Patents

Literature

36results about How to "Reduce the number of shutdowns" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Firm can plastic and preparation method thereof

Owner:宜兴市炉顶密封工程有限公司

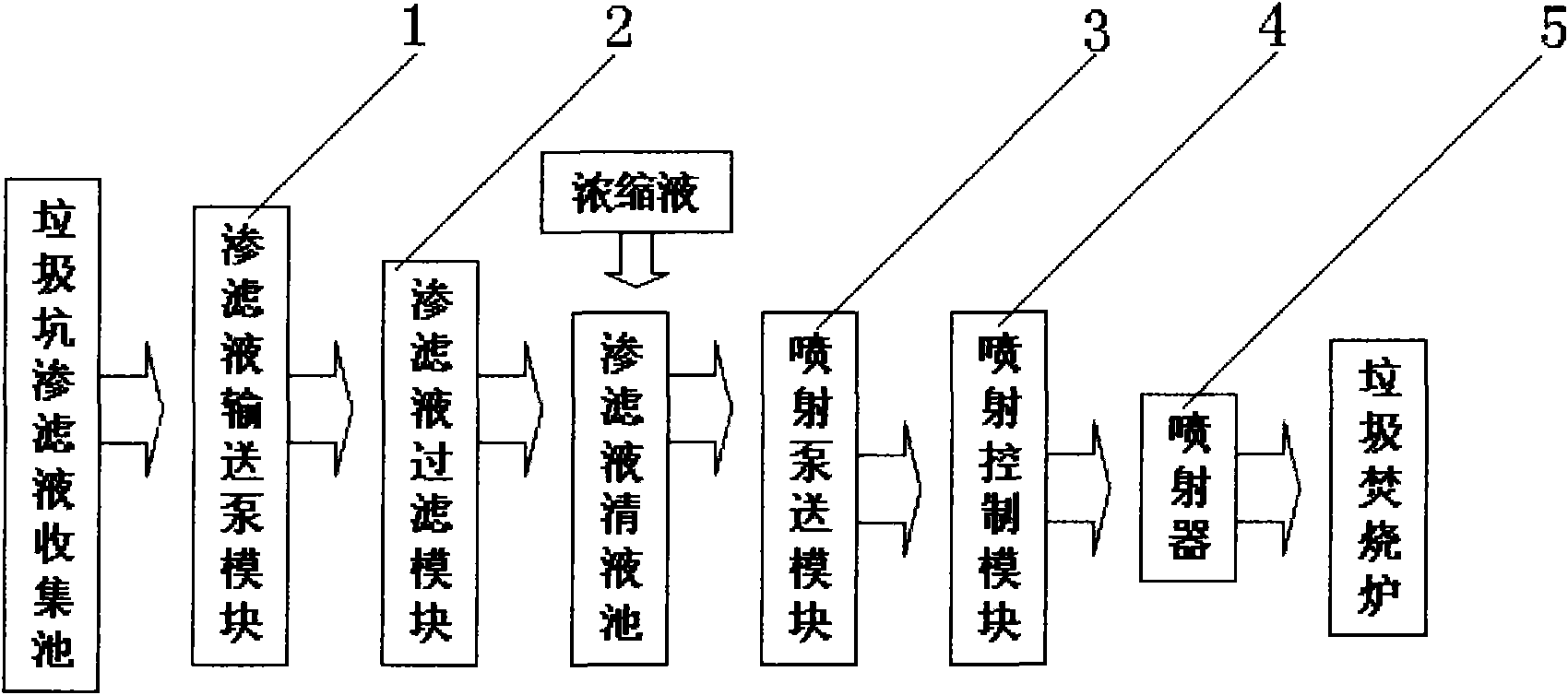

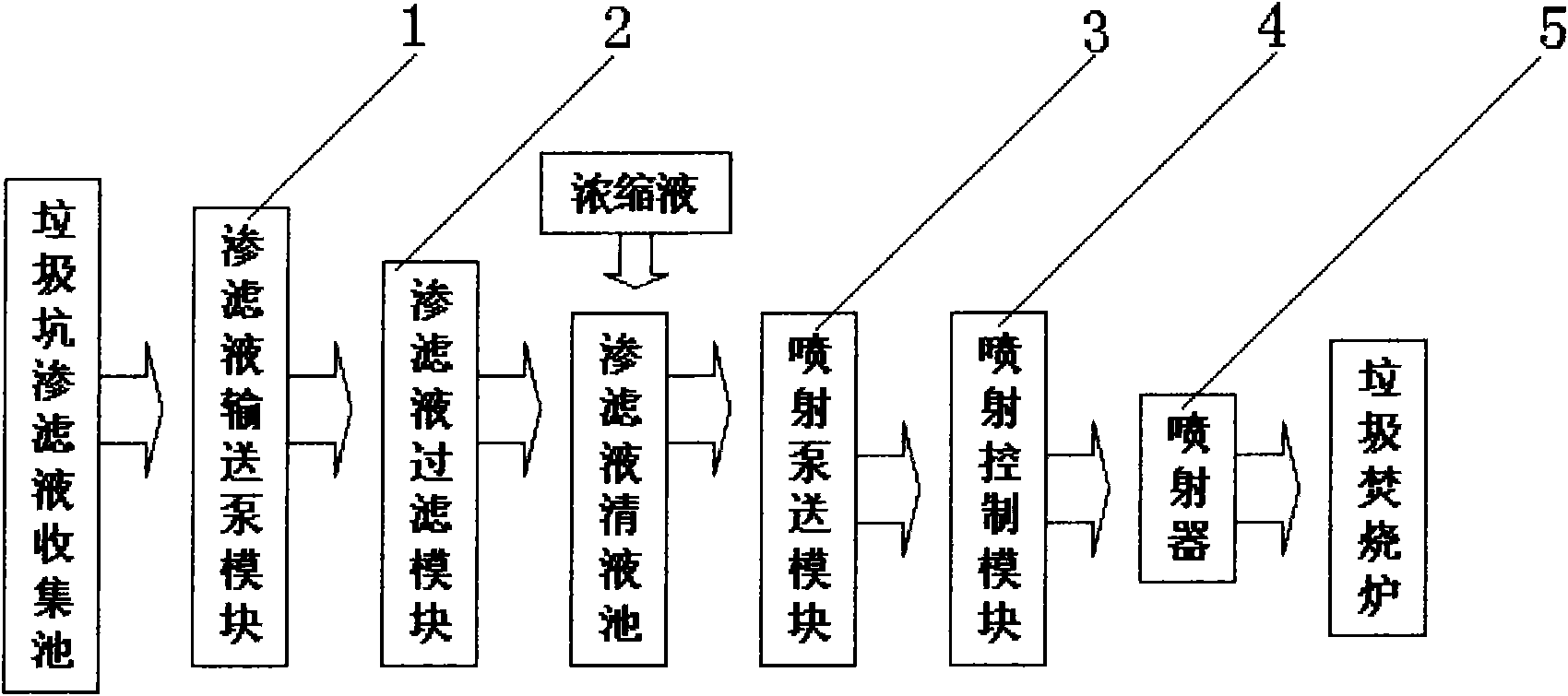

Process for spraying and treating percolate

ActiveCN101979921AExtended operating cycleReduce cokingIncinerator apparatusAutomatic controlBurn treatment

The invention relates to a process for treating garbage percolate, in particular to a process for spraying and treating percolate and aims to provide a reliable and efficient garbage percolate treatment method for spraying the garbage percolate for burning treatment. The garbage percolate can be prevented from polluting the environment and the pollution problem can be solved completely. In order to fulfill the aim, the process for spraying and treating the percolate is provided and comprises the following steps of: collecting the percolate; filtering the percolate; and spraying the percolate. A technical process for spraying, burning and treating the percolate is simple and is convenient to operate. Stock garbage percolate can be decomposed fully or concentrated solution produced in other treatment modes can be treated simultaneously and secondary pollution is avoided; and compared with other treatment modes, the process has low construction, operation and maintenance costs, small floor area and high automatic control degree and is convenient to operate.

Owner:SHANGHAI TECHSPRAY ENG

Scale inhibitor for boiler and water supply pipeline

ActiveCN104692545APromote biodegradationImprove the environmentSpecific water treatment objectivesWater treatment locationCarboxylic acidPolymer

The invention discloses a scale inhibitor for a boiler and a water supply pipeline. The scale inhibitor is prepared by the following steps: firstly, mixing starch, sodium humate and sodium lignin sulfonate evenly to obtain material A; mixing an organic carboxylic acid polymer with an organic phosphonic acid evenly, and preparing liquid B; dissolving the material A into pure water to prepare a water solution; dropwise adding hydrogen peroxide, and then reacting; dropwise adding the liquid B to the obtained reaction liquid dropwise adding a caustic soda solution to control the pH value, and then carrying out heating reaction; reacting and cooling to a room temperature, thus obtaining a product liquid scale inhibitor; and mixing the scale inhibitor with sodium carbonate or sodium carbonate and caustic soda evenly when in use. According to the scale inhibitor disclosed by the invention, high-temperature adsorption capacity and dispersion force of starch, sodium humate and sodium lignin sulfonate are improved through chemical modification; and the scale inhibitor has temperature tolerance and hardness resistance. When the scale inhibitor enters a high-temperature zone of a boiler body, the scale inhibiting performance for scale forming matters is relatively high; a water supply system of the boiler is prevented from being scaled; the scale inhibiting performance of a high-temperature system of the boiler is improved; and a strong guarantee is provided for safe operation of the boiler.

Owner:QINYANG QINGQUAN IND CO LTD

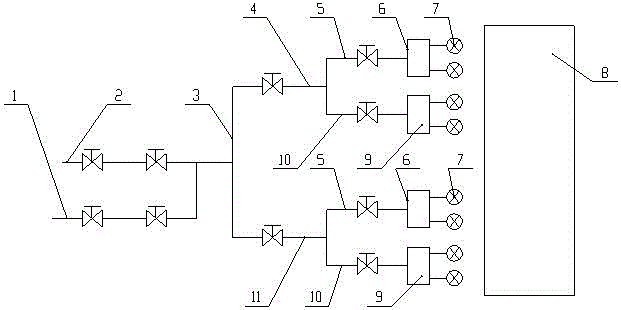

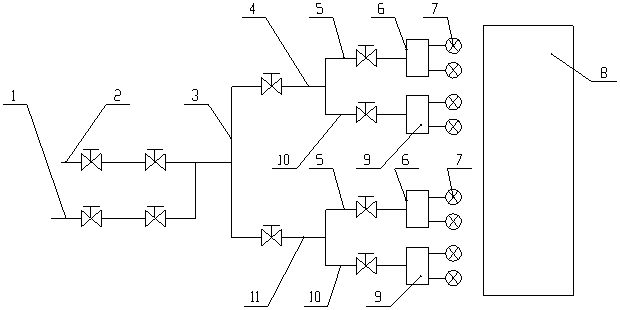

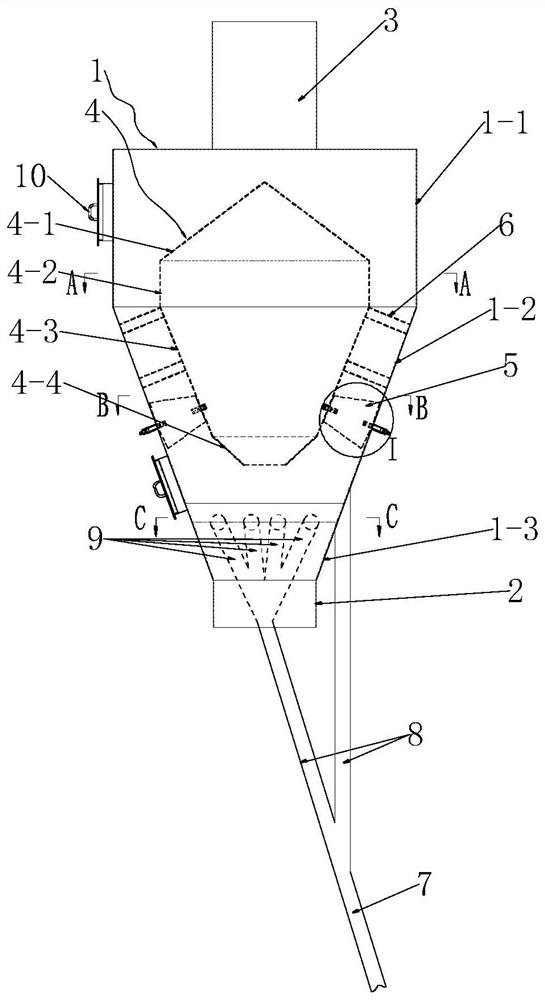

Process for on-line cleaning to double rotational flow gas burner

ActiveCN105402730AExtended continuous operating cycleExtended service lifeGaseous fuel burnerSpray nozzleSystem maintenance

The invention discloses a process for on-line cleaning to a double rotational flow gas burner. The process comprises the following steps: A), determining a purging medium; B), determining purging loops and the quantity thereof before the burner; C), distributing and determining the quantity of the purging branch pipe loops of a swirl plate spray nozzle set inside the burner; D), determining the quantity N of the purging branch pipes of a swirl plate spray nozzle of the burner according to the quantity N of swirl plates, and then accessing N spray nozzles, so as to form a spray nozzle set purging loop component; E), selecting the model of and making a swirl plate purging spray nozzle of the burner; F), determining the fixing way of the swirl plate purging spray nozzle of the burner and a pipeline; G), controlling and designing of the valve of a purging pipeline; and H), running test: 1, nitrogen purging; and 2, water purging. The process provided by the invention has a reasonable structure, can be used for on-line cleaning to the blockage of the swirl plates of the double rotational flow gas burner, can enable the continuous operating period of the burner to be prolonged greatly, and prolongs the service life of the double rotational flow gas burner; and on-line running and operation are simple, and system maintenance is small.

Owner:JIANGSU JIULIAN METALLURGY MACHINERY

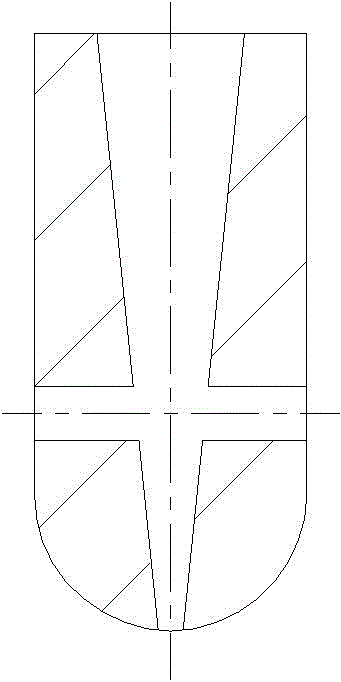

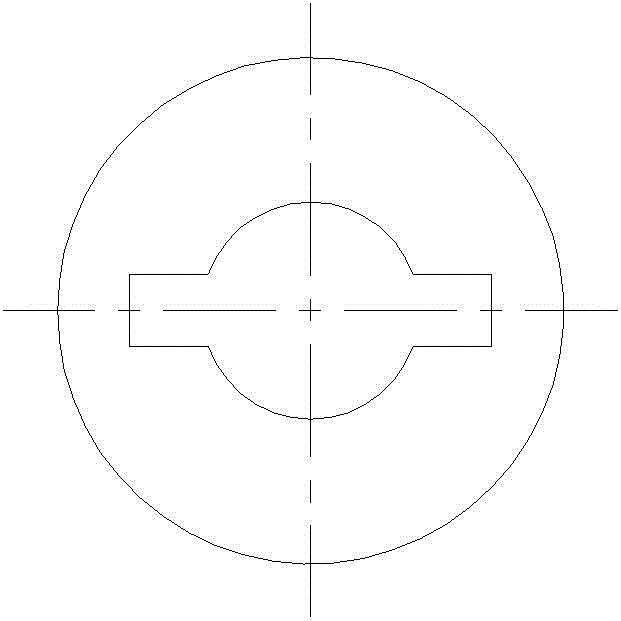

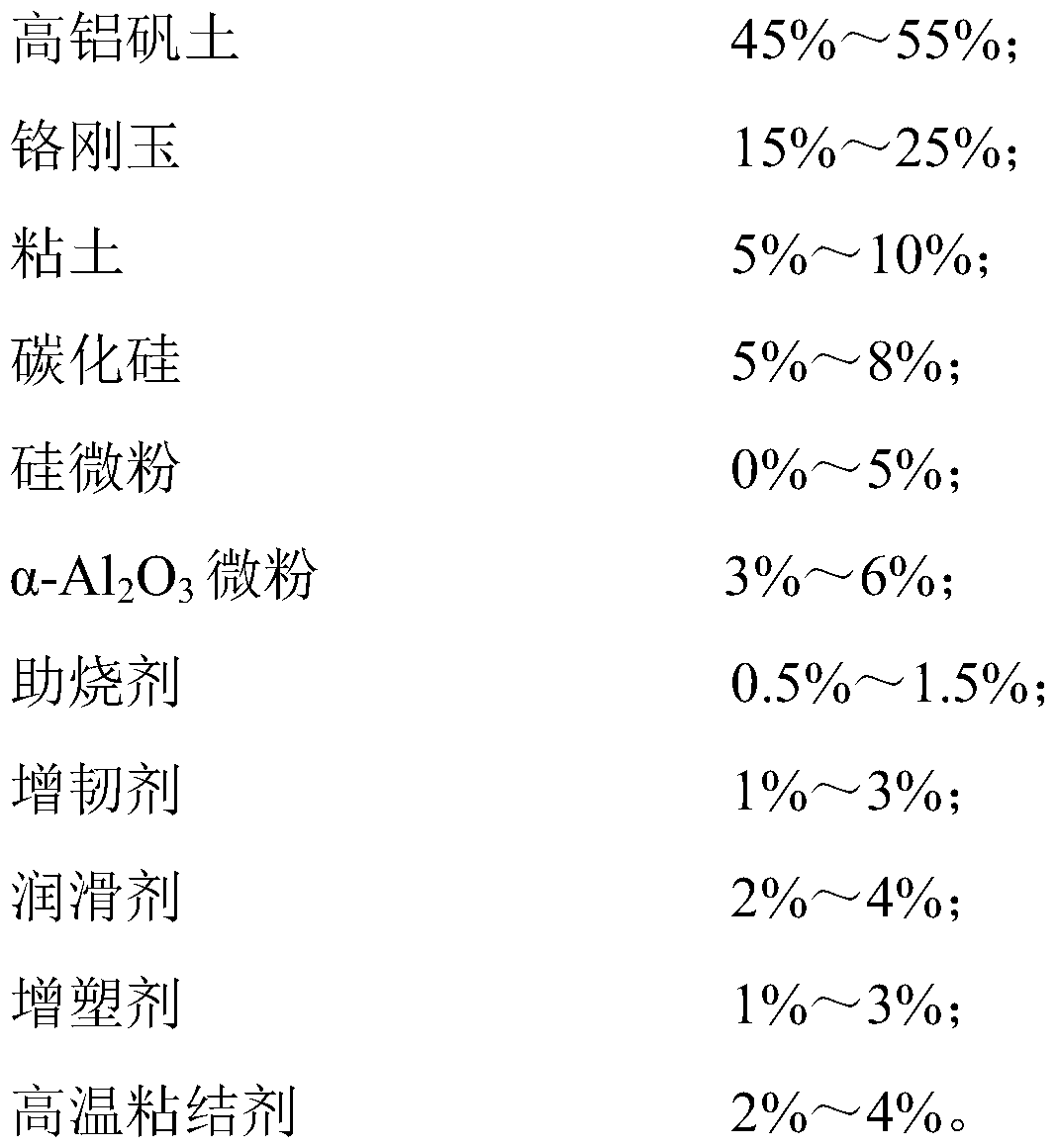

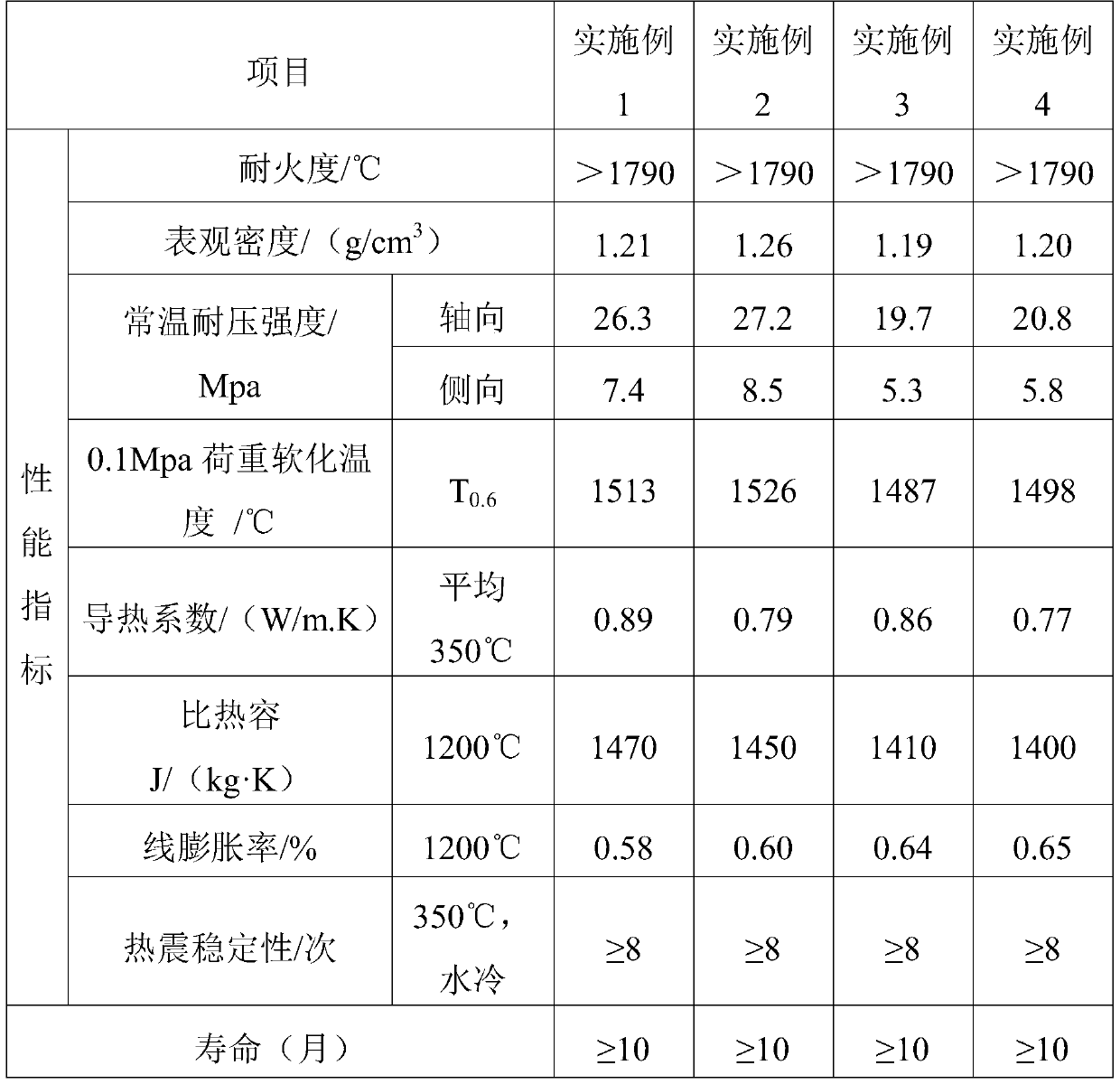

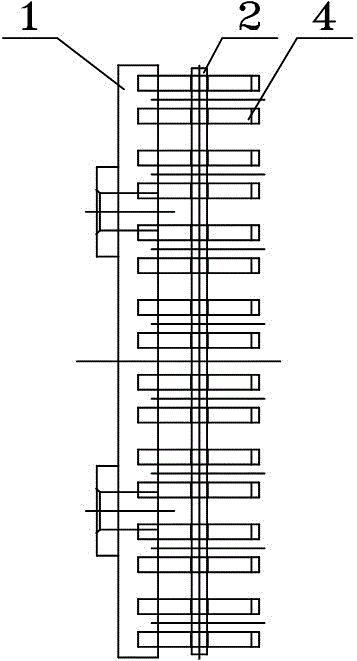

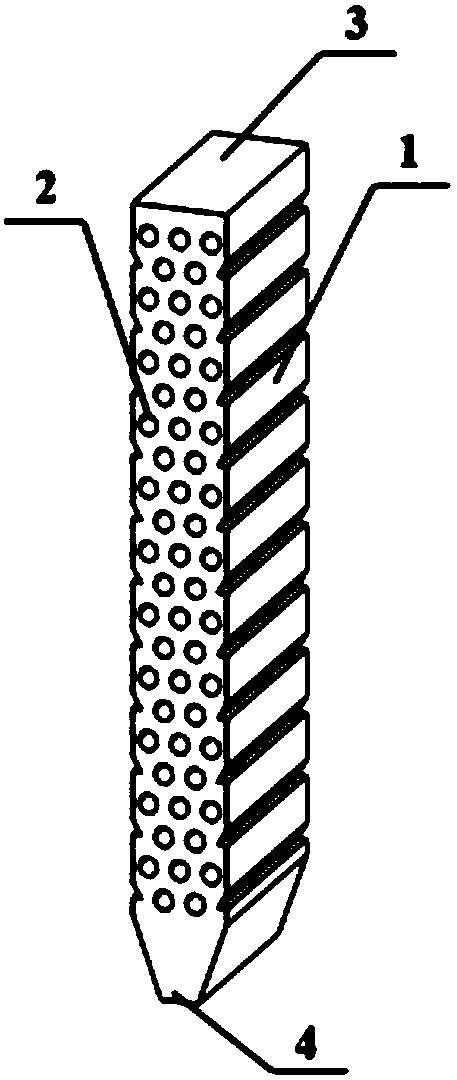

Honeycomb body used for regenerative heating furnace and production method of honeycomb body used for regenerative heating furnace

InactiveCN110372343AMeet the temperature requirementsHigh refractorinessCeramicwareCombustionPlasticizer

The invention discloses a honeycomb body used for a regenerative heating furnace and a production method of the honeycomb body used for the regenerative heating furnace. According to the honeycomb body, high bauxite and pink funsed alumina are adopted as main components, clay is adopted as a binder, silicon carbide, silica powder and alpha-Al2O3 powder are added, a sintering aid, a toughener, a lubricant, a plasticizer and a high-temperature binder are added at the same time, and through technology steps of mixing, vacuum pugging, extrusion, forming drying, firing and the like, the honeycomb body used for the regenerative heating furnace is produced. The honeycomb body meets the technology requirements of a regenerative combustion technology, has performance of large heat storage capacity,stable high-temperature performance, high heat exchange efficiency and a long service life, the number of times of blowing out due to replacement of honeycomb bodies of a steel plant can be decreased, the production operation rate of the heating furnace is improved, the equipment maintenance cost is reduced, and effects of increasing production and practising economy are truly achieved, so that the honeycomb body used for the regenerative heating furnace has obvious economic benefits and very wide use prospects.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

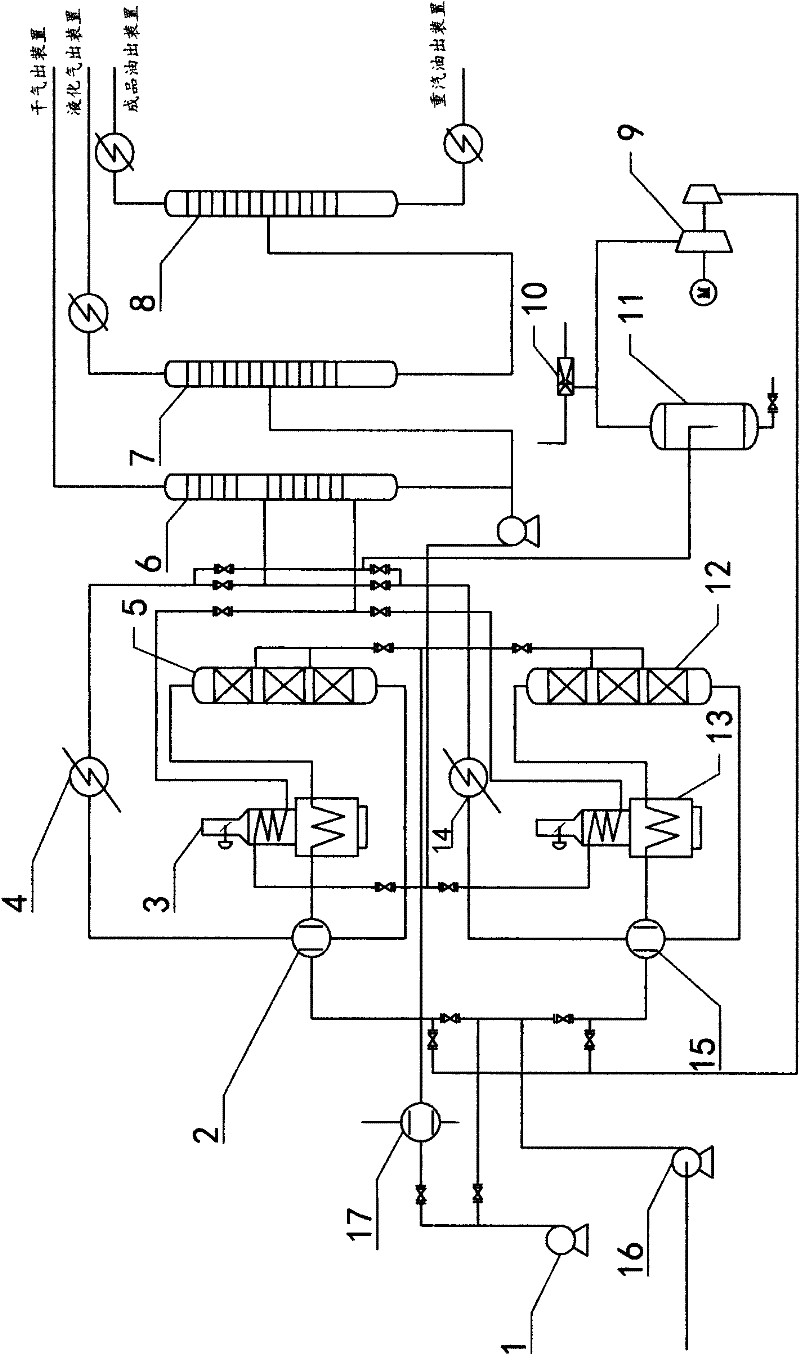

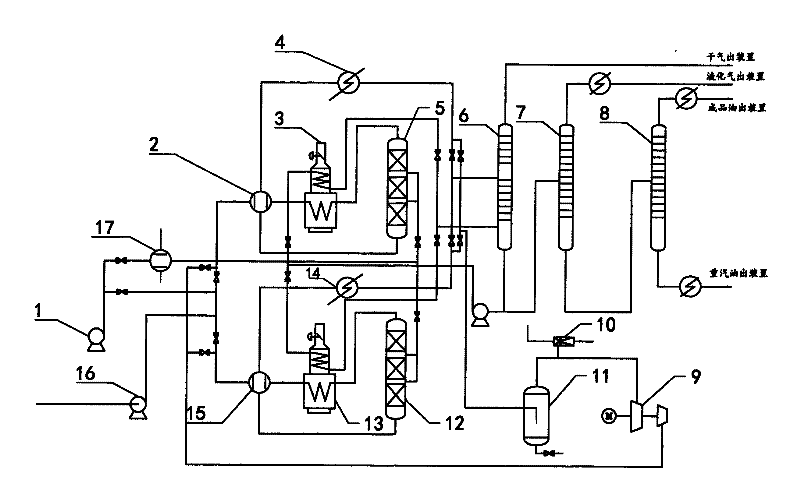

Method for producing gasoline blended component with high octane number from refinery gas and light hydrocarbons

InactiveCN102226102AReduce olefin contentFully recycleGaseous mixture working upNaphtha treatmentDesorptionMass ratio

The invention relates to a method and device for producing a gasoline blended component with high octane number from refinery gas and light hydrocarbons, belonging to the technical field of aromatization of light hydrocarbons. The device comprises heating furnaces, reactors and an absorption-desorption tower which are serially connected, and is characterized in that: (1) two groups of the heating furnaces and the reactors that are parallelly connected are used for cycle operation; (2) in the reactor, the process conditions are as follows: the reaction temperature is 320-420 DEG C, the pressure is 0.8-2.0 MPa, the mass space velocity of 0.4-0.8 h<-1>, and the mass ratio of light hydrocarbon component to low-octane number gasoline is (30:70)-(10:90); (3) the light hydrocarbon component in the reactor is one of catalysis dry gas, coking dry gas and catalytic coking liquefied gas or a mixture thereof; and the low-octane number gasoline is one of ordinary / reduced pressure straight-run gasoline, field condensate oil, hydrogenated naphtha and cracked gasoline or any combination thereof; and (4) a stabilizer column and a heavy component eliminating tower are serially connected on the rear side of the absorption-desorption tower. The method and the device provided by the invention adopt two groups of the heating furnaces and the reactors that are parallelly connected for cycle operation, so as to realize continuous operation of reaction regeneration. In addition, the method and the device have strong adaptability and low energy consumption, and can directly remove part of the heavy components in the gasoline component so as to reduce the dry point of the gasoline product. During regeneration, the suction pressure regeneration combined process is used, so as to greatly shorten the coking time.

Owner:SHANDONG JINCHENG PETROCHEMICAL GRP CO LTD

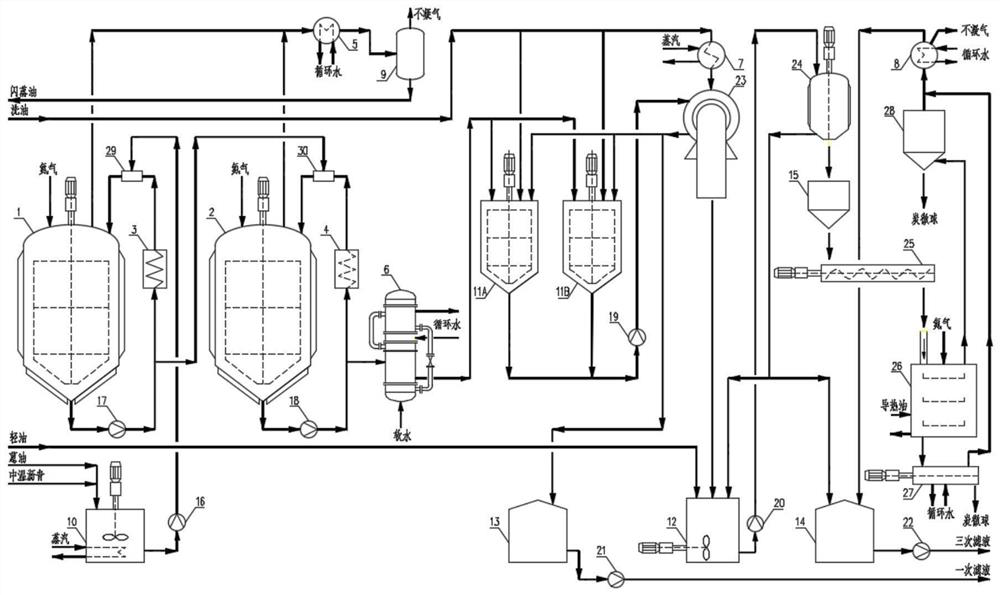

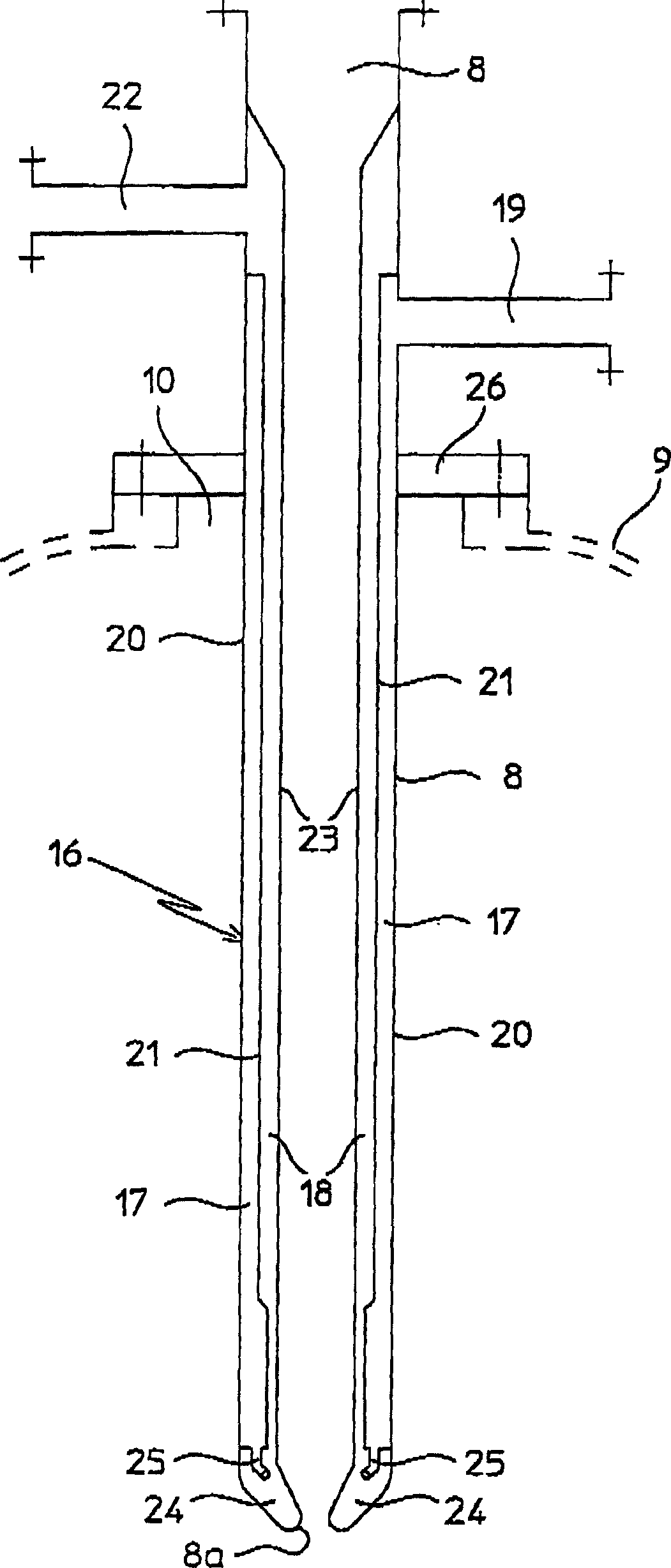

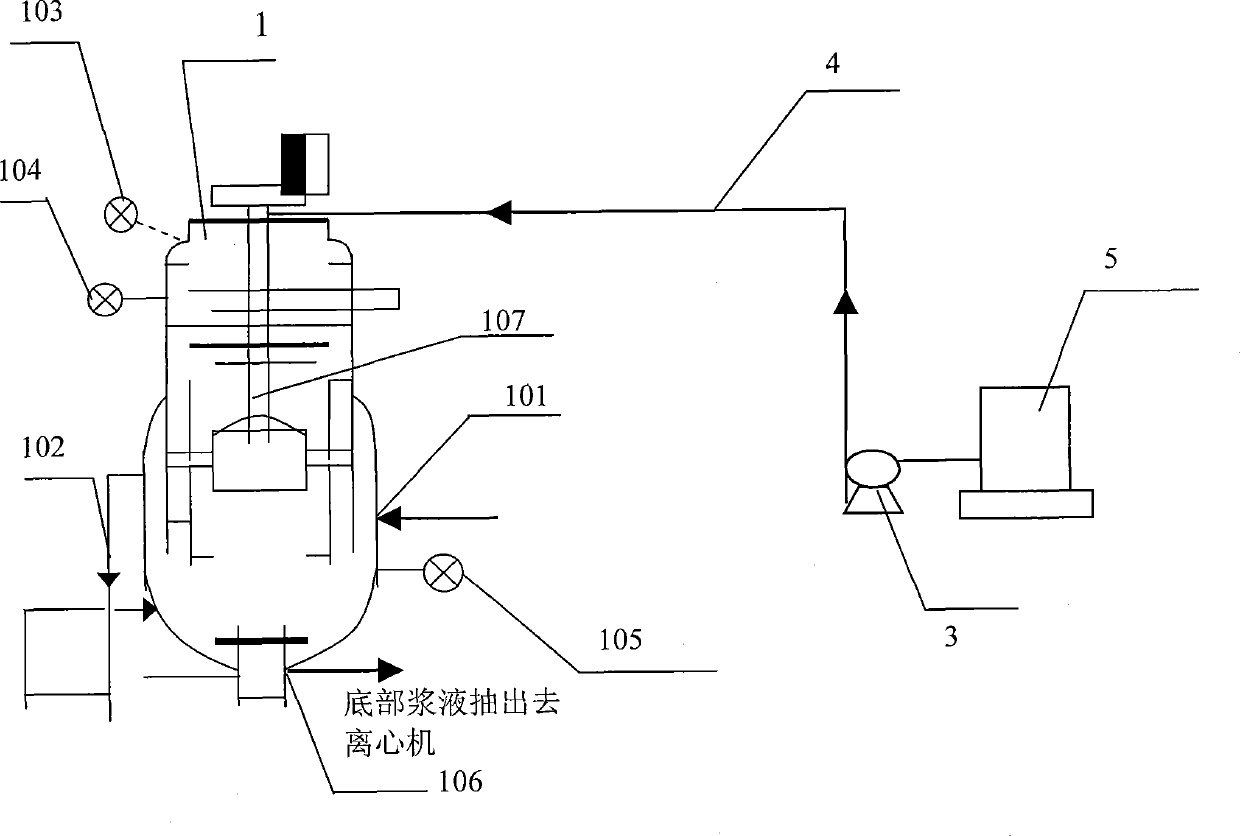

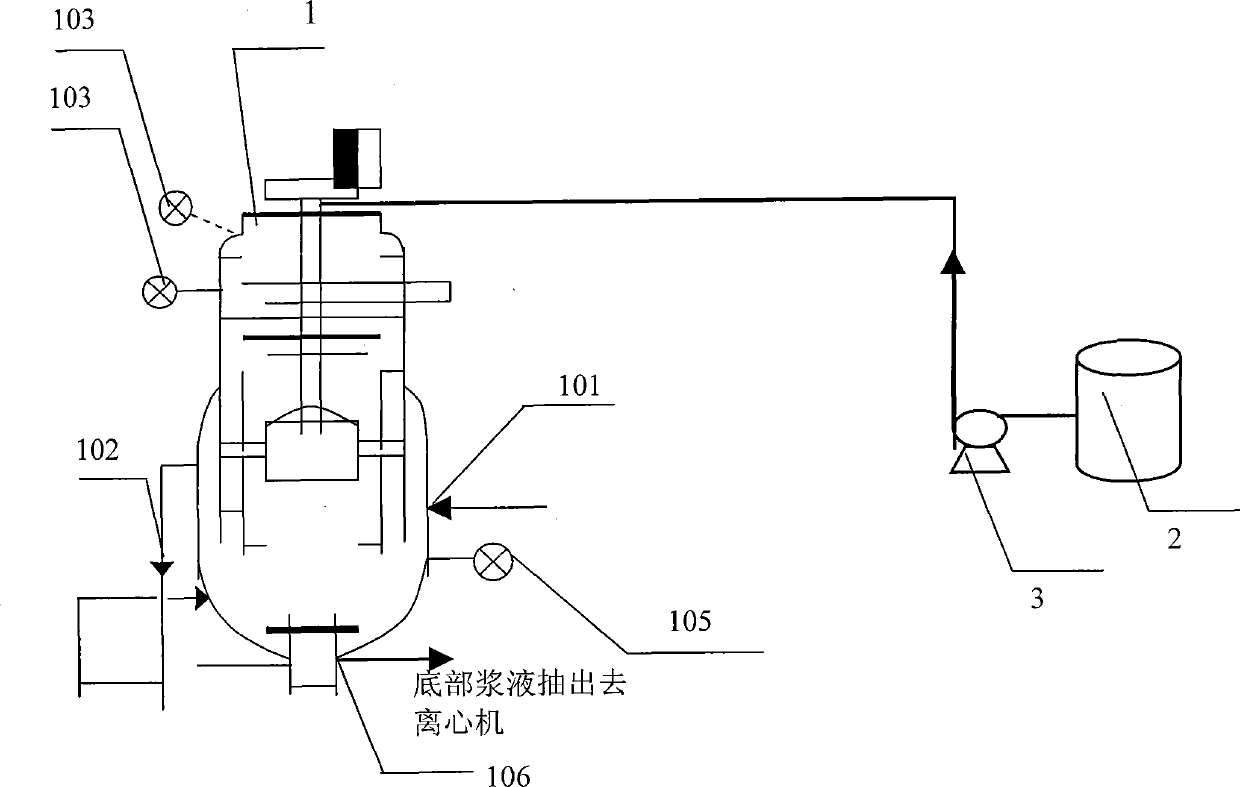

Continuous production process of mesocarbon microbeads

ActiveCN112573504AEasy to handleRealize continuous productionCarbon preparation/purificationThermodynamicsMicrosphere

The invention provides a continuous production process of mesocarbon microbeads. The continuous production process comprises the following steps: uniformly mixing medium-temperature asphalt and anthracene oil in a raw material tank, mixing the obtained mixture with a circulating material which comes from a heating kettle and is heated by a heating furnace of the heating kettle, feeding the mixed materials into the heating kettle, heating the mixed materials to a certain temperature by the heating kettle, mixing one part of the mixed materials with a circulated reacted material which comes froma reaction kettle and is heated by a heating furnace of the reaction kettle, feeding the finally obtained mixture into the reaction kettle, keeping a certain temperature in the reaction kettle, and carrying out thermal polycondensation reaction to obtain carbon microsphere-containing intermediate asphalt; and cooling, washing, separating, drying and cooling the intermediate asphalt to obtain a finished product, namely themesocarbon microbeads. The process is simple in technological process, high in automation degree, easy to operate, low in energy consumption, low in equipment investment, good in environment-friendly effect and suitable for large-scale industrial continuous production.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

Emergency blowout control method for large slab heating furnace

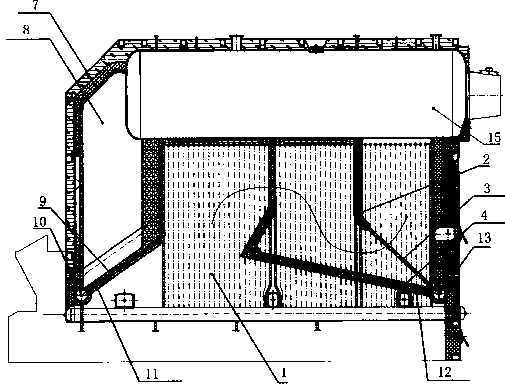

ActiveCN101818243AReduce the number of shutdownsShorten the timeFurnace typesHeat treatment furnacesProduction lineCombustion

The invention relates to an emergency blowout control method for a large slab heating furnace. The emergency blowout control and alarm of the slab heating furnace is realized by the steps of reasonably selecting automatic blowout conditions and technological parameters, setting a blowout interlocking plant and a movement time sequence, changing the control mode for the coal gas control valve, adding a sound alarm for the low-pressure blowout alarm signal of coal gas, air and instrument air in the blowout procedure, and popping up an alarm picture. The invention has obvious effect on the heating furnaces of hot-strip 1700 mm and 1780 mm production lines. Even when coal-gas low pressure, combustion-fan power-fail, instrument-air low pressure, evaporation cooling system power-cut and other faults occur, no safety or equipment accident happens. Thus, the invention greatly reduces the frequency and time of heating furnace blowout and creates favorable conditions for smooth steel rolling production and yield enhancement.

Owner:ANGANG STEEL CO LTD

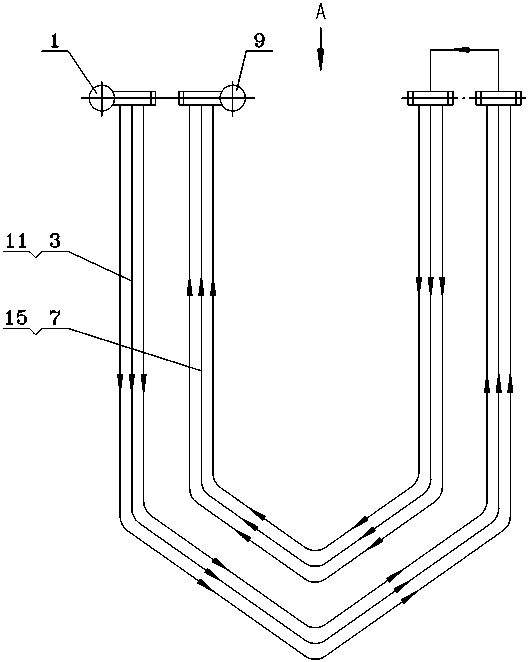

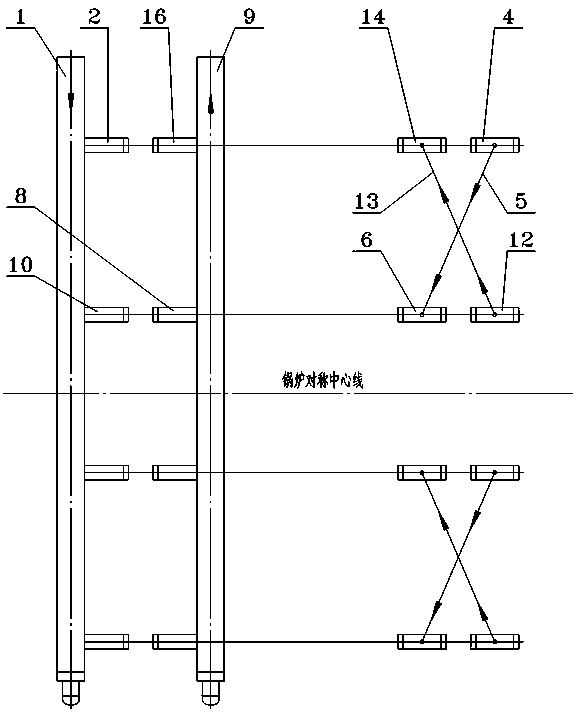

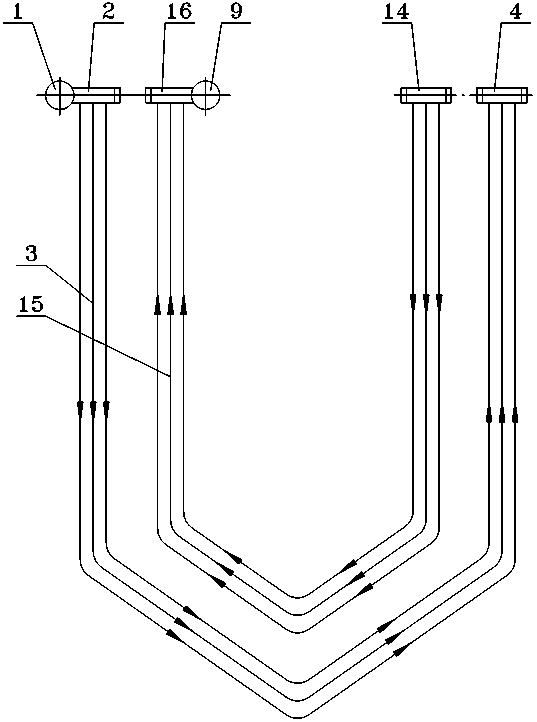

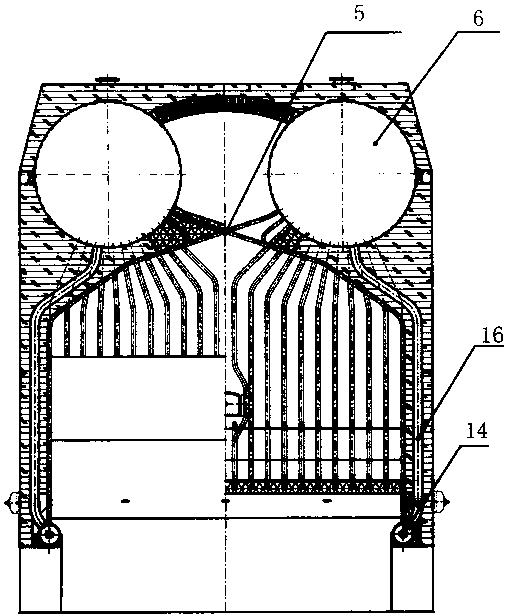

Cross mixed flow superheater

PendingCN109708096AReduce wall temperatureEliminate thermal deviation of working fluidSteam superheatersMixed flowCross connection

The invention discloses a cross mixed flow superheater. A superheater pipe screen comprises two sets of near center pipe screens and two sets of far center pipe screens separately arranged in a boilerin the boiler width direction; the two sets of near center pipe screens and the two sets of far center pipe screens are both connected with a superheater inlet header and a superheater outlet header;the near center pipe screens and the far center pipe screens approaching each other are connected through uniform temperature pipes; and near center pipe screen return headers with higher temperatures at the middle part of a hearth and far center pipe screen return headers with lower temperatures on two sides of the hearth are across connected, so that steam flows from the near center pipe screens to the far center pipe screens or from the far center pipe screens to the near center pipe screens for mixed flowing and mixed heating. The steam temperature of superheater pipe screen outlets separately arranged in the boiler width direction reaches the same parameters, so that the working medium heat deviation caused by different arrangement position temperature fields can be effectively eliminated, the wall temperature of superheated pipe screens in high-temperature areas is lowered, and the high-temperature corrosion in the areas is relieved and improved.

Owner:JINAN BOILER GRP

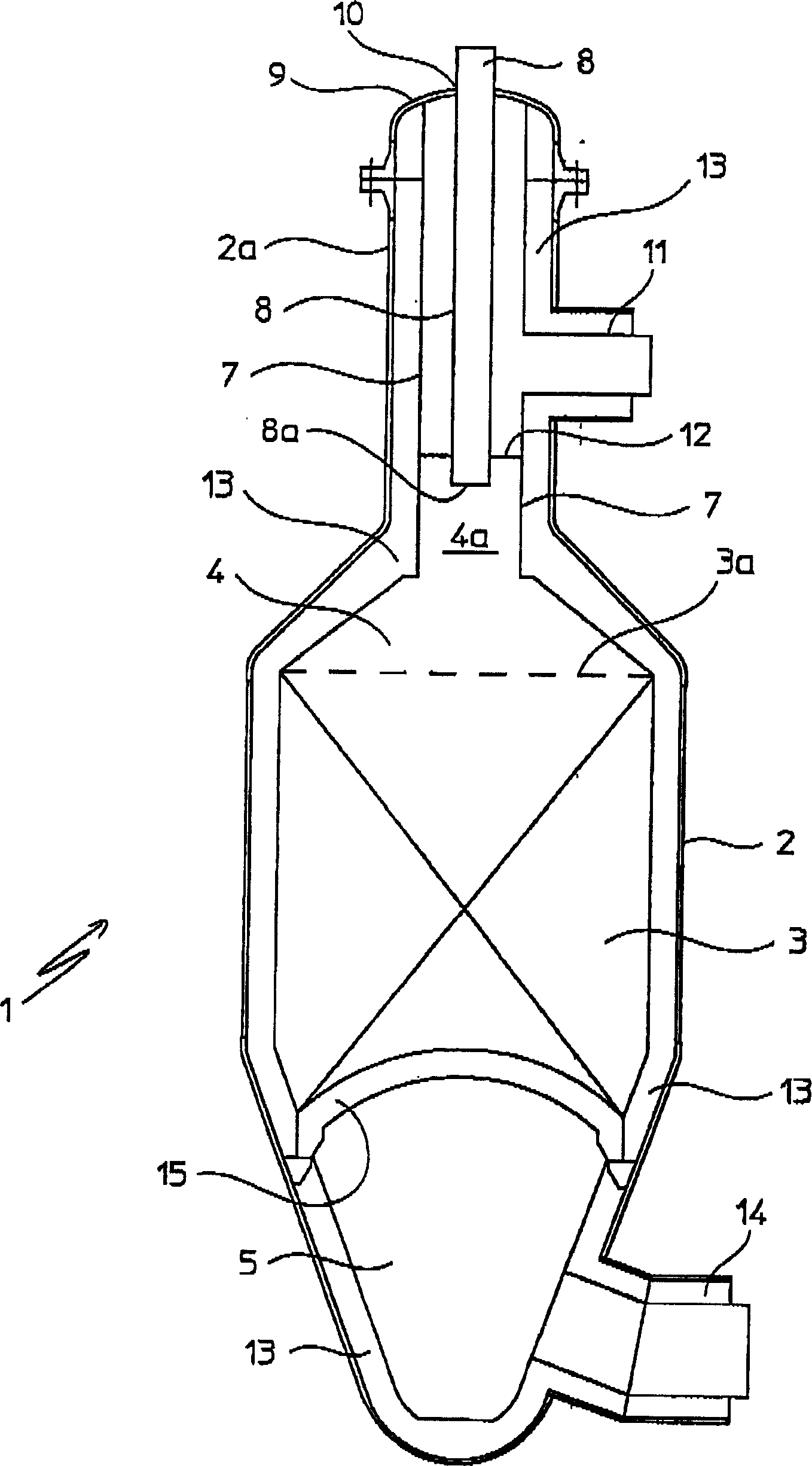

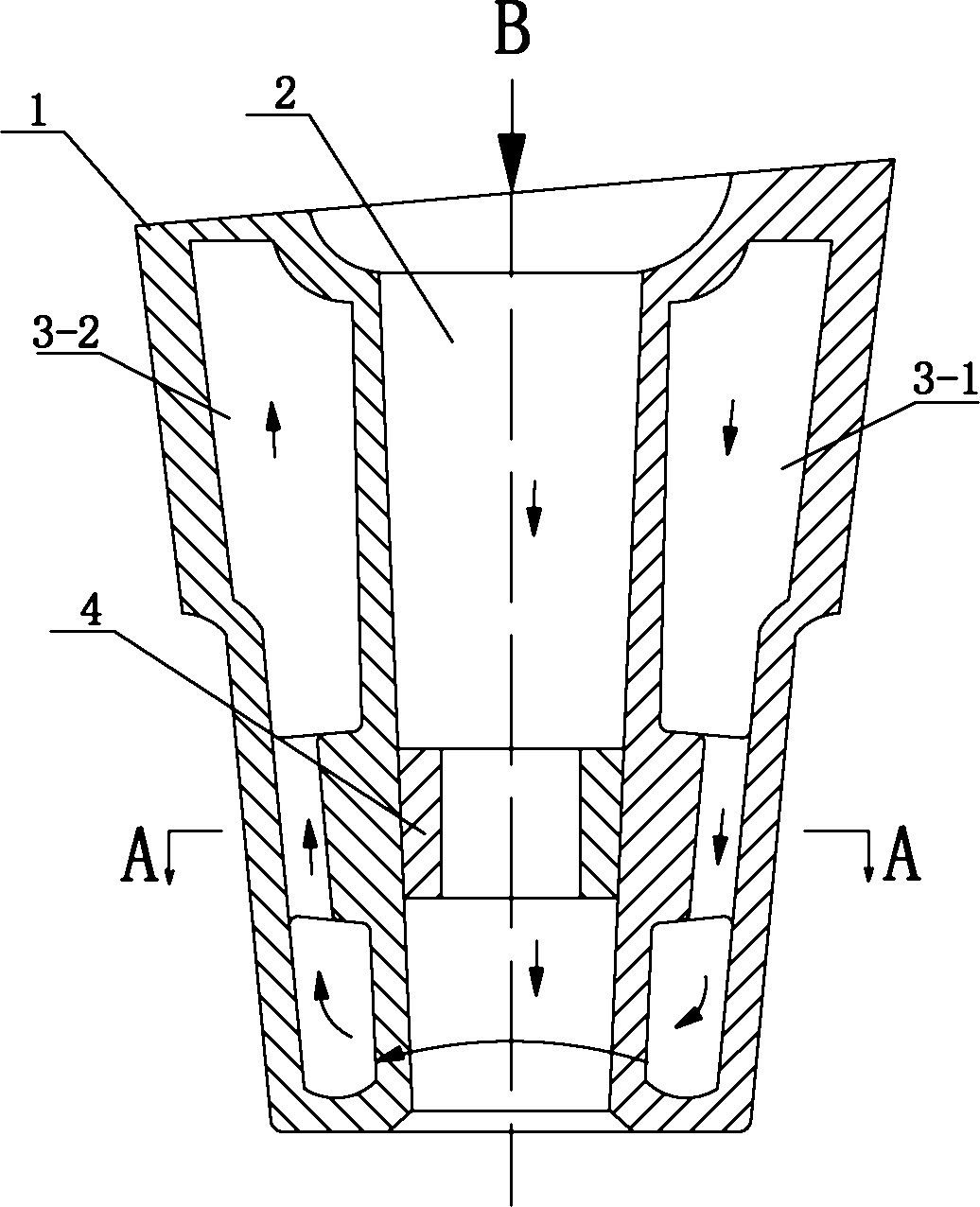

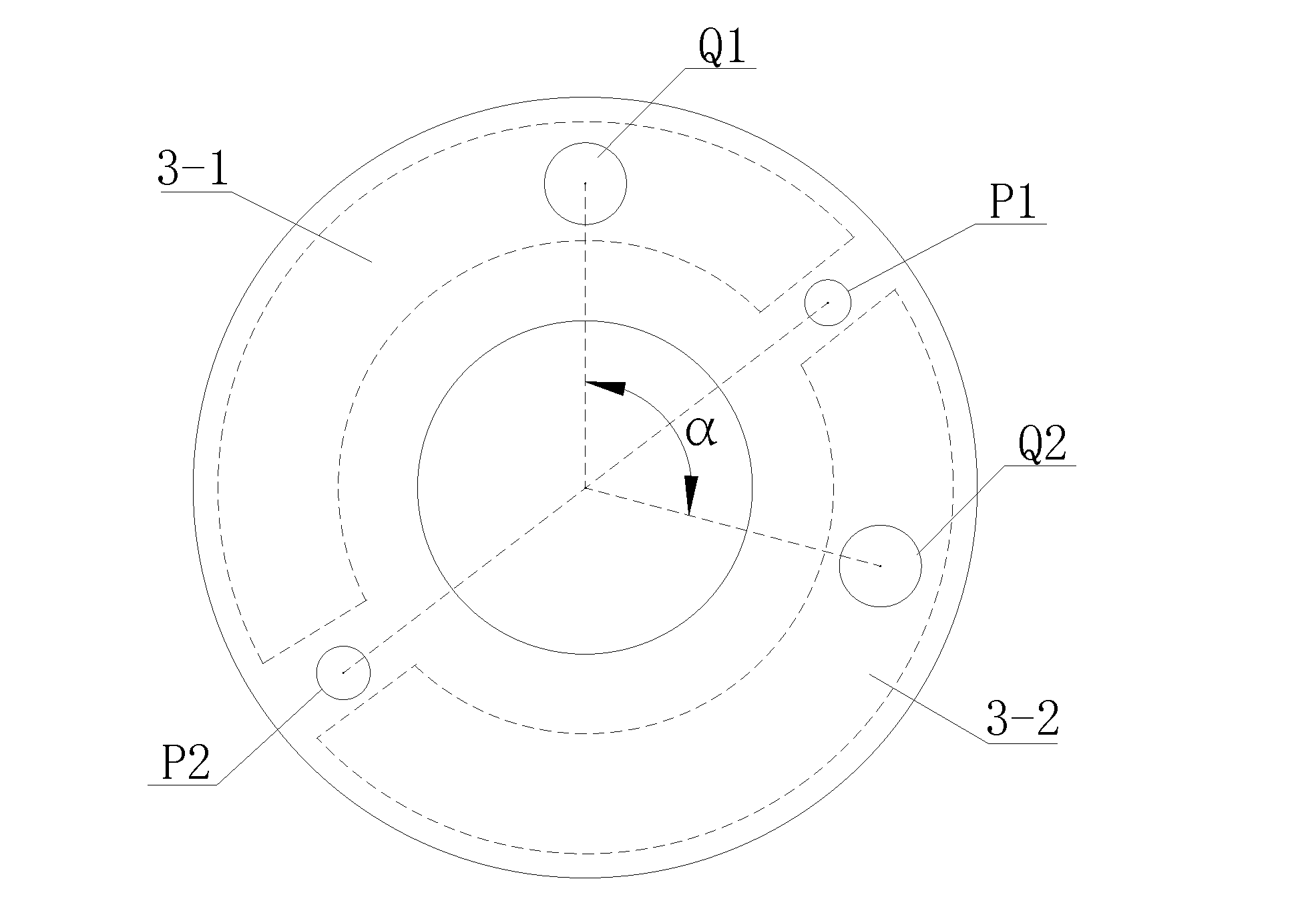

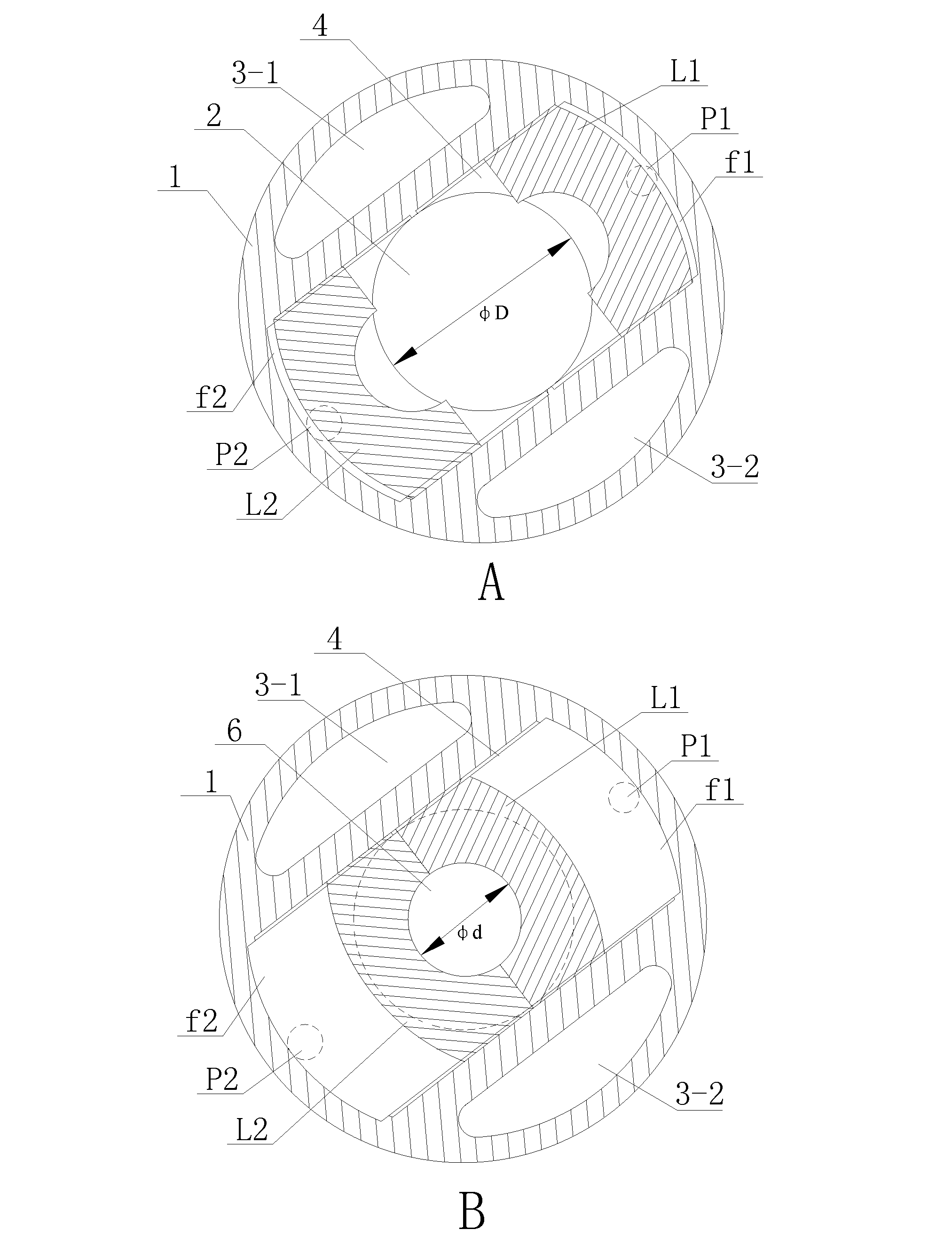

Secondary reforming equipment

InactiveCN1565959AIncreased operating lifeReduce the number of shutdownsBurnersHydrogenCombustion chamberEngineering

A secondary renormalization equipment for burning a portion of renormalized gas with oxygen which comprises a catalyzing bed, firing chambers are arranged on the catalyzing bed in fluid connection, and a tool for feeding the gas flow containing oxygen and part of the renormalized gas into the combustion chambers.

Owner:CASALE CHEM SA

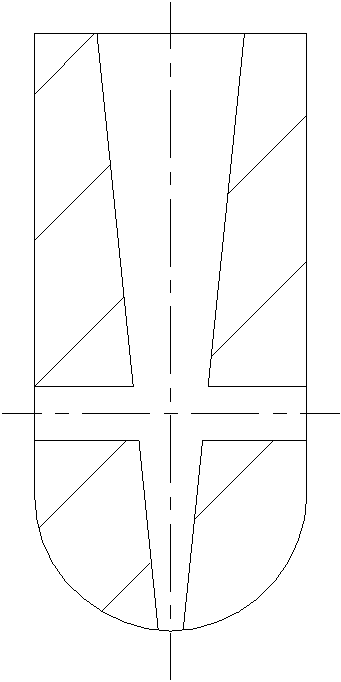

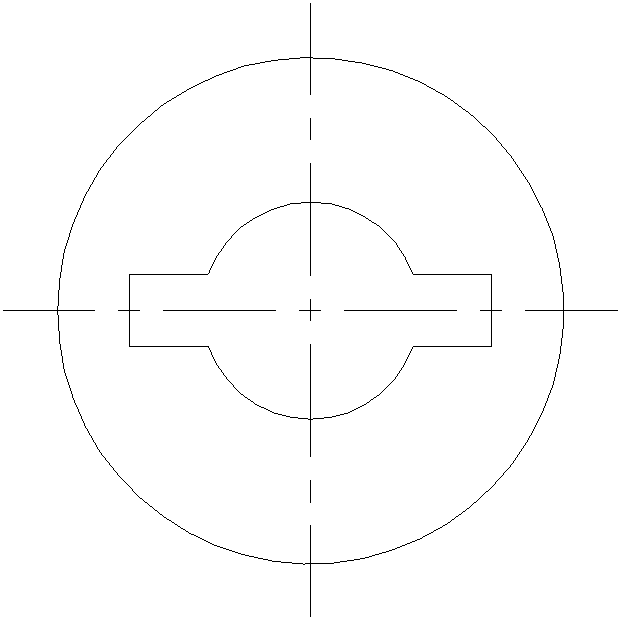

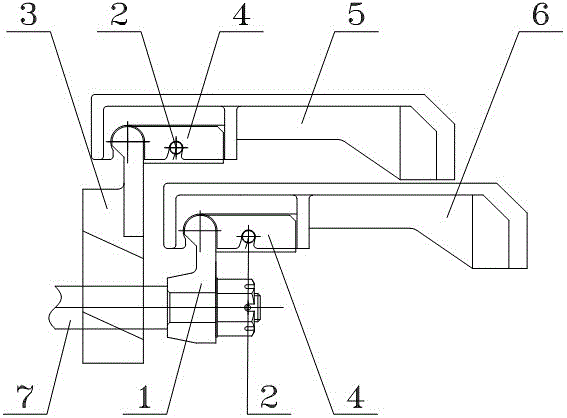

Blast furnace reducing tuyere short set

The invention relates to a blast furnace reducing tuyere short set which comprises a short set body provided with an air inlet end and an air outlet end, wherein the short set is internally provided with an air flue, a valve cavity is arranged between the middle of the short set body and the air outlet end, the air flue expands towards two opposite radial directions of the short set body simultaneously so as to form the valve cavity, the valve cavity is internally provided with a pair of throttle cores, when the pair of throttle cores is at a radial approaching position, the air flue is at the throttle state that a circulation surface is locally covered, when the pair of throttle cores is at a radial separation position, the air flue is at an opening state that the circulation surface is completely opened, and the valve cavity is provided with two control holes capable of controlling the throttle core to move; and the short set is also provided with a cooling channel for cooling the short set. After the structure of the buffer precooling slag liquid pool is adopted, the internal diameter of the tuyere short set can be adjusted in the production process of the blast furnace according to the furnace condition, and blowing-in speed can be improved in real time according to needs under the condition that the constant blowing-in pressure is maintained.

Owner:宗品禾

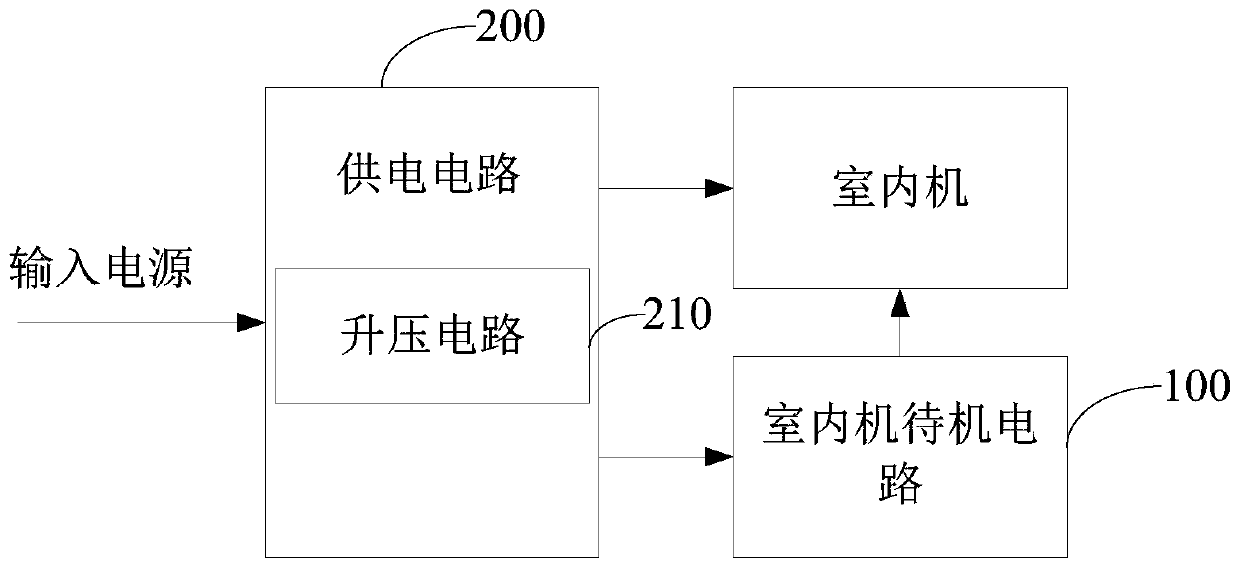

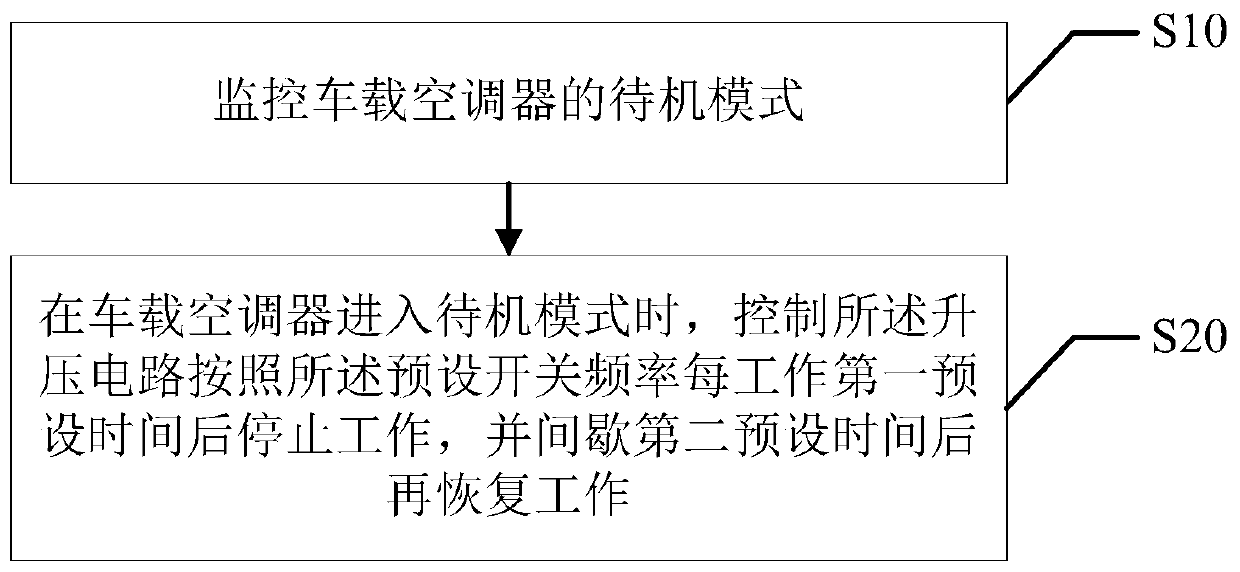

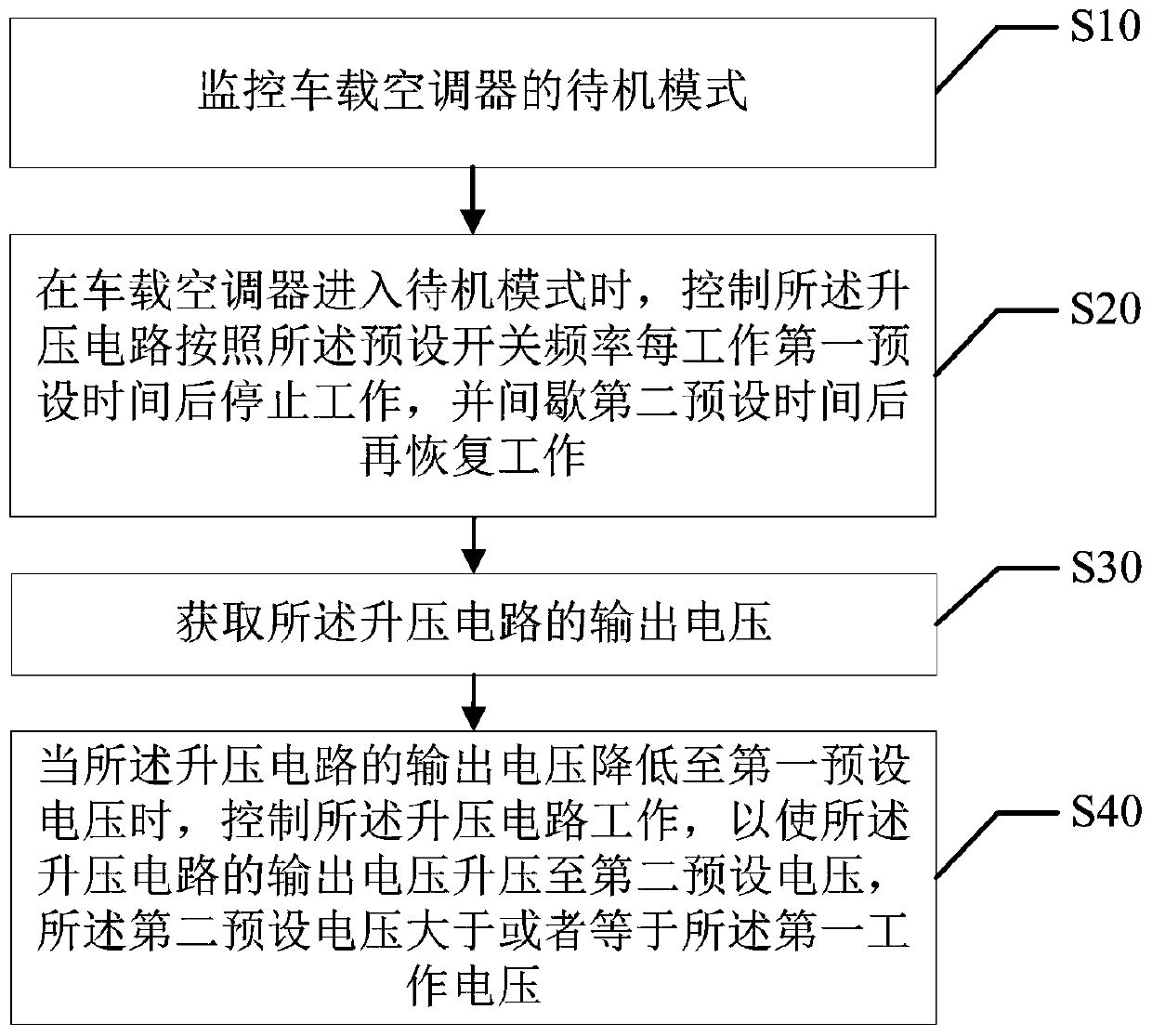

Vehicle-mounted air conditioner as well as low power consumption standby method and circuit thereof

ActiveCN110667334AReduce standby power consumptionImprove battery lifeAir-treating devicesVehicle heating/cooling devicesIn vehicleStandby power

The invention discloses a vehicle-mounted air conditioner as well as a low power consumption standby method and circuit thereof. The vehicle-mounted air conditioner comprises an indoor unit standby circuit and a power supply circuit used for providing standby voltage to the indoor unit standby circuit to control the standby of an indoor unit, wherein the power supply circuit comprises a boosting circuit used for performing boosting adjustment on an input power supply at a preset switching frequency. The low power consumption standby method of the vehicle-mounted air conditioner comprises the following steps that a standby mode of the vehicle-mounted air conditioner is monitored; and when the vehicle-mounted air conditioner enters the standby mode, the boosting circuit is controlled to stopworking after working for first preset time according to the preset switching frequency, and restart to work after intermittently resting for second preset time. According to the vehicle-mounted airconditioner as well as the low power consumption standby method and circuit thereof, the standby power consumption of the vehicle-mounted air conditioner is reduced.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

Spraying and washing process of ammonium sulfate crystallizer by non-saturator method

ActiveCN102381719BTake advantage ofEasy to optimizeSolution crystallizationAmmonia compoundsDistillationEvaporation

The invention discloses a spraying and washing process of an ammonium sulfate crystallizer by a non-saturator method, comprising the steps of: spraying and washing the ammonium sulfate crystallizer by ammonia still stronger ammonia water obtained by an ammonia distillation process; washing the attachment on the inner surface of the ammonium sulfate crystallizer; and controlling the acidity of the circulating mother liquor in the ammonium sulfate crystallizer. The mass concentration of the ammonia still stronger ammonia water is 3-6% at 40-55 DEG C. The invention has the maximum advantage of combining the ammonium sulfate crystallizer by non-saturator method with technical characteristics of ammonia distillation, washing ammonium sulfate crystal and attachment on the inner surface of the washing crystallizer by temperature of ammonia and stronger ammonia water in ammonia evaporation stronger ammonia water generated by ammonia distillation and neutralizing a part of free acid in the ammonium sulfate liquor in condition that the production flow does not change. The invention is beneficial to optimize and improve the ammonium sulfate crystallization process and comprehensively utilizing ammonia resources as an important means of energy conservation and emission reduction.

Owner:BAOWU CHARCOAL MATERIAL TECH CO LTD

A technology for online cleaning of double-swirl gas burners

ActiveCN105402730BExtended continuous operating cycleExtended service lifeGaseous fuel burnerSystem maintenanceNitrogen

The invention discloses a process for on-line cleaning to a double rotational flow gas burner. The process comprises the following steps: A), determining a purging medium; B), determining purging loops and the quantity thereof before the burner; C), distributing and determining the quantity of the purging branch pipe loops of a swirl plate spray nozzle set inside the burner; D), determining the quantity N of the purging branch pipes of a swirl plate spray nozzle of the burner according to the quantity N of swirl plates, and then accessing N spray nozzles, so as to form a spray nozzle set purging loop component; E), selecting the model of and making a swirl plate purging spray nozzle of the burner; F), determining the fixing way of the swirl plate purging spray nozzle of the burner and a pipeline; G), controlling and designing of the valve of a purging pipeline; and H), running test: 1, nitrogen purging; and 2, water purging. The process provided by the invention has a reasonable structure, can be used for on-line cleaning to the blockage of the swirl plates of the double rotational flow gas burner, can enable the continuous operating period of the burner to be prolonged greatly, and prolongs the service life of the double rotational flow gas burner; and on-line running and operation are simple, and system maintenance is small.

Owner:JIANGSU JIULIAN METALLURGY MACHINERY

A rare earth electrolyzer repair paste and non-stop repair method

The invention provides a rare earth electrolytic cell repair paste and a non-stop repair method, which relate to the technical field of rare earth electrolysis, and include a binder and a dry material at a ratio of 1:3 in parts by weight; wherein the dry material includes The following components in parts by weight: 20-27 parts of graphite powder, 51-55 parts of anthracite powder and 18-26 parts of rare earth fluoride powder; , form a protective layer with a dense structure, and its own oxidation consumption is slow, and it has strong corrosion resistance to the fluoride salt melt in the rare earth electrolytic cell. Due to the existence of the repair paste, the upper edge of the graphite tank is isolated from the air to avoid Or delay the further oxidation loss of the upper edge of the graphite tank body, effectively prolonging the service life of the graphite tank of the rare earth electrolytic tank.

Owner:LESHAN YOUYAN RARE EARTH NEW MATERIAL CO LTD

Emergency blowout control method for large slab heating furnace

ActiveCN101818243BReduce the number of shutdownsShorten the timeFurnace typesHeat treatment furnacesProduction lineCombustion

The invention relates to an emergency blowout control method for a large slab heating furnace. The emergency blowout control and alarm of the slab heating furnace is realized by the steps of reasonably selecting automatic blowout conditions and technological parameters, setting a blowout interlocking plant and a movement time sequence, changing the control mode for the coal gas control valve, adding a sound alarm for the low-pressure blowout alarm signal of coal gas, air and instrument air in the blowout procedure, and popping up an alarm picture. The invention has obvious effect on the heating furnaces of hot-strip 1700 mm and 1780 mm production lines. Even when coal-gas low pressure, combustion-fan power-fail, instrument-air low pressure, evaporation cooling system power-cut and other faults occur, no safety or equipment accident happens. Thus, the invention greatly reduces the frequency and time of heating furnace blowout and creates favorable conditions for smooth steel rolling production and yield enhancement.

Owner:ANGANG STEEL CO LTD

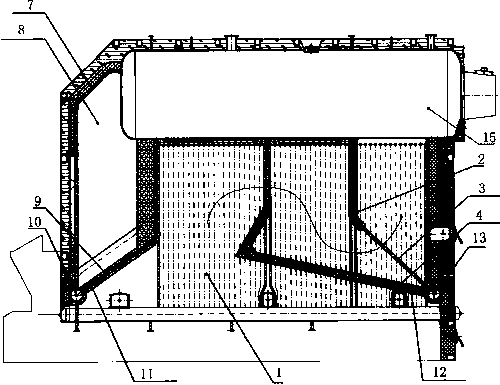

Wear-resistant reciprocating grate support structure

The invention discloses an anti-wear reciprocating fire grate supporting structure. The movable grate piece and the fixed grate piece are clamped on the movable shelf and the fixed shelf respectively, and the movable shelf and the fixed shelf are connected with a positioning plate set corresponding to the fire grate piece, and the two positioning plate sets of the positioning plate set The distance between them is slightly greater than the thickness of the grate ribs; the ribs of the grate can be inserted between the two positioning plates, which can prevent the movable or fixed grate from moving left and right, so as to keep the gap between the grate even and not As for the phenomenon of poor ventilation caused by coal leakage and blockage of ventilation holes, the combustion of fuel is more uniform and sufficient, thereby improving combustion efficiency. The movable grate and the fixed grate are respectively supported by separate support rods to prevent wear and friction between the movable grate and the fixed grate, improve the service life of the reciprocating grate, reduce the number of shutdowns of the boiler, and reduce the boiler The maintenance cost is reduced, and the efficiency of the boiler is improved.

Owner:JINAN BOILER GRP

Pyrolysis furnace with wear-resistant radiation pipes

PendingCN107903926AExtended service lifeExtended operating cycleIndirect heating destructive distillationSpecial form destructive distillationEngineeringMechanical engineering

The invention relates to a pyrolysis furnace with wear-resistant radiation pipes. The pyrolysis furnace comprises pipe caps, the radiation pipes and a mounting part, and the horizontal and vertical distances between the two radiation pipes arranged in the pyrolysis furnace are identical; each of the pipe caps has a triangular cross section and comprises an arc-shaped plate part and vertical plateparts arranged on the two sides of the arc-shaped plate part; and the vertical plate parts are fixedly connected with the upper part of the corresponding radiation pipe through rectangular sheets, sothat a falling material is prevented from directly impacting the radiation pipe, and the falling-off of the material is facilitated. The pyrolysis furnace provided by the invention has the beneficialeffects that the service lives of the radiation pipes are prolonged, the maintenance expense of the pyrolysis furnace is reduced, the frequency of shutdowns of the pyrolysis furnace is reduced in theoperation process, the potential safety hazards and the economic losses caused by radiation pipe wear are reduced, the safe and normal operation of the regenerative rapid pyrolysis furnace is ensured,and the operation cycle of the pyrolysis furnace is prolonged.

Owner:北京恒丰亚业科技发展有限公司

Blast furnace reducing tuyere short set

The invention relates to a blast furnace reducing tuyere short set which comprises a short set body provided with an air inlet end and an air outlet end, wherein the short set is internally provided with an air flue, a valve cavity is arranged between the middle of the short set body and the air outlet end, the air flue expands towards two opposite radial directions of the short set body simultaneously so as to form the valve cavity, the valve cavity is internally provided with a pair of throttle cores, when the pair of throttle cores is at a radial approaching position, the air flue is at the throttle state that a circulation surface is locally covered, when the pair of throttle cores is at a radial separation position, the air flue is at an opening state that the circulation surface is completely opened, and the valve cavity is provided with two control holes capable of controlling the throttle core to move; and the short set is also provided with a cooling channel for cooling the short set. After the structure of the buffer precooling slag liquid pool is adopted, the internal diameter of the tuyere short set can be adjusted in the production process of the blast furnace according to the furnace condition, and blowing-in speed can be improved in real time according to needs under the condition that the constant blowing-in pressure is maintained.

Owner:宗品禾

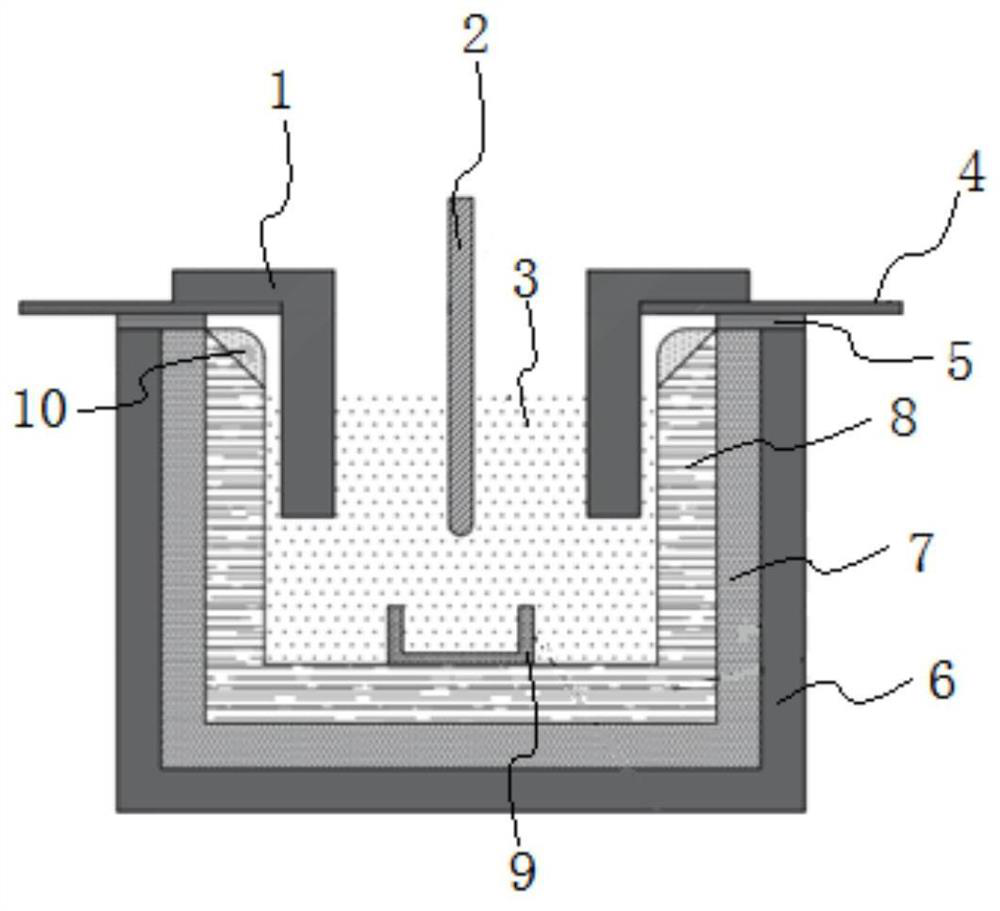

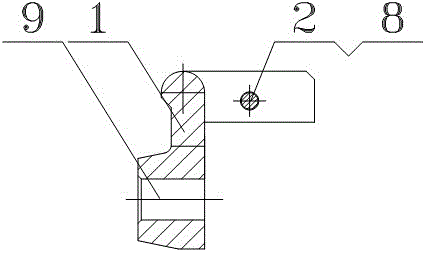

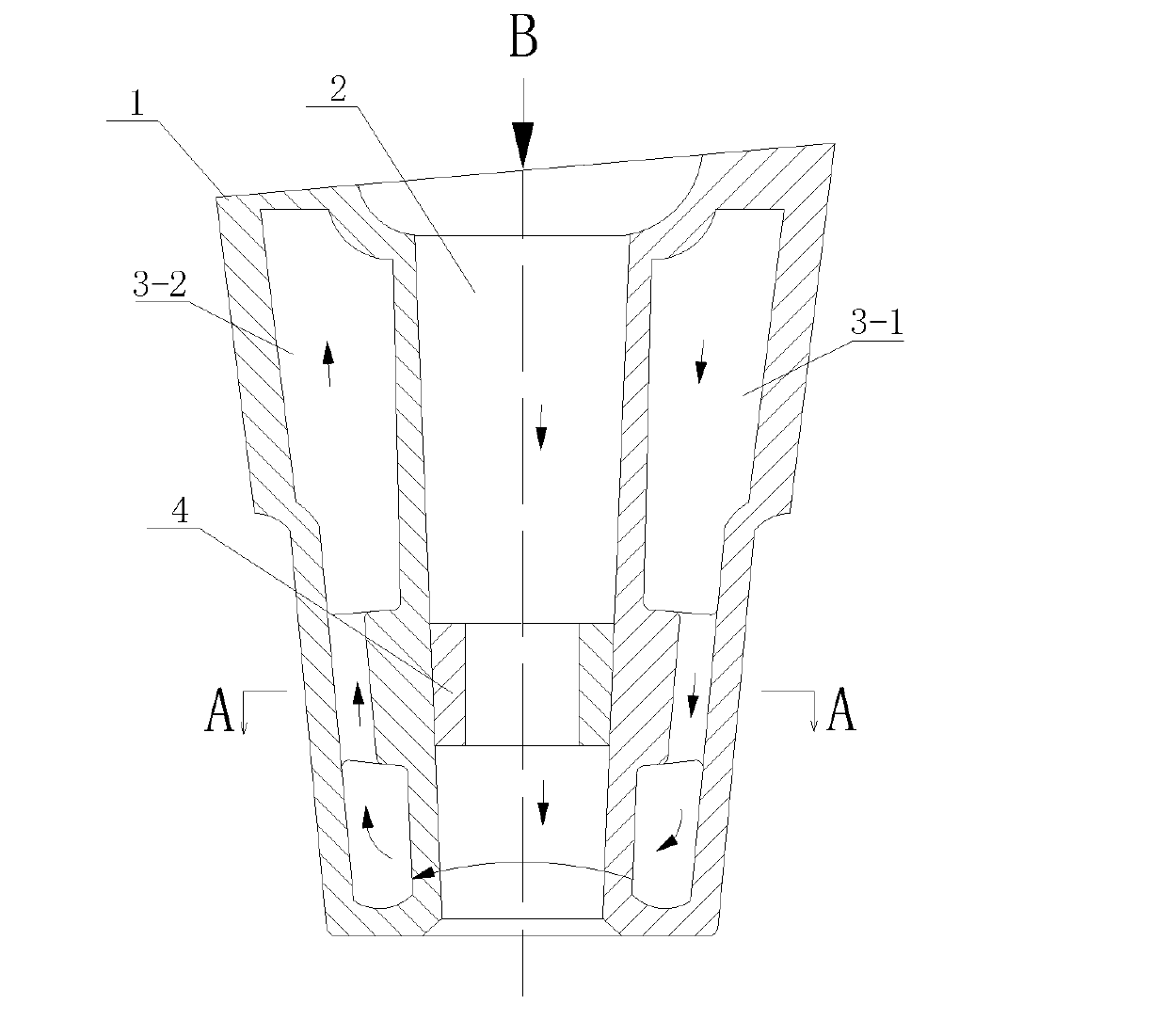

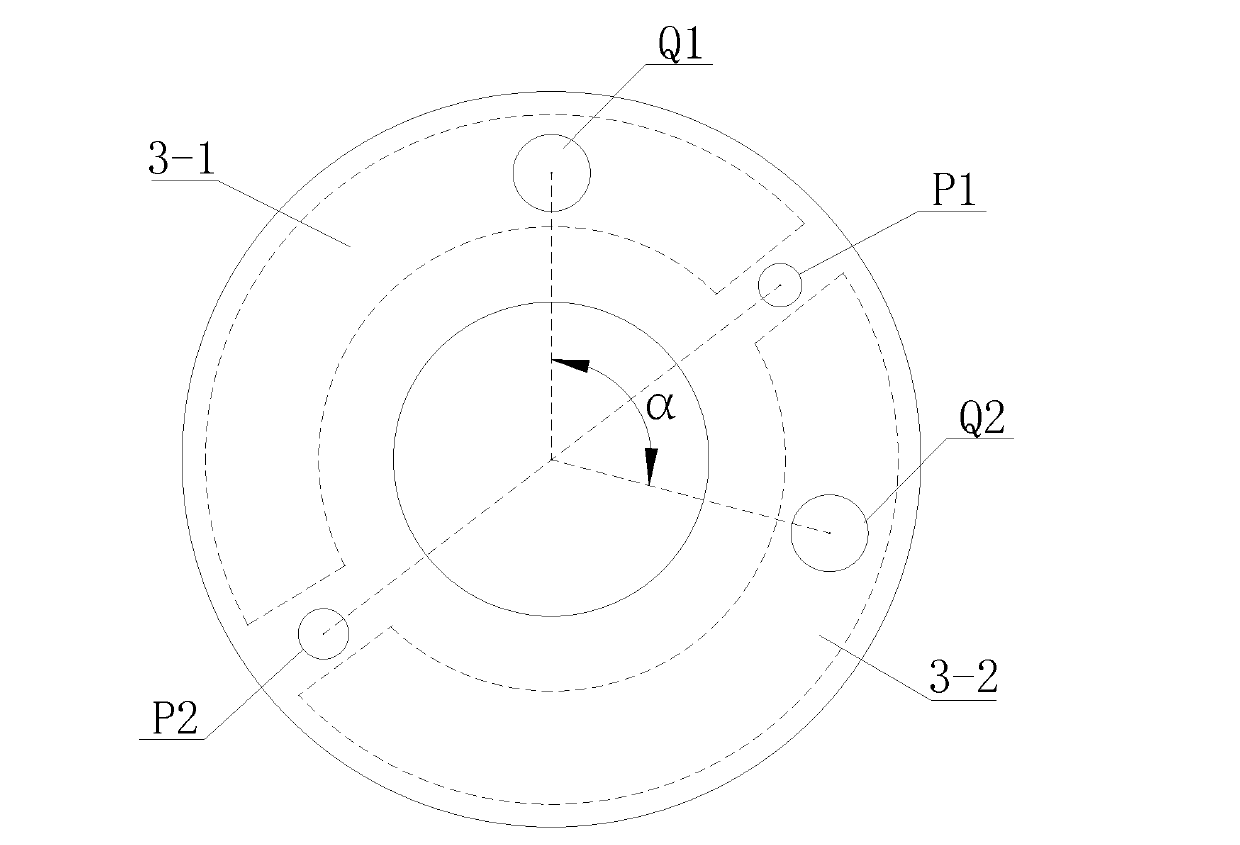

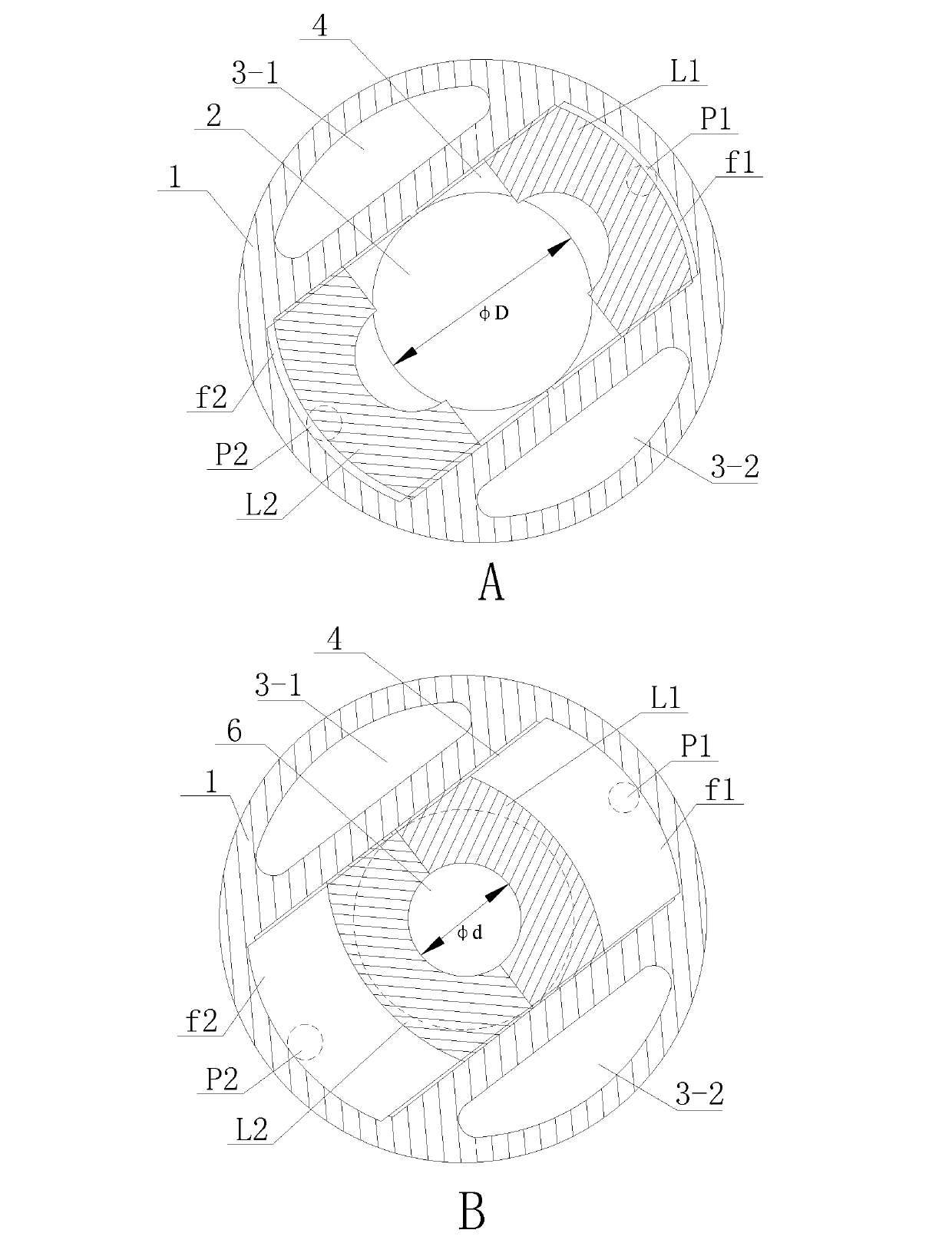

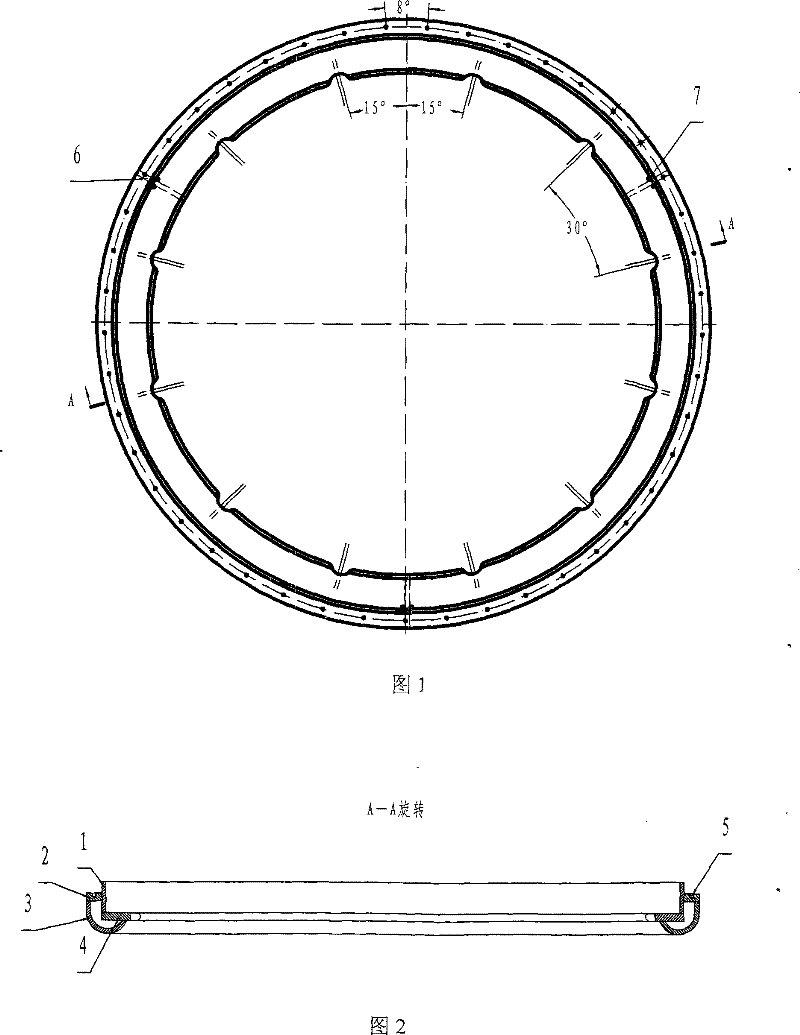

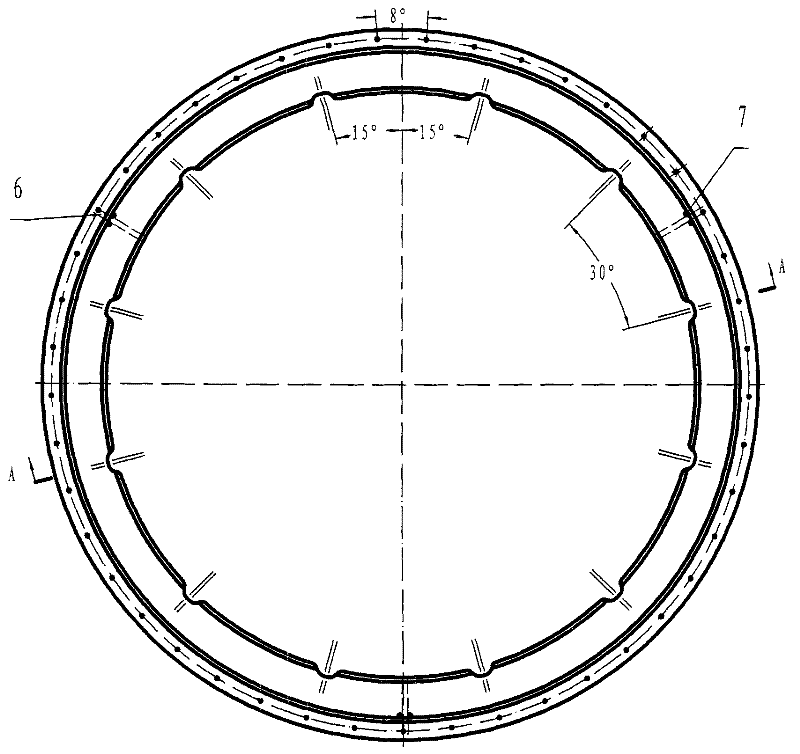

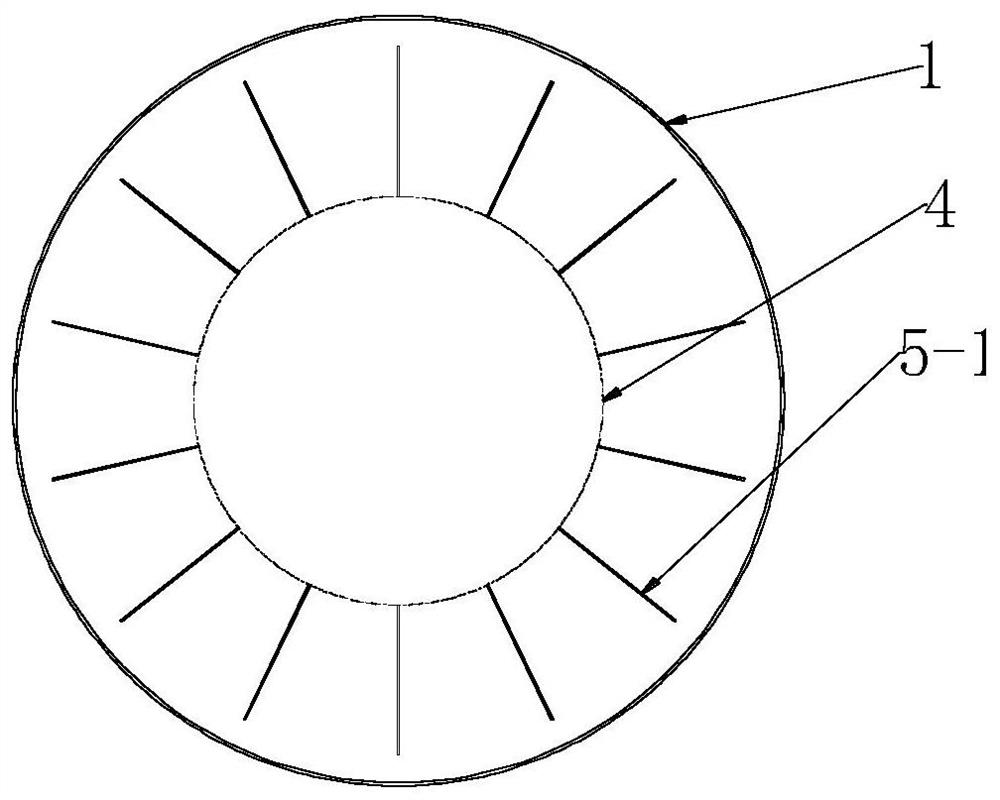

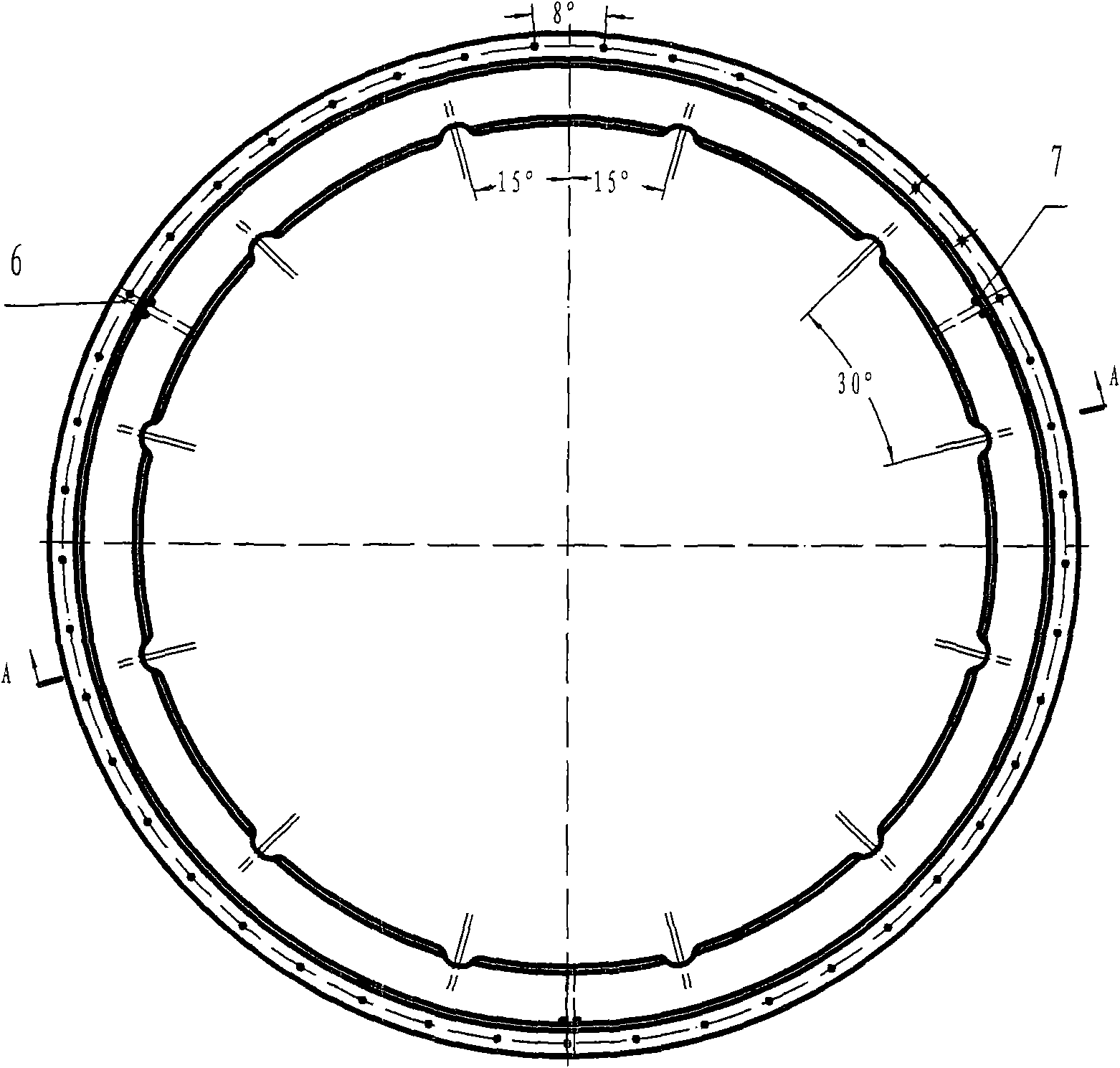

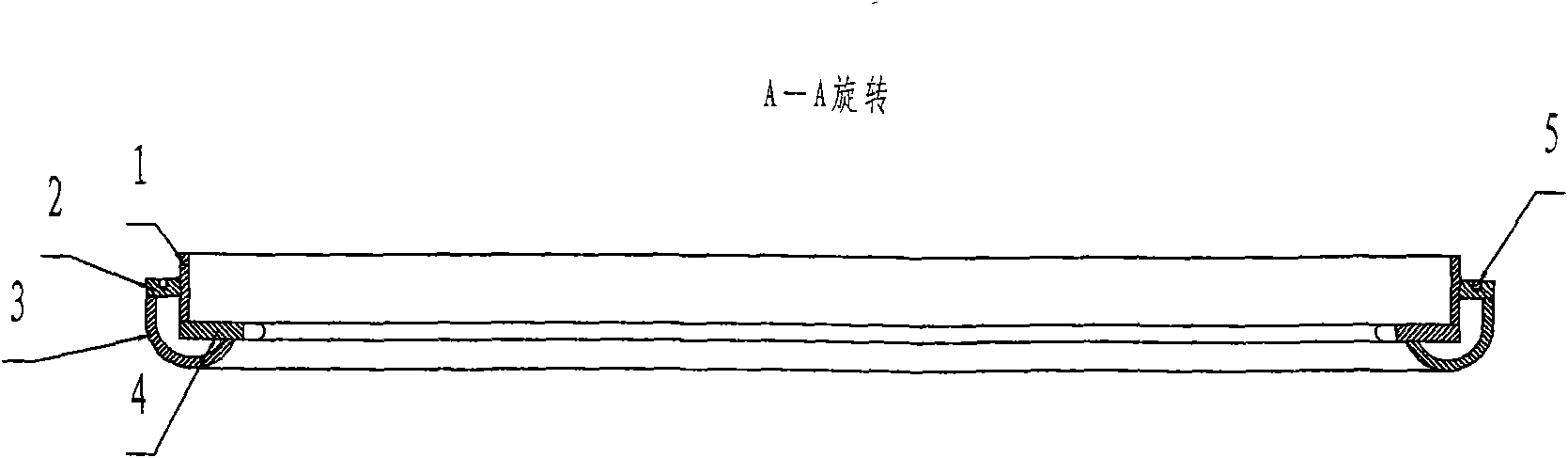

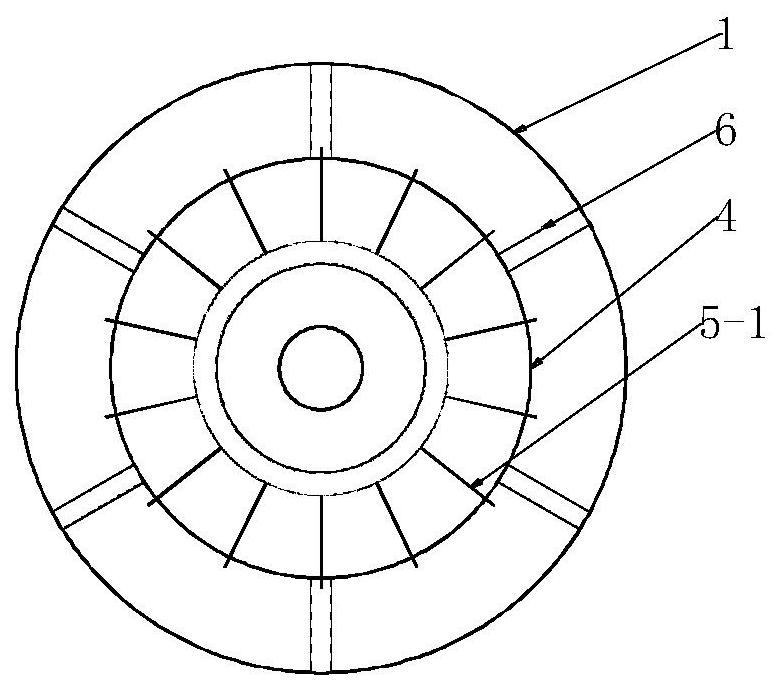

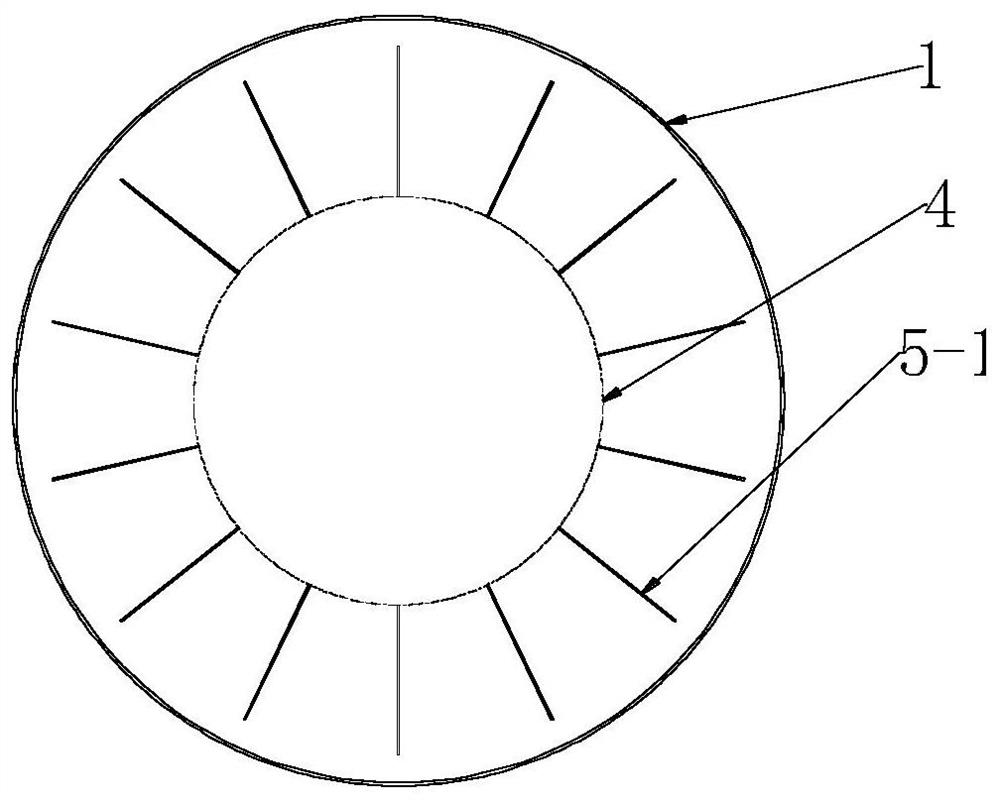

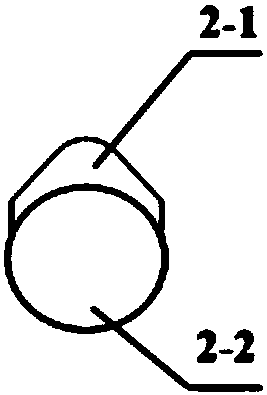

Integral type water cooling bottom part ring of combination holder of closed submerged arc furnace and process for producing same

InactiveCN101527979BEasy to useQuality improvementElectric discharge heatingWater leakageEngineering

The invention provides an integral type water cooling bottom part ring of a combination holder of a closed submerged arc furnace and a process for producing the same. The bottom part ring consists of an inner side stainless steel ring-shaped plate (1), a water cooling protection sleeve insulated plate ring plate (2), a semi-circular ring body (3), a contact element protection support ring plate (4) and a clapboard (6), wherein the inner side stainless steel ring-shaped plate(1) is in welding connection with the stainless steel ring plate (2) and the contact element protection support ring plate (4); and the circular ring body (3) is in welding connection with the ring plate (2) and the contact element protection support ring plate (4) so as to form the integral type water cooling bottom part ring. The bottom part ring has the advantages of solving the problems of water leakage due to frequent poking and frequent shut-down of a furnace for exchange, meeting the operating requirements in the production of the combination holder of the closed calcium carbide furnace, effectively improving the quality of an electrode pole, greatly improving the use effect of the holder, fully meeting the requirements on protection and guide of an electrode pole electric conduction device, and avoiding water leakage phenomenon occurring while in use, along with better economical efficiency; moreover, the bottom part ring also has the advantages of greatly prolonging the service life and greatly lowering the frequency of the shut-down of the furnace due to the fault of the bottom part ring.

Owner:YUNNAN YUNWEI CO LTD

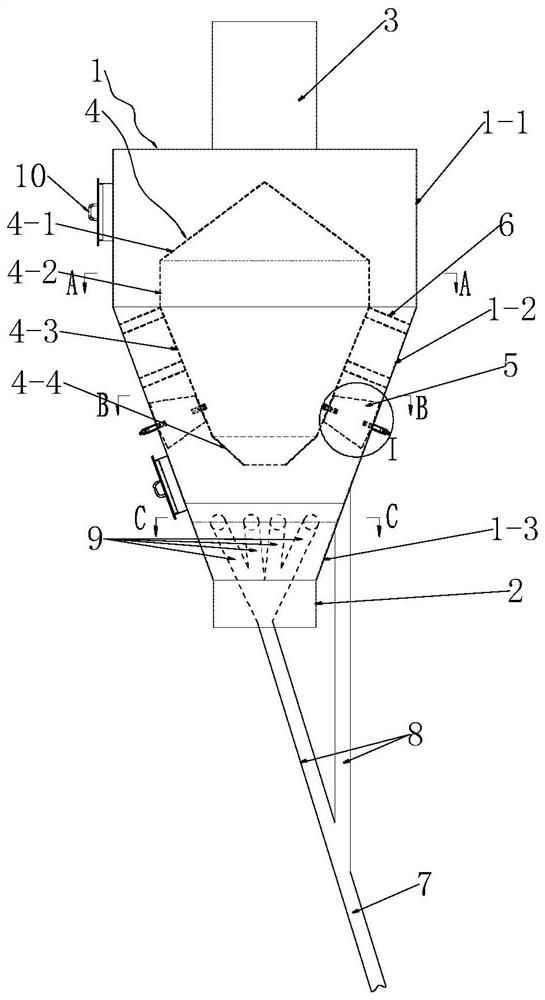

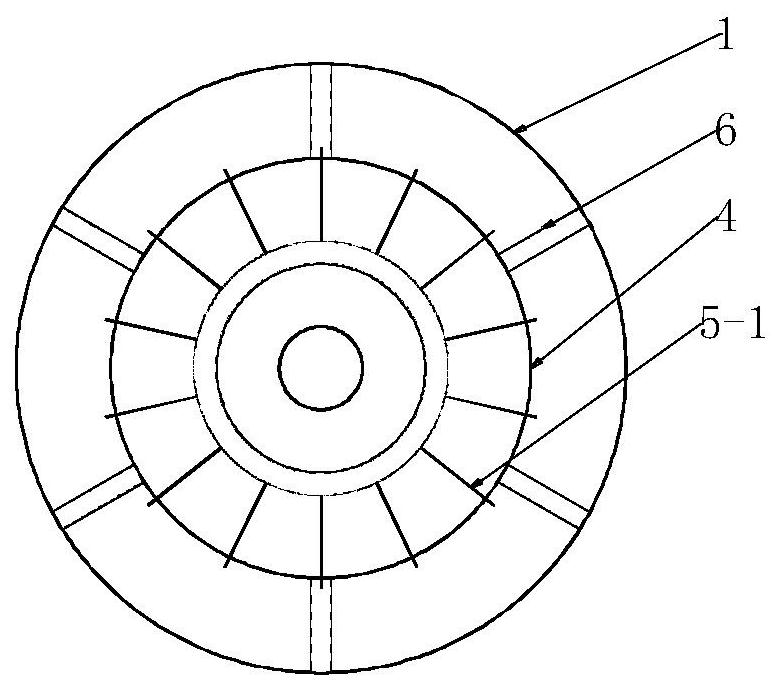

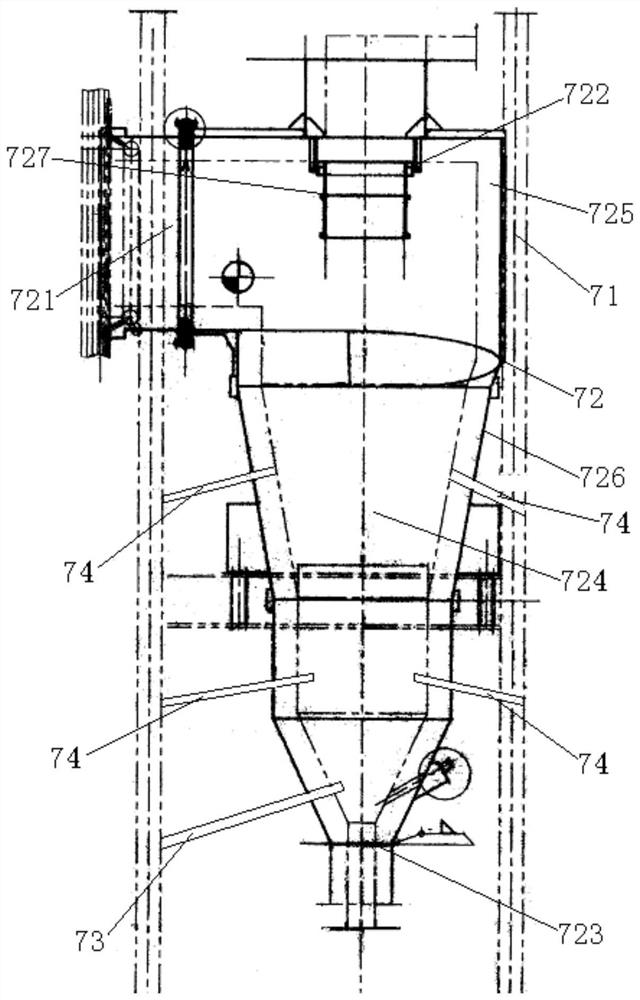

Air flow separator for gypsum powder

ActiveCN111617963AReduce the burden of separationEasy to separateGas current separationCalcium/strontium/barium sulfatesThermodynamicsEngineering

The invention discloses an air flow separator for gypsum powder, and belongs to the gypsum powder production equipment. The technical aim of the air flow separator for the gypsum powder is how to avoid accumulation of large particles at the furnace bottom of a boiling furnace, guarantee the boiling effect, improve the quality of the gypsum powder, meanwhile decrease the number of times of furnacecleaning, lower the labor intensity of workers and improve the working efficiency. According to the adopted scheme, the air flow separator structurally comprises an air flow separating cylinder, a feeding cylinder is arranged at the lower end of the air flow separating cylinder, and a discharging cylinder is arranged at the upper end of the air flow separating cylinder; a material blocking cylinder is arranged on the upper position of the inner middle of the air flow separating cylinder, and an air blocking structure is arranged between the outer side wall of the material blocking cylinder andthe inner side wall of the air flow separating cylinder; and a large particle flowing-out structure is arranged on the lower position of the middle of the air flow separating cylinder, the inlet endof the large particle flowing-out structure is located on the lower position of the inner middle of the air flow separating cylinder, and the outlet end of the large particle flowing-out structure islocated at the oblique lower part outside the air flow separating cylinder.

Owner:山东腾飞机电科技有限公司

Integral type water cooling bottom part ring of combination holder of closed submerged arc furnace and process for producing same

InactiveCN101527979AMeet protectiveSatisfaction OrientationElectric discharge heatingWater leakageEngineering

The invention provides an integral type water cooling bottom part ring of a combination holder of a closed submerged arc furnace and a process for producing the same. The bottom part ring consists of an inner side stainless steel ring-shaped plate (1), a water cooling protection sleeve insulated plate ring plate (2), a semi-circular ring body (3), a contact element protection support ring plate (4) and a clapboard (6), wherein the inner side stainless steel ring-shaped plate(1) is in welding connection with the stainless steel ring plate (2) and the contact element protection support ring plate (4); and the circular ring body (3) is in welding connection with the ring plate (2) and the contact element protection support ring plate (4) so as to form the integral type water cooling bottom part ring. The bottom part ring has the advantages of solving the problems of water leakage due to frequent poking and frequent shut-down of a furnace for exchange, meeting the operating requirements in the production of the combination holder of the closed calcium carbide furnace, effectively improving the quality of an electrode pole, greatly improving the use effect of the holder, fully meeting the requirements on protection and guide of an electrode pole electric conduction device, and avoiding water leakage phenomenon occurring while in use, along with better economical efficiency; moreover, the bottom part ring also has the advantages of greatly prolonging the service life and greatly lowering the frequency of the shut-down of the furnace due to the fault of the bottom part ring.

Owner:YUNNAN YUNWEI CO LTD

A gypsum powder air separator

ActiveCN111617963BReduce the burden of separationEasy to separateGas current separationCalcium/strontium/barium sulfatesThermodynamicsEngineering

The invention discloses a gypsum powder airflow separator, which belongs to the gypsum powder production equipment. The technical problem to be solved by the invention is how to avoid the accumulation of large particles at the bottom of the boiling furnace, ensure the boiling effect, improve the quality of the gypsum powder, and at the same time reduce the times of cleaning the furnace, To reduce the labor intensity of workers and improve the work efficiency, the technical scheme adopted is as follows: the structure includes an airflow separation cylinder, a feed cylinder is arranged at the lower end of the airflow separation cylinder, a discharge cylinder is arranged at the upper end of the airflow separation cylinder, and an upper middle part of the airflow separation cylinder is arranged. The position is provided with a material blocking cylinder, a wind blocking structure is set between the outer side wall of the material blocking cylinder and the inner side wall of the airflow separation cylinder, and a large particle outflow structure is set at the lower position of the middle part of the airflow separation cylinder, and the inlet end of the large particle outflow structure is located in the airflow. At the lower position in the middle of the separation cylinder, the outlet end of the large particle outflow structure is located at the obliquely lower position outside the air separation cylinder.

Owner:山东腾飞机电科技有限公司

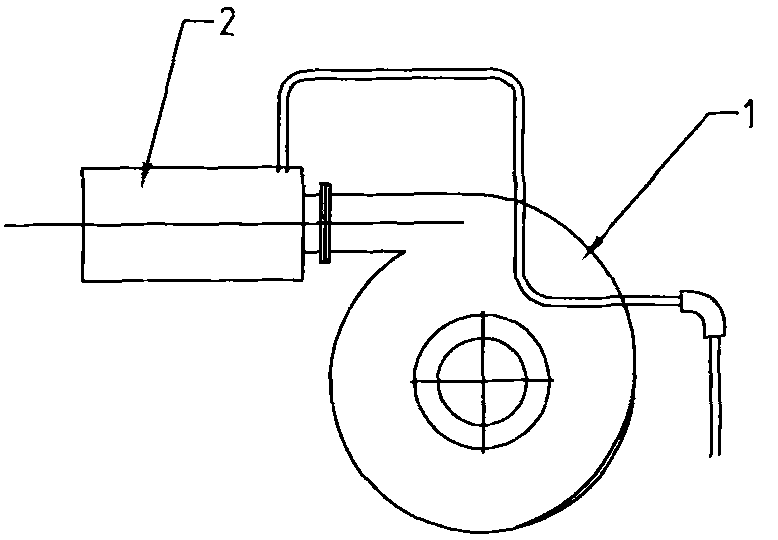

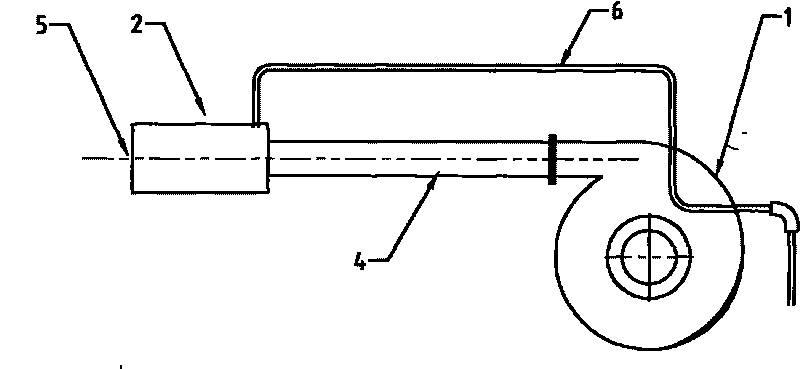

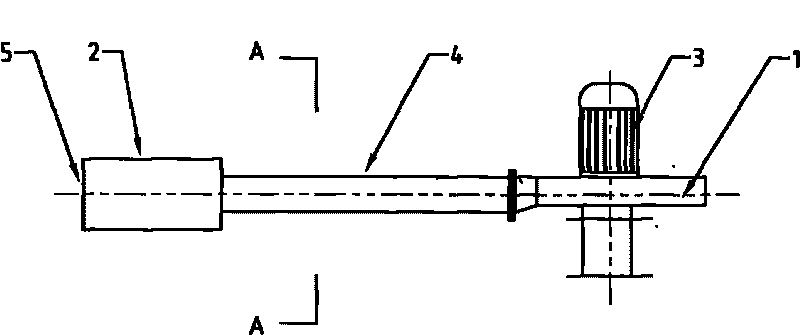

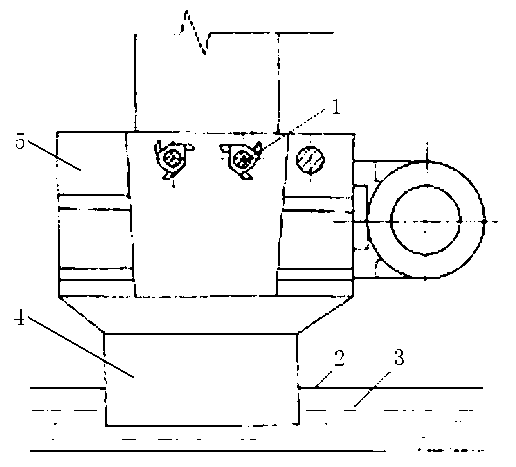

Combustor of large rotating furnace

InactiveCN101761925AExtend your lifeLow costBurnersProcess efficiency improvementCombustorEngineering

The invention relates to a combustor of a large rotating furnace, belonging to a component of a smelting furnace. The combustor of the large rotating furnace mainly comprises an air blower (1), an air blower motor (3) and a cylindrical high titanium steel burner nozzle (2) , wherein an air tube (4) is additionally arranged between an air outlet of the air blower (1) and the cylindrical high titanium steel burner nozzle (2) so as to lengthen a distance between the centre of the air blower motor (3) and a fire port (5). By using the combustor of the large rotating furnace, the air blaster motor can be protected against high temperature damage, the service life of the air blaster motor is prolonged, and the production cost is reduced.

Owner:CHENZHOU CITY JINGUI SILVER IND CO LTD

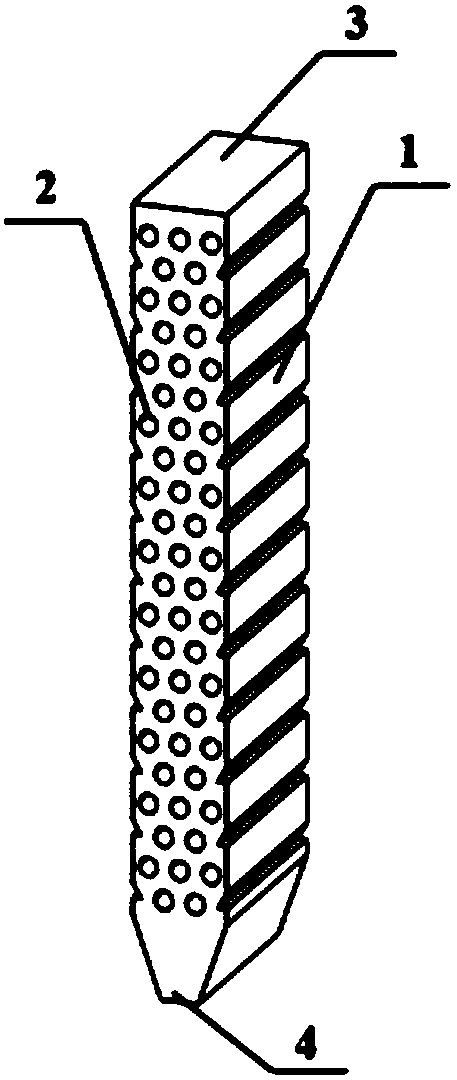

Firm can plastic and preparation method thereof

The invention discloses firm can plastic and a preparation method thereof. The firm can plastic comprises the following components in percentage by mass: 80 to 90 percent of a mixture of silicon carbide and mullite, 2 to 12 percent of silicon-containing micropowder of which the particle size is less than 2,200 meshes and 8 to 18 percent of low-temperature agglutinant, wherein the silicon carbide accounts for 5 to 15 percent of the mixture and the mullite accounts for 85 to 95 percent of the mixture. The preparation method comprises the following specific steps of: sequentially mixing for the first time, bundling, mixing for the second time, extruding, blanking and packing by taking the mullite and silicon carbide as a matrix material, and phosphoric acid and aluminium phosphate as a bonding agent. The firm can plastic has the advantages of effectively prolonging the service life of a refractory material, effectively improving the reliability of the refractory material, reducing the consumption and blowing out times of the refractory material, being used under the working condition of a dry coke quenching furnace, increasing the economic benefit and saving resources, along with high wear resistance and high compressive strength and compactness at normal temperature. The preparation method has the advantages of capability of improving the quality of the product, simple process and easy operation.

Owner:宜兴市炉顶密封工程有限公司

Long-service-life honeycomb heat accumulator

The invention relates to a production method of silicate, and provides a long-service-life honeycomb heat accumulator, which is used for solving the problem of short service life caused by the conventional unreasonable product formula. The long-service-life honeycomb heat accumulator is prepared from the following raw materials in percentage by weight: 62-85 percent of aluminum oxide, 8-17 percent of zirconite, 3-12 percent of Datong clay, 0.5-1.5 percent of magnesia serving as a fluxing agent, 0.6-1.8 percent of silicon micropowder, 0.8-2.5 percent of bonding agent and 1.5-3.5 percent of glycerol. The method comprises the following steps of: fully mixing the raw materials into pug; mulling the pug in vacuum, and molding; drying at the temperature of 150 DEG C for 10-15 hours; and firing in a high-temperature furnace at the temperature of 1,350-1,450 DEG C for 4-5 hours to generate a honeycomb heat accumulator of which the main crystal phase is corundum, wherein reducing flame is adopted at the temperature of below 800 DEG C in the firing process, and oxidizing flame is adopted at the temperature of over 800 DEG C to the end of the firing process. The production process is easy to control, and the honeycomb heat accumulator has the advantages of high thermal stability and high strength.

Owner:山西科德垣环保材料有限公司

Flue gas separation device

ActiveCN112413577AReduce the number of shutdownsSmooth burningHuman health protectionFluidized bed combustionShock waveFlue gas

The invention discloses a flue gas separation device. The flue gas separation device comprises a mounting frame; a flue gas separator is arranged on the mounting frame in a supporting mode; a flue gasinlet allowing flue gas to be separated to enter the flue gas separator, a flue gas outlet allowing separated fine particle flue gas to enter downstream treatment and a flue gas exhaust port allowingseparated coarse particle flue gas to return to a circulating fluidized bed again are formed in the flue gas separator; a shock wave air cannon is further arranged on the mounting frame in a supporting mode; the blasting end of the shock wave air cannon communicates with a flue gas channel of the flue gas separator; and the shock wave air cannon is used for discharging instant air shock waves tothe flue gas channel according to a set frequency so as to crush bonded ash blocks hardened on the wall of the flue gas channel into return ash, and then the return ash is discharged into the circulating fluidized bed through the flue gas exhaust port. In the flue gas separation device, the instantaneous air shock waves can also effectively prevent flue gas from hardening on the wall of the flue gas channel during separation, so that less bonded ash blocks are formed, flue gas is smoothly discharged from the flue gas channel, the amount of return ash returned to a hearth is increased, and a boiler is stable in combustion.

Owner:安化华晟生物能源有限责任公司

Horizontal water boiler with ash holes

InactiveCN109958984AIncrease heightExtended stayWater-tube boilersFire-tube steam boilersInsulation layerCombustion

The invention relates to a horizontal water boiler with ash holes. The upper portion of the boiler is provided with a boiler shell. The downtake tubes are connected with a front header box, a rear header box and a side header box. The front header box is connected with a front arch and a front shed tube to extend into the boiler shell. The rear header box is connected with a rear arch to extend into the boiler shell. The side header box is connected with a side water-cooled wall. Side water-cooled wall tubes are crossed to extent into the boiler shell. The boiler shell is arranged on the outerportion of a boiler hearth. The horizontal water boiler is characterized in that the front arch comprises a refractory slab formed by wrapping water tubes through refractory cement, and a slab body is provided with the multiple ash holes. Under the condition that the original height remains unchanged, the rear arch is additionally arranged to increase the height of the boiler hearth in disguise,the combustion effect is good, and the thermal efficiency is high. The side water-cooled wall tubes are crossed to extent into the boiler shell. The boiler shell is arranged outside the boiler hearth,so that the boiler shell does not make direct contact with flames and high-temperature flue gas. The defect of swelling of the boiler shell is overcome fundamentally. The heat transfer effect is improved. The service life of the boiler shell is prolonged. The boiler is internally provided with a smoke chamber, and the defect that a heat insulation layer falls off easily and leaks air is overcome.Through arrangement the front arch and the ash holes, ash removing is convenient, and the boiler shutdown frequency is reduced.

Owner:济宁市海螺电子商务有限公司

Heat accumulation type rapid pyrolysis furnace with wear-resisting radiation tubes

PendingCN107936997AExtended service lifeExtended operating cycleIndirect heating destructive distillationSpecial form destructive distillationMetallurgyIndustrial engineering

The invention relates to a heat accumulation type rapid pyrolysis furnace with wear-resisting radiation tubes. The heat accumulation type rapid pyrolysis furnace comprises a pipe cap, a mounting partand the radiation tubes, wherein the horizontal and vertical distances between each two radiation tubes arranged in the pyrolysis furnace are the same; the pipe cap is an arc-shaped plate with an ovalcross section; the mounting part is arranged on the radiation tubes; the arc-shaped plate is arranged on the mounting part so that the pipe cap is located above the radiation tubes, and a condition that the radiation tubes are directly impacted by materials is avoided. According to the heat accumulation type rapid pyrolysis furnace provided by the invention, a condition that tube walls of the radiation tubes are directly washed is avoided, so that the radiation tubes are not damaged and abraded and the service life of the radiation tubes is prolonged; the overhauling cost of the pyrolysis furnace is reduced, and the number of times of blowing down the pyrolysis furnace in an operation process is reduced; the potential safety hazards and the economic loss, caused by abrasion of the radiation tubes, are reduced; safe and normal operation of the heat accumulation type rapid pyrolysis furnace is ensured and the operation cycle of the pyrolysis furnace is prolonged.

Owner:北京恒丰亚业科技发展有限公司

Slag remover

The invention discloses a slag remover which comprises a chain-slat conveyer box body, a water seal and a remover body, wherein a slag crusher is mounted on the remover body; a dust falling port is formed in the lower part of the remover body; the water seal is arranged inside the chain-slat conveyer box body; and the dust falling port is formed in the water seal. The slag remover has the advantages that the faults are relatively reduced, the maintenance intensity is reduced, the shutdown frequency is reduced, the load of a motor is reduced, the phenomenon of motor burning is basically eliminated, the dust removal speed is increased, and the service life is prolonged.

Owner:大连锅炉集团有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com