Honeycomb body used for regenerative heating furnace and production method of honeycomb body used for regenerative heating furnace

A honeycomb body and heating furnace technology, which is applied in the field of metallurgical refractory materials, can solve the problems affecting the normal operation of regenerative furnace quality equipment, product performance that cannot meet the use requirements, and poor smoke resistance, and achieves improved smoke resistance. Gas erosion performance, improved high temperature volume stability, and excellent slag resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

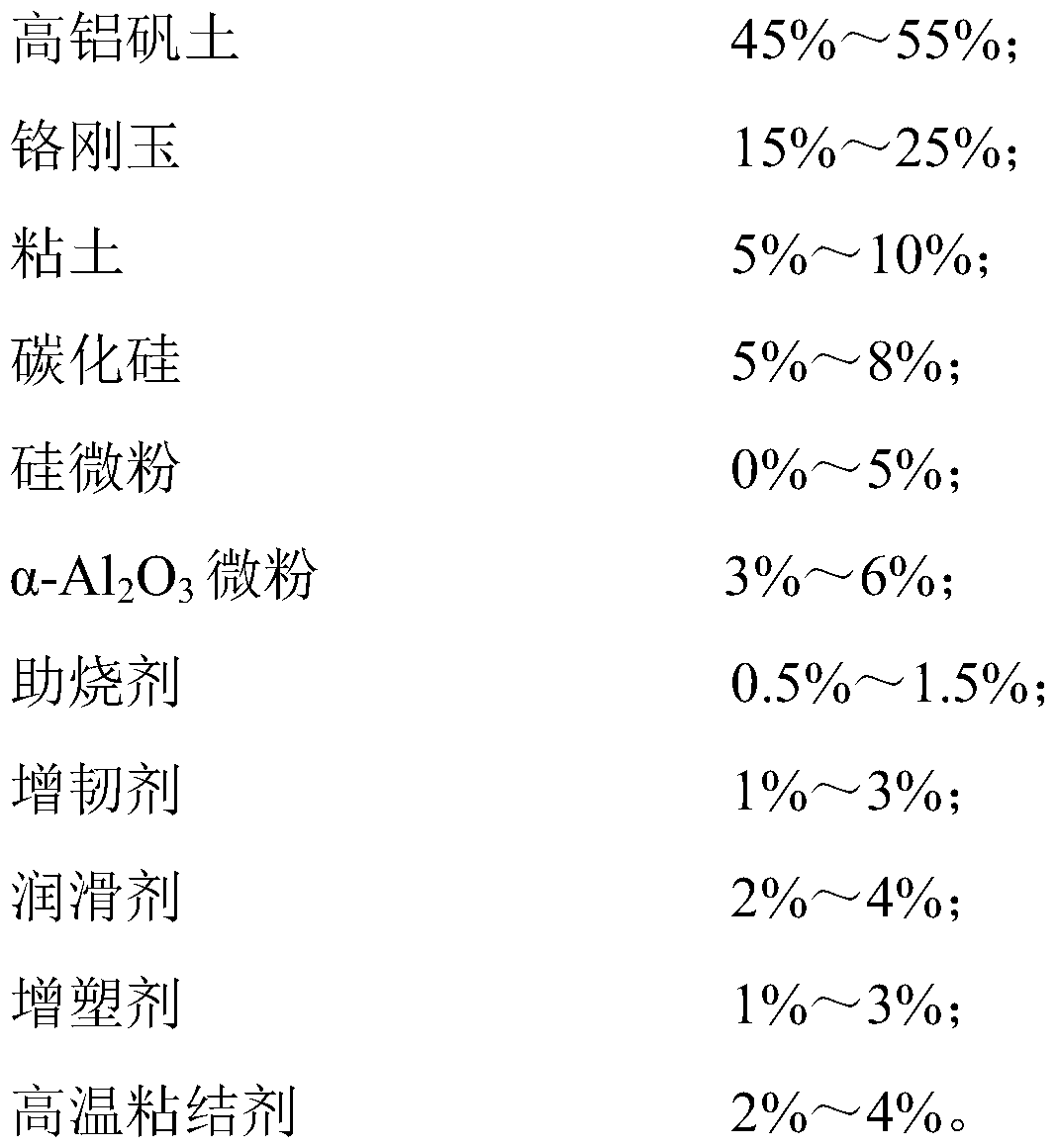

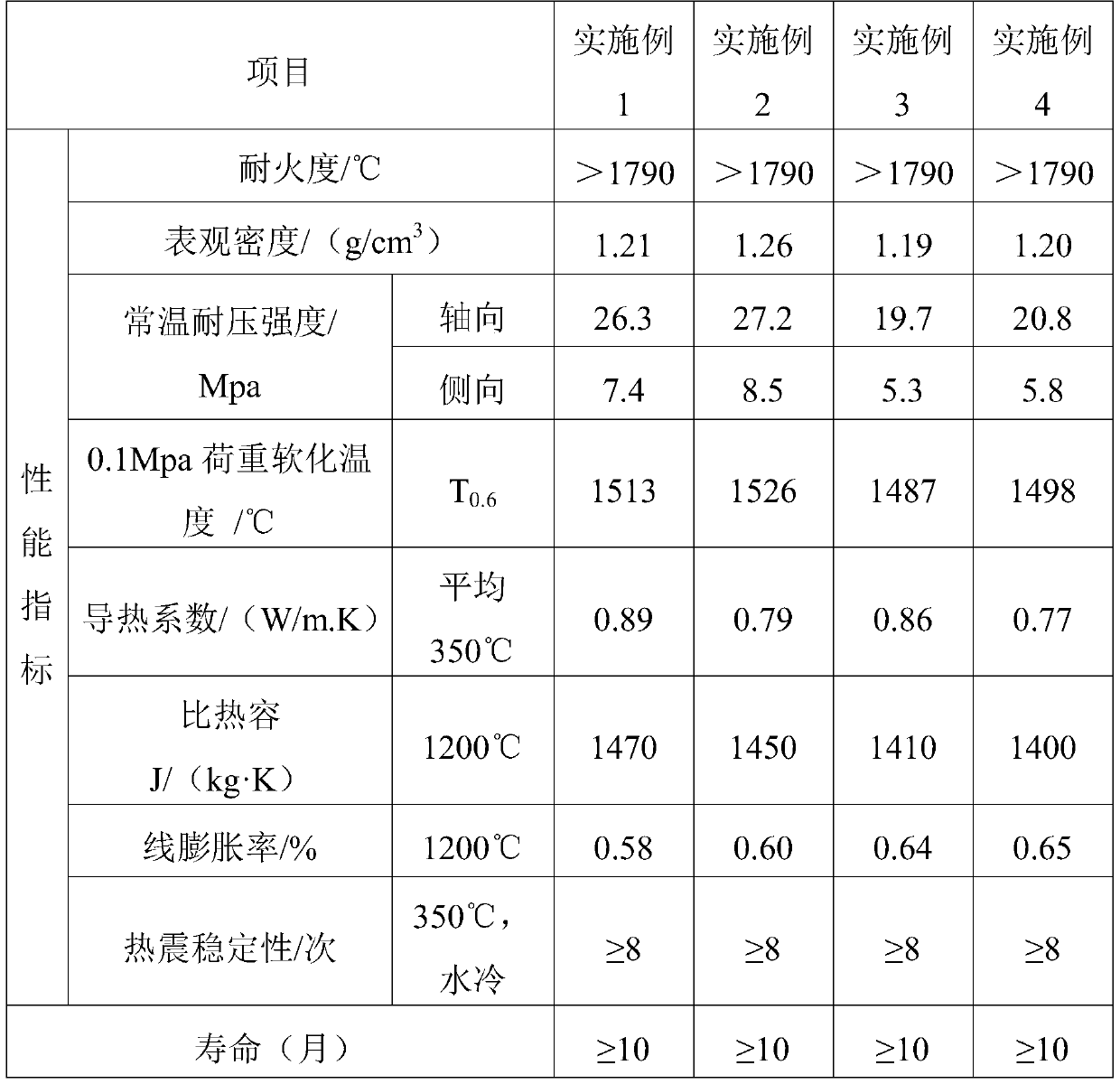

[0035] The raw materials of the honeycomb body for the regenerative heating furnace of each embodiment of the present invention and their contents in parts by weight are listed in Table 1, and the preparation methods of Examples 1-4 are the same. The above-mentioned various raw materials were weighed and prepared according to the ratio shown in Table 1, and water was added to the mixer to mix them thoroughly, and stirred into a mud-like material. The honeycomb bodies for regenerative heating furnaces of Examples 1 to 4 were obtained by putting them into a kiln for rapid drying, then grinding them, drying them again, and finally putting them into a high-temperature kiln at 1400° C. for firing.

[0036] The ratio of each embodiment of table 1

[0037] project Example 1 Example 2 Example 3 Example 4 High alumina bauxite powder 45 47 50 55 Chrome corundum powder 20 25 18 15 clay powder 10 6 8 5 Silicon carbide powder 8 5 6 5 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com