Method for extracting and separating neutral nitride in coal tar by utilizing non-toxic biodegradable ionic liquid

An ionic liquid, biodegradation technology, applied in the direction of organic chemistry, can solve the problems of by-product generation, high toxicity, poor degradability, etc., to achieve the effect of recycling, high selective separation, and increased energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

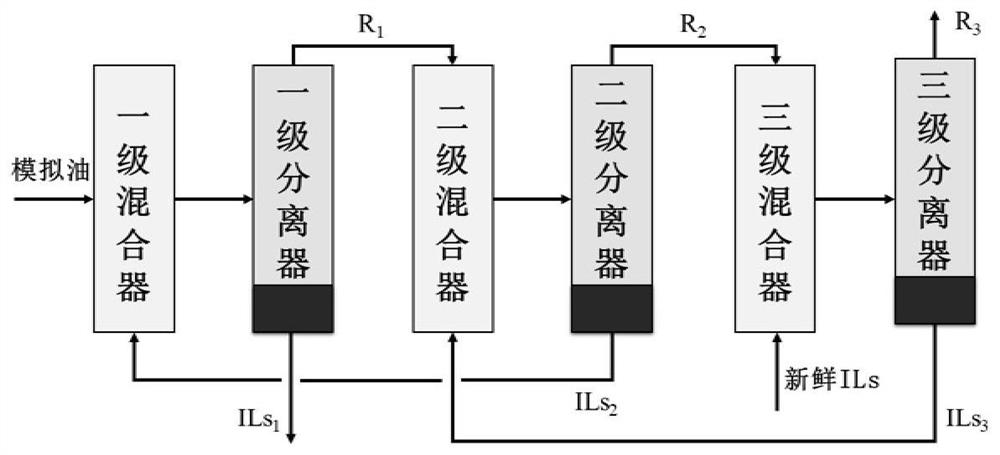

Method used

Image

Examples

Embodiment 1

[0045] A method for extracting and separating neutral nitrogen compounds in coal tar by using nontoxic and biodegradable ionic liquids, comprising the steps of:

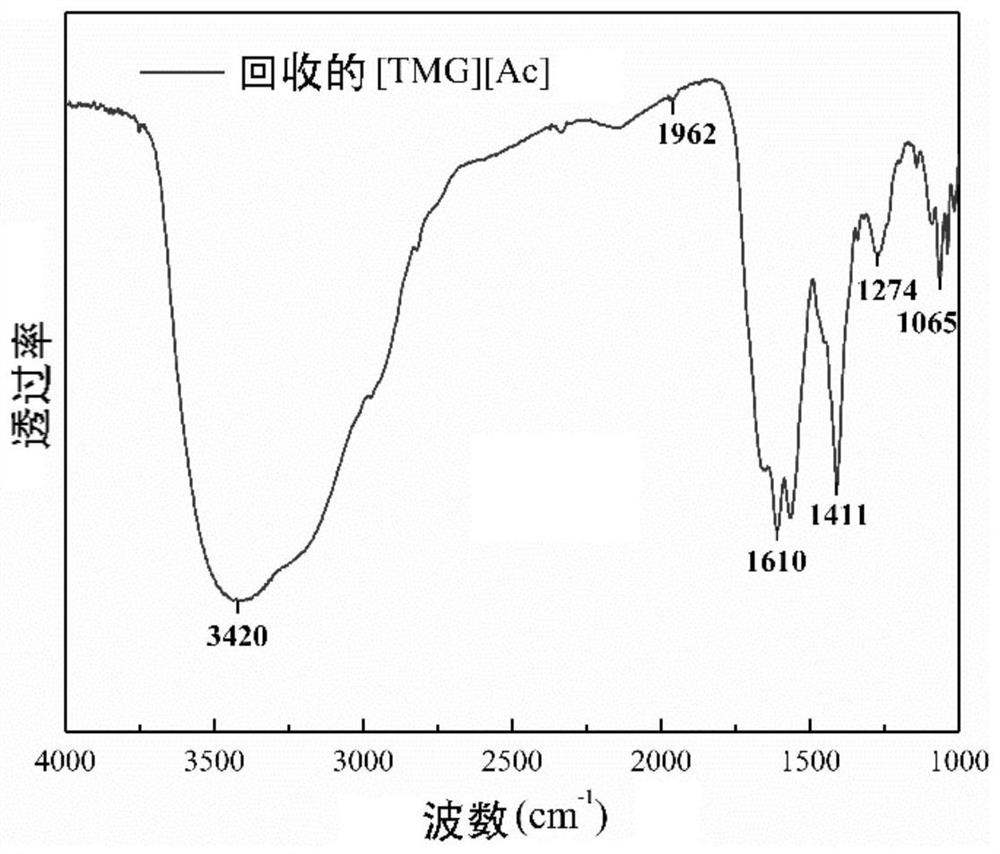

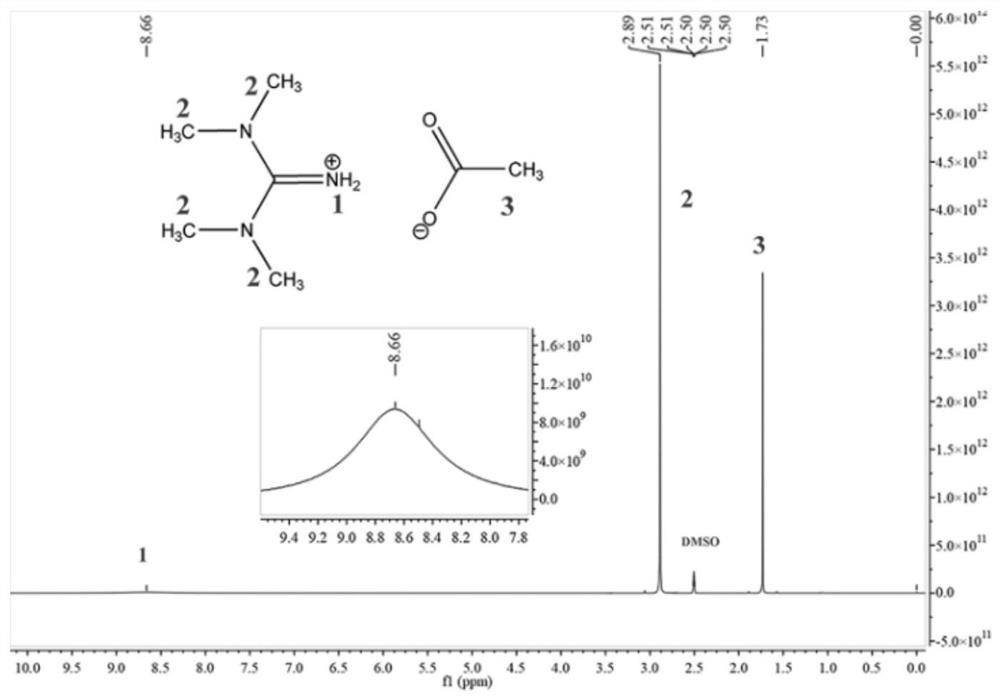

[0046] (1) Weigh the tetramethylguanidine and acetic acid used in the synthesis of the ionic liquid at a molar ratio of 1:1.2. First put tetramethylguanidine and tetramethylguanidine 3 times the volume of solvent n-hexane (tetramethylguanidine and solvent are completely miscible) into a round bottom flask, place in a magnetic stirring constant temperature water bath, set the initial temperature to 25 °C, stirring continuously to mix well. Under the condition of stirring, add the acid drop by drop into the round bottom flask through the constant pressure dropping funnel, at the beginning the dropping rate is 0.1-0.2ml / min. Adjust the rate to 0.5-1ml / min, and after adding 1 / 3 of the total mass of the acid, adjust the rate of addition to 2-6ml / min until the addition is completed. After completion, the tetramethylguani...

Embodiment 2

[0056]A method utilizing non-toxic biodegradable ionic liquid to extract and separate neutral nitrogen compounds in coal tar, as described in Example 1, the difference is: simulated oil I is replaced by simulated oil II; other steps and conditions and implementation Example 1 is consistent.

[0057] The preparation steps of simulated oil II (replacing anthracene oil) include: configure base oil according to the mass ratio of toluene:n-heptane=1:1, dissolve 1.5g carbazole and 1-3g N-methylpyrrolidone in 100g base oil Take the supernatant to obtain simulated oil II.

[0058] In this embodiment, the extraction efficiency of the neutral nitrogen compound carbazole is 99.12%, the recovery rate of the neutral nitrogen compound is 99.10%, and the recovery rate of the extraction agent tetramethylguanidine-based ionic liquid is 100.00%.

Embodiment 3

[0060] A method for extracting and separating neutral nitrogen compounds in coal tar by using nontoxic and biodegradable ionic liquids, comprising the steps of:

[0061] (1) Weigh tetramethylguanidine and formic acid used in the synthesis of ionic liquids in a molar ratio of 1:1.2. First put tetramethylguanidine and tetramethylguanidine 3 times the volume of solvent n-hexane (tetramethylguanidine and solvent are completely miscible) into a round bottom flask, place in a magnetic stirring constant temperature water bath, set the initial temperature to 25 °C, stirring continuously to mix well. Under the condition of stirring, add the acid drop by drop into the round bottom flask through the constant pressure dropping funnel, at the beginning the dropping rate is 0.1-0.2ml / min. Adjust the rate to 0.5-1ml / min, and after adding 1 / 3 of the total mass of the acid, adjust the rate of addition to 2-6ml / min until the addition is completed. After completion, the tetramethylguanidine-ba...

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com