Patents

Literature

72 results about "Carbolineum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Carbolineum is an oily, water-insoluble, flammable, dark brown mixture from coal tar components, smelling of tar. It contains among other things anthracene and phenol. Because of its rot-resisting and disinfecting effect, Carbolineum was used over many years for the preservation of wooden structures such as railroad ties, telephone poles, cabins, etc.

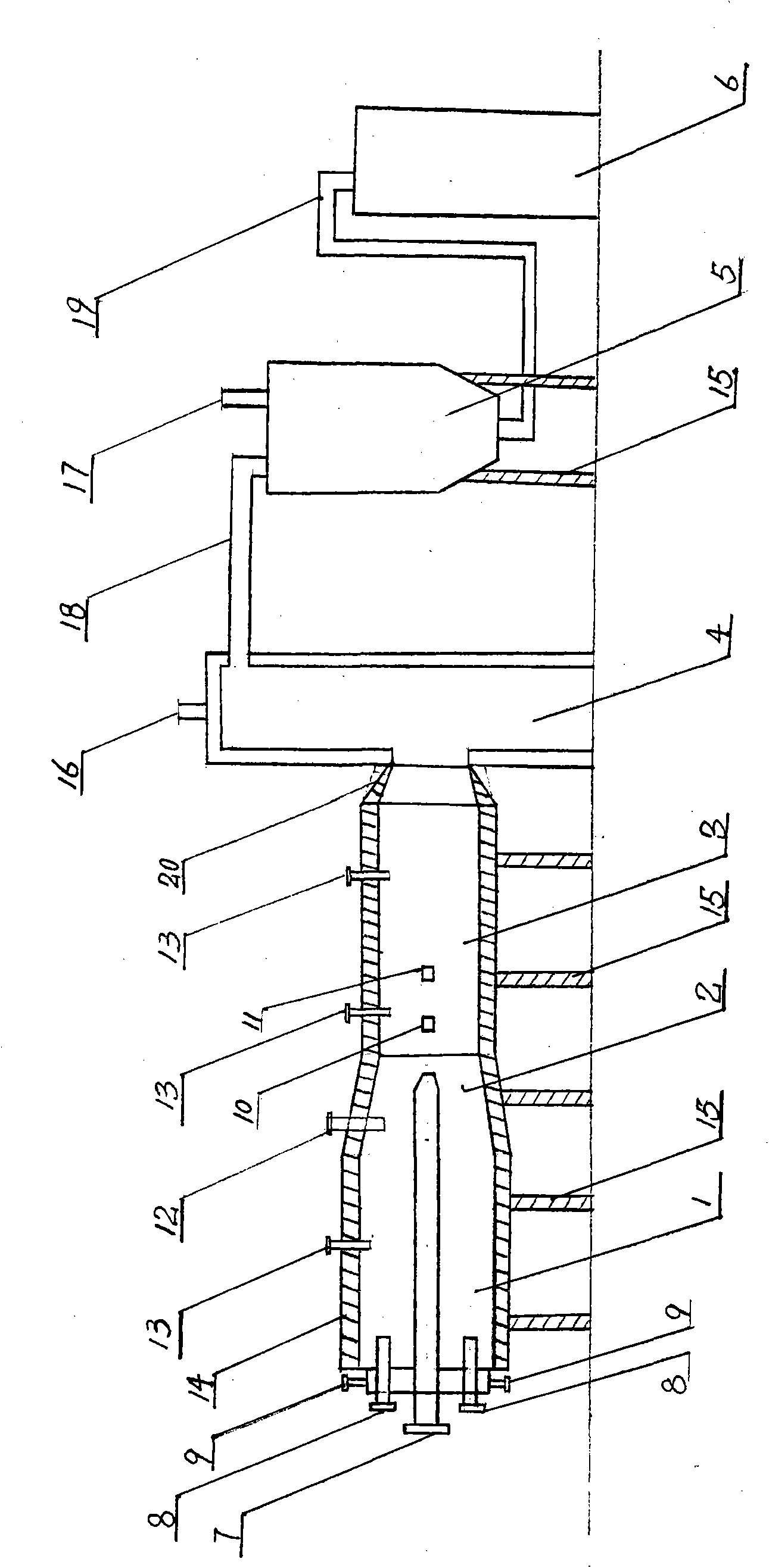

Two-tower type pressure reducing coke tar distillation process and apparatus therefor

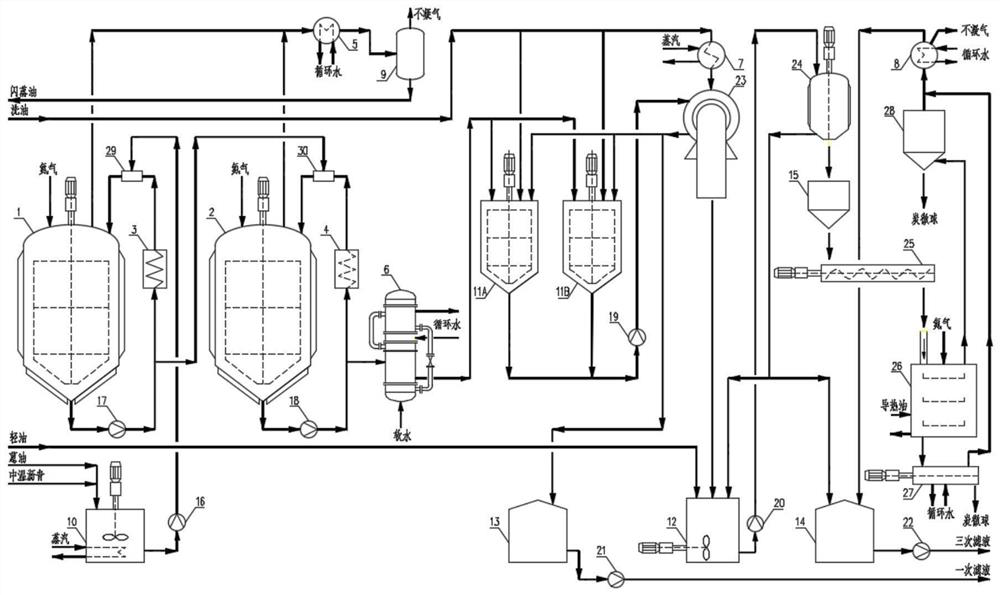

ActiveCN101475819ASolve the technical problems of dealing with large-scale tarShort processTar working-up by distillationReboilerHeat conducting

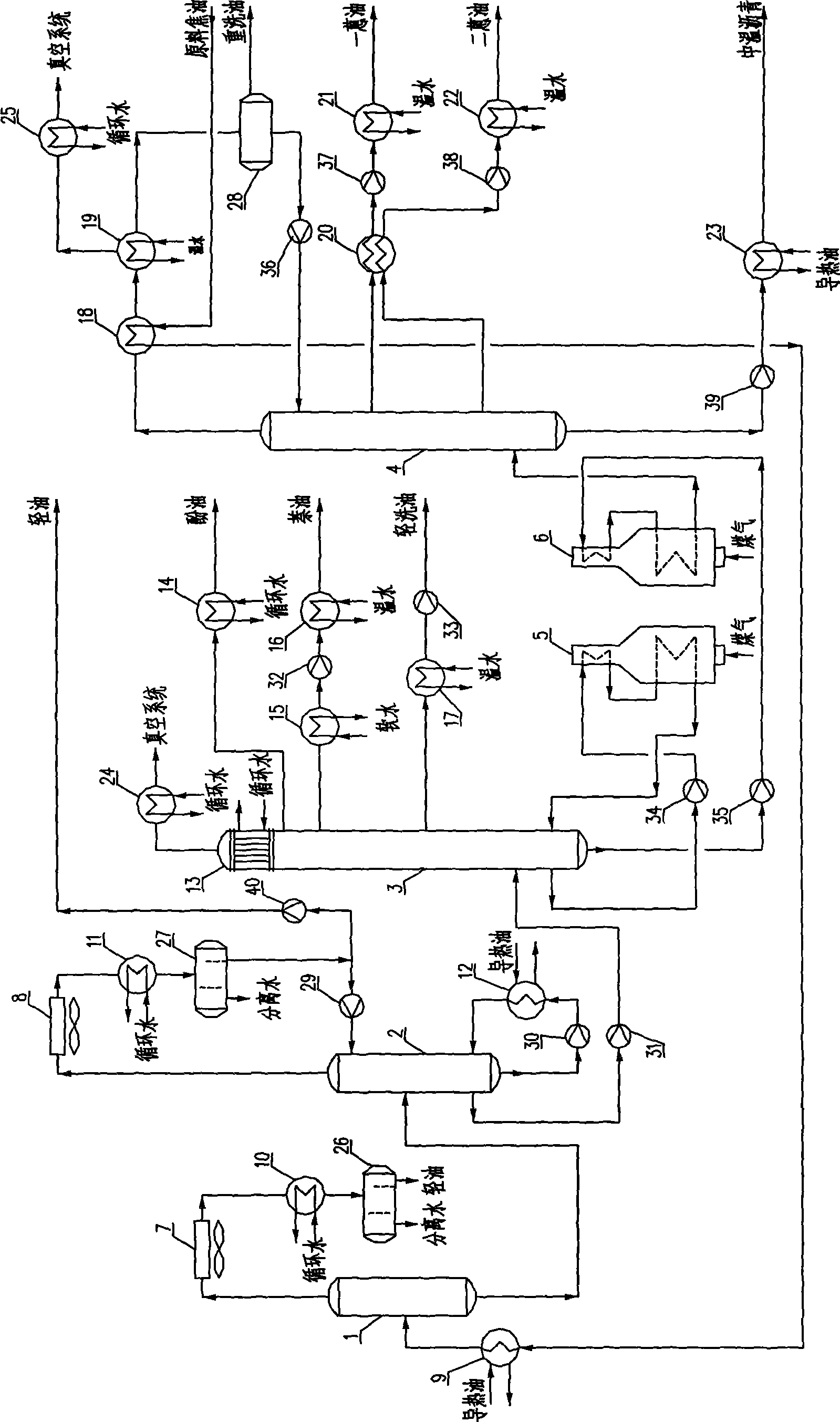

The invention relates to a two-tower type process for distilling vacuum tar and a device thereof. The process comprises the following steps: removing the moisture and light oil distillate of raw tar in a pre-dehydration tower and a dehydration tower at normal pressure; performing decompressing operations in a No.1 distillation tower to obtain carbolic oil, naphthalene oil and light washing oil distillate; and performing decompressing operations in a No.2 distillation tower to obtain heavy washing oil, first anthracene oil, second anthracene oil and mid-temperature pitch. The heat for the pre-dehydration tower and the dehydration tower is supplied by heat conducting oil; the heat for the No.1 distillation tower is supplied by heating the mixed oil on the bottom of the tower circularly in a No.1 tubular heating furnace; and the heat for the No.2 distillation tower is supplied by heating the mixed oil on the bottom of the No.1 distillation tower in a No.2 tubular heating furnace and then performing flash distillation on the mixed oil on the bottom of the No.2 tower. The main devices comprise the dehydration tower, the No.1 distillation tower, the No.2 distillation tower, a dehydration tower reboiler, the No.1 tubular heating furnace, the No.2 tubular heating furnace, a heat exchanger for each distillate, a cooler, a steam generator and the like. The process has the advantages of short technological flow, less device investment, and less energy consumption, thus the process is applicable to large scale coal tar processing engineering.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Modified coal tar, and producing method

InactiveCN1760331AIncrease electrode contentHigh strengthWorking-up pitch/asphalt/bitumen by chemical meansSmall footprintPhenol

A modified coal asphalt with linear resin molecule structure and adjustable softening point is prepared from one or more of coal tar, antracene oil, phenol oil, naphthelene oil and the coal asphalt with softening point lower than 130 deg.C through using acid to regulate pH value, and polymerizing reaction on formaldehyde or tripolyformaldehyde or polyformaldehyde which controlling temp, pressure and time.

Owner:任利华

Process for producing needle coke from compounded and blended components such as washing oil, anthracene oil and asphalt in medium and low temperature coal tar as raw materials

InactiveCN107868671AEasy to handleStrong targetingCoking carbonaceous materialsTar working-up by solvent extractionCarbolineumCalcination

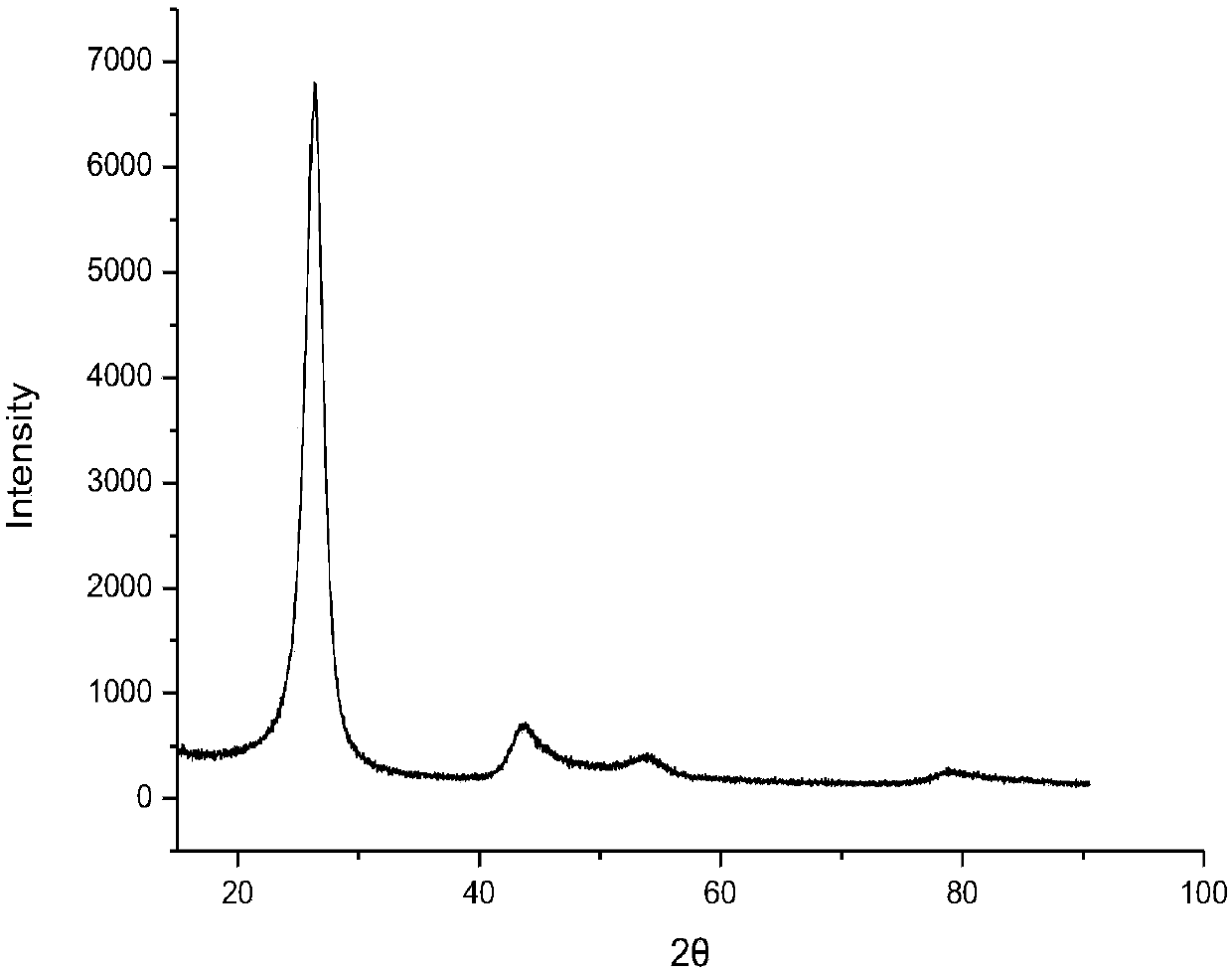

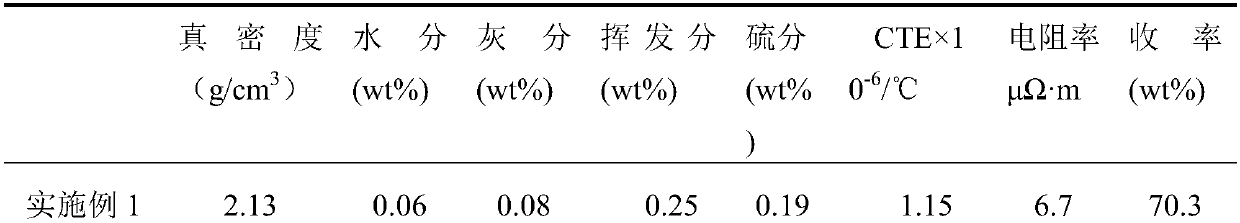

The invention provides a process for producing needle coke from compounded and blended components such as washing oil, anthracene oil and asphalt in medium and low temperature coal tar as raw materials. The process comprises the steps as follows: raw material pretreatment of the medium and low temperature coal tar, fraction cutting of the components such as the washing oil, the anthracene oil andthe asphalt in the medium and low temperature coal tar, blending of the compounding raw materials, and preparation of the needle coke with thermal polymerization and calcination processes. The ideal raw materials for the needle coke are prepared from fractions of the coal tar by compounding and blending, formation of a wide-area ordered fibrous structure from an intermediate phase can be greatly promoted in a thermal polymerization process by means of reasonable raw material components, and a needle coke product with excellent performance is obtained after calcination.

Owner:SHAANXI YULIN ENERGY GRP CO LTD +1

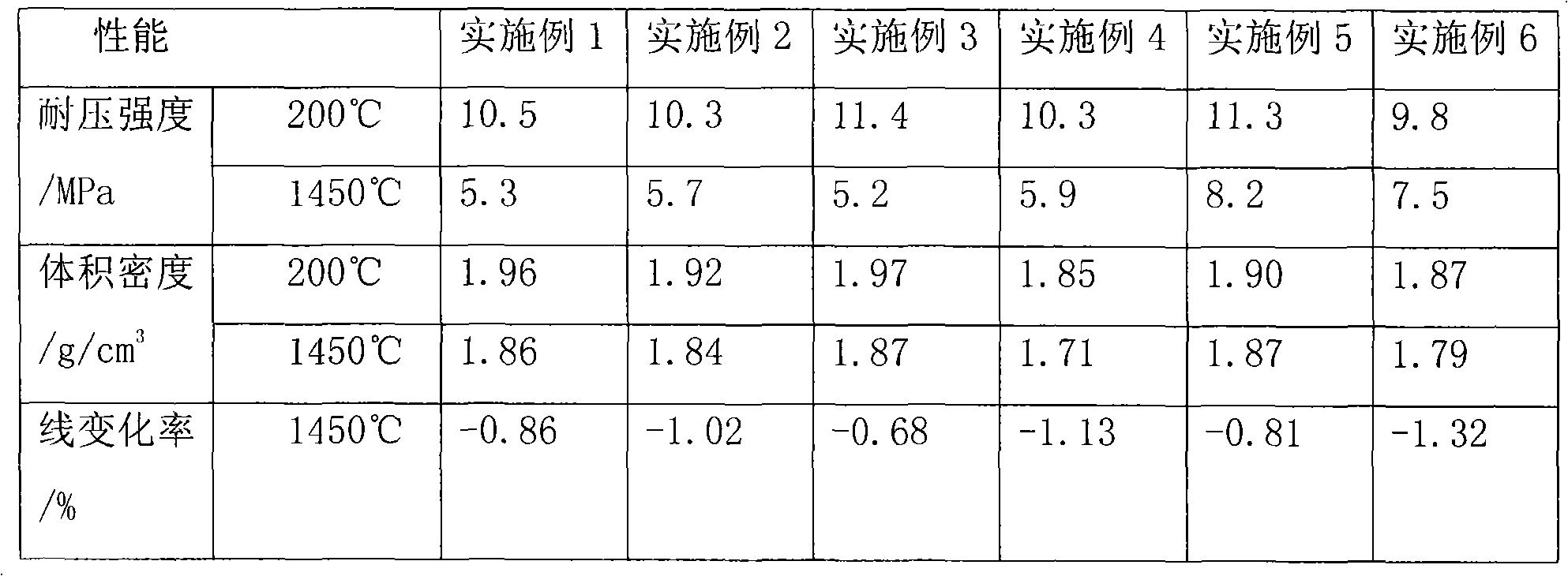

Blast furnace taphole clay and manufacturing technology method thereof

InactiveCN101602604AHigh strengthImprove environmental performanceBlast furnace componentsBlast furnace detailsManufacturing technologyRefractory

The invention relates to taphole clay for maintaining the a blast furnace iron notch and a preparation method thereof, aiming at solving the defects of heavy population or high cost caused by the full application of tar, carbolineum or phenolic resin, difficult low temperature tapping, complex process, and the like of the prior art. The measure is as follows: the blast furnace taphole clay, which is characterized by including the components according to parts by weight: 70 to 97 parts of refractory material matrix, 5 to 15 parts of carbon-containing material and 15 to 30 parts of composite binder, wherein the carbon-containing material is asphalt or regenerative carbon powder; and the composite binder is the mixture of phenolic resin and tar. The technology comprises the following steps: the components formed the refractory material matrix are uniformly mixed and are heated to the temperature ranging from 30 to 100 DEG C; the carbon-containing material is heated to 20 to 80 DEG C; the composite binder is heated to 35 to 90 DEG C; the heated refractory material matrix is stirred with the carbon-containing material for 5 to 15min; the heated composite binder is added into the mixture obtained in the last step, and the action of rolling compaction is executed for 20 to 60min; and the rolled and compacted materials are added into an extruder to be shaped and packed for standby use. The invention has the advantages of low pollution, favorable strength of the taphole clay, high application property, favorable associativity of old and new taphole clay and simple process.

Owner:WUHAN IRON & STEEL (GROUP) CORP

Anhydrous stemming for blast furnace

InactiveCN102584284AMeet the requirements of intensified smeltingGuarantee normal productionCarbide siliconAnthracene

The invention discloses anhydrous stemming for a blast furnace. The anhydrous stemming is made of the following raw materials in percentage by weight: 16-22 percent of alumina, 18-22 percent of coke, 14-16 percent of clay, 18-22 percent of composite powder, 6-7 percent of modified pitch, 4-6 percent of kyanite and 11-18 percent of composite binder. The composite binder consists of tar and anthracene oil, wherein the weight ratio of tar to anthracene oil is 3:7. The composite powder consists of the following raw materials in percentage by weight: 34-38 percent of brown aluminum oxide, 14-18 percent of sericite, 18-22 percent of silicon carbide and 26-30 percent of silicon nitride. The anhydrous stemming for the blast furnace has the advantages that the qualification rate of iron notch depth is improved, the opening leakage and reopening rate and the dill immobility rate are reduced, the molten iron drainage time is prolonged, the anti-scouring and anti-erosion capacity is stronger, theprobability of iron notch opening leakage and the moisture of the iron notch are greatly reduced and the material consumption during iron notch opening at the front of the furnace is lower.

Owner:CHONGQING SHENGZHU SCI&TECH DEVCO

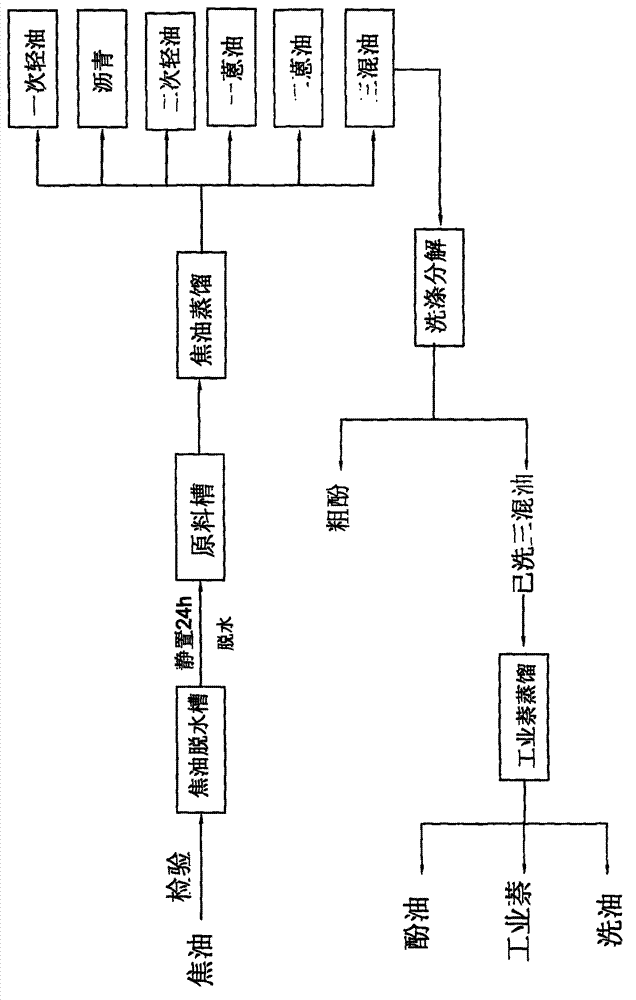

Processing method of coal tar

InactiveCN103242902AAvoid pollutionReduce energy consumptionTreatment with plural serial refining stagesWater insolubleDistillation

The invention relates to a processing method of coal tar. The processing method is characterized by comprising the following steps of: dewatering tar; distilling the tar; sequentially distilling the dewatered tar by adopting continuous type distillation devices, namely a first-stage evaporator and a second-stage evaporator, to respectively obtain light oil, asphalt, anthracene oil II, anthracene oil I, mixed oil III; washing and decomposing: alkalizing the mixed oil III to generate water-soluble phenoxide which can be separated from water-insoluble naphthalene washing distillates so as to provide a raw material for industrial naphthalene; evaporating the separated neutral phenoxide to obtain pure sodium phenolate; decomposing by using sulphuric acid to finally obtain crude phenol of which phenol content is more than or equal to 83%; and distilling industrial naphthalene: dewatering washed mixed distillates, carrying out heat exchange with industrial naphthalene steam to 190-210 DEG C, cutting phenol oil distillates in a primary distillation tower, and cutting the industrial naphthalene and wash oil distillates in a rectifying tower. The process method disclosed by the invention is simple and reasonable in process, reduces the energy consumption and plays an energy conservation role by sufficiently utilizing the afterheat of products in the distillation process of the tar and prevents the flue gas from polluting the environment by arrangement of an exhaust cleaning tower in a washing and decomposing procedure.

Owner:新疆宝鑫炭材料有限公司

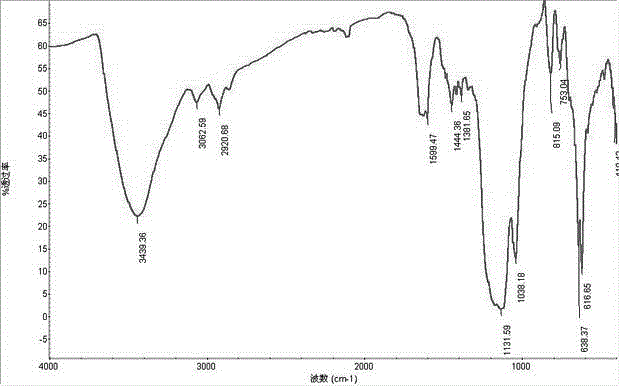

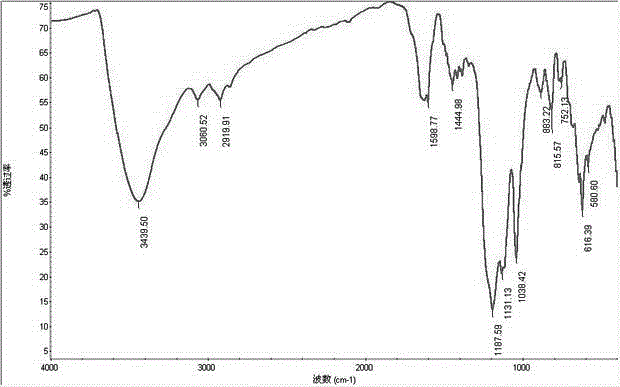

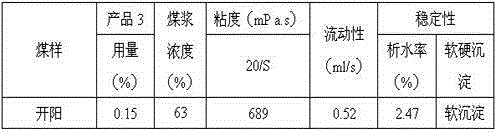

Tar-type coal water slurry additive prepared from composite raw materials and production technology of tar-type coal water slurry additive

InactiveCN105695001ADeployment ratio wideWide variety of sourcesLiquid carbonaceous fuelsFuel additivesAnthraceneCoal water

The invention discloses a tar-type coal water slurry additive prepared from composite raw materials and a production technology of the tar-type coal water slurry additive.The tar-type coal water slurry additive is synthesized by mixing the main materials such as scrubbing oil, naphthalene oil, anthracene oil and papermaking wastewater in different mass ratios, subjecting a mixture to processes such as sulfonation and condensation, and adding a pore blocking agent carbonate into a synthesized product.The tar-type coal water slurry additive has the advantages that the tar-type coal water slurry additive has the characteristic of general dispersants, namely improvement in coal surface hydrophility; electrostatic repulsion among particles is enhanced, so that improvement in coal slurry fluidity is benefited; since strong stereo-hindrance effect is generated, slurry rheologic stability is achieved; the tar-type coal water slurry additive has specific cooperative synergism characteristic, and accordingly mutually complementary cooperative synergism is achieved; the tar-type coal water slurry additive is good for slurry forming ability of coal types different in coalification degree, is particularly applicable to low-rank coal, and is high in slurry forming concentration and excellent in coal slurry fluidity and stability under the condition that additive coal-based consumption is not more than 1.0%.

Owner:兖矿水煤浆气化及煤化工国家工程研究中心有限公司

Wettable cathode paste and its using method

The invention relates to a cathode paste for slit connection between the moistening cathode blocks of aluminum cell and method of use, wherein the cathode paste comprises binder with 1:4-5 weight ratio and dry matter with 8mm particle size, the composition by weigh percent of the dry matter is, calcinations anthracite coal 10%-60%, calcinations petroleum coke 5%-15%, metallurgy coke 5%-30%, TiB2 15%-60%, coal pitch 20%-80% containing 5%-20% wt. percent of artificial graphite or native graphite, coal tar 5%-80%, anthracene oil 5%-40% as binder.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

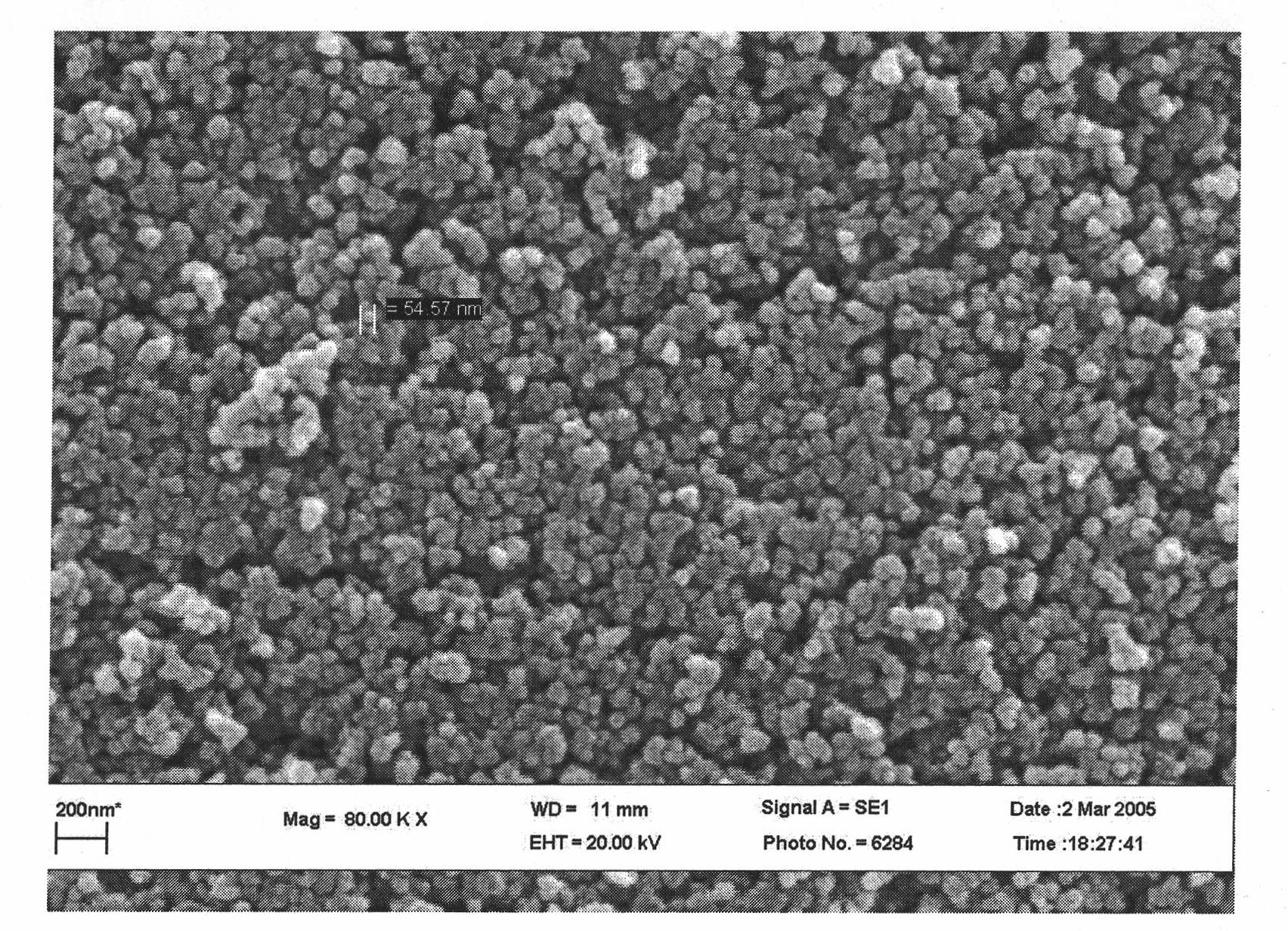

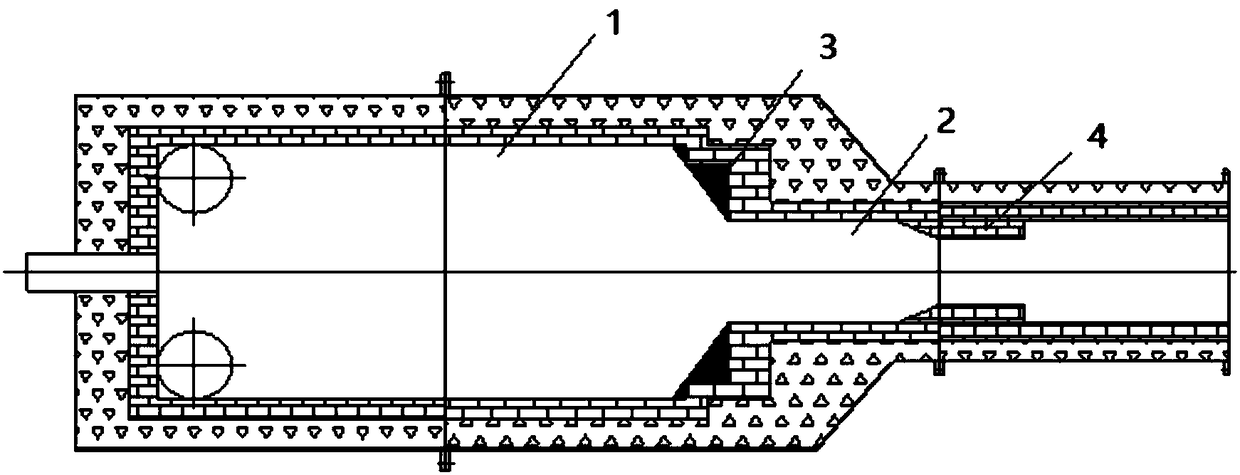

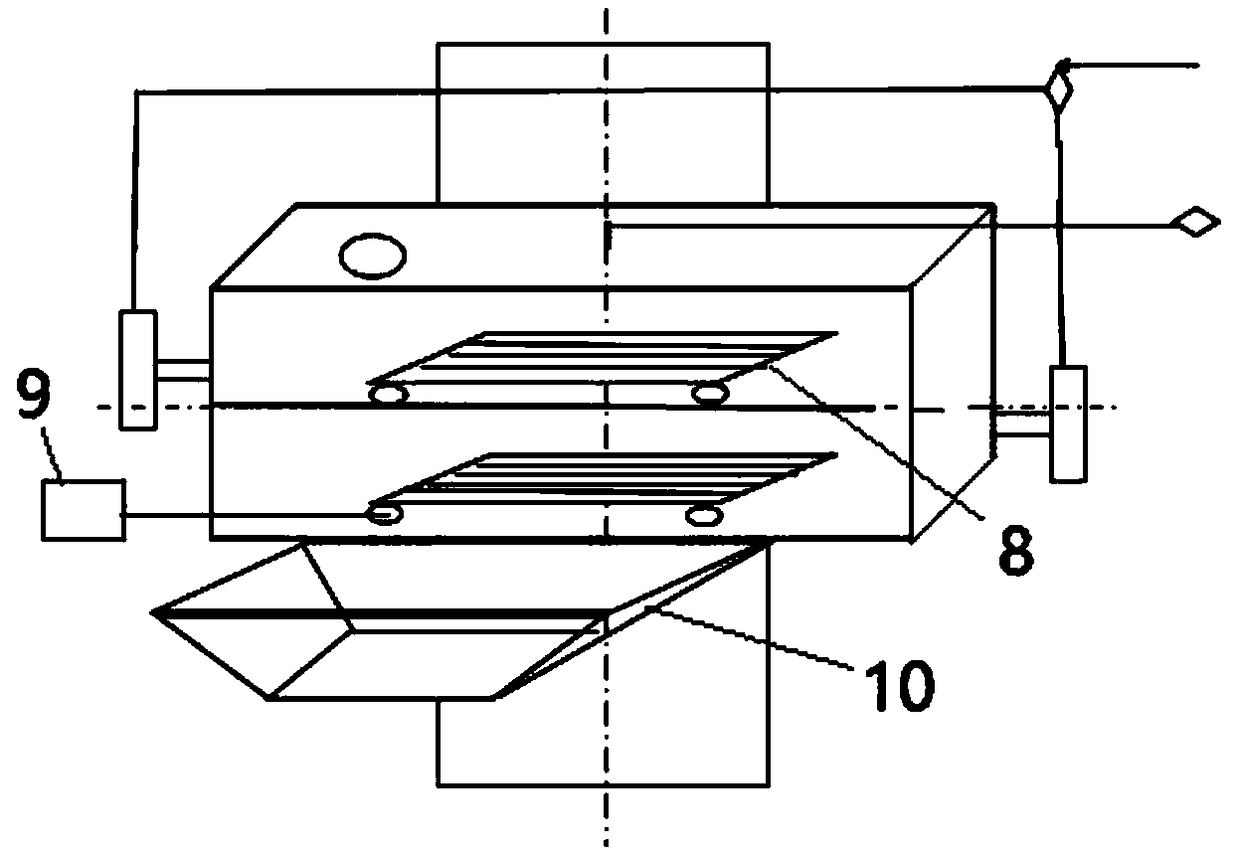

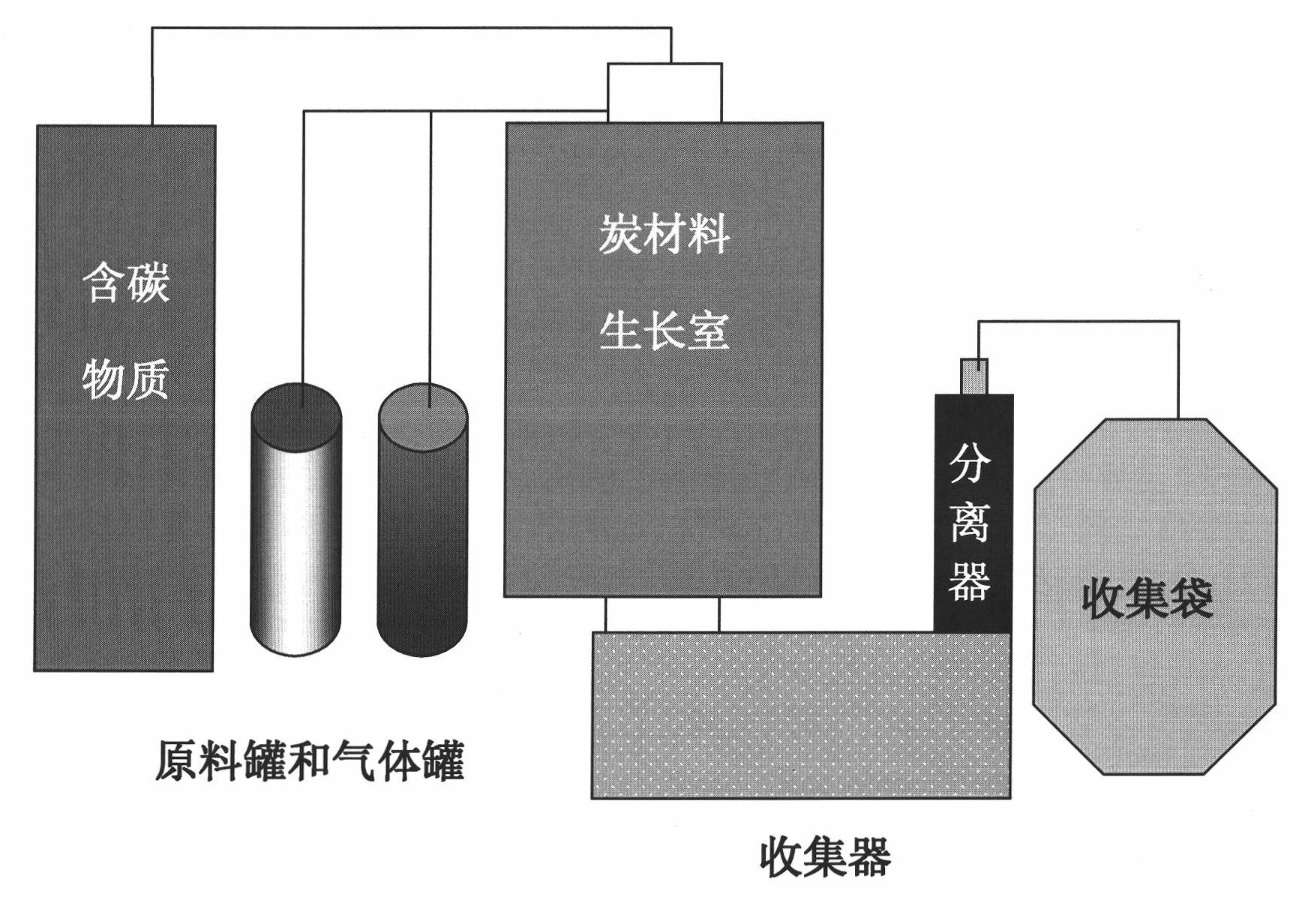

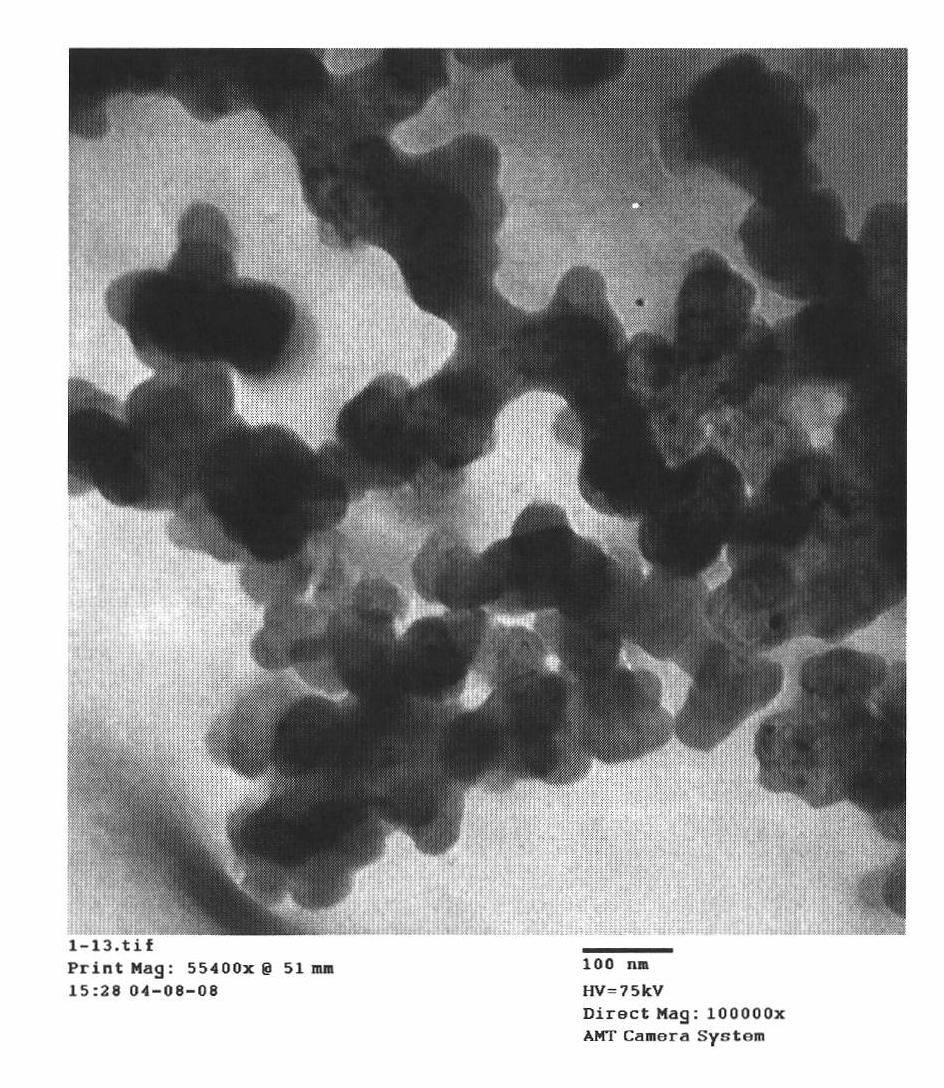

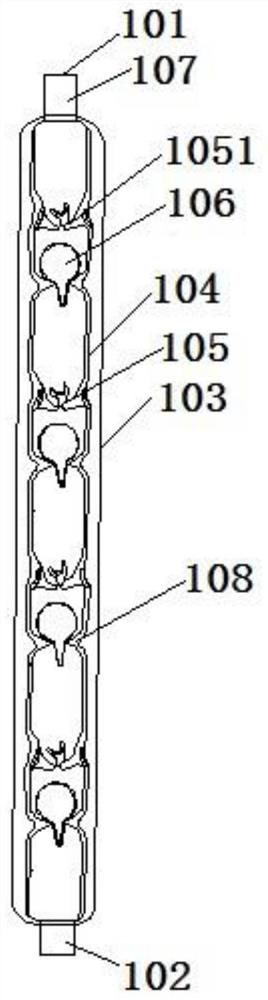

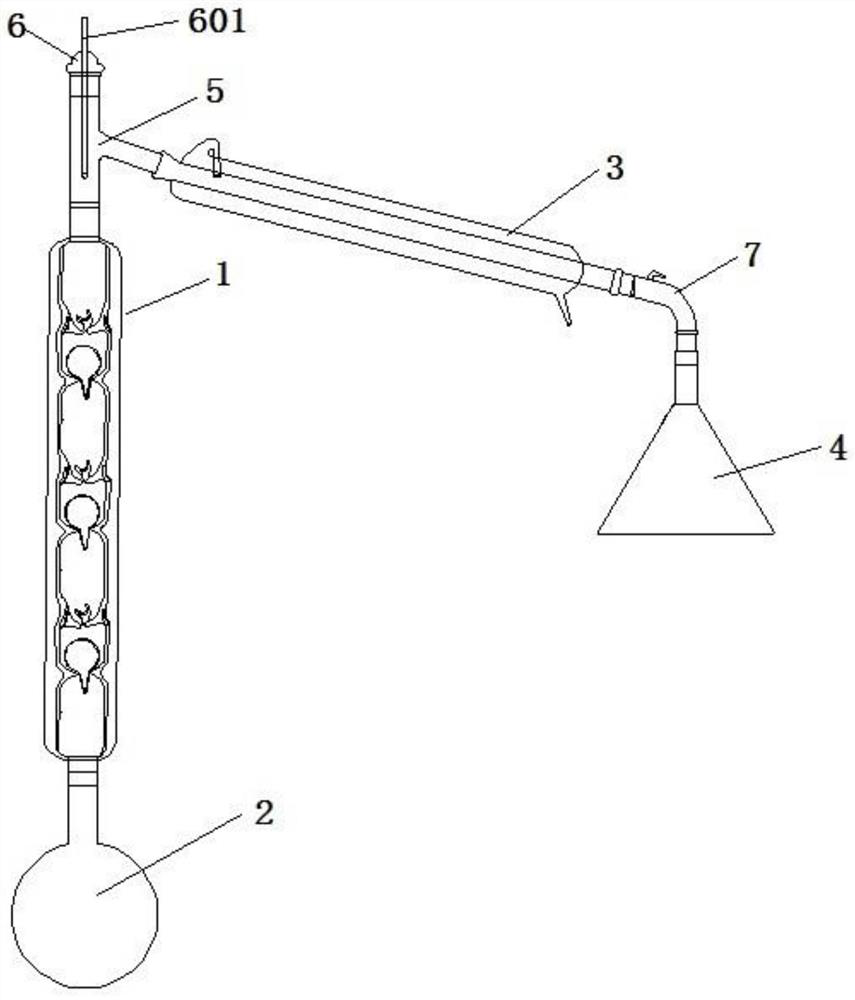

Process and equipment for continuously preparing nano carbon ball

The invention provides a process and equipment for continuously preparing nano carbon ball, wherein carbon-containing raw materials such as aromatic hydrocarbons heavy oil, coal tar, mixed benzene, coke-oven gas, anthracene oil, naphthalene oil, phenol oil, CH4 or C2H2 are applied; natural gas is used as fuel, and combusted with air through a heating stove to provide reaction heat for a cracking furnace; the other part of carbon-containing raw materials flows in a rate of 1000-3000 m3h-1, and is gasified and sprayed into the heated cracking furnace, simultaneously, catalyst and auxiliary agent are sprayed into the heated cracking furnace; raw materials undergo cracking reaction at the reaction temperature with isolation and dilution of protection gas; the product obtained from the cracking reaction is sent to a heat exchanger to be cooled by heat exchange; and solid nano carbon balls are obtained after being separated by a separator. The invention realizes continuous production of nano carbon material from gas by cracking reaction in the cracking furnace, is suitable for the application of a plurality of carbon raw materials with low cost for industry use, and utilizes heat which is by-product of raw materials to meet the need for keeping the reaction furnace temperature, and thus power consumption is reduced, production cost is saved, and nano carbon balls are prepared continuously with reduced cost.

Owner:乌鲁木齐西峰合创石油化工有限责任公司 +1

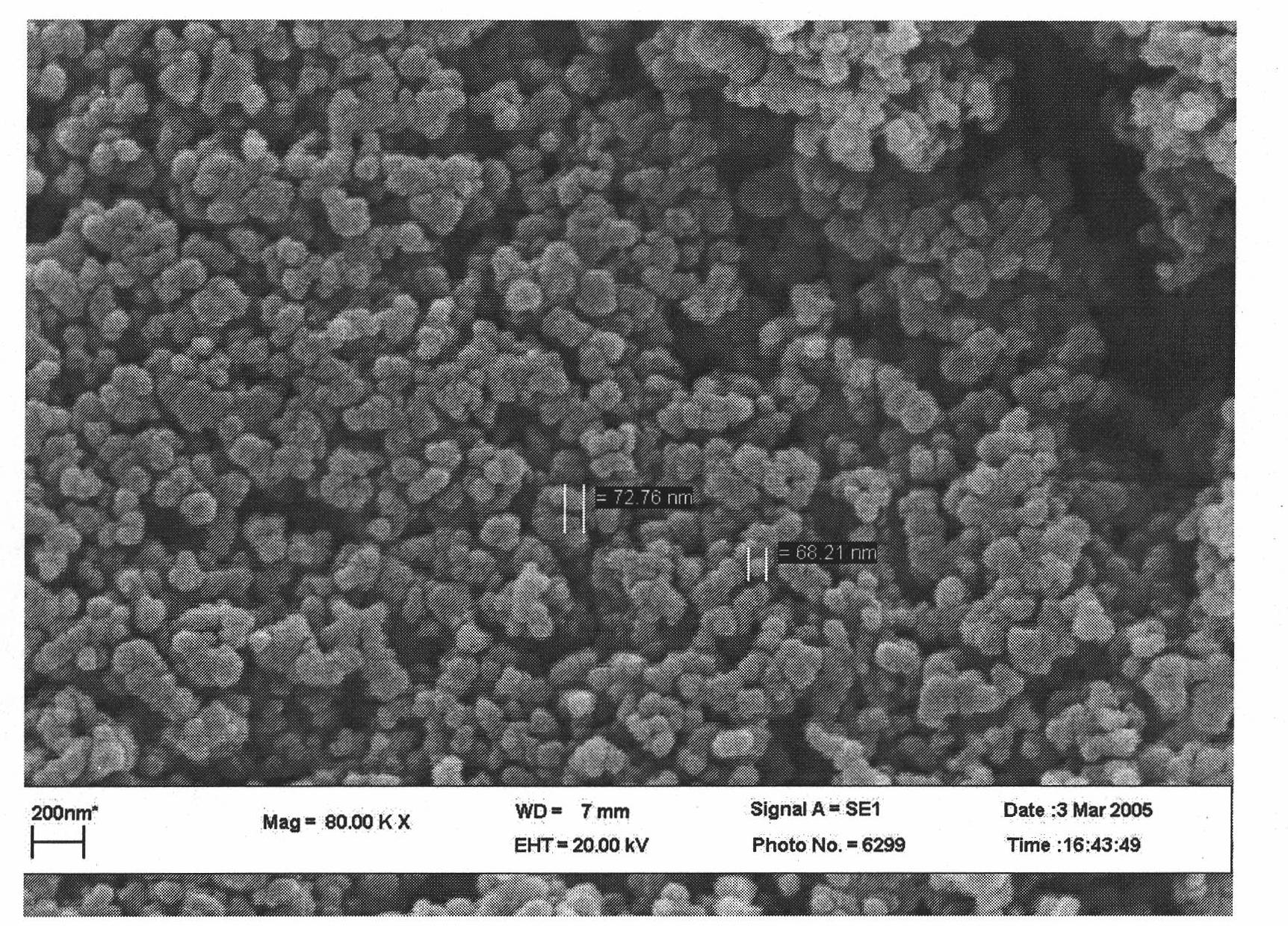

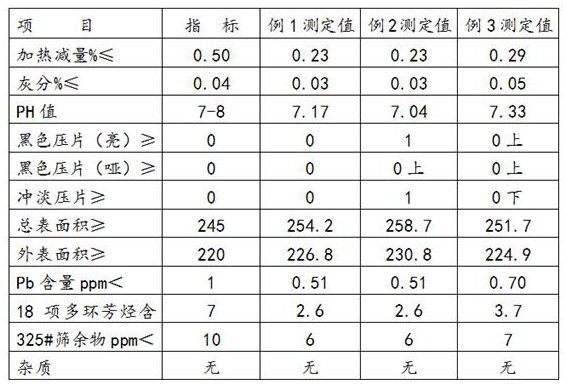

Production method of high-purity conductive carbon black

The invention provides a production method of high-purity conductive carbon black. According to the method, anthracene oil is taken as raw oil for producing conductive carbon black, when the anthracene oil is subjected to heating distillation, the quantity of fractional distillation at 360 DEG C is larger than 68%, and the quantity of fractional distillation at temperature lower than 300 DEG C issmaller than 10%. A carbon black generation reaction is executed in a multi-stage reaction furnace under the condition that the temperature of a reaction stage of the reaction furnace is kept at 1700-1760 DEG C; pure soft water is taken as process quenched water to terminate the carbon black cracking reaction and serves as secondary quenched water, and impurity-free high-purity powdery carbon black is obtained; the pure soft water as granulation water is mixed with an adhesive in a static mixer, the impurity-free high-purity powdery carbon black is mixed for granulation with the granulation water and the adhesive in a granulator, a small amount of diesel oil is added to serve as a granulation aid in the granulation process, and high-purity conductive carbon black particles are obtained. The particles produced with the method have high dispersity, low resistance, stable structural performance and high purity, are uniform and are conveniently produced and processed by a customer.

Owner:HANCHENG HEIMAO CARTON BLACK

Tecnique for producing mesothermal and modified asphaltum in intermittent single kettle type

InactiveCN1563278ASimple production processTechnical operation is easy to controlWorking-up pitch/asphalt/bitumen by distillationEngineeringTower

A method for preparing mesotherm and modified asphalt in single tower at onece time includes dewatering coal tar material to be water content less than or equal to 5%, heating hearth temperature to be 800-900 deg.C for causing negative pressure at interval tower with vacuum degree of 0.04-0.075 Pa, heating and distilling to extract out trivalent oil and anthrasol, obtaing mesotherm asphalt by cooling residue and heating mesotherm asphalt to obtain modified asphalt through cooling.

Owner:朱小花

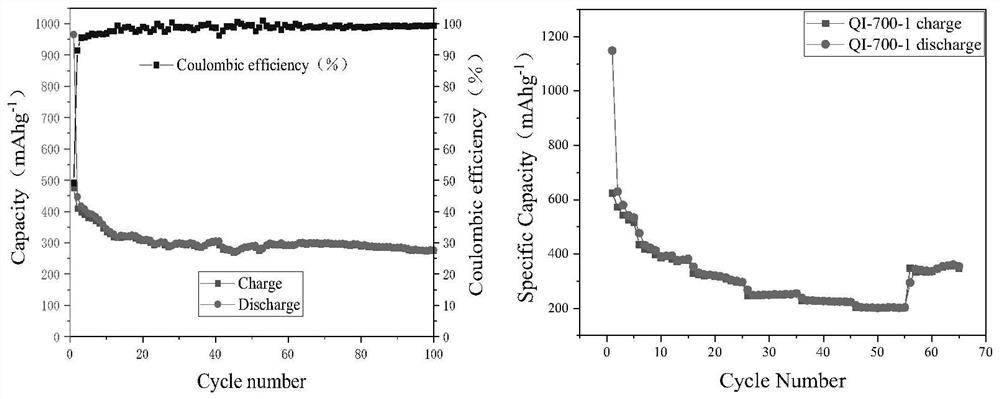

Preparation method for carbon cathode material of lithium ion battery

InactiveCN103346326ARaise the ratioImprove electrical performanceCell electrodesOrganosolvCarbolineum

The invention provides a preparation method for a carbon cathode material of a lithium ion battery. The method comprises the following steps of: performing polyreaction on petroleum asphalt or coal pitch used as a raw material at the temperature of 400-460 DEG C; at the later stage of reaction, sampling and observing by use of a polarizing microscope; when the system interphase content reaches 20-80%, terminating the reaction; cooling and then smashing so as to obtain a raw material A; preparing a raw material B from powdered carbon, natural graphite powder, artificial graphite powder or a mixture thereof, wherein the average grain diameter of any of the powdered carbon, the natural graphite powder and the artificial graphite powder is 10-25 mu m; preparing a raw material C from organic solvents such as heavy oil, absorber oil and anthracene oil; mixing the raw material A, the raw material B and the raw material C at a temperature of 150-200 DEG C according to the condition that A / B is equal to (5-70) / (30-95) or (A+B) / C is equal to (20-70) / (30-80); then performing thermal treatment at a temperature of 400-600 DEG C while stirring; and finally performing carbonizing treatment and graphitization treatment. The carbon cathode material prepared by the preparation method provided by the invention has the advantages of high capacity and long cycle life.

Owner:大连宏光锂业有限责任公司

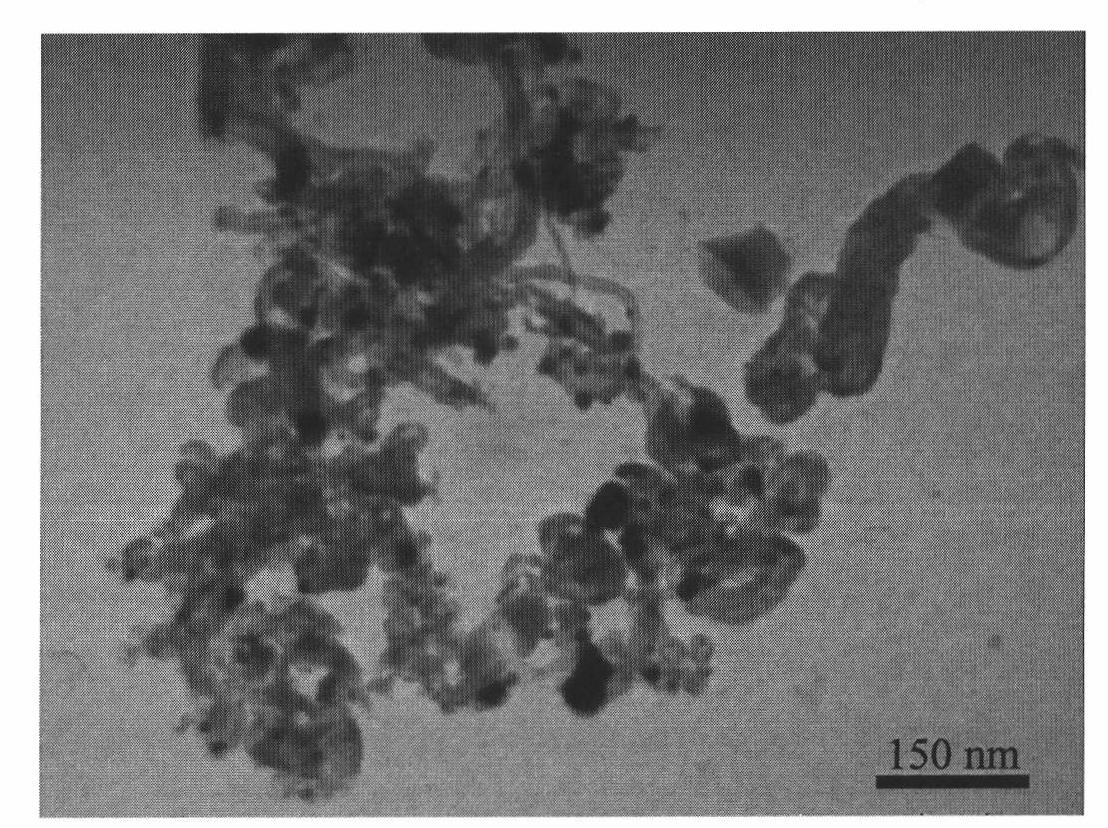

Process and device for industrial production of carbon nanofiber

The invention relates to a process and equipment for preparing carbon nanofiber. A liquid-state or gas-state hydrocarbon is taken as a carbon source, and the carbon source is one or the mixture of aromatic heavy oil, residual oil, coal tar, mixed benzene, coal pitch, coke oven gas, anthracene oil, naphthalene oil, carbolic oil, CH4, C2H2 or toluene. The process comprises the following steps of: uniformly mixing the carbon source and a catalyst in a static mixer according to a certain proportion; spraying under a high pressure by using a honeycomb duct and introducing into a cracking reaction furnace; performing a cracking reaction at the material flow speed of between 1,000 <3>h<-1> and 3,000 m<3>h<-1> at the temperature of between 1,000 DEG C and 1,400 DEG C under the pressure of between 0.5 MPa and 3.0 MPa so as to obtain carbon nanofiber; separating gas from solid by using a cyclone separator; and recycling hot air stream for preheating raw materials so as to save energy. The diameter of the prepared carbon nanofiber can be between 20 nanometers and 100 nanometers, the length is between 300 nanometers and 5 microns, and the content of fiber in a product is up to 90 percent. In a method, gas-state and liquid-state carbon-containing hydrocarbons are taken as the carbon source, so that carbon source is very rich, and price is low. The invention has the characteristics that: the method is safe and easy and is easy to realize industrial production, price is low, carbon source transformation rate is high, and the like.

Owner:BEIJING UNIV OF CHEM TECH +1

Binder for magnesium carbonaceous fire-resistant material

InactiveCN101486885AReduce manufacturing costImprove product qualityBituminous material adhesivesAldehyde/ketone condensation polymer adhesivesPolyesterDistillation

The invention relates to a bonding agent used for magnesia carbon-containing refractory materials , which consists of materials with weight proportions as follows: 100 proportions of phenolic resin; aromatic polyester and coal tar pitch with the weight accounting for 15-30% of the weight of the phenolic resin or polyamide resin; coal tar distillation anthracene oil product with the weight accounting for 50-60% of the weight of the coal tar pitch; and solvent with the weight accounting for 17-32% of the weight sum of the four materials. The beneficial effects are as follows: a series of products of the bonding agent used for the magnesia carbon-containing refractory materials are provided, and the production cost is reduced greatly, thus having obvious economic and social benefits. The product quality is stable and reliable, the performance of the bonding agent meets the standard of the existing bonding agent by inspection, and solid content and residual carbon amount are significantly higher than the existing bonding agent of the refractory materials, thus leading the performance indicators of the refractory materials to be improved.

Owner:周惠兴

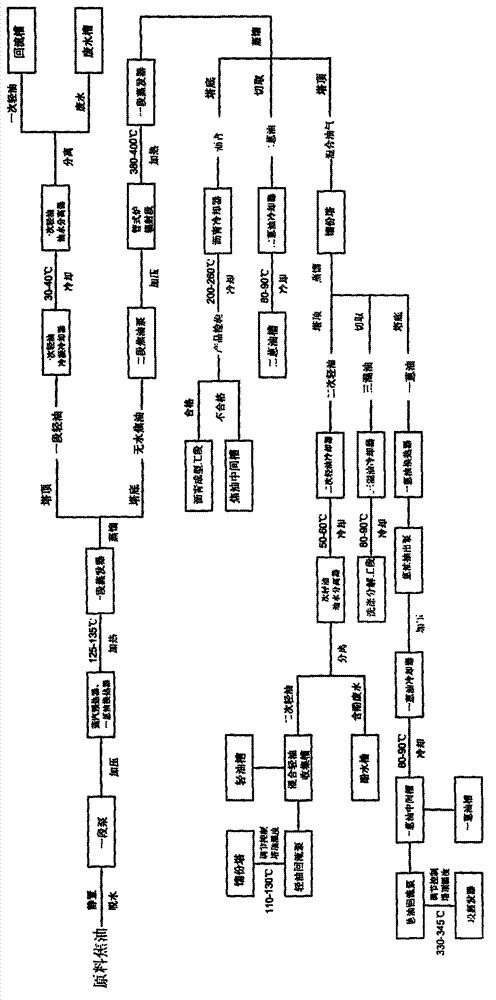

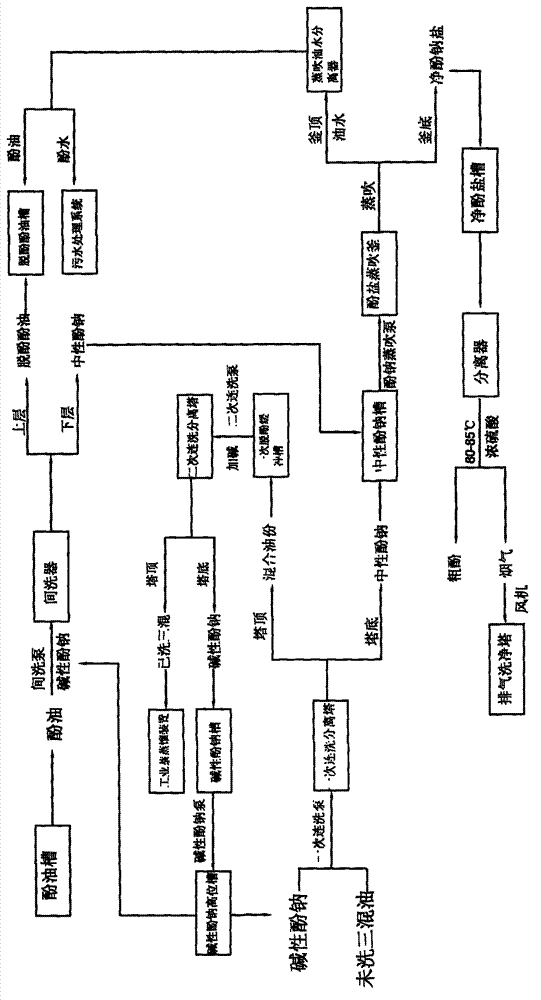

A kind of method for measuring coal tar three mixed naphthalene oil

ActiveCN110196202BImprove extraction efficiencyImprove extraction qualityWeighing by removing componentThermodynamicsDistillation

The invention relates to a method for measuring coal tar trimixed naphthalene oil, comprising the following steps: (1) weighing the dehydrated coal tar whose quality is X; (2) putting the coal tar into a distillation bottle of a fractionation device, and The fractionation device is connected and assembled; (3) start heating the retort in step (2), cut off the distillate segment with a temperature of 180-250°C and weigh the weight X1 of the distillate and measure the purity Z; (4) continue to reheat the retort The coal tar in the heating is heated until crystallization occurs in the distillate, and the heating is stopped, the temperature at this time is recorded, and the weight X2 of the distillate in the receiver at this time is weighed; (5) according to step (3) and step (4 ) fraction weight calculation of the content Y1 of naphthalene in coal tar and the content Y2 of three mixed naphthalene oils. The method for measuring coal tar trimixed naphthalene oil predicts the yield of trimixed naphthalene oil in actual production, can reduce the content of anthracene oil in the trimixed naphthalene oil, and improves the purity of the trimixed naphthalene oil, which can be used to guide practice Production.

Owner:马钢奥瑟亚化工有限公司

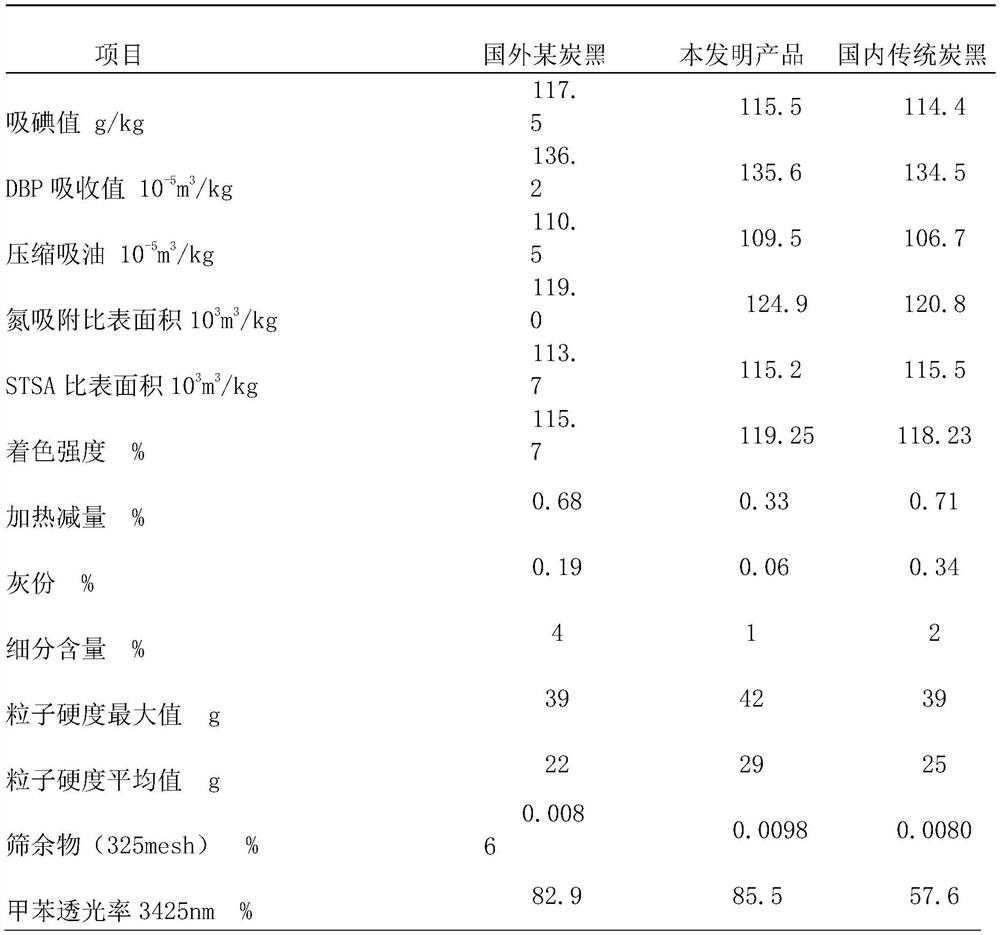

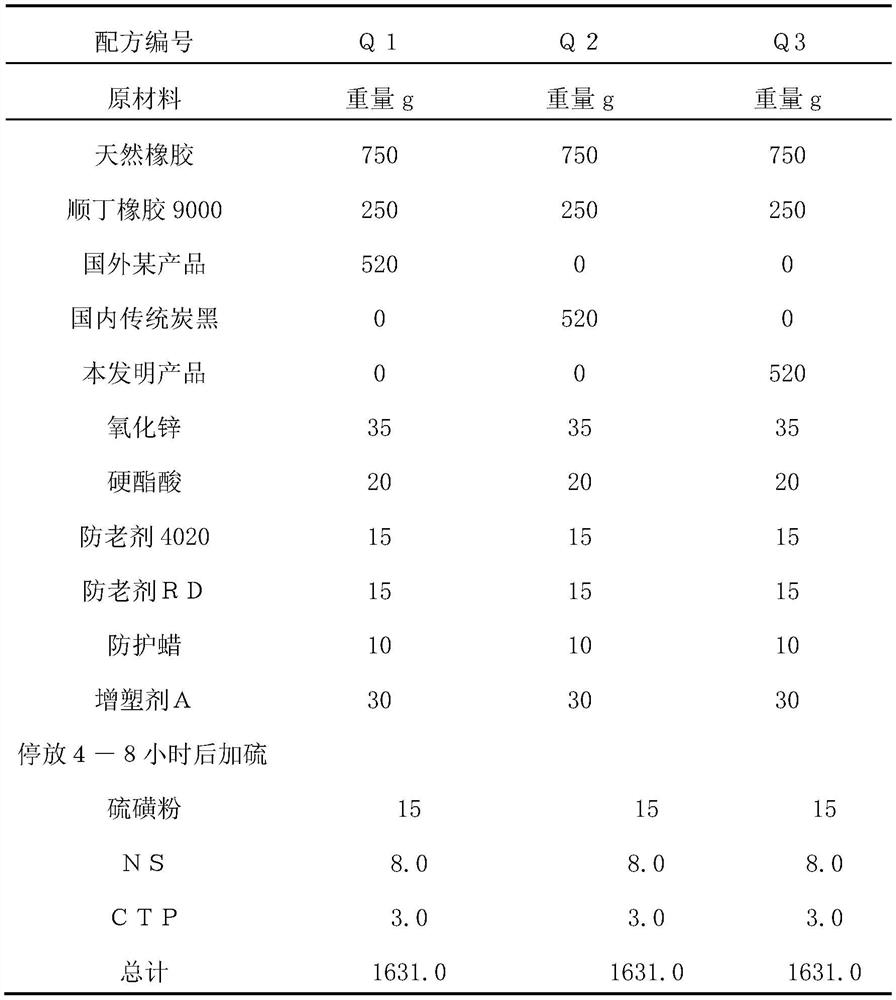

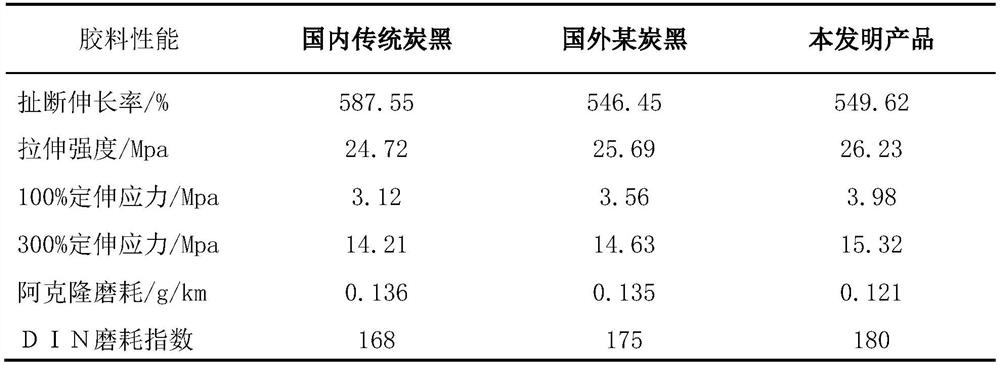

Production method of carbon black for green tire with high wear resistance and low rolling resistance

ActiveCN113637339AIncrease surface areaSimple structurePigmenting treatmentForeign matterRolling resistance

The invention relates to a production method of carbon black for a green tire with high wear resistance and low rolling resistance, which comprises the steps of adopting 100% high-quality anthracene oil as a production raw material, carrying out secondary treatment by a slag, oil and water three-phase separator to remove moisture and impurities, keeping the high temperature of 1950-2050 DEG C in a multi-section reaction furnace to generate carbon black reaction, adding a novel non-metal ion filler, terminating the reaction by adopting desalted softened water as quenching water, recycling waste heat of carbon black flue gas, obtaining powdery carbon black for tires with high wear resistance and low rolling resistance through collection of a bag filter box, a pipeline foreign matter removal device and the like, and finally obtaining finished carbon black through granulation of a granulator, drying, screening, magnetic cleaning, packaging and the like. The product produced by the invention has better stress at definite elongation and stronger wear resistance, which indicates that the carbon black has excellent wear resistance and low rolling resistance, and is low-rolling-resistance wear-resistant carbon black required by the current green tire industry.

Owner:万达集团股份有限公司 +1

Formula of imitative wood filling slurry for building formwork supporting keel and processing method

The invention relates to a formula of imitative wood filling slurry of a building formwork supporting keel and a processing method. The formula comprises reclaimed rubber powder, plant fibers, hydraulic cementing materials, an additive agent and water. The processing method comprises the following steps of: (1) detecting and adjusting the particle size of the reclaimed rubber powder to accord with a combination requirement for later use; (2) carrying out immersion treatment on sawdust or pulverized matters of crop platycodon grandiflorum by using antiseptic oil or coal tar or anthracene oil for later use; (3) firstly, placing the reclaimed rubber powder, the plant fibers and the hydraulic cementing materials processed for later use in a high-speed mixing device according to the proportion of the components, adding water and the additive agent after mixing for 2-3 minutes, mixing for 2-3 minutes again to prepare the imitative wood filling slurry for the building formwork supporting keel. The imitative wood filling slurry has the remarkable advantages of low cost, high strength and convenience for processing.

Owner:YUNNAN INST OF BUILDING RES

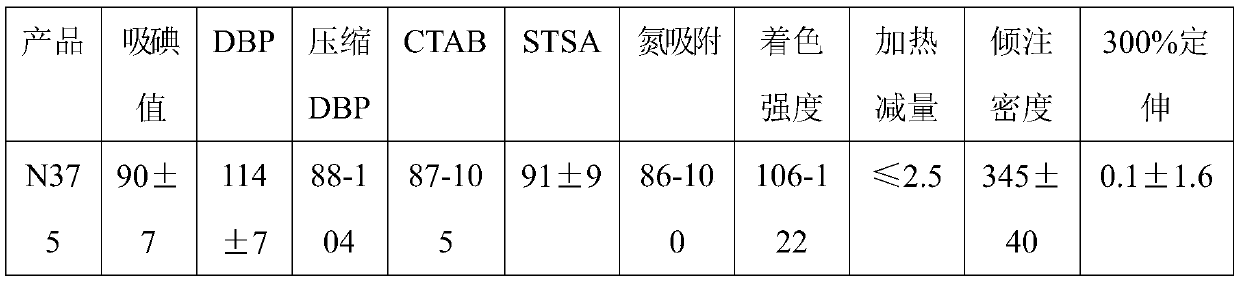

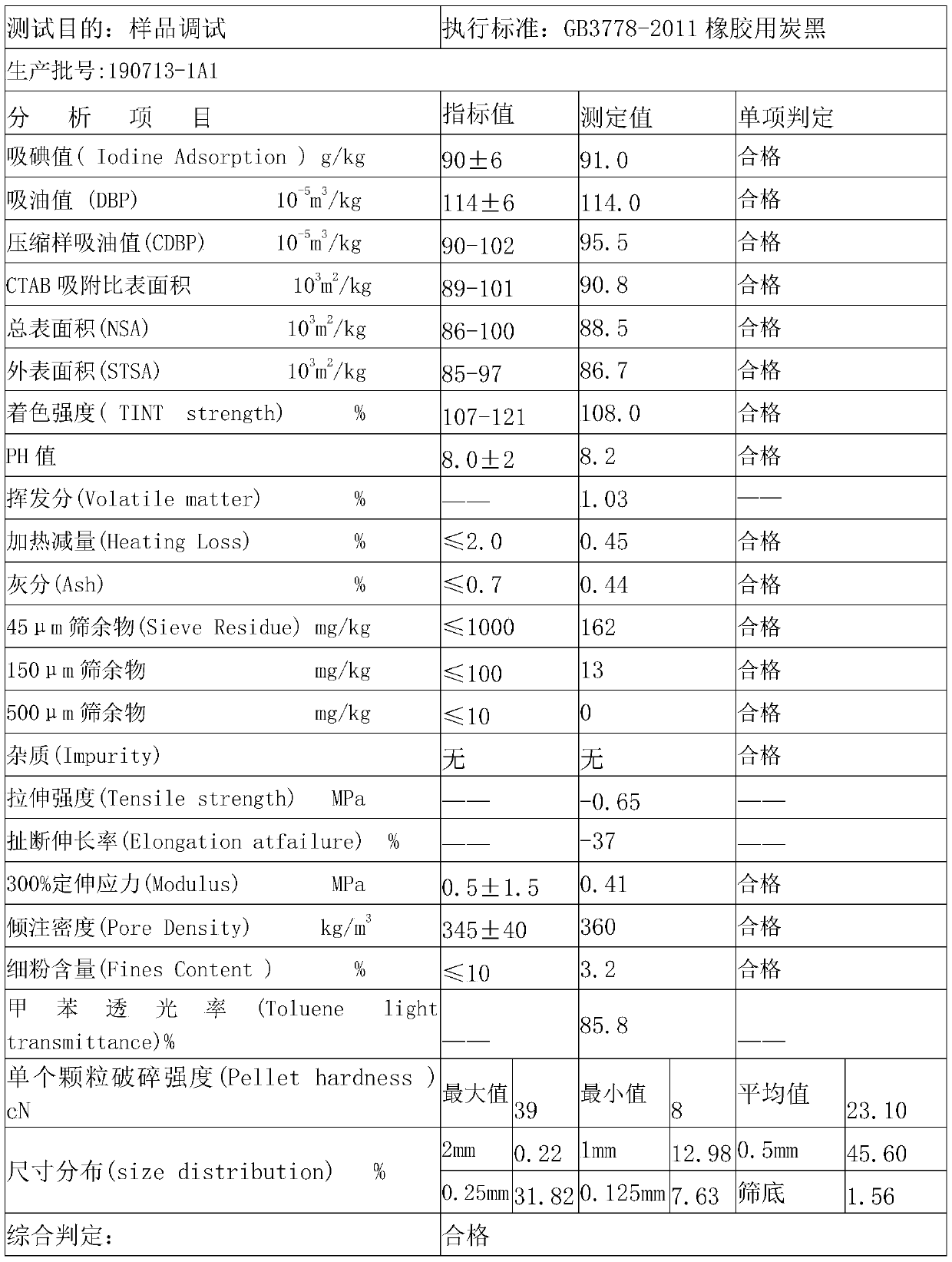

Method for producing N375 carbon black from blended oil

InactiveCN110684376AImprove product qualityReduce manufacturing costPigmenting treatmentProcess engineeringCarbolineum

The invention discloses a method for producing N375 carbon black from blended oil. Carbon black production raw material oil is composed of 50% of ethylene bottom oil, 20% of anthracene oil and 30% ofcoal tar through proportioning or 35% of ethylene bottom oil, 35% of anthracene oil and 30% of coal tar. The method has the technical effects that 1) the source of carbon black production raw materialoil is expanded, a part of coal tar series oil is replaced by ethylene bottom oil as the carbon black production raw material oil; 2) an oil formula is optimized and adjusted, control on internal indexes of carbon black is intensified, the product quality is improved, and the production cost is lowered; 3) the supply channels of the carbon black production raw material oil are expanded, a part ofother oil products are supplemented, the shortage of tar supply is alleviated, and a technical foundation for further reducing the cost of raw materials and increasing the benefits is made; and 4) carbon black raw material oil with stable supply sources and lower price is obtained, and stable operation of carbon black production equipment is ensured.

Owner:HANDAN BLACK CAT CARBON BLACK

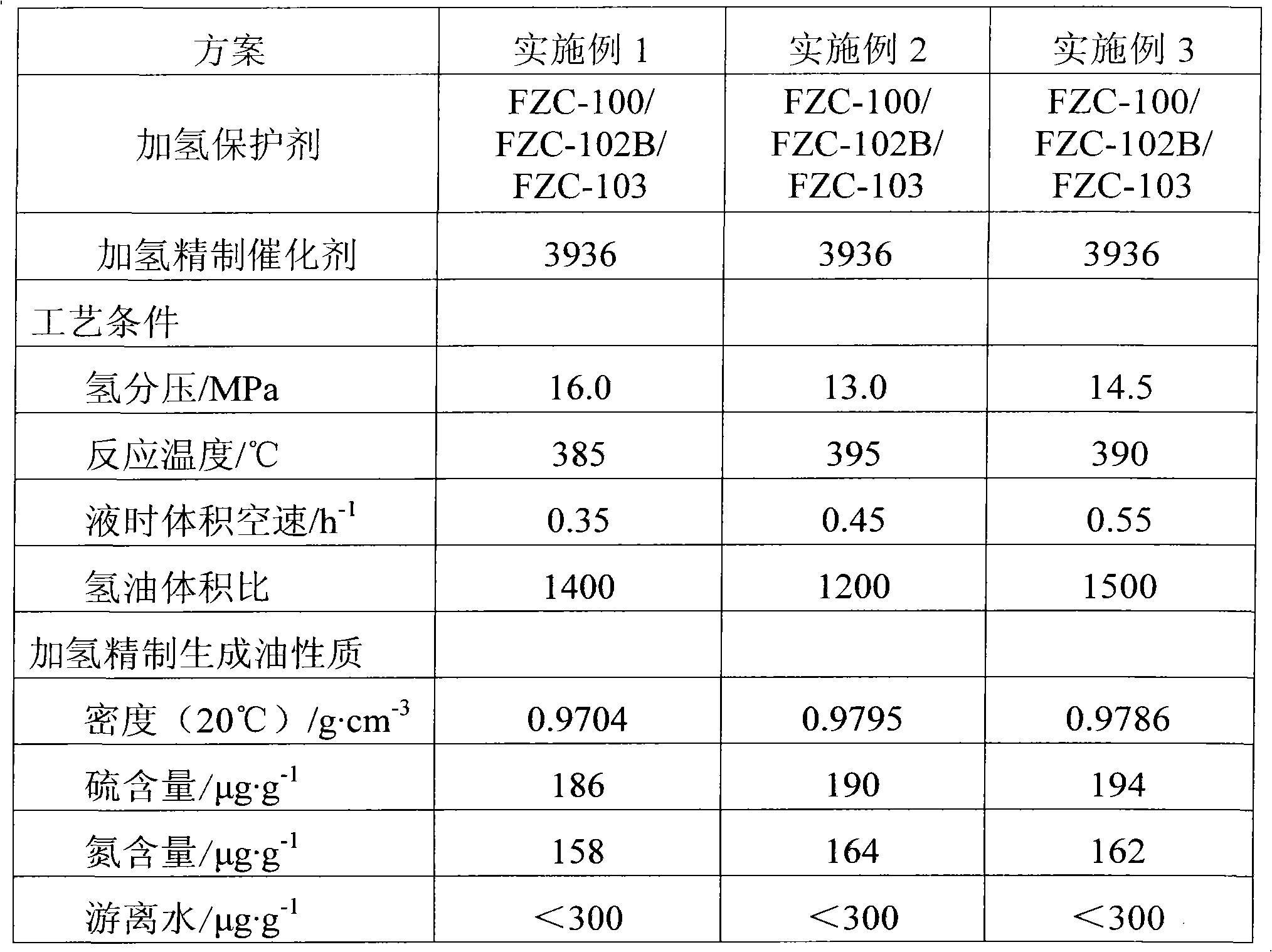

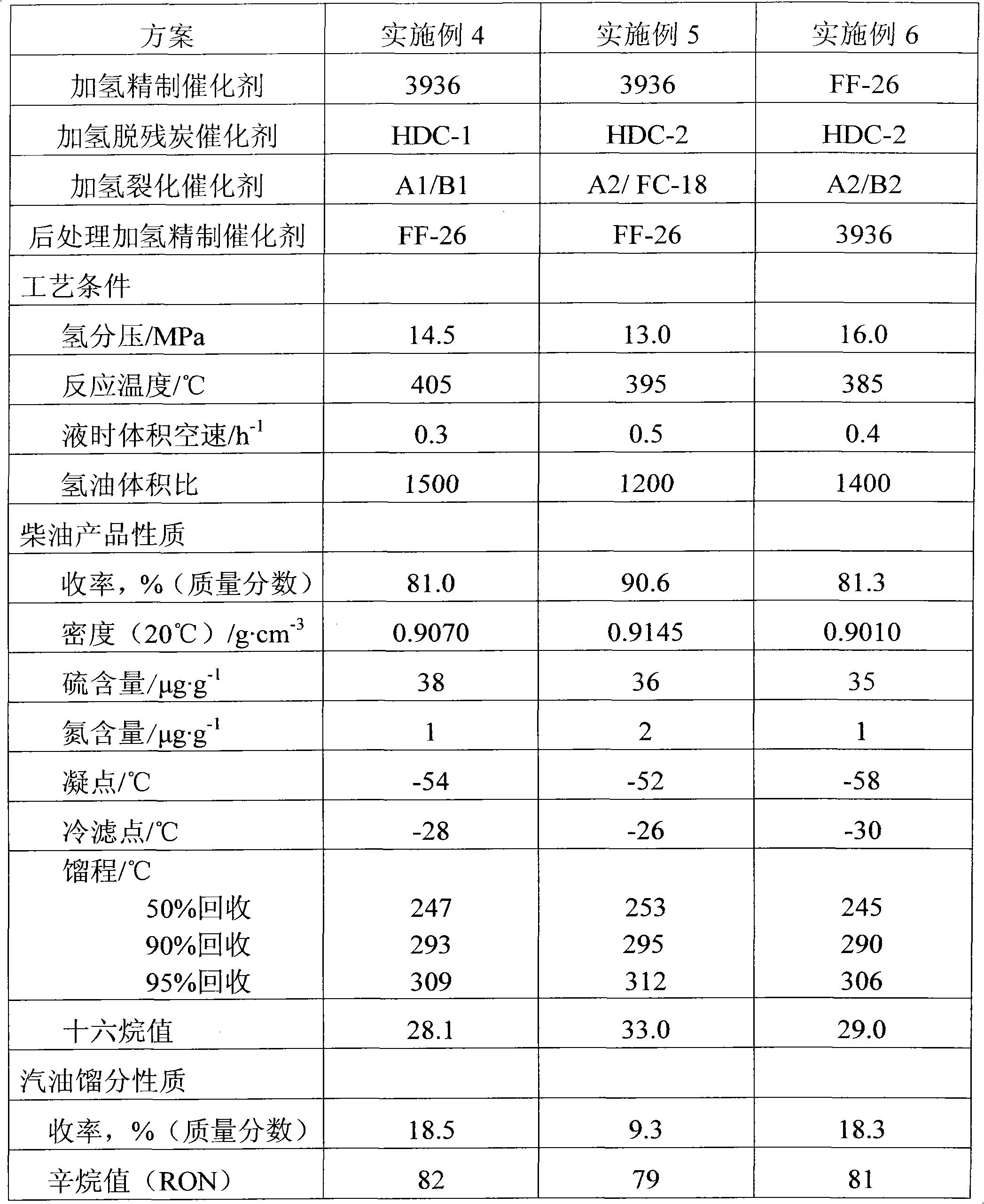

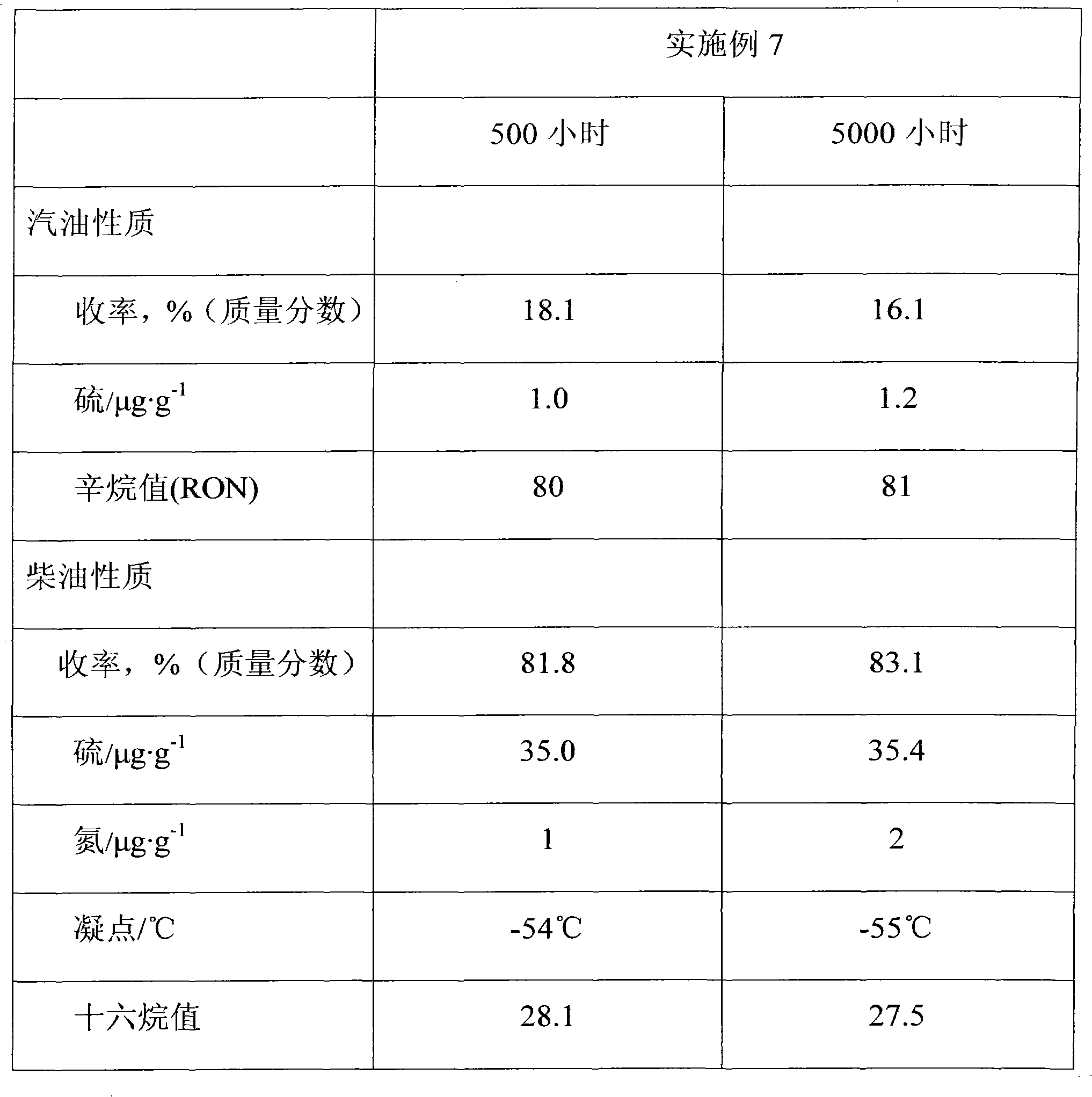

Method for hydrogenating deeply-drawing carbolineum

ActiveCN102041077AIncrease added valueLarge amount of raw materialsTreatment with hydrotreatment processesAnthraceneResidual carbon

The invention discloses a method for hydrogenating deeply-drawing carbolineum. The two-section hydrocracking process is applied to the method. The deeply-drawing carbolineum passes through a hydrorefining reaction area firstly to obtain a hydrorefining product; the obtained hydrorefining product is separated to obtain a liquid phase product which enters a hydrocracking reaction area, is sequentially contacted with a hydrorefining catalyst, a hydrogenating residual carbon removing catalyst and a hydrocracking catalyst for reaction to obtain a hydrocracking product; and the hydrocracking product is separated to obtain gasoline and diesel oil fractions. By using the method, the deeply-drawing carbolineum is processed, the range of raw materials is widened, the deeply-drawing carbolineum can be converted to maximum extent, the yield of lightweight fuel oil can be improved and the added value of carbolineum is improved; meanwhile, the activity of the hydrocracking catalyst can be effectively protected, so that the device can operate for a long period.

Owner:CHINA PETROLEUM & CHEM CORP +1

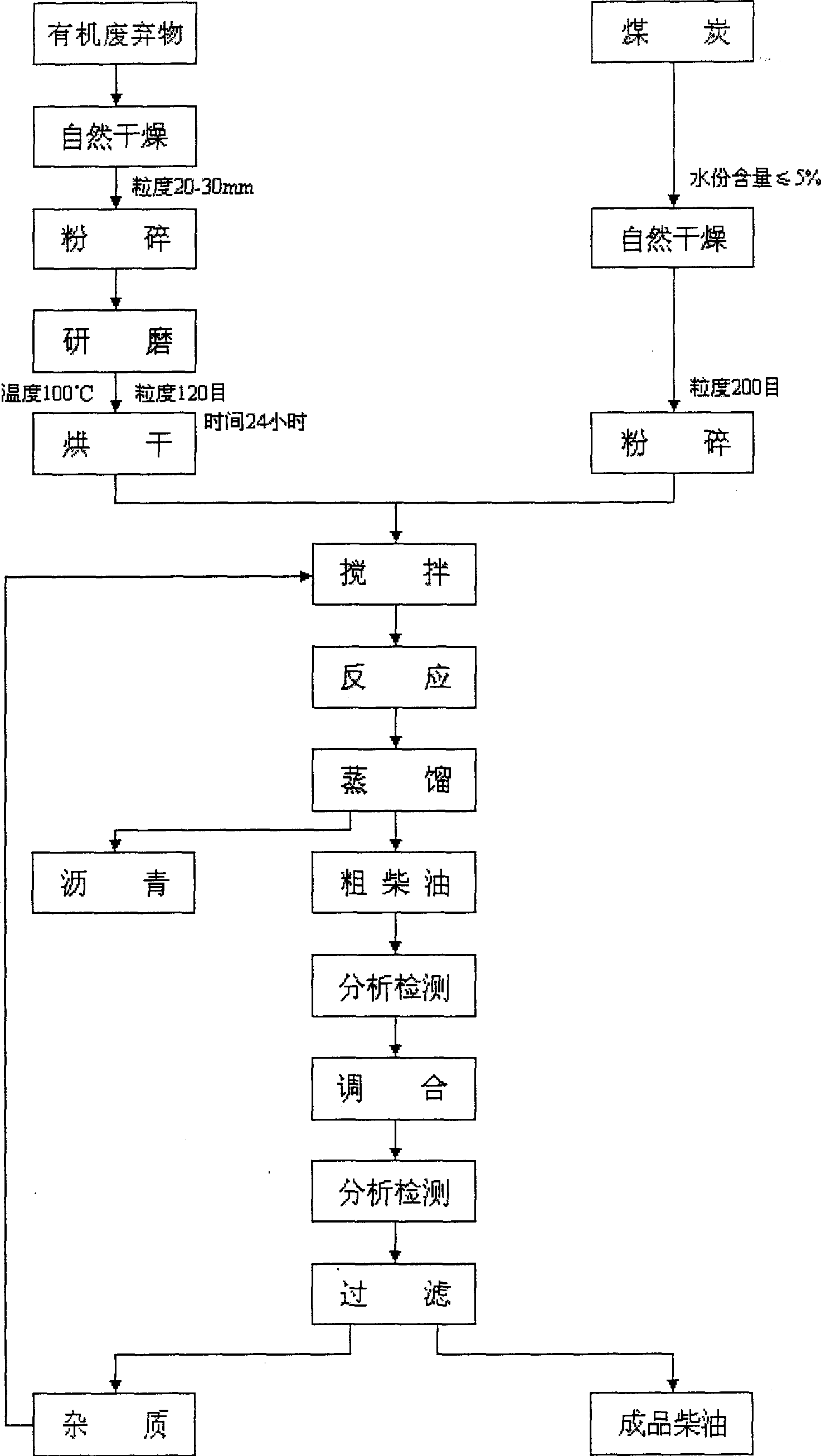

Method for preparing substituted diesel oil by utilizing organic waste and coal

InactiveCN1803983ARaw materials are easy to getLow priceBiofuelsLiquid hydrocarbon mixture productionAnthraceneSlag

The disclosed alternate diesel oil contains (weight ratio):35-15 coal, 25-45 organic waste as one or more of the corn core, peanut hull, rice hull and brewing slag; 30 refined anthracene oil as solvent or 340-380Deg distillate oil in kettle when continual running, 9 methanol or hexadecanol as auxiliary agent, and 1 catalyst. To the great cost and complex device and technique, this invention comprises natural drying, crushing, reacting, distilling, and blending with agent; and is welcomed by user as its well practical effect.

Owner:任春山

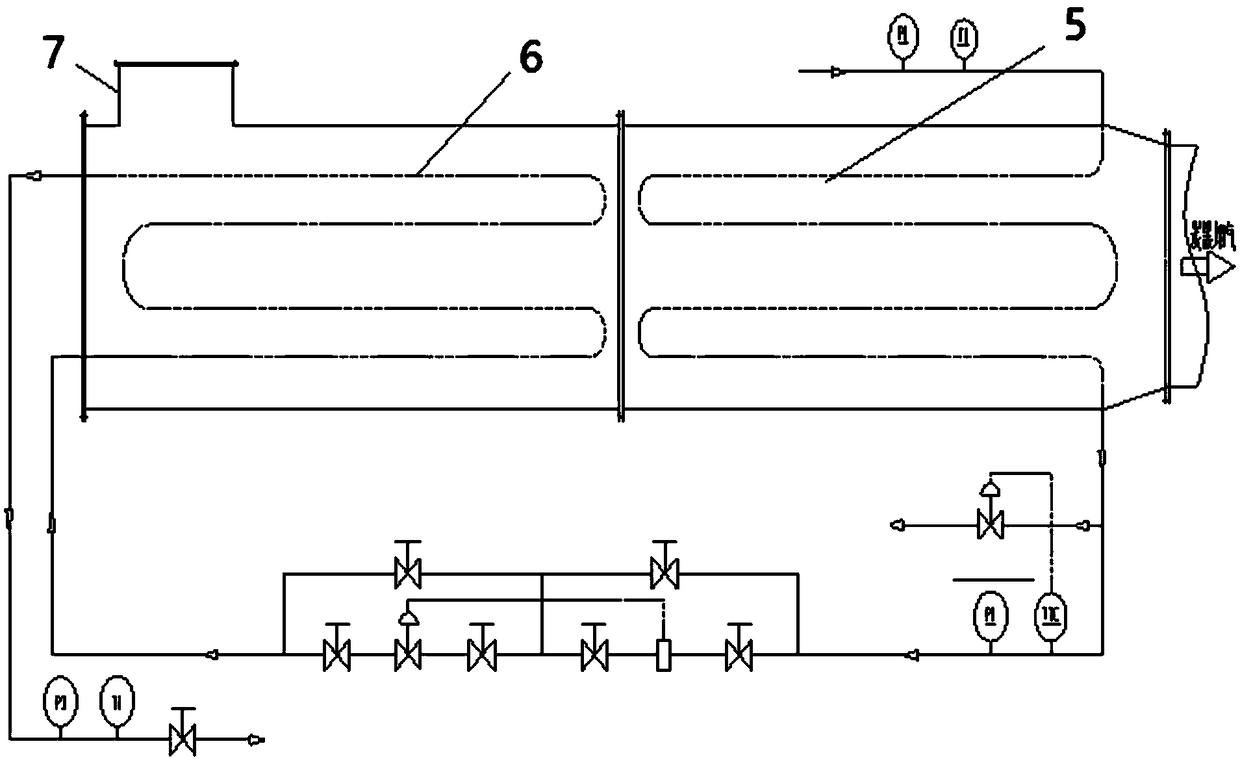

Continuous production process of mesocarbon microbeads

ActiveCN112573504AEasy to handleRealize continuous productionCarbon preparation/purificationThermodynamicsMicrosphere

The invention provides a continuous production process of mesocarbon microbeads. The continuous production process comprises the following steps: uniformly mixing medium-temperature asphalt and anthracene oil in a raw material tank, mixing the obtained mixture with a circulating material which comes from a heating kettle and is heated by a heating furnace of the heating kettle, feeding the mixed materials into the heating kettle, heating the mixed materials to a certain temperature by the heating kettle, mixing one part of the mixed materials with a circulated reacted material which comes froma reaction kettle and is heated by a heating furnace of the reaction kettle, feeding the finally obtained mixture into the reaction kettle, keeping a certain temperature in the reaction kettle, and carrying out thermal polycondensation reaction to obtain carbon microsphere-containing intermediate asphalt; and cooling, washing, separating, drying and cooling the intermediate asphalt to obtain a finished product, namely themesocarbon microbeads. The process is simple in technological process, high in automation degree, easy to operate, low in energy consumption, low in equipment investment, good in environment-friendly effect and suitable for large-scale industrial continuous production.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

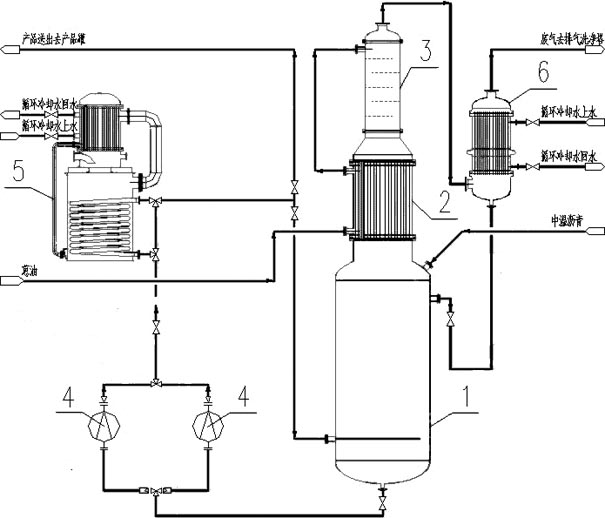

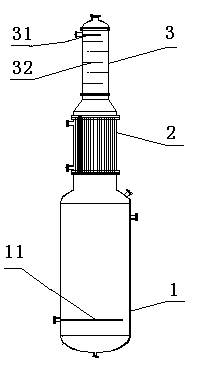

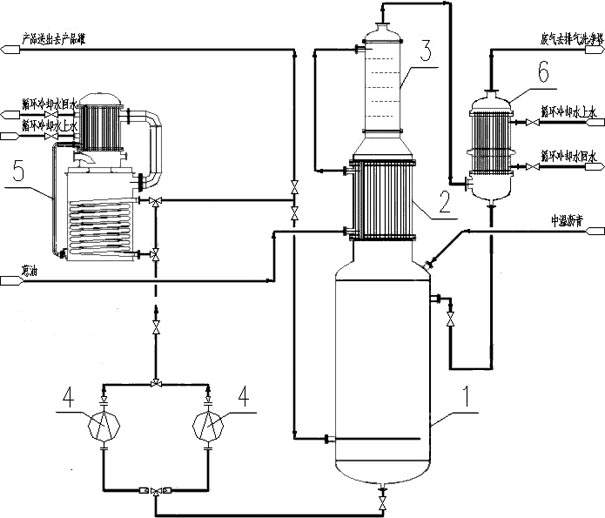

Device and process for preparing and producing oils for processing coal tar

The invention discloses a device and a process for preparing and producing oils for processing coal tar. The device comprises an oil distributing tank, an oil gas condenser, an oil gas capturer, an oil distributing conveying pump, an oil distribution gasification and condensation cooler, a waste gas cooler and the like. The process is as follows: anthracene oil is pumped to a shell side of the oil gas condenser at the upper part of the oil distributing tank, enters the oil gas capturer, then enters the shell side of the oil gas condenser from top to bottom, enters the oil distributing tank, then is mixed with medium-temperature asphalt in the oil distributing tank, and then is circulated to the oil distributing tank through the oil distributing conveying pump and the oil distribution gasification and condensation cooler; oil generated during the oil distribution sequentially passes through the oil gas condenser, the oil gas capturer and the waste gas cooler; the anthracene oil is completely recycled, and waste gas after the anthracene oil is removed is washed with gas absorber oil and then discharged into atmosphere; and the final product is conveyed to a product tank through a product conveying pipeline. The device and process thereof are simple and convenient for operation; and the obtained product has the advantages of stable quality, good product quality, high yield and nopollution during the production.

Owner:SHANGHAI INST OF TECH

Silicon carbide hot melt solid repairing paste and preparation method thereof, and blast furnace and submerged arc furnace taphole repair method

The invention relates to a silicon carbide hot melt solid repairing paste and a preparation method thereof, and relates to the technical field of blast furnace and submerged arc furnace taphole repairing. The silicon carbide hot melt solid repairing paste is prepared by mixing silicon carbide powder, graphite powder, metal silicon powder, medium temperature modified pitch and anthracene oil according to a specific proportion; the silicon carbide powder with three particle size ranges is mixed and used according to reasonable gradation. The raw materials are easy to obtain and reasonable in matching, rapid repairing of the taphole can be achieved, limitation by the shape of the taphole is avoided, and the advantages that the service lifetime is long, and slag hanging and iron hanging are not prone to occurring after repairing are achieved. The embodiment of the invention further provides a method for repairing the taphole of the blast furnace and the submerged arc furnace, the silicon carbide hot melt solid repairing paste is adopted for repairing, operation is easy and convenient, and rapid repairing of the taphole of the blast furnace and the submerged arc furnace can be achieved.

Owner:河南远洋新材料技术有限公司

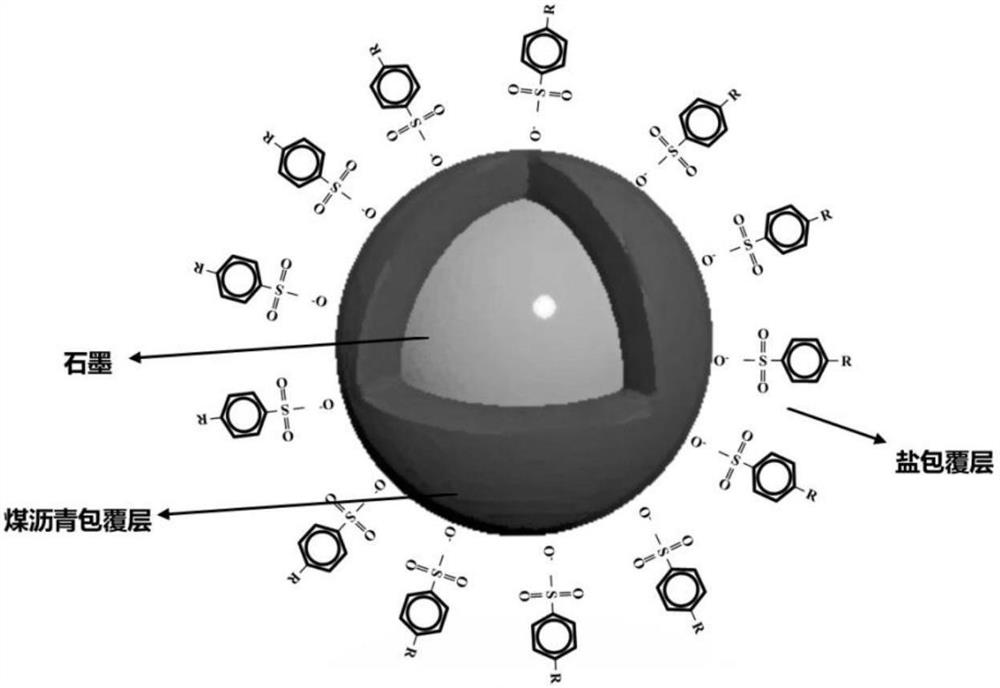

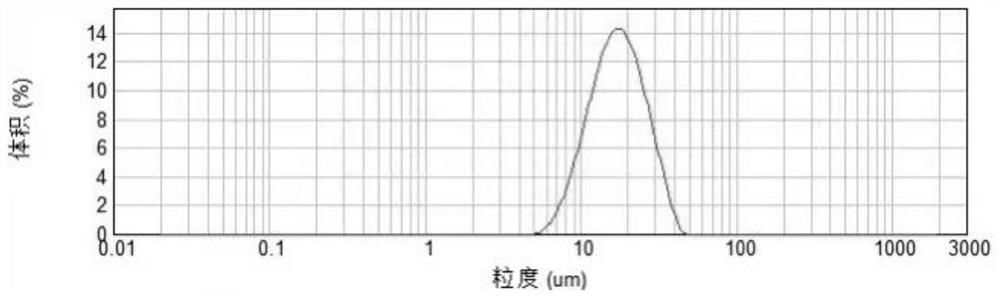

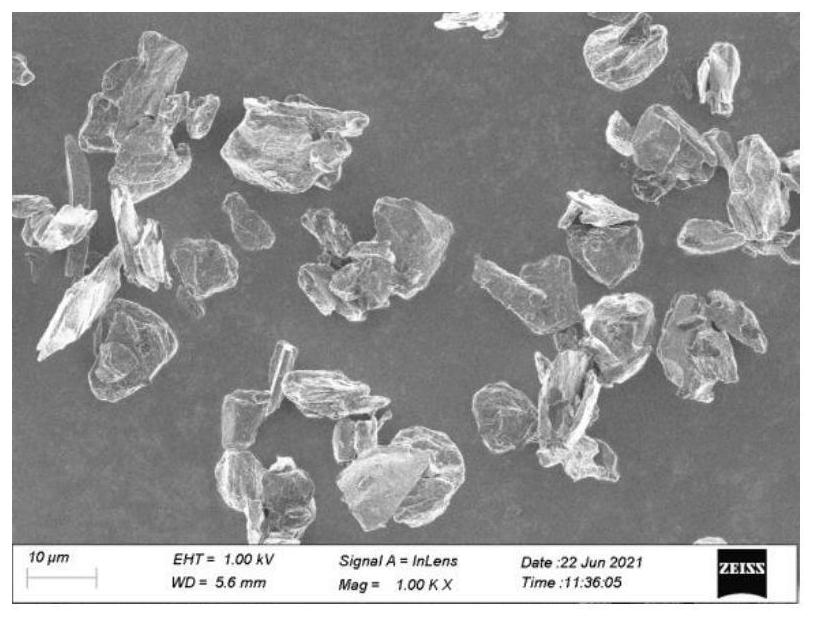

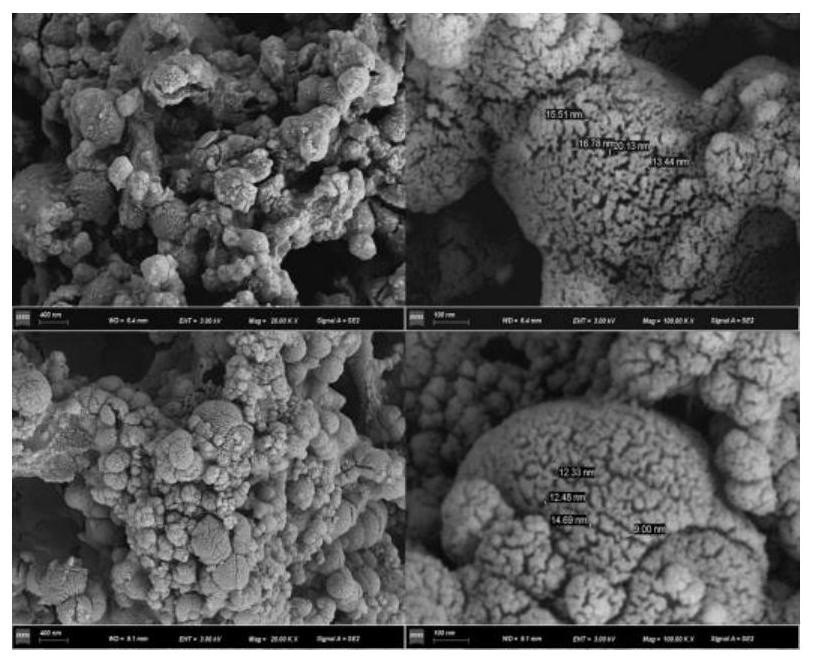

Composite graphite coated product, graphite composite material and preparation method and application of composite graphite coated product and graphite composite material

PendingCN114050238AElasticCompact structureNegative electrodesSecondary cellsDischarge efficiencyCarbolineum

The invention discloses a composite graphite coated product, a graphite composite material and a preparation method and application of the composite graphite coated product and the graphite composite material. The preparation method of the composite graphite coated product comprises the following steps: (1) carrying out heat treatment on a mixed solution of single-particle artificial graphite A and a coating agent A to obtain single-particle artificial graphite B; wherein the coating agent A is asphalt and / or anthracene oil; and the asphalt comprises coal asphalt and / or petroleum asphalt; and (2) carbonizing a mixed solution of single-particle artificial graphite B and a coating agent B to prepare a composite graphite coated product; wherein the coating agent B is one or more of asphalt, anthracene oil and resin; the asphalt comprises coal asphalt and / or petroleum asphalt; the carbonization temperature ranges from 1200 DEG C to 1700 DEG C. The graphite composite material containing the composite graphite coated product has the characteristic of compact surface coating layer structure, and shows better first discharge efficiency, capacity retention ratio and rate capability when being applied to the lithium ion battery as a negative electrode material.

Owner:SHANGHAI SHANSHAN TECH CO LTD

Anti-rusting and anticorrosive paint for steel and iron and preparation method thereof

InactiveCN105925045AHigh bonding strengthIncreased durabilityAnti-corrosive paintsCyclohexanoneCarbolineum

The invention discloses an anti-rusting and anticorrosive paint for steel and iron and a preparation method thereof. Solid red lead, vinylacetylene, ethylenediamine, aluminum powder, dibutyl phthalate, acetone, anthracene oil, coal pitch, talcum powder, mica powder, iron oxide red, zinc chrome, wollastonite powder and cyclohexanone are weighed and taken; the raw materials are agitated, and then are ground, so as to prepare the anti-rusting and anticorrosive paint for the steel and the iron. The anti-rusting and anticorrosive paint for the steel and the iron has favorable bonding strength to metal of the steel, the iron and the like, adapts to cold contraction, does not fall off, does not crack, has bonding strength of 4.2MPa to 4.6MPa, viscosity of 20s to 60s, flexibility of 1mm to 3mm, adhesive force of level 1, heat resistance which does not change within 8h to 12h at 100 DEG C, shock strength of 50kg / cm to 90kg / cm, fineness of 20 to 30 microns, solid content of 40 to 60 percent and good durability, has quite good acid resistance, alkali resistance and chemical corrosion resistance, and has quite good heat resistance and mechanical properties.

Owner:WUXI EPIC TECH

Production method of pigment carbon black applied to leather color paste

ActiveCN113527915AHigh purityHigh light transmittancePigmenting treatmentAir preheaterCombustion chamber

The invention relates to the technical field of pigment carbon black, and discloses a production method of pigment carbon black applied to leather color paste. Natural gas serves as fuel, anthracene oil serves as a raw material, potassium hydroxide serves as an additive, the natural gas and hot air heated through a high-temperature air preheater are completely combusted in a combustion chamber to generate high-temperature combustion residual gas, and the additive and raw oil are fully mixed in a mixer and then sprayed into the high-temperature combustion residual gas through a raw oil gun. Under the action of thermal kinetic energy provided by high-temperature combustion residual gas, raw oil is cracked to generate carbon black, demineralized water is sprayed into high-temperature flue gas in a horizontal quenching section (vaporization) for direct cooling to terminate a carbon black generation reaction (main reaction), medium-pressure steam is sprayed in a vertical quenching section to perform an activation reaction (side reaction) on carbon black particles, and the carbon black obtained by the method disclosed by the invention has the characteristics of high purity, good blackness, strong covering power, easiness in dispersion compared with products of the same series, and the like.

Owner:WUHAI BLACK CAT CARBON BLACK

Epoxy asphalt quick-drying material

InactiveCN103772909ATemperature resistantCold resistantBuilding insulationsCyclohexanoneDiethylenetriamine

The invention discloses an epoxy asphalt quick-drying material, which comprises the following components in parts by mass: 25-30 parts of epoxy resin, 80-100 parts of solid red lead, 10-15 parts of zinc chrome, 4-8 parts of dimethylbenzene, 2-4 parts of methylbenzene, 6-8 parts of cyclohexanone, 20-28 parts of anthracene oil, 20-25 parts of coal tar pitch, 5-8 parts of curing agent, 1-1.5 parts of n-butyl alcohol, 12-15 parts of mica powder, 10-14 parts of talc powder, 1-2 parts of cured tung oil and 5-20 parts of diethylenetriamine. The time for surface dry is within 1.5-3 hours and the time for hard dry is within 20-22.5 hours, and the product is 80-100s in viscosity, less than or equal to 80 microns in fineness, and high in ductility and shear resistance. The product has temperature resistance and cold resistance as well as excellent fatigue resistance and aging resistance, and can be produced on a large scale to replace the conventional material continuously.

Owner:NANTONG SOUTHEAST HIGHWAY ENG

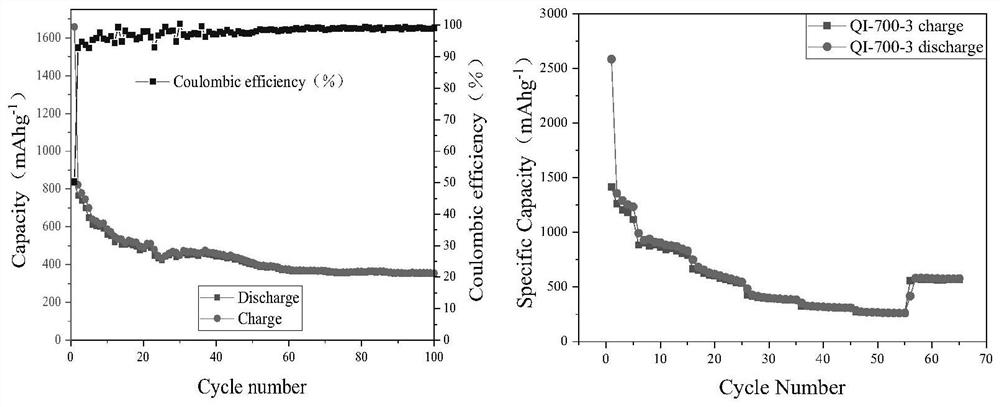

Lithium ion battery negative electrode material and preparation method thereof

ActiveCN113830768AImprove conductivityImprove performanceCarbon compoundsCell electrodesElectrical batteryQuinoline

The invention provides a lithium ion battery negative electrode material and a preparation method thereof. The preparation method comprises the following steps: mixing coal tar pitch with a solvent which is a mixed solvent consisting of kerosene, absorber oil or anthracene oil in a certain proportion, conducting stirring at a certain temperature and pressure, and conducting standing and settling to obtain a coal tar pitch quinoline insoluble substance; mixing the coal tar pitch quinoline insoluble substances with a quinoline solution, performing centrifugal separation, and collecting solids; sequentially washing the solid with a quinoline solution and a toluene solution which are heated to 70 DEG C, and conducting drying; mixing the dried solid with KOH according to a certain proportion, conducting grinding, and conducting activating in a furnace under the protection of inert gas; and washing the activated product with an acid solution and water until the product is neutral, and conducting drying to obtain the lithium ion battery negative electrode material. The preparation method has the advantages of environmental friendliness, no pollution, simplicity in operation, low raw material price and excellent property of the battery negative electrode material.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

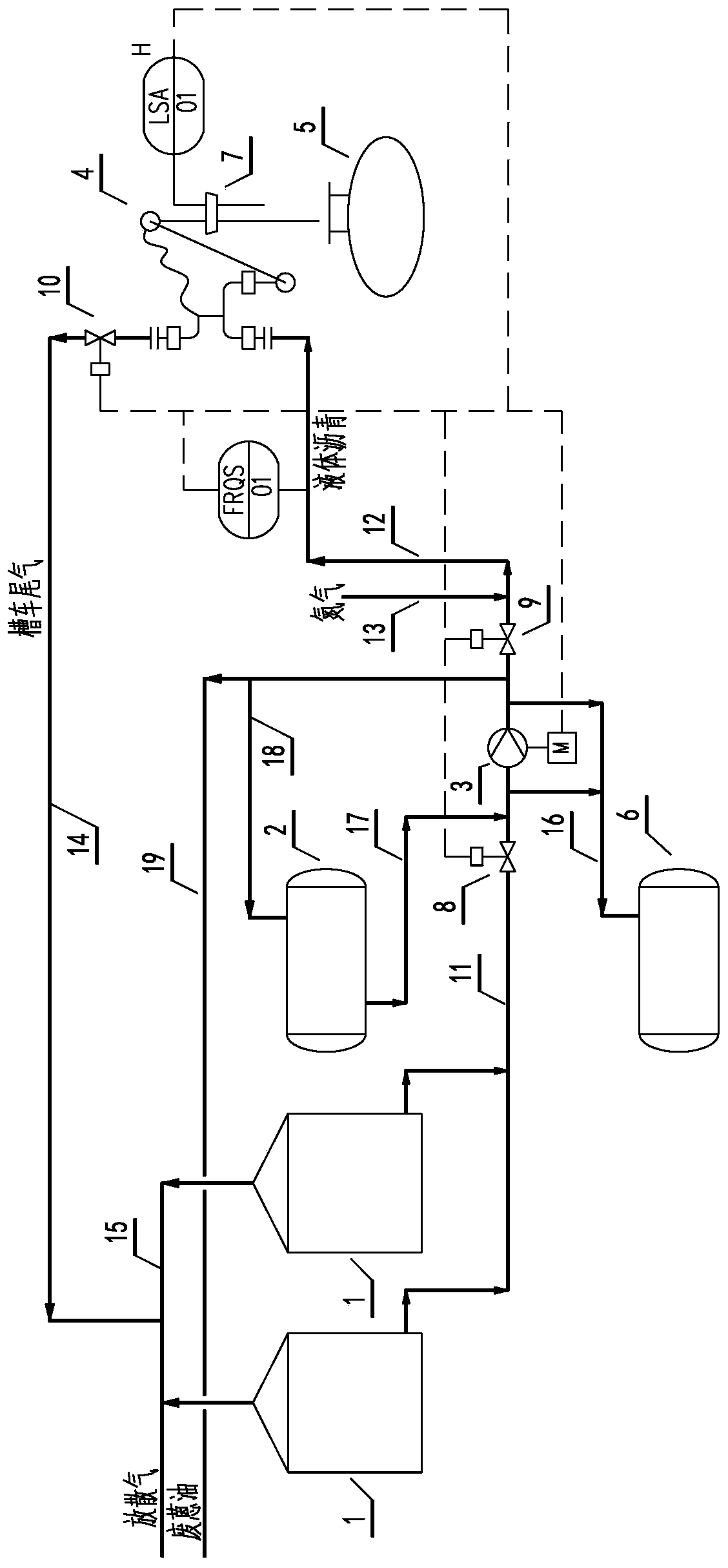

Pumping liquid asphalt loading system and process

PendingCN110885057APracticalOvercoming technical barriersLiquid transferring devicesProcess engineeringCarbolineum

The invention relates to a pumping liquid asphalt loading system and process. The system comprises a loading system and a maintenance and cleaning system. The loading system comprises an asphalt storage tank, an asphalt loading pump, an automobile loading arm and an automobile tank car. The maintaining and cleaning system comprises an anthracene oil tank and an underground emptying tank. The process comprises the following steps of 1) carrying out loading preparation; 2) loading asphalt; 3) purging and moving the vehicle; and 4) maintaining and cleaning. The maintenance and cleaning system isadditionally arranged on the basis of the asphalt loading system, a technical barrier restricting an application of a liquid asphalt pumping and loading process is overcome, and the process has high practicability, is suitable for intermittent operation of liquid asphalt loading and is good for application and popularization. An operation procedure is simple and convenient, and whole-process automatic operation can be achieved.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

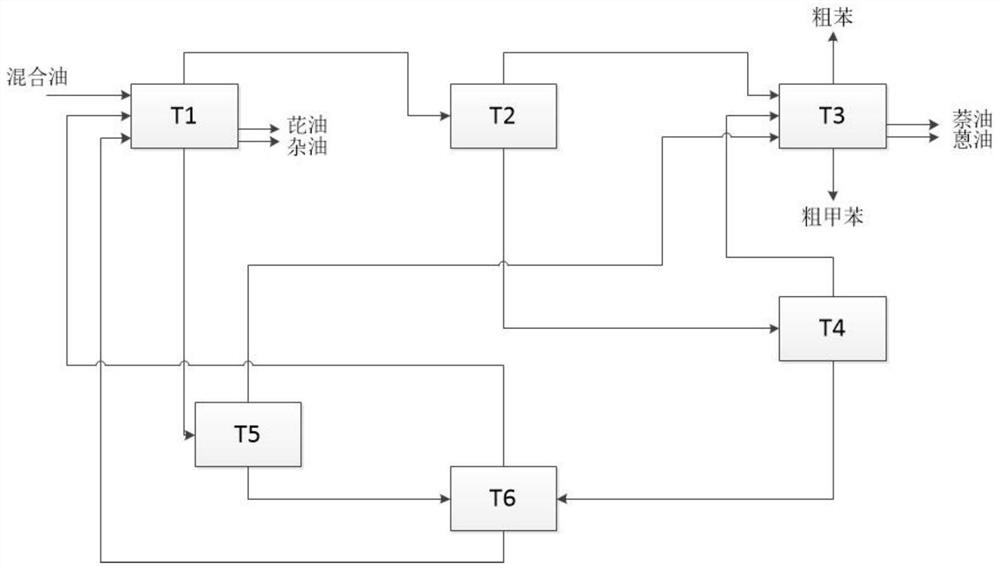

Oil product separation and refining method

ActiveCN112250539AIncrease added valueHigh purityDistillation purification/separationHydrocarbonsAnthraceneEconomic benefits

The invention relates to the technical field of oil product production, and particularly discloses an oil product separation and refining method which comprises the following steps of rectifying by virtue of a plurality of rectifying towers according to components and properties of an aromatic hydrocarbon mixed oil product, and strictly controlling parameters of each rectifying tower to obtain crude benzene, crude methylbenzene, naphthalene oil, anthracene oil and pyrene oil with relatively high purity. The additional value of the original mixed oil product and the economic benefit of the coalhydrogasification technical process are improved. Furthermore, the connecting sequence of a plurality of rectifying towers is optimized, a set of simple and reasonable technological process is designed, energy transfer in the rectifying process is ingeniously utilized while the product quality is not affected, and the purpose of saving energy is achieved.

Owner:ENN SCI & TECH DEV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com