Production method of high-purity conductive carbon black

A technology of conductive carbon black and production method, applied in the direction of fibrous filler, etc., can solve the problem that the carbon black reaction furnace cannot meet the production conditions of high-purity and high-performance conductive carbon black, the filtration and purification of production raw materials are not thorough, and the setting range of process parameters is not. Reasonable and other problems, to achieve the effect of convenient particles, uniform particles, stable structure and performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

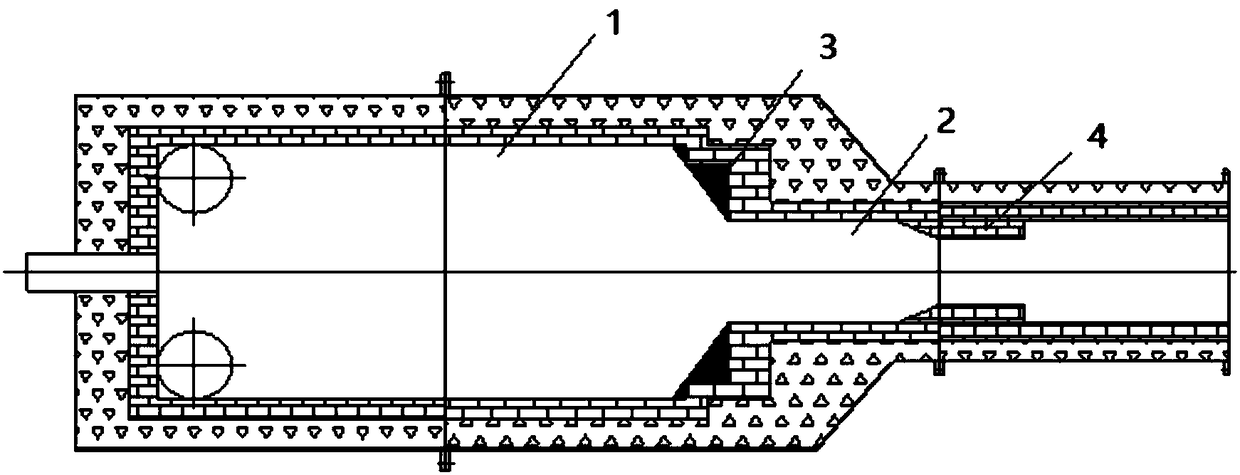

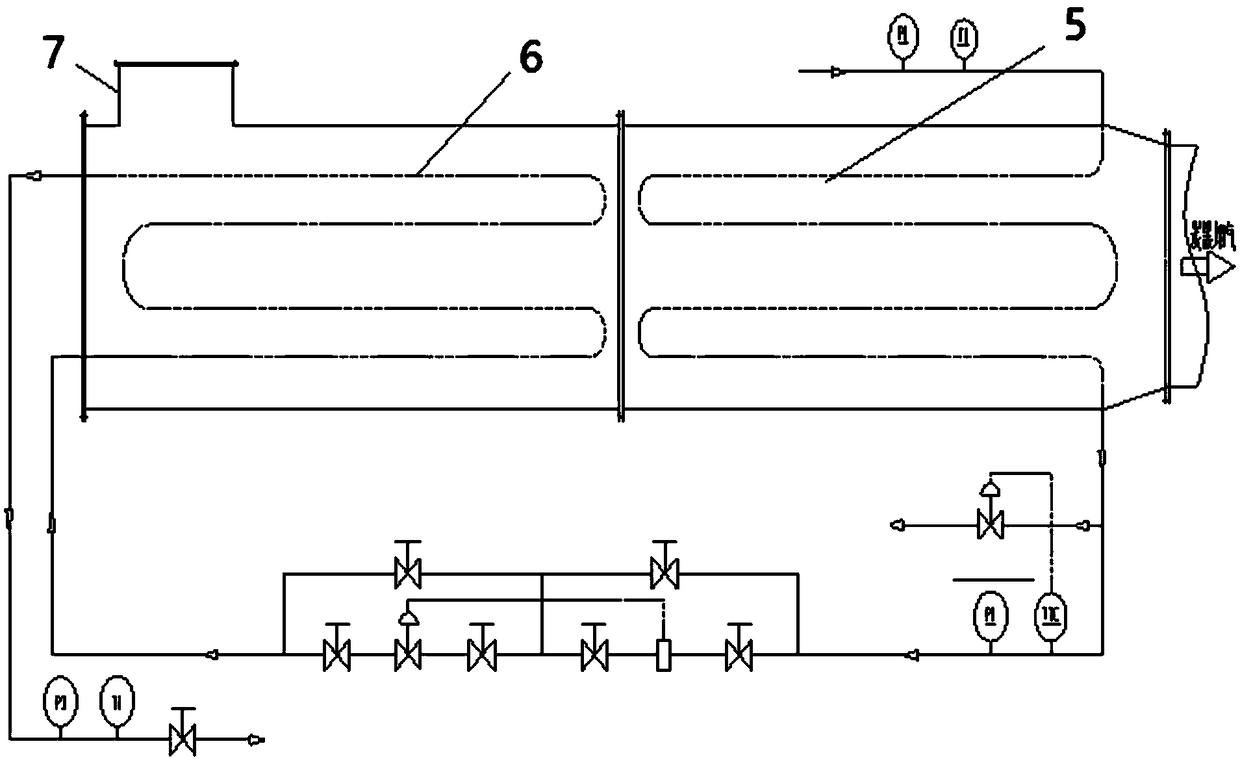

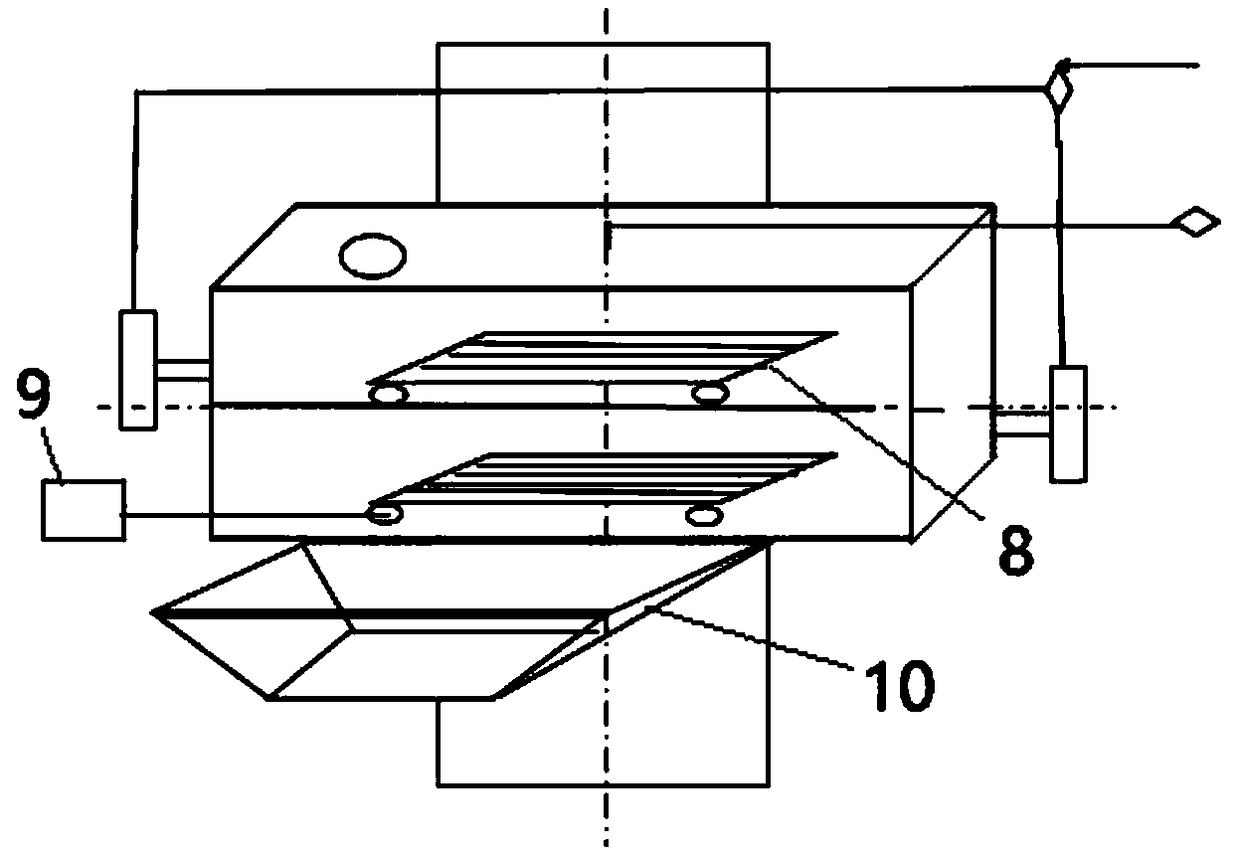

[0019] The present invention is achieved in that a kind of production method step of high-purity conductive carbon black is:

[0020] 1) Primary processing of anthracene oil: Anthracene oil is transported by a transport vehicle to the depot unloading pool, heated to 80°C-90°C by high-pressure steam, and the raw oil is filtered from the tank truck and then unloaded into the deoiling pool, in the deoiling pool Install a filter and then filter. During the oil unloading process, large particles of impurities are filtered out. The filtered anthracene oil is stored in the oil unloading tank for 48-72 hours, so that impurities such as free carbon and oil (water) in the anthracene oil can be separated naturally. Layer separation, the oil (water) is pumped from the oil to the flash dehydration system, the steam coil is used to indirectly heat the oil and water to separate and remove the water, and the anthracene oil is dehydrated to a moisture content of ≤0.5%. After dehydration, the an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com