Process and device for industrial production of carbon nanofiber

A technology of nano carbon fiber and process method, which is applied in the chemical characteristics of fibers, textiles and paper making, etc., can solve the problems of unrecyclable heat energy, uncontinuous production, large reactor, etc., and achieves high yield, easy control of the reaction, comprehensive The effect of low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

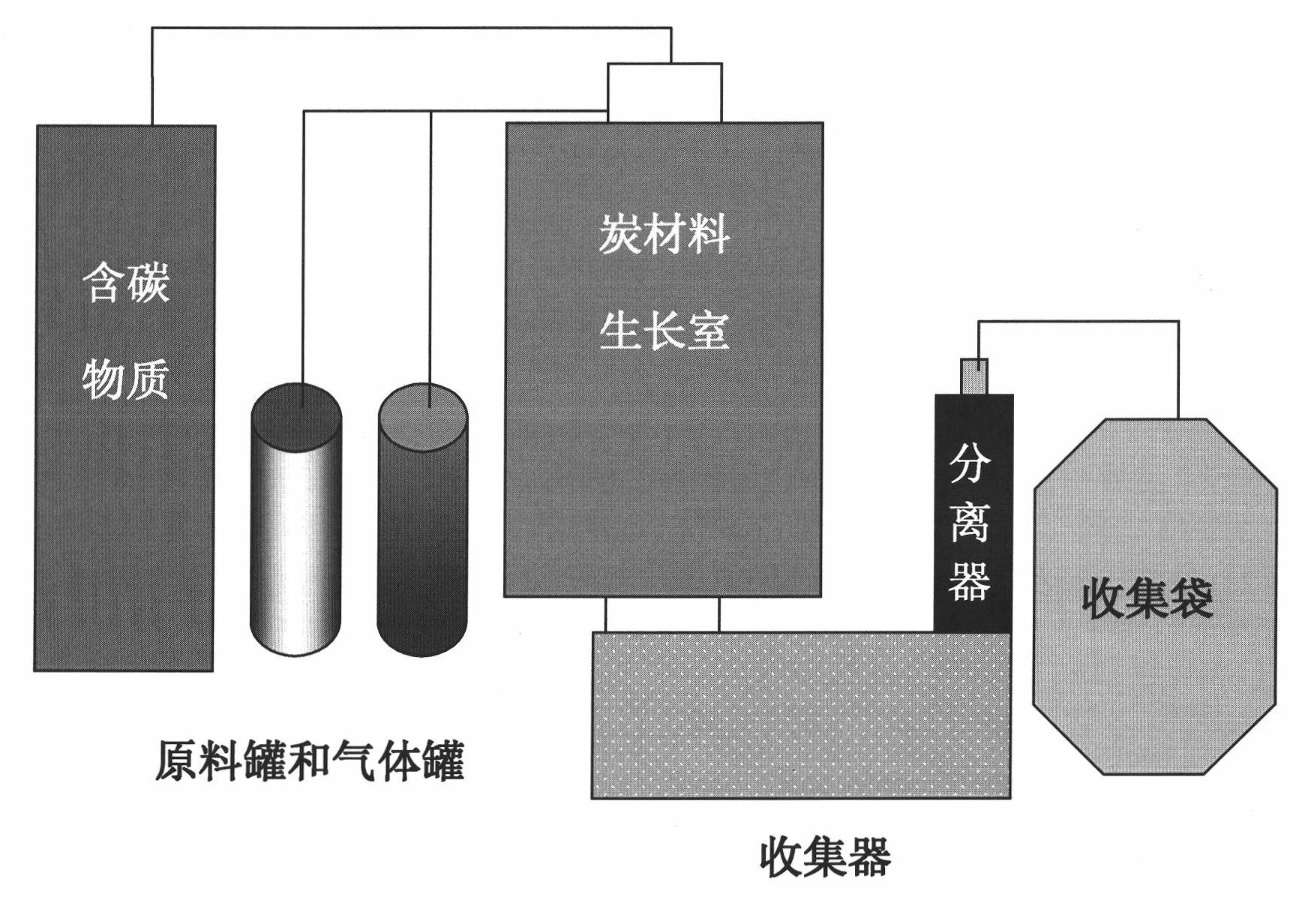

Method used

Image

Examples

Embodiment 1

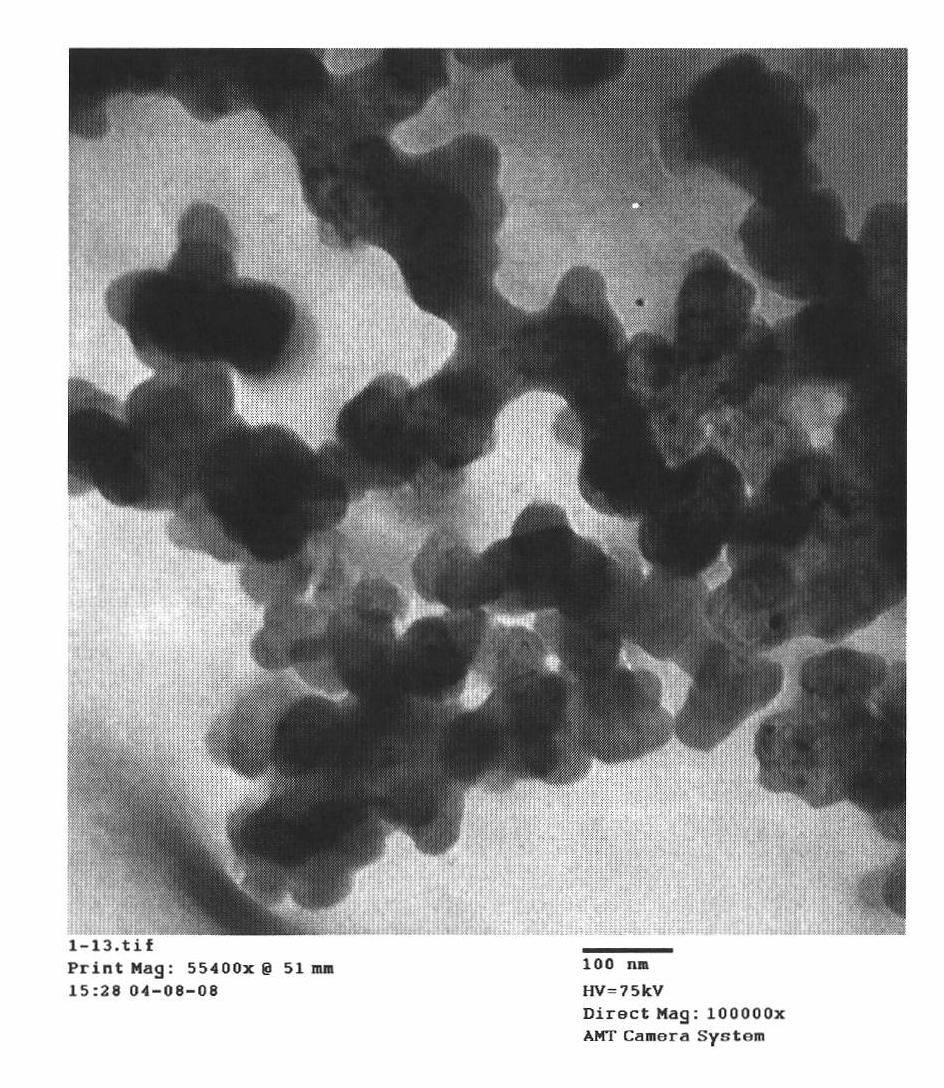

[0027] Embodiment 1: Taking coal tar as raw material, the material flow rate is 1500m 3 h -1 , pressure 1.5MPA, pyrolysis furnace temperature 1000 ℃, produced carbon nanofibers, transmission electron microscope photos as attached figure 2 As shown, it can be found that the diameter of the product is 40-50nm, and it is a carbon nanofiber formed by a chain of carbon spheres.

Embodiment 2

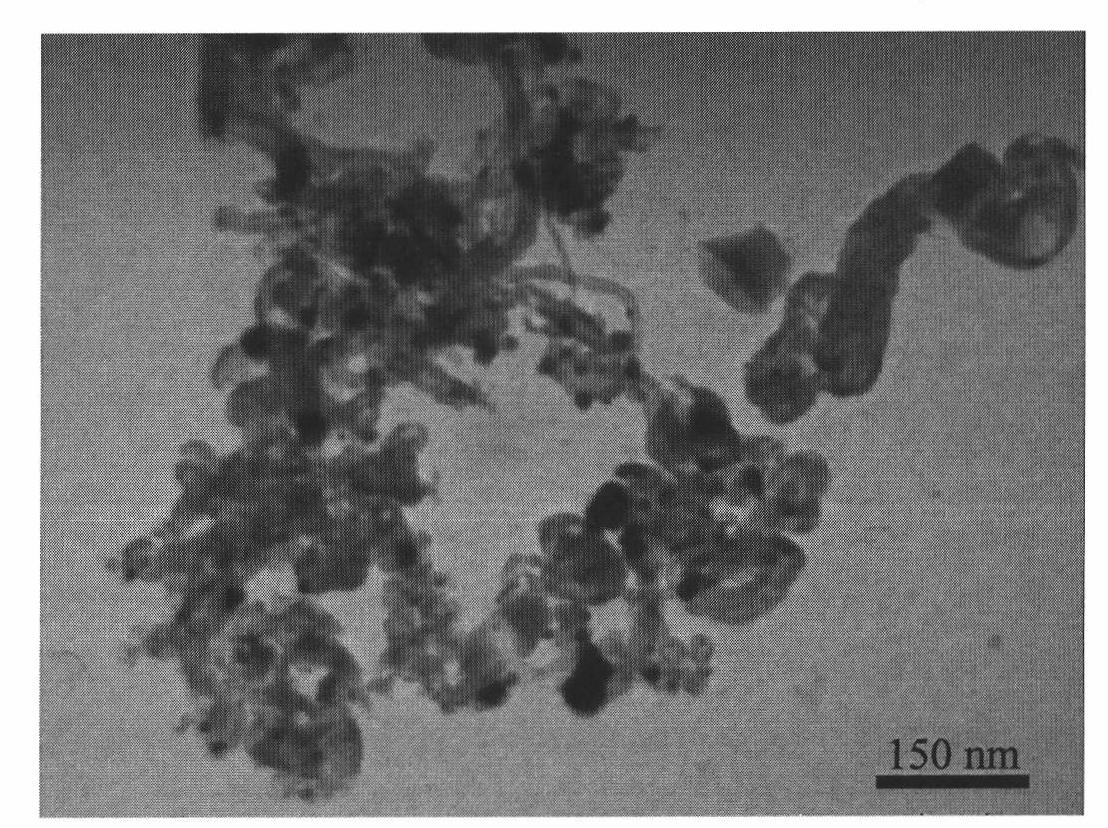

[0028] Embodiment 2: Taking mixed benzene as raw material, the material flow rate is 2000m 3 h -1 , pressure 2MPA, pyrolysis furnace temperature 1200 ℃, produced carbon nanofibers, transmission electron microscope photos as attached image 3 As shown, the products range in diameter from 20-100 nm and contain metal catalysts.

Embodiment 3

[0029] Embodiment 3: Taking heavy aromatics as raw material, the material flow rate is 1000m 3 h -1 , pressure 3MPA, pyrolysis furnace temperature 1300 ℃, produced carbon nanofibers, transmission electron microscope photos as attached Figure 4 As shown, the product is a hollow carbon fiber structure with a diameter ranging from 50-100 nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com