Incinerator flue gas purification system

A flue gas purification system and incinerator technology, applied in chemical instruments and methods, dispersed particle separation, combined devices, etc., can solve problems such as low processing efficiency, inappropriateness, and reduced dust filtration efficiency, and achieve the goal of improving slag discharge efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

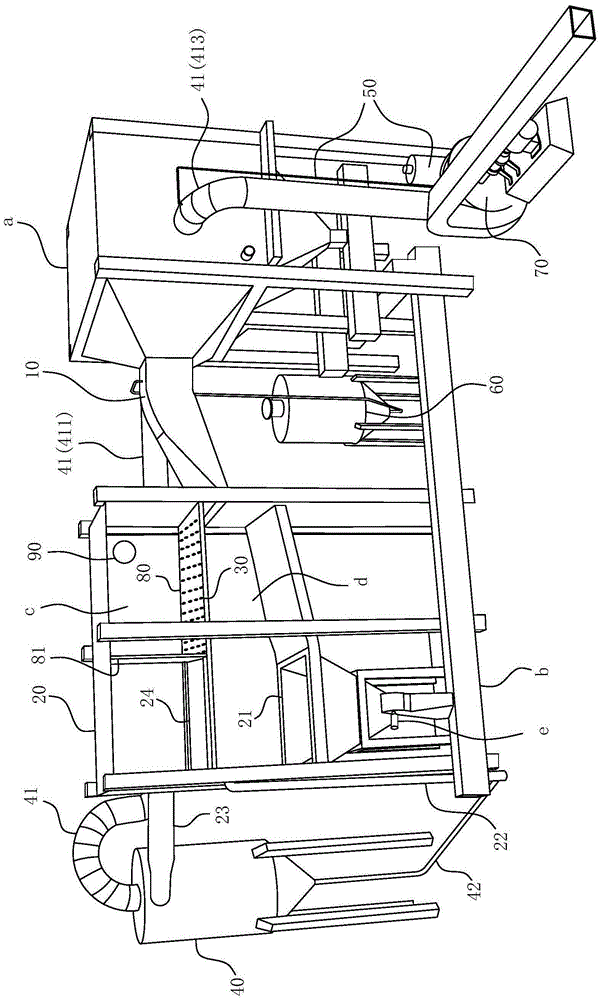

[0039] For ease of understanding, combined here Figure 1-4 Specifically set forth the component structure of the present invention and its specific work flow:

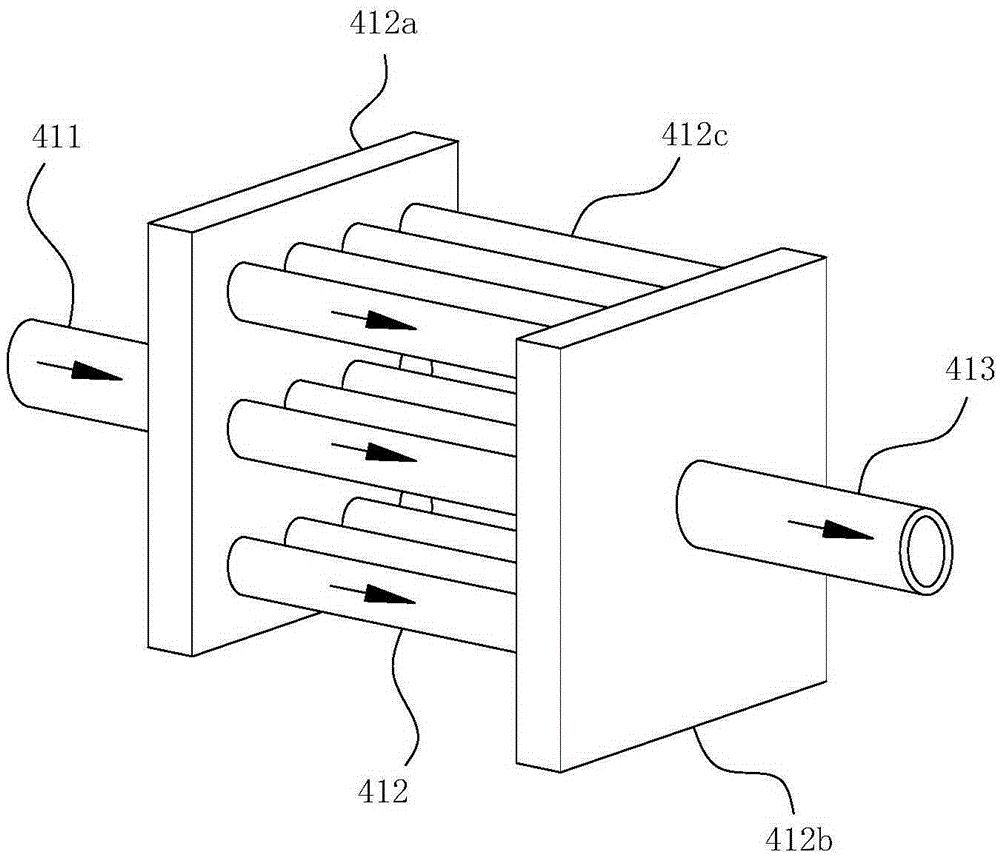

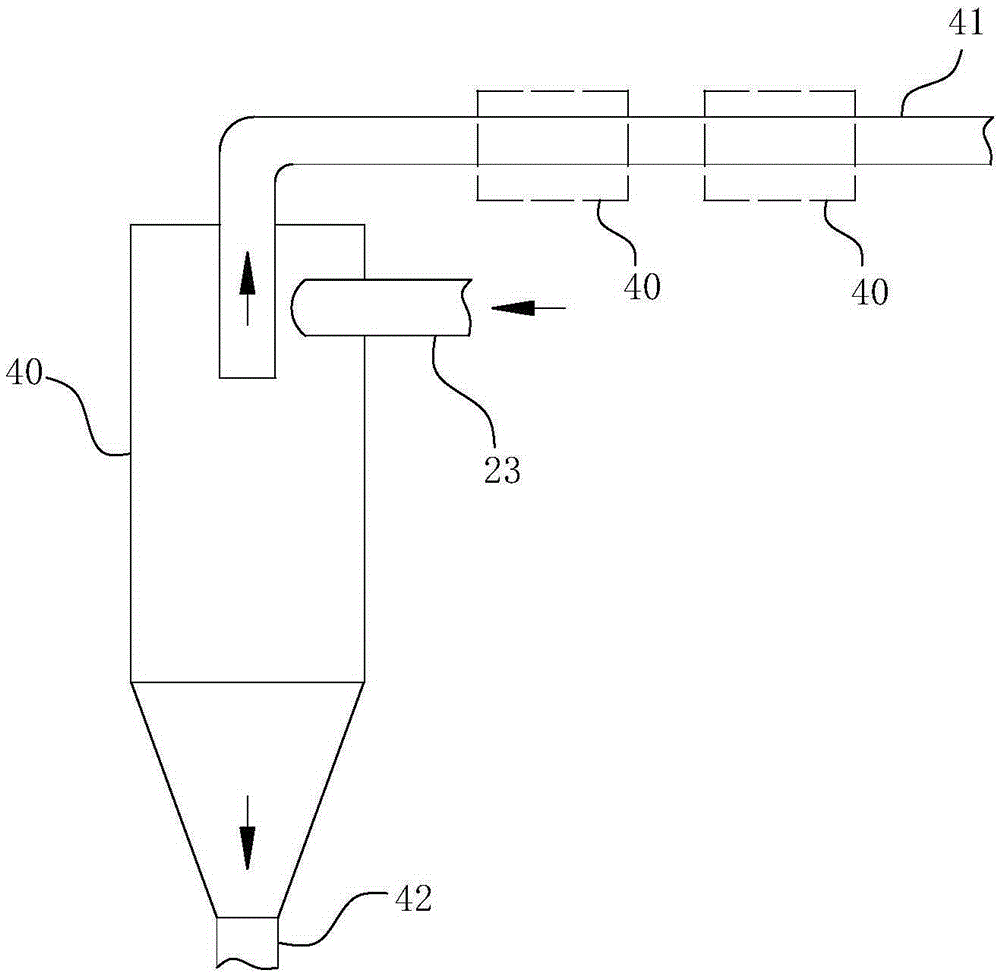

[0040] The specific implementation structure of the present invention is as Figure 1-3 As shown, it includes a processing chamber 20 , a cyclone separator 40 and a draft blower 70 sequentially arranged along the working path of the system. Among them, the treatment chamber 20 communicates with the tail end of the flue a through the flue gas outlet pipe 10, the ash outlet of the lime distributor 60 is arranged at the lumen of the flue gas outlet pipe 10, and the cyclone separator 40 and the treatment chamber 20 are connected by a steam outlet pipe The road 23 communicates, and the air outlet pipe 41 communicates between the drainage fan 70 and the cyclone separator 40 . In order to ensure the water vapor separation efficiency, multiple water vapor separation components of the same type or different types can be arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com