Continuous production process of mesocarbon microbeads

A technology of mesocarbon microspheres and production process, which is applied in the field of continuous production process of mesocarbon microspheres, can solve the problems that the production capacity cannot reach the design load, the enterprise does not obtain economic benefits, the processing capacity of a single set of devices is small, and the like. Avoid furnace tube coking, reduce construction investment and operating costs, and avoid repeated heating and cooling effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

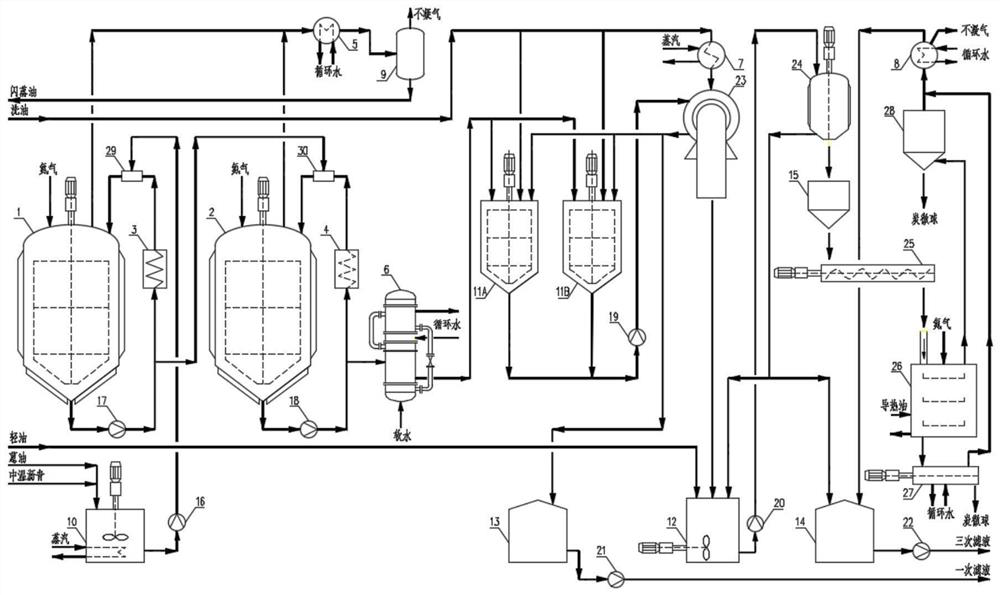

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

[0032] 【Example】

[0033] Such as figure 1 As shown, a continuous production process of mesophase carbon microspheres, the process includes the following process:

[0034] (1) Preparation of carbon microspheres

[0035] After medium-temperature asphalt and anthracene oil are uniformly mixed in the raw material tank 10, they are mixed with the circulating material that comes to the heating kettle 1 and heated by the heating kettle heating furnace 3, and then sent into the heating kettle 1. After being heated to a certain temperature by the heating kettle 1, a part of it is mixed with the After mixing the reacted materials from the reactor 2 and heated by the reactor heating furnace 4, they are sent into the reactor 2, and the inside of the reactor 2 is kept at a certain temperature, and after the thermal polycondensation reaction, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com