Large-luminosity-angle spherical bulb with diamond light-emitting surfaces

A volume luminescence and diamond technology, applied in the field of electronics, can solve the problems of difficulty in obtaining a large light angle, difficult to achieve, and limited adjustment of the light angle by the lens.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

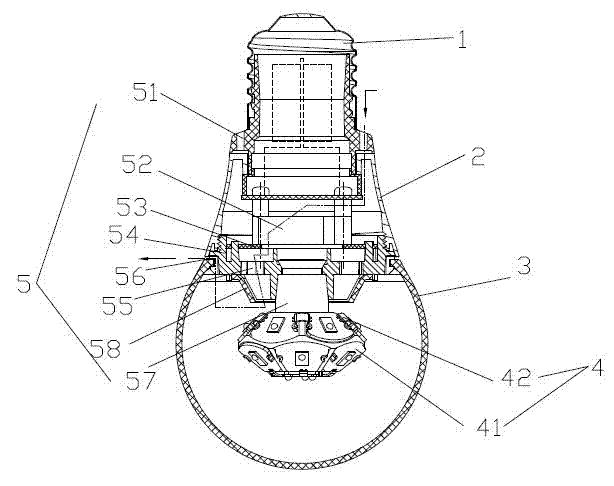

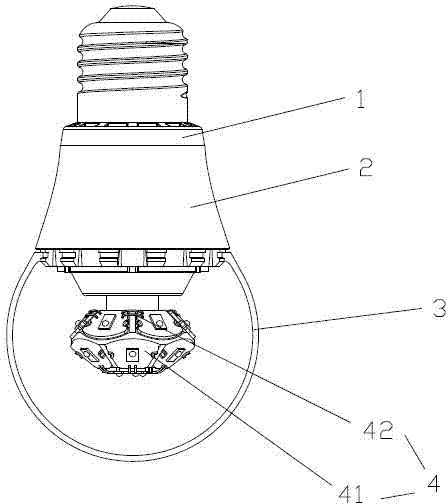

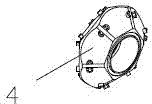

[0032] Such as figure 1 - Figure 14 The embodiment of the present invention shown is a high-luminosity angle bulb with a diamond body light-emitting surface, including: lamp base insulator 1: clamped on the lamp body; lamp body 2: connected to the heat dissipation device in the bulb and the lamp base insulator; lampshade 3: with The heat dissipation device in the bulb cooperates, which is a large hemispherical structure; the diamond polyhedron and the LED light-emitting component 4: are arranged in the near center of the lampshade, and the light-emitting component can be fixed by a self-generated boss; it also includes a substrate 41: there is an LED light source on it, and the front is set There are solder joints for mutual connection, and a heat-conducting film is pasted on the back; flexible bridge 42: connected and positioned between the subst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com