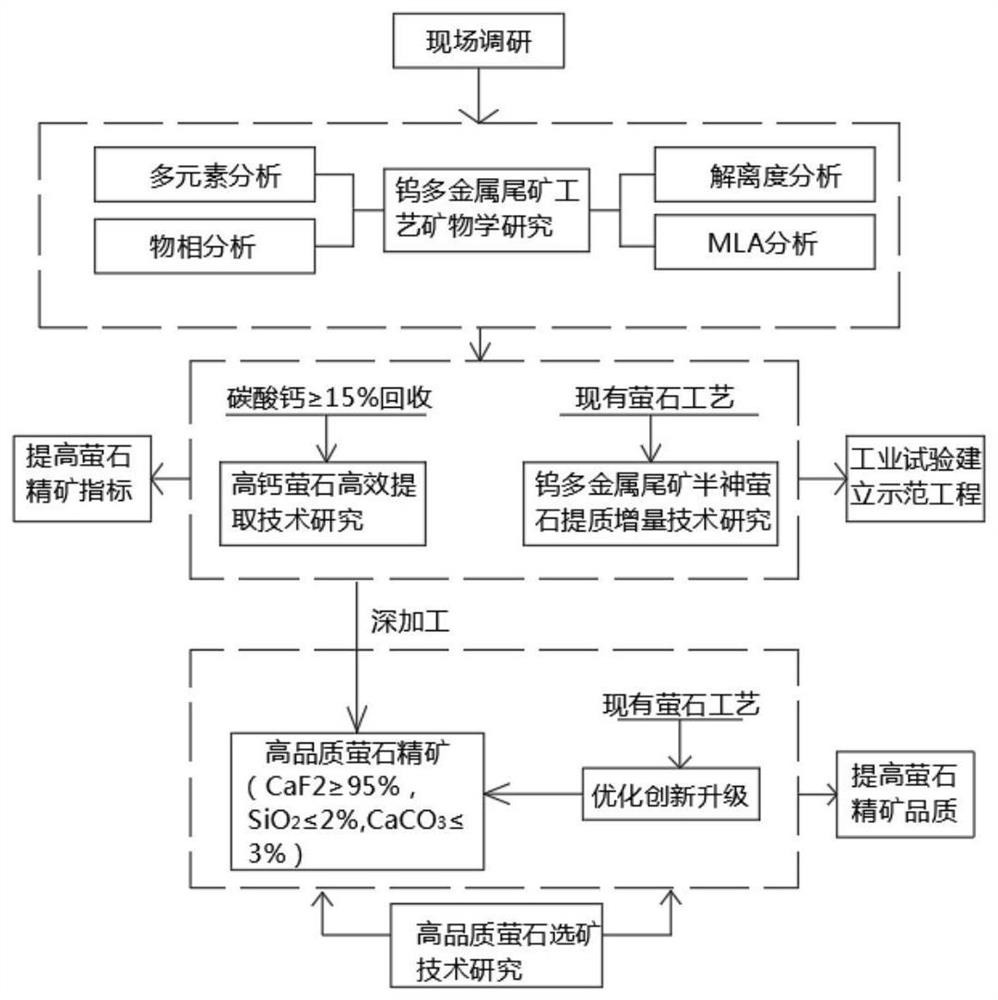

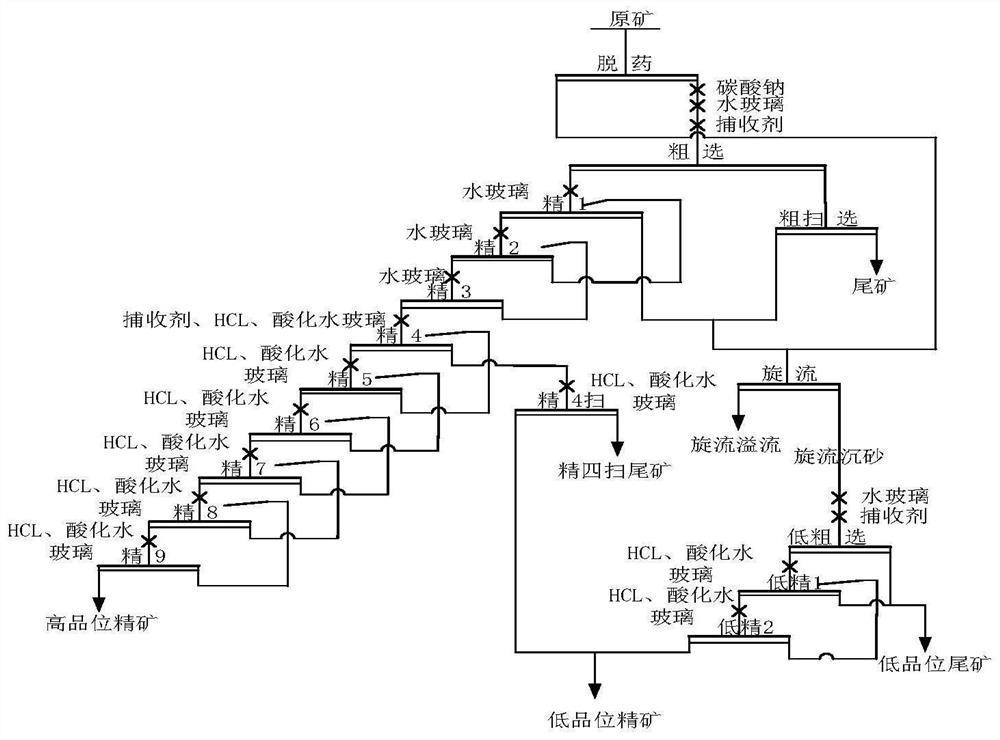

Beneficiation process for flotation of associated fluorite in floating tungsten tailings

PendingCN114100840AEfficient separationEfficient and selective separationFlotationWet separationElement analysisMaceral

The invention belongs to the technical field of beneficiation for recycling associated fluorite in floating tungsten tailings, and particularly relates to a beneficiation process for flotation of associated fluorite in floating tungsten tailings, which comprises the following operation steps: S1, discovering problems existing in associated fluorite ore in floating tungsten tailings through field investigation and survey, and S2, determining the content of associated fluorite in the floating tungsten tailings through multi-element analysis, phase analysis, dissociation degree analysis and MLA analysis. And S3, according to the basis provided by the tungsten polymetallic tailing process mineralogy research, efficient separation of fluorite and gangue minerals, efficient selective separation of fluorite and carbonate and efficient activation of fluorite are achieved, the recovery rate of fluorite concentrate is increased, and the recovery rate of the fluorite concentrate is increased. And efficient enrichment and recovery of roughed fluorite are achieved.

Owner:湖南有色郴州氟化学有限公司

Method for preparing crown ether functionalized porous microsphere adsorbent by one-step double-emulsion template method

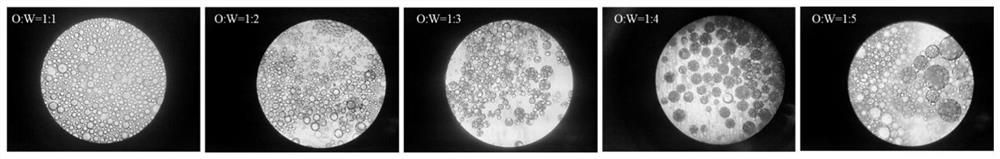

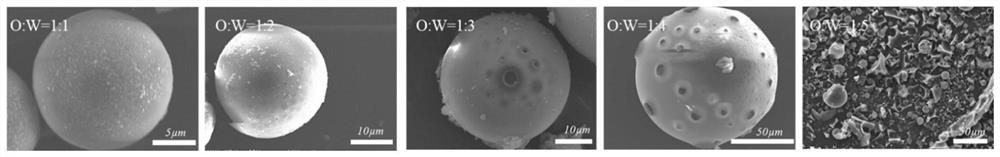

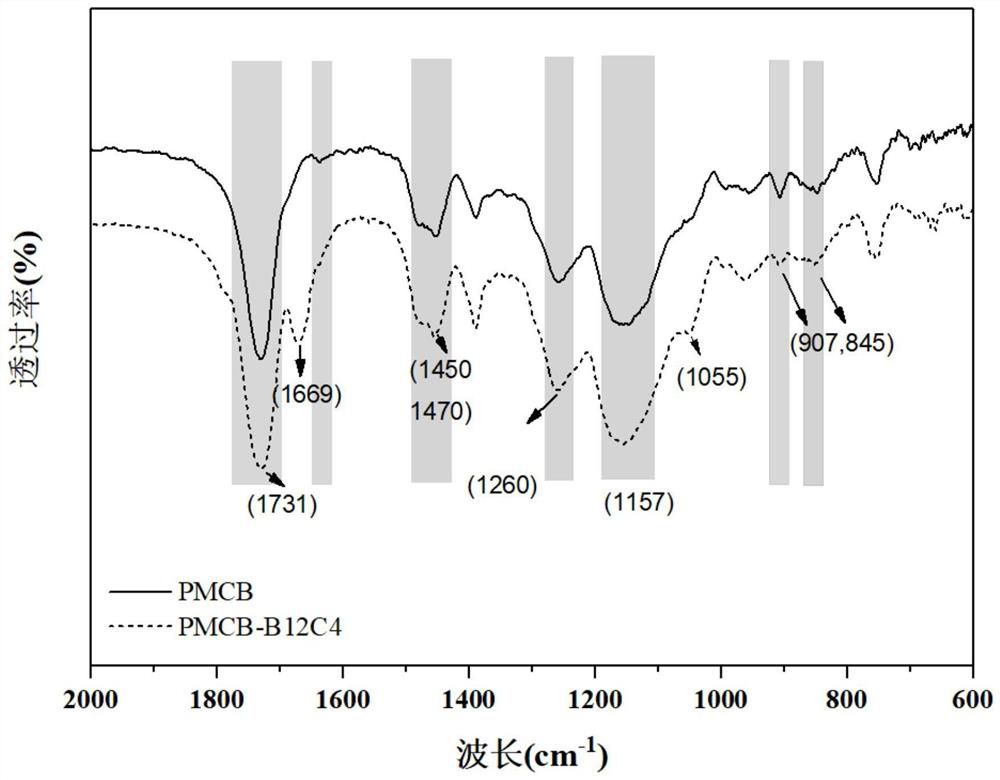

PendingCN112642412AEfficient and selective separationExcellent mechanical mass transfer kinetic performanceOther chemical processesProcess efficiency improvementSelective adsorptionAdsorption separation

The invention belongs to the technical field of preparation of chemical separation functional materials, and relates to a preparation method of a crown ether modified porous microsphere adsorbent. A water-in-oil-in-water double emulsion prepared by dynamically adjusting amphipathy of a block copolymer through one-step stirring is used as a template and is combined with an ultraviolet-induced polymerization way to obtain porous multi-cavity microspheres, and porous microspheres with the surfaces rich in crown ether active sites are prepared through an interface post-modification strategy; and a series of treatment is carried out to obtain a functional adsorbent, and the adsorbent is used for selective adsorption separation on Li<+> in salt lake brine. The crown ether modified porous multi-cavity microsphere adsorbent prepared by the preparation method disclosed by the invention has rapid adsorption kinetics and stable thermodynamic properties, and has excellent acid-base response characteristics.

Owner:JIANGSU UNIV

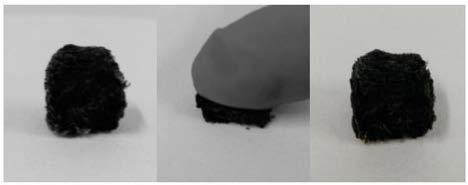

A preparation method of graphene composite foam for oil-water separation

ActiveCN106732422BGood flexibilityImprove cycle lifeIon-exchange process apparatusFatty/oily/floating substances removal devicesFreeze-dryingAnti bacteria

The invention relates to the field of polymer materials, in particular to a preparation method of graphene composite foam for oil-water separation. The preparation method comprises the steps that reduction and crosslinking are conducted on oxidized graphene by dopamine, a hydrothermal method is used to make the oxidized graphene form a three-dimensional structure in self-assembly mode, chitosan / graphene composite foam is prepared by soaking and freeze-drying with a chitosan solution, and finally the chitosan / graphene composite foam is fluoridized to prepare the fluoridized graphene composite foam. The obtained chitosan / graphene composite foam has super amphipathicity in the air and underwater super lipophobicity, after the fluoridation, the chitosan / graphene composite foam has super hydrophobicity, and chitosan and raphene have the advantages of good flexibility, high selective separation efficiency and long cycle service life; the foam can exist stably in a corrosive medium; water takes use of gravity to go through the chitosan / graphene composite foam and does not need to be driven by external force; non-toxic biological materials such as the dopamine and the chitosan are used, the foam is green and environmentally friendly, an anti-bacteria effect of the chitosan serves as a function of purifying a water body during the oil-water separation.

Owner:青岛石创科技有限公司

Magnetic separation using nanoparticles

ActiveUS10350320B2Efficient and selective separationFast bindingLavatory sanitoryDeodrantsNanoparticleAlbumin solution

Nanoparticles as described herein are configured to bind to bacterial contaminants, such as Gram positive bacteria, Gram negative bacteria, and endotoxins. The nanoparticles include a core comprising a magnetic material; and a plurality of ligands attached to the core. The ligands include, for example, bis(dipicolylamine) (“DPA”) coordinated with a metal ion, e.g., Zn2+ or Cu2+, to form, e.g., bis-Zn-DPA or bis-Cu-DPA, which can bind to the bacterial contaminants. The nanoparticles can be included in compositions for use in methods and systems to separate bacterial contaminants from liquids, such as liquids, such as blood, e.g., whole or diluted blood, buffer solutions, albumin solutions, beverages for human and / or animal consumption, e.g., drinking water, liquid medications for humans and / or animals, or other liquids.

Owner:MASSACHUSETTS INST OF TECH +1

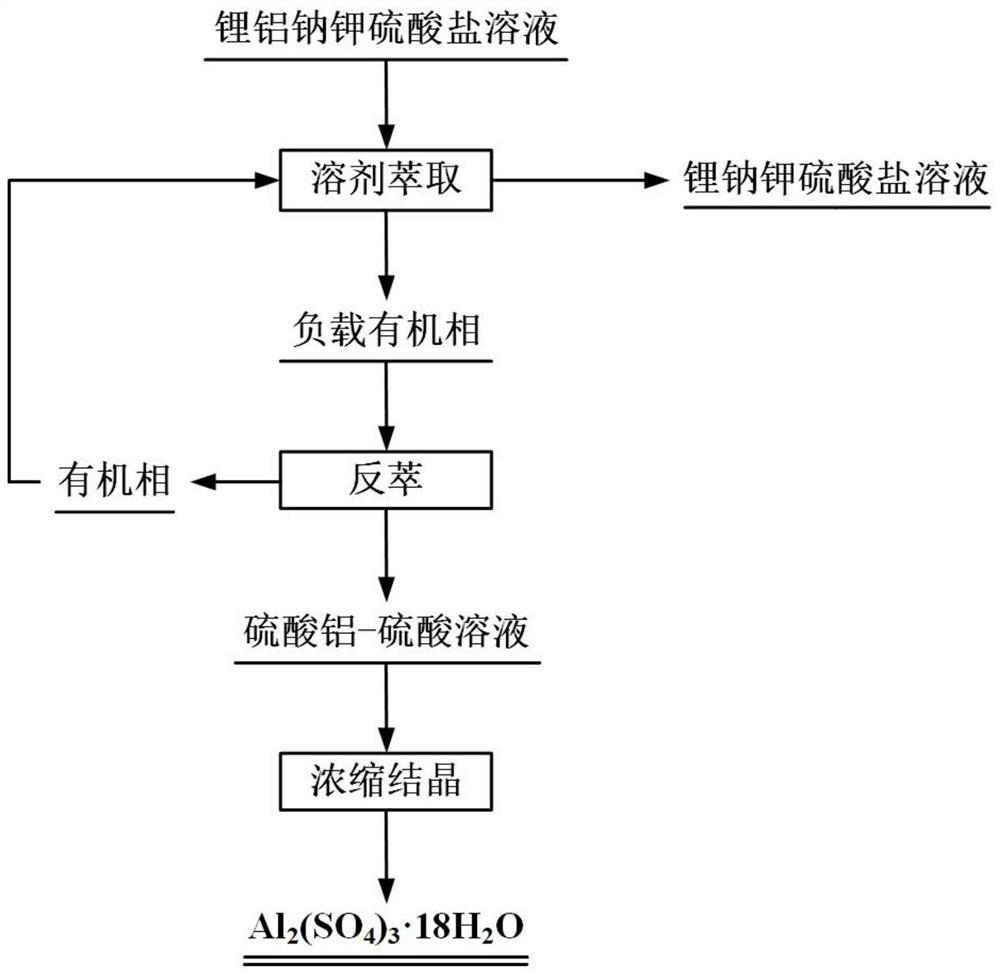

Method for selectively extracting and recovering aluminum from sulfate solution containing lithium, sodium, potassium and aluminum

ActiveCN113636582AHigh stripping rateEasy to strip and regenerateProcess efficiency improvementLithium carbonates/bicarbonatesAluminium saltsPotassium ions

The invention belongs to the technical field of ion extraction, and provides a method for selectively extracting and recovering aluminum from a sulfate solution containing lithium, sodium, potassium and aluminum, the method comprises the following steps: mixing the sulfate solution containing lithium, sodium, potassium and aluminum with an extraction organic phase, extracting and layering to obtain a loaded organic phase and a lithium-sodium-potassium sulfate solution; mixing the loaded organic phase with the strip liquor, and carrying out reverse extraction and layering to obtain an organic phase and an aluminum sulfate solution; sequentially performing evaporation, concentration and cooling crystallizationthe on the aluminum sulfate solution and obtaining Al2 (SO4) 3.18 H2O. According to the method, efficient selective separation of aluminum ions and lithium, sodium and potassium ions can be realized in a relatively wide pH value range, the extraction rate and the reverse extraction rate of the aluminum ions are very high, and high-purity Al2 (SO4) 3.18 H2O is obtained; the extraction organic phase is easy to reextract and regenerate, the extraction agent does not need saponification treatment, and the method has high economic benefits and environmental benefits.

Owner:CENT SOUTH UNIV

Method for preparing low-density lipoprotein affinity adsorption hemodialysis membrane material

ActiveCN102258946BDoes not affect the performance of the bodyPerformance is not affectedSemi-permeable membranesOther chemical processesEnvironmental resistancePhosphate

The invention belongs to the fields of membrane surface engineering and bioseparation engineering and aims at providing a method for preparing a low-density lipoprotein affinity adsorption hemodialysis membrane material. The method provided by the invention comprises the following steps: prewashing the hemodialysis membrane material; placing the prewashed hemodialysis membrane material into a plasma processor cavity; introducing inert gas and activated gas until atmosphere ingredients are constant and then carrying out plasma processing; immersing into a heparin solution; adding a coupling agent to carry out an oscillation reaction; carrying out oscillation washing by utilizing a PBS (Phosphate Buffer Solution); and repeatedly washing with clean water and perform filter drying to obtain the low-density lipoprotein affinity adsorption hemodialysis membrane material. In the method provided by the invention, active reaction groups are introduced into by utilizing a constant-pressure and low-temperature plasma activation modification processing method; the reaction is only carried out on the surface of the material, the body performance of the material is not influenced, and simultaneously the method has the characteristics of high efficiency, low cost, low energy consumption, environmental friendliness and the like; the hydrophilia and blood compatibility of the surface of a macromolecule separation membrane material can be greatly improved; and the blockage effect caused by membrane pollution in the hemodialysis course can be effectively reduced.

Owner:江苏巨之澜科技有限公司

A method for separating antimony in hydrochloric acid-chloride solution

ActiveCN109988921BEfficient separationHigh purityProcess efficiency improvementChloride saltPhysical chemistry

The invention discloses a method for separating antimony in a hydrochloric acid-chlorine salt solution, comprising: adding an oxidizing agent to the hydrochloric acid-chlorine salt solution, controlling the reaction conditions, oxidizing trivalent antimony in the solution to pentavalent antimony, and making the pentavalent antimony Antimony is precipitated to precipitate pentavalent antimony oxides, thereby obtaining pentavalent antimony oxide precipitation slurry; aging the pentavalent antimony oxide precipitation slurry to allow the pentavalent antimony oxide crystals to grow, and then solidifying Liquid separation, so as to obtain the pentavalent antimony oxide solid and the solution after antimony removal, that is, to realize the separation of antimony. The invention not only can efficiently and selectively separate antimony and has a high recovery rate of antimony, but also has simple technological process and easy operation.

Owner:BEIJING MINING & METALLURGICAL TECH GRP CO LTD

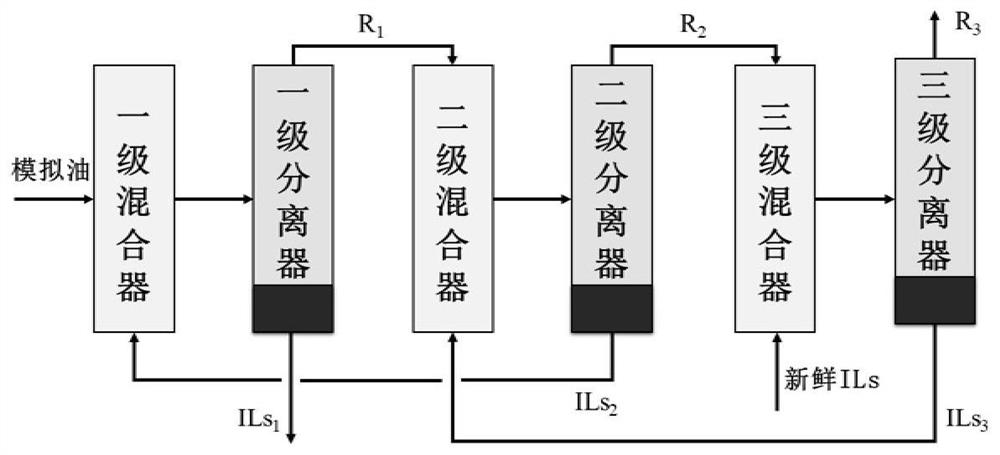

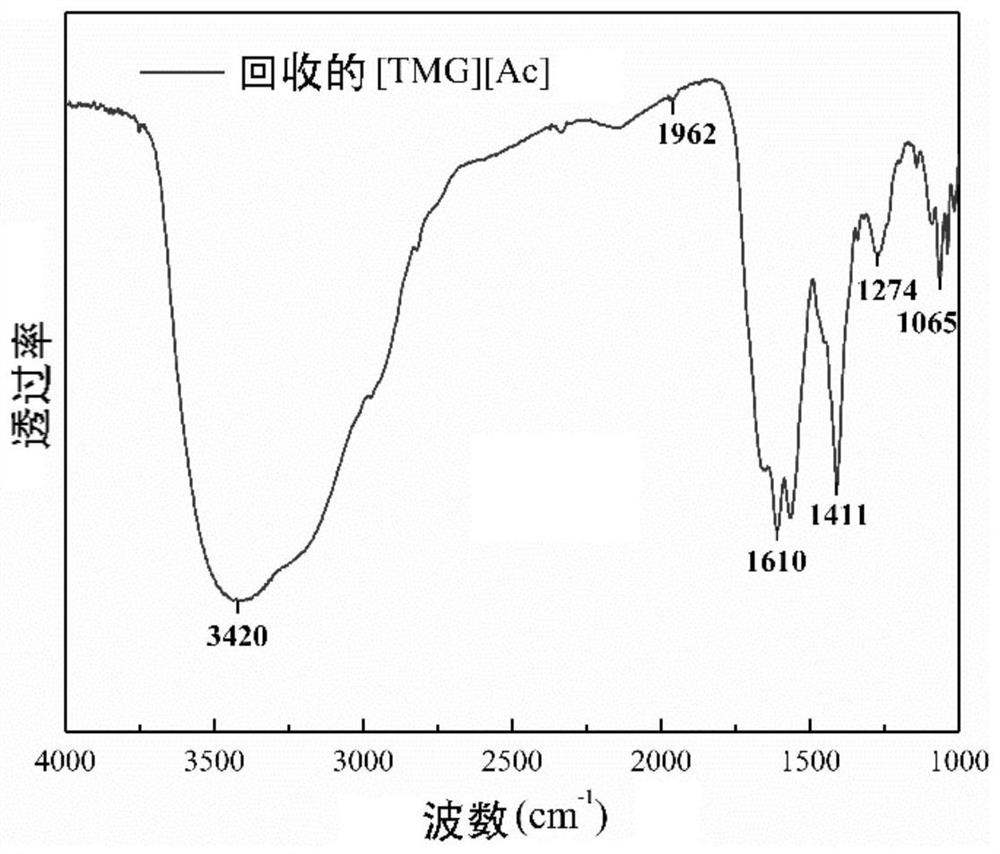

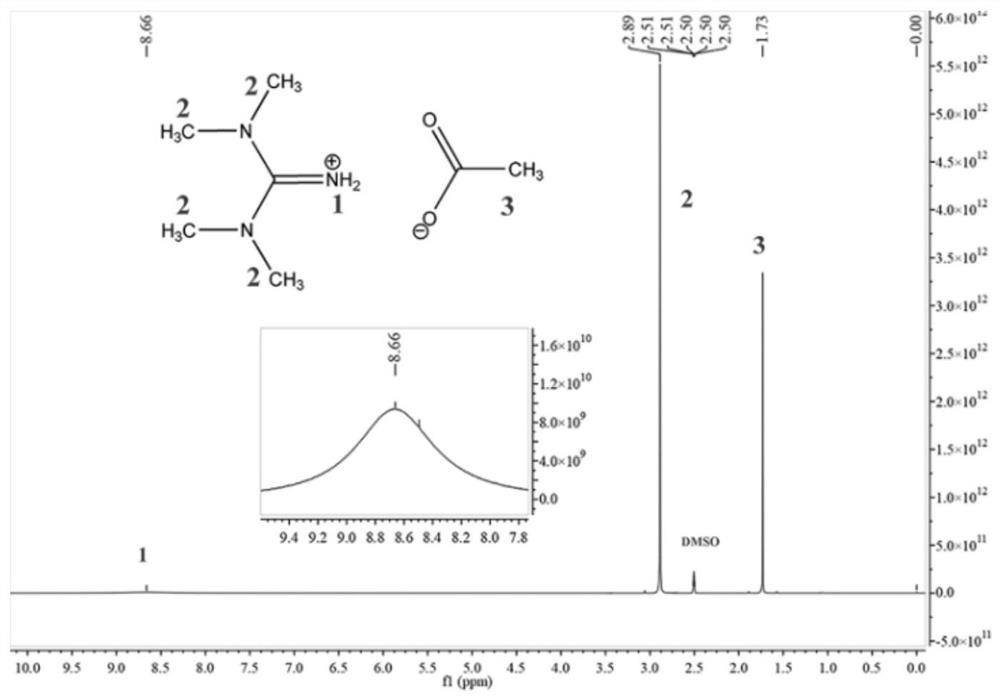

Method for extracting and separating neutral nitride in coal tar by utilizing non-toxic biodegradable ionic liquid

The invention provides a method for extracting and separating neutral nitrides in coal tar by utilizing non-toxic biodegradable ionic liquid. One or a combination of more than two of n-hexane, n-heptane, n-octane or n-dodecane is used as a solvent, and the non-toxic biodegradable tetramethylguanidyl ionic liquid is synthesized by a one-step method; and extracting and separating to obtain the neutral nitride through three-stage counter-current extraction, back extraction and reduced-pressure flash evaporation processes by taking the neutral nitride as an extracting agent. The tetramethylguanidyl ionic liquid is non-toxic, biodegradable, simple to synthesize, high in yield and purity, low in energy consumption, low in cost, small in waste liquid generation amount, green and environment-friendly. According to the method, the removal rate of high-boiling-point neutral nitrides in the wash oil and the anthracene oil is greatly increased, the excellent extraction and separation effect is achieved, and the extraction efficiency is high. The extraction and separation process is simple, and the device is reasonable; the nontoxic biodegradable tetramethylguanidyl ionic liquid is high in recovery rate and purity, can be recycled, and is safe and environment-friendly.

Owner:SHANDONG UNIV OF SCI & TECH

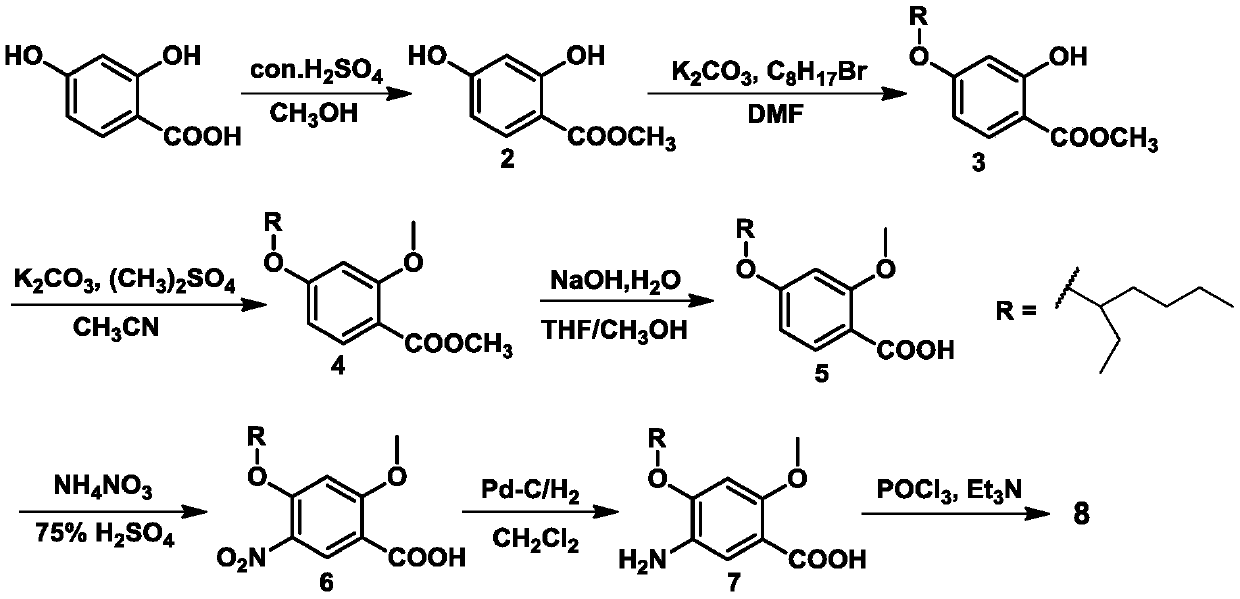

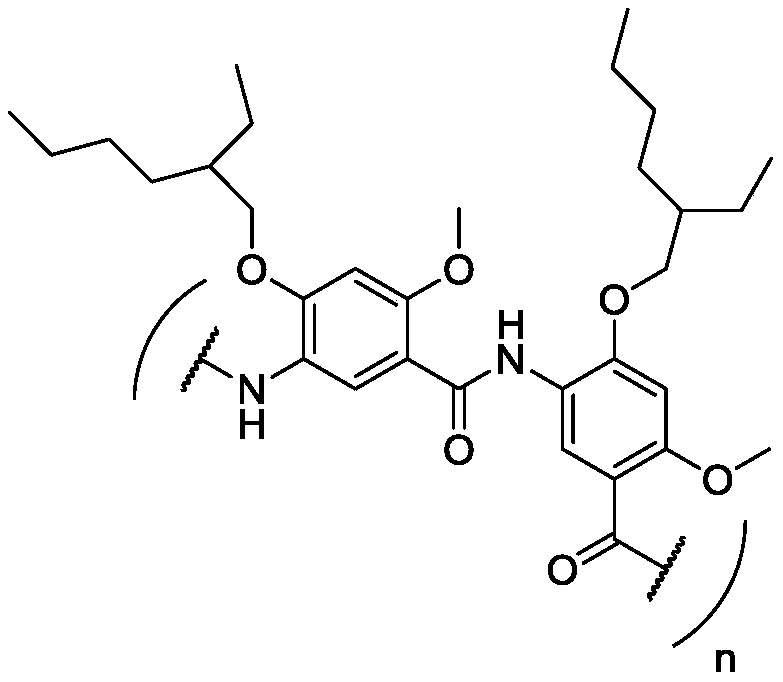

Application of asymmetric oligopolyamide extractant containing 2-ethylhexyl side chains in separation of transition metal elements

InactiveCN110358912AGuaranteed efficient selectivityEfficient and selective separationProcess efficiency improvementEthyl phosphateIon

The invention relates to an application of an asymmetric oligopolyamide extractant containing 2-ethylhexyl side chains in separation of transition metal elements, and belongs to the technical field ofnoble metal extraction recovery. Due to the fact that the extractant contains three-center hydrogen bonds, the conformation of the oligomer is in a plane meniscus shape, and the oligomer is capable of selectively complexing metal ions with an unclosed cavity and carbonyl oxygen in the cavity, so that the selective separation of the ions is achieved; and the asymmetric oligopolyamide extractant containing 2-ethylhexyl side chains is good in chemical stability and easy to synthesis and obtain, can be used for selectively separating silver from the transition metal elements under different acidity, and in addition, the extractant has the advantages of high extraction speed, high phase separation speed and the like, so that the asymmetric oligopolyamide extractant containing 2- ethylhexyl side chain has practical application prospect.

Owner:CHONGQING TECH & BUSINESS UNIV

Ionic liquid- polyacrylamide gel, preparation method and purpose thereof

InactiveCN102229688BImprove efficiencyGood reproducibilityMaterial analysis by electric/magnetic meansCross-linkElectrophoresis

The invention relates to an ionic liquid-polyacrylamide gel, a preparation method and a purpose thereof, and belongs to the technical field of protein separation and analysis. The ionic liquid-polyacrylamide gel comprises a monomer, a cross-linking agent, a gel buffer system, a catalyst, an accelerator and an ionic liquid, wherein the ionic liquid has cations having no more than 4 carbon atoms onan alkyl carbon chain, and has a mass concentration of 0.05-1.0%(w / v). The ionic liquid, the monomer, the cross-linking agent and the gel buffer system are mixed together, and added with the catalystand the accelerator to be mixed uniformly; and the mixture is solidified to obtain the ionic liquid-polyacrylamide gel. The ionic liquid-polyacrylamide gel can be applied to protein electrophoretic separation, namely, an ionic liquid-sodium dodecyl sulfate-polyacrylamide gel is used for electrophoresis separation of an SDS treated protein. Especially, for different proteins having a same or a similar molecular weight, a rapid, simple, green and efficient separation thereof can be realized.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

A method for separating polysaccharides and proteins using choline ionic liquid two-phase system

ActiveCN104861082BSelective separation greenEfficient and selective separationPeptide preparation methodsFreeze-dryingEthanol precipitation

The invention relates to a method for separating polysaccharide and protein by using a choline ionic liquid two-phase aqueous system, belongs to the technical field of bioactive substance separation and purification, and particularly relates to application of the ionic liquid two-phase aqueous system composed of choline chloride [Ch]Cl and inorganic phosphate K3PO4 in selective separation of fungal polysaccharide and protein. The method is mainly characterized by comprising the following steps: after degreasing crushed fungi mycelium or sporocarp with petroleum ether, using hot water with the temperature of 95 DEG C for reflux extraction for 8 hours, centrifuging, concentrating, dialyzing, and freeze-drying, so as to obtain a fungus aqueous extract; carrying out extraction separation by using the ionic liquid two-phase aqueous system composed of choline chloride[Ch]C1 and inorganic phosphate K3P04; carrying out lower-layer inorganic salt phase dialysis, ethanol precipitation and freeze-drying so as to obtain fungal polysaccharide; carrying out extraction on an upper-layer ionic liquid phase by using dichloromethane, concentrating and recycling an ionic liquid. The ionic liquid two-phase aqueous system provided by the invention is suitable for industrial production of active polysaccharides, has the effects of being green, quick and efficient, the ionic liquid can be recycled for use, the production cost is lowered, and the ionic liquid two-phase aqueous system can be commonly used for the selective separation of various fungal polysaccharide and protein.

Owner:东台海滨科技创业园管理有限公司

Method and reagent for increasing yield of selectively dispersed semiconducting carbon nanotubes

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Method for recycling copper indium gallium selenide from copper indium gallium selenide solar thin film battery waste

ActiveCN108359802BEfficient and selective separationEfficient recyclingPhotography auxillary processesEnergy inputIndiumSlag

The invention provides a method for recovering copper indium gallium selenium from waste of a copper indium gallium selenium solar thin film cell, and belongs to the technical field of resource secondary utilization. The method comprises the steps that the waste in a copper indium gallium selenium (CIGS) solar thin film cell chamber is smashed and milled, then is subjected to sulfatizing roastingto obtain crude selenium and roasting materials, the roasting materials are leached by adding water, and a copper sulfate product is obtained by purifying and crystallizing a water leaching solution;water leaching slag is subjected to alkaline leaching, then an alkali leaching solution is electrolyzed, and gallium metal is obtained; inorganic acid is added to alkali leaching slag for acid leaching, and metal indium powder is obtained by reducing and purifying an acidic leaching solution by formaldehyde, hydrazine hydrate, and iron powder or a mixture of two or three of the formaldehyde, the hydrazine hydrate, and the iron powder in any proportion; and acidic leaching slag is returned for sulfatizing roasting. The purity of the obtained crude selenium is larger than 98%, the purity of theobtained metal indium powder is less than 99%, and the purity of the obtained metal gallium is larger than 99%. The recovery rates of four valuable elements are all above 95%. The method for recovering the copper indium gallium selenium from the waste of the copper indium gallium selenium solar thin film cell is simple to operate, high in safety, high in reliability, and low in cost, scale production is easy to achieve, the environmental protection requirements are met, and the application prospects are broad.

Owner:UNIV OF SCI & TECH BEIJING

A method for selective flotation separation of molybdenum rhenate in alkaline leaching solution

ActiveCN110777270BEfficient and selective separationHigh recovery rateFlotationActivated carbonMeth-

The invention discloses a method for selective flotation separation of molybdenum-rhenate in alkaline leaching solution. The method is to adjust the pH value of the alkaline leaching solution containing molybdate and rhenate to 7.1-12, and then add triethylenetetramine , Tetraethylenepentamine, methyl violet 10B and cocamidopropyl betaine are organic modified activated carbon collectors and surfactants, inflated flotation, the foam product is a rhenium-rich component, and the remaining liquid is a molybdenum-rich solution . The method has good selective separation effect on molybdenum and rhenium, simple process flow and low cost, and is especially suitable for separating rhenium and molybdenum in alkaline leaching solutions with low rhenium content and high molybdenum content.

Owner:ZHENGZHOU UNIV

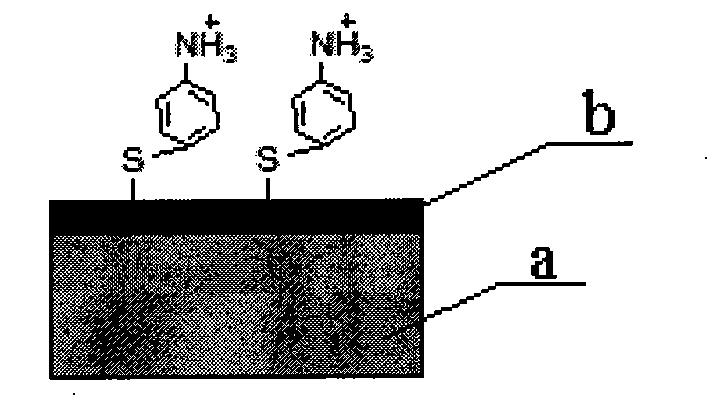

Method for separating genistein monomer from daidzein monomer

InactiveCN101525324BEfficient and selective separationHigh purityOrganic chemistryUltrafiltrationDaidzeinP-mercaptoaniline

Owner:SHANGHAI NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com