A gypsum powder air separator

An air flow separator and air flow separation technology, which are applied in the separation of solids from solids by air flow, solid separation, chemical instruments and methods, etc., can solve the problems affecting product quality and work efficiency, gypsum powder quality decline, and labor intensity. and other problems, to achieve the effect of good promotion and use value, prolonged drying time and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

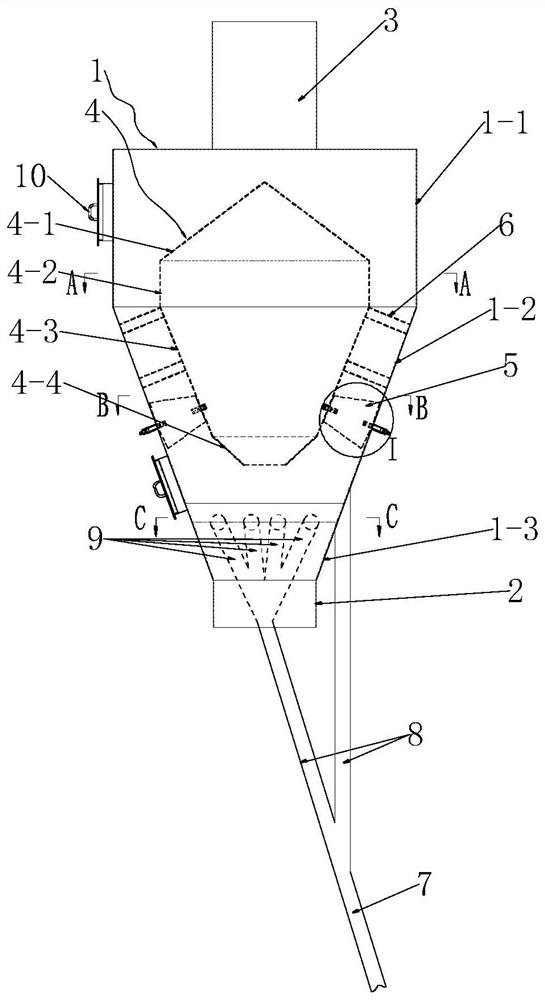

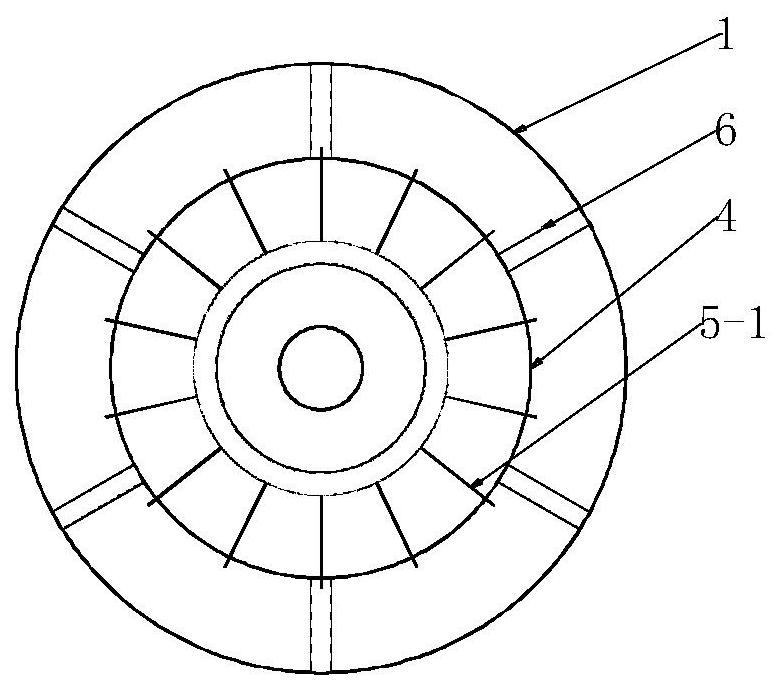

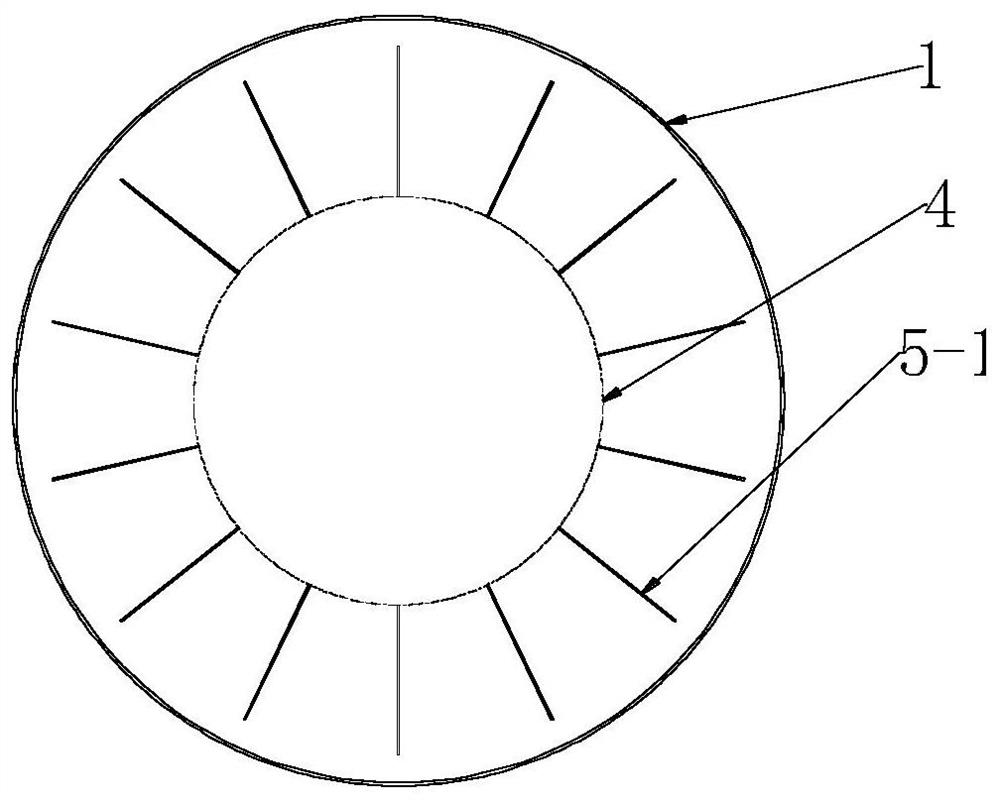

[0034] as attached figure 1 As shown, the structure of the gypsum powder airflow separator of the present invention mainly includes an airflow separation cylinder 1, a material blocking cylinder 4, a wind blocking structure 5 and a large particle outflow structure. The air separation cylinder 1 is a cylinder structure composed of a cylindrical deceleration part 1-1, a conical blocking part 1-2 and a conical buffer part 1-3 arranged in sequence from top to bottom; the upper end of the cylindrical deceleration part 1-1 is installed with a The inner diameter of the barrel 3, the discharge barrel 3 is smaller than the inner diameter of the cylindrical deceleration part 1-1; the inner diameter of the cylindrical deceleration part 1-1 is not less than the maximum inner diameter of the cone stopper 1-2, and the cone stopper is wider than 1-2. The structure with a narrow lower part is arranged at the lower end of the cylindrical deceleration part 1-1 and the minimum inner diameter of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com