Oil product separation and refining method

A technology for oil products and separation, applied in the direction of distillation purification/separation, hydrocarbon purification/separation, chemical instruments and methods, etc., can solve problems such as low price, affecting the overall economics of the hydrogasification process, and complex components. Achieve the effect of increasing added value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0070] In this example, the aromatic hydrocarbon mixed oil in the coal hydrogasification product is used as the raw material. Under normal pressure, the temperature is 40°C. The main composition of the mixed oil is shown in the following table:

[0071] components benzene naphthalene Pyrene Anthracene Philippines Fluorene Toluene Xylene molecular formula C 6 h 6

C 10 h 8

C 16 h 10

C 14 h 10

C 14 h 10

C 13 h 10

C 7 h 8

C 8 h 10

Proportion, wt% 33.74 25.09 12.35 0.23 6.07 3.24 0.67 0.2

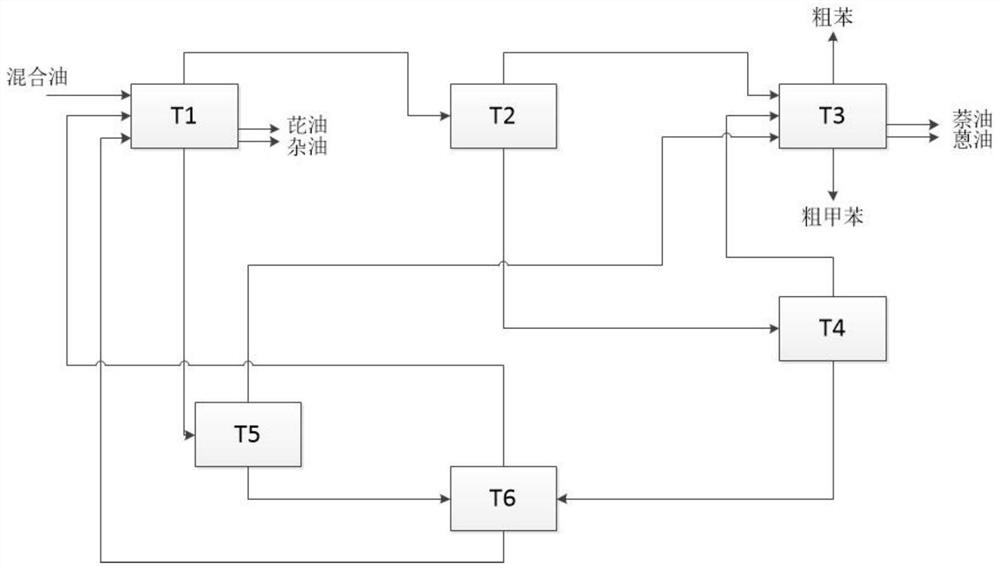

[0072] according to figure 1 The shown process flow separates and refines the mixed oil:

[0073] When the entire process is initially started up, the mixed oil entering the first rectification tower T1 is all heated to the required temperature with the help of an external heat source (such as a reboiler). The mixed oil in the first rectification tower T1 first exchanges heat with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com