Patents

Literature

66results about How to "Meet the temperature requirements" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

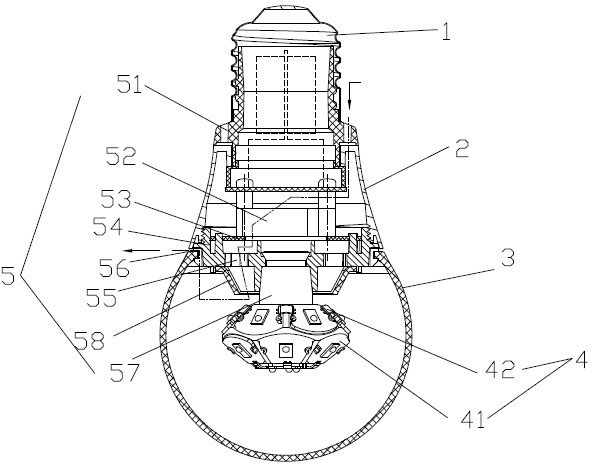

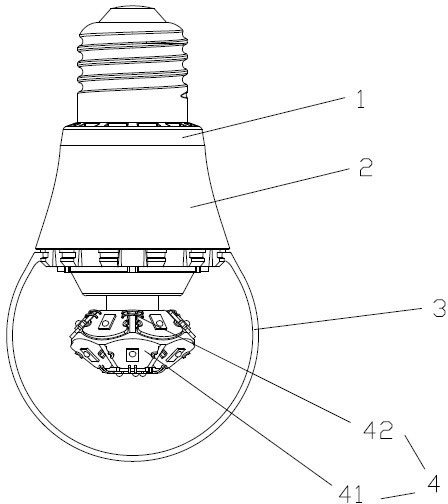

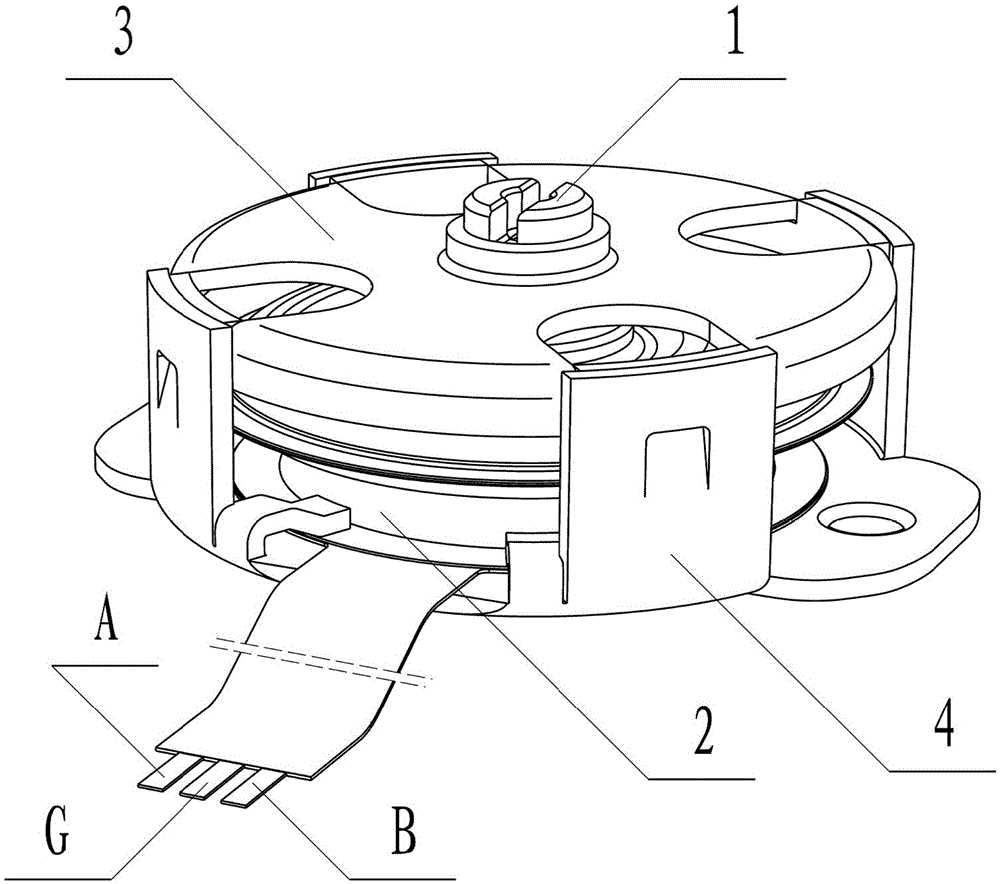

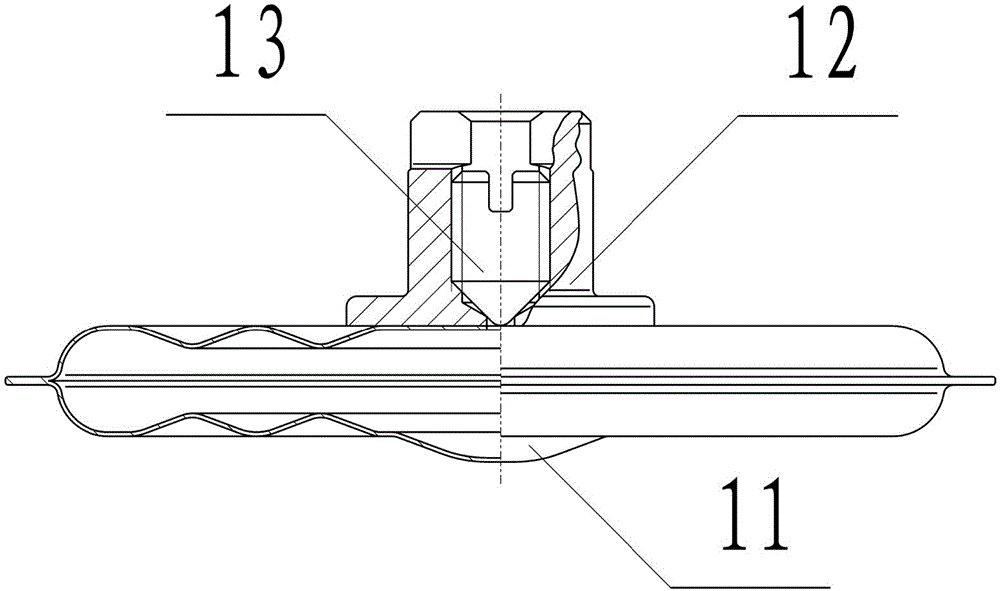

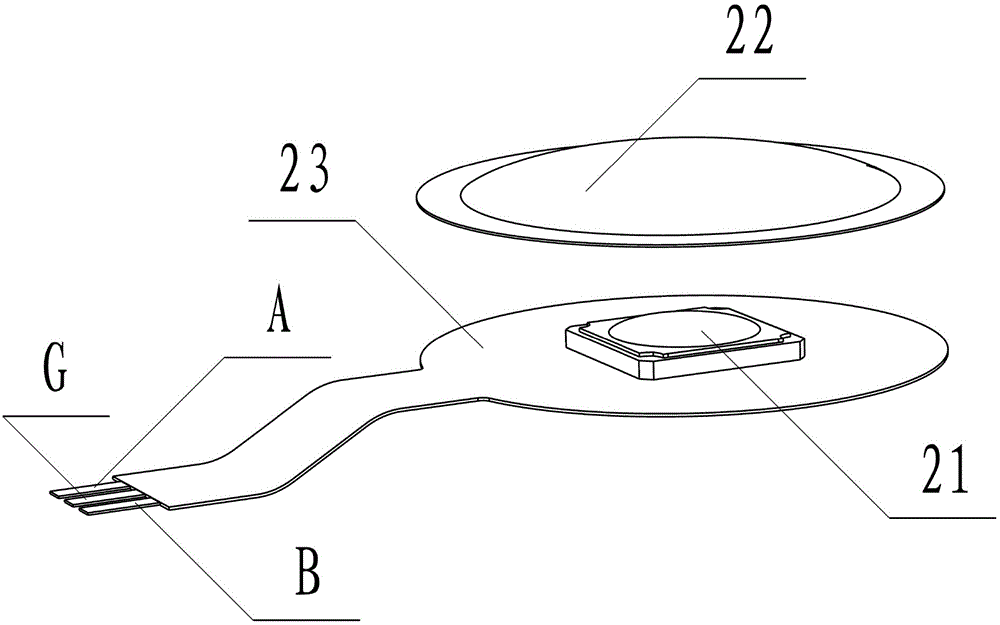

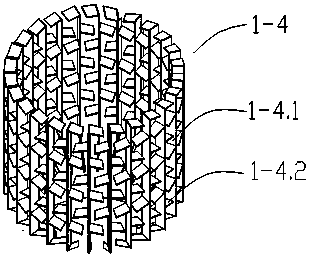

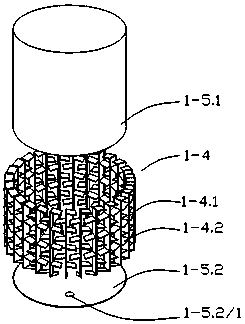

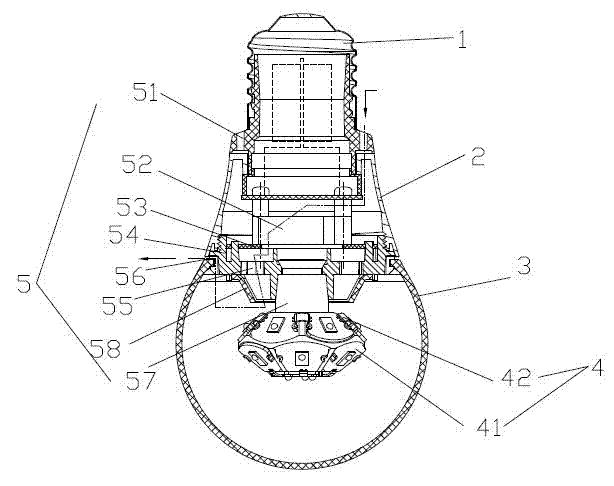

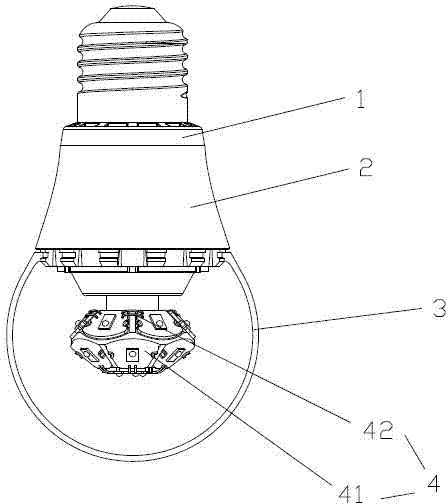

Large-luminosity-angle spherical bulb with diamond light-emitting surfaces

ActiveCN102128370AAchieve coolingIncrease the light transmission anglePoint-like light sourceLighting heating/cooling arrangementsEngineeringLight head

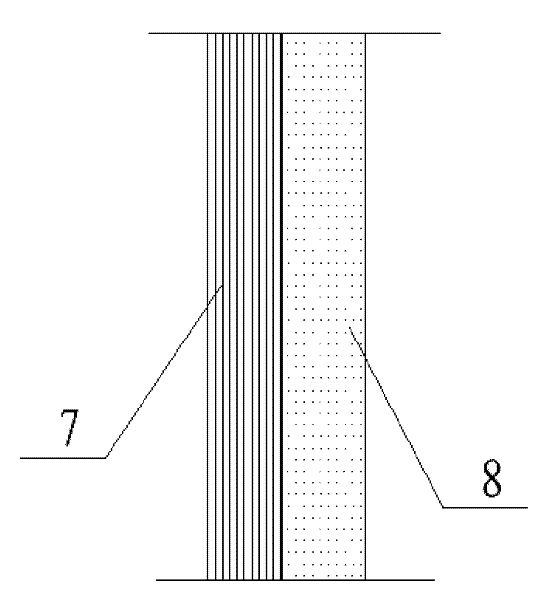

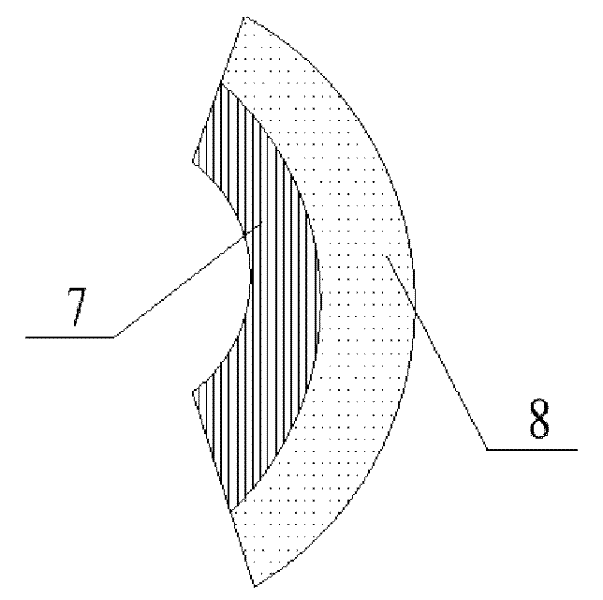

The invention provides a large-luminosity-angle spherical bulb with diamond light-emitting surfaces, comprising a lamp head insulating body, a lamp body, a lamp shade, a diamond polyhedron and LED (Light-Emitting Diode) light-emitting component and an in-bulb cooling device, wherein the lamp body connects the in-bulb cooling device and the lamp head insulating body; the lamp shade is matched with the in-bulb cooling device; the diamond polyhedron and LED light-emitting component is arranged near the center in the lamp shade and is combined by substrates, flexible connecting bridges, a diamond polyhedral heat-conducting installing body; the substrates are provided with LED light sources, and the front surfaces of the substrates are provided with welding points used for connecting; the flexible connecting bridges are connected among the substrates through circuits; the diamond polyhedral heat-conducting installing body is diamond-like and has N sides, can be used for fixing a light-emitting component and can be set into any angle and shape; and the in-bulb cooling device is communicated with the lamp head, the lamp body and the lamp shade to form an airflow inlet and outlet channel. In the large-luminosity-angle spherical bulb provided by the invention, the lamp shade is designed into a shape larger than a hemisphere, which can increase a light-transmitting angle, the LED light-emitting component is made into a diamond structure so as to realize multidirectional positive and negative surface irradiation, and the in-bulb cooling device can carry out forced air-cooling on the in-bulb radiating fins and radiating fins in the lamp body.

Owner:SICHUAN LIANKAI LIGHTING CO LTD

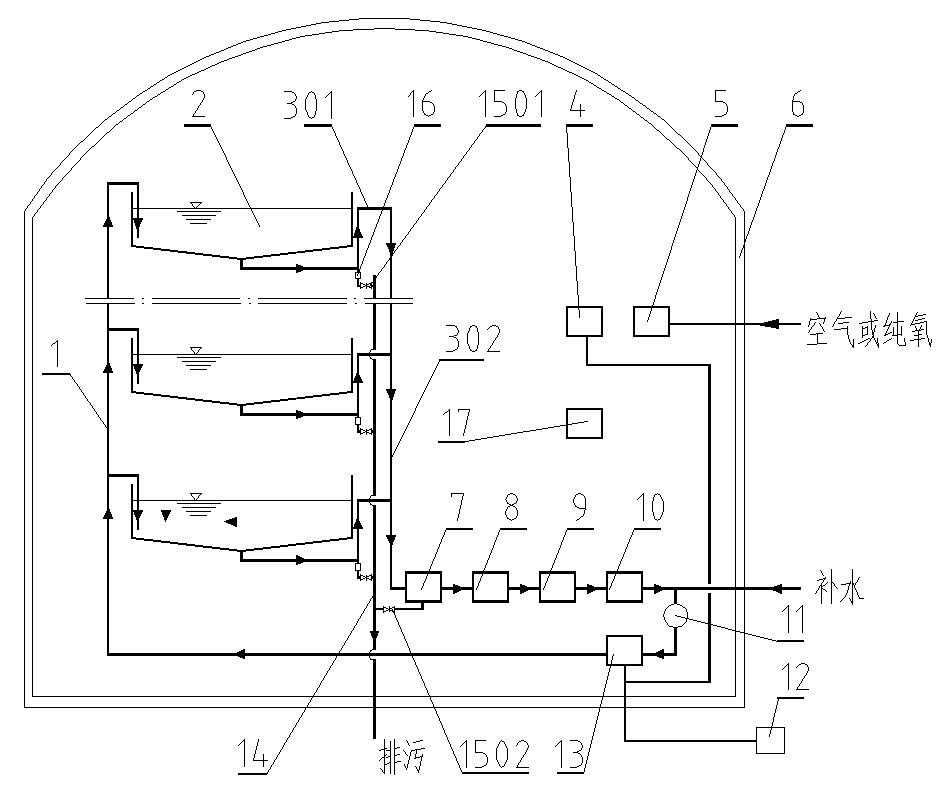

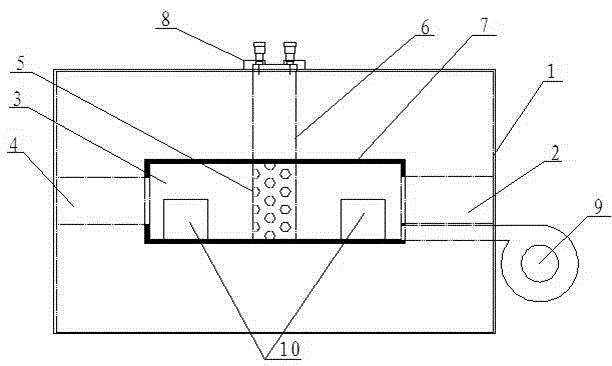

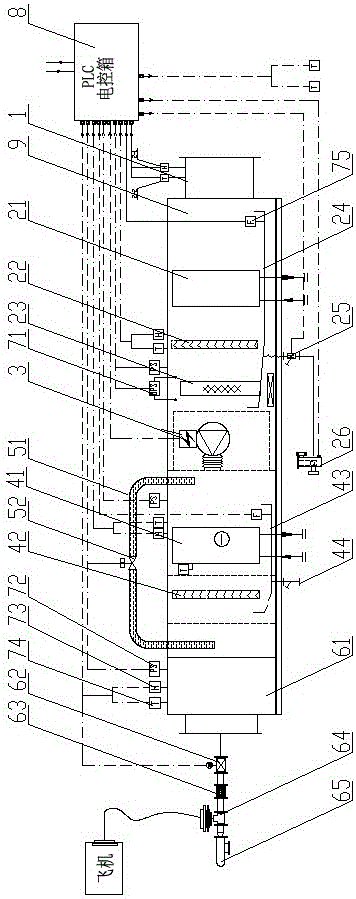

Closed-type constant-temperature multi-layer water circulation turtle cultivation system

InactiveCN103181362AAchieve purification effectAchieve reuseAnimal husbandryEcological environmentBiological filter

The invention discloses a closed-type constant-temperature multi-layer water circulation turtle cultivation system which comprises a multilayer turtle cultivation pool devices, a cultivation water environment adjusting device, an indoor air environment adjusting device and a cultivation system operation control device, wherein the multilayer turtle cultivation pool device comprises a plurality of turtle cultivation pools, circulating water return pipes, circulating water outlet branch pipes and main circulating water outlet pipes, primary solid liquid precipitation devices, blow-down valves and pollution discharge blow-down pipes; the cultivation water environment adjusting device comprises a solid-liquid separator, a blow-down valve, a sterilizer, a protein separator, a biological filtering device or tank, a circulating pump and a water heating device; and the indoor air environment adjusting device comprises an air heating device, an air oxygenating device and an insulation building. According to the closed type constant-temperature multi-layer water circulation turtle cultivation system, turtle cultivation environments can be comprehensively controlled, the land, the water and the energy are saved, an optimal ecological environment suitable for turtles to rapidly grow is established, turtle cultivation is free of drugs, and healthy and safe food sanitation requirements are met.

Owner:ZHEJIANG UNIV

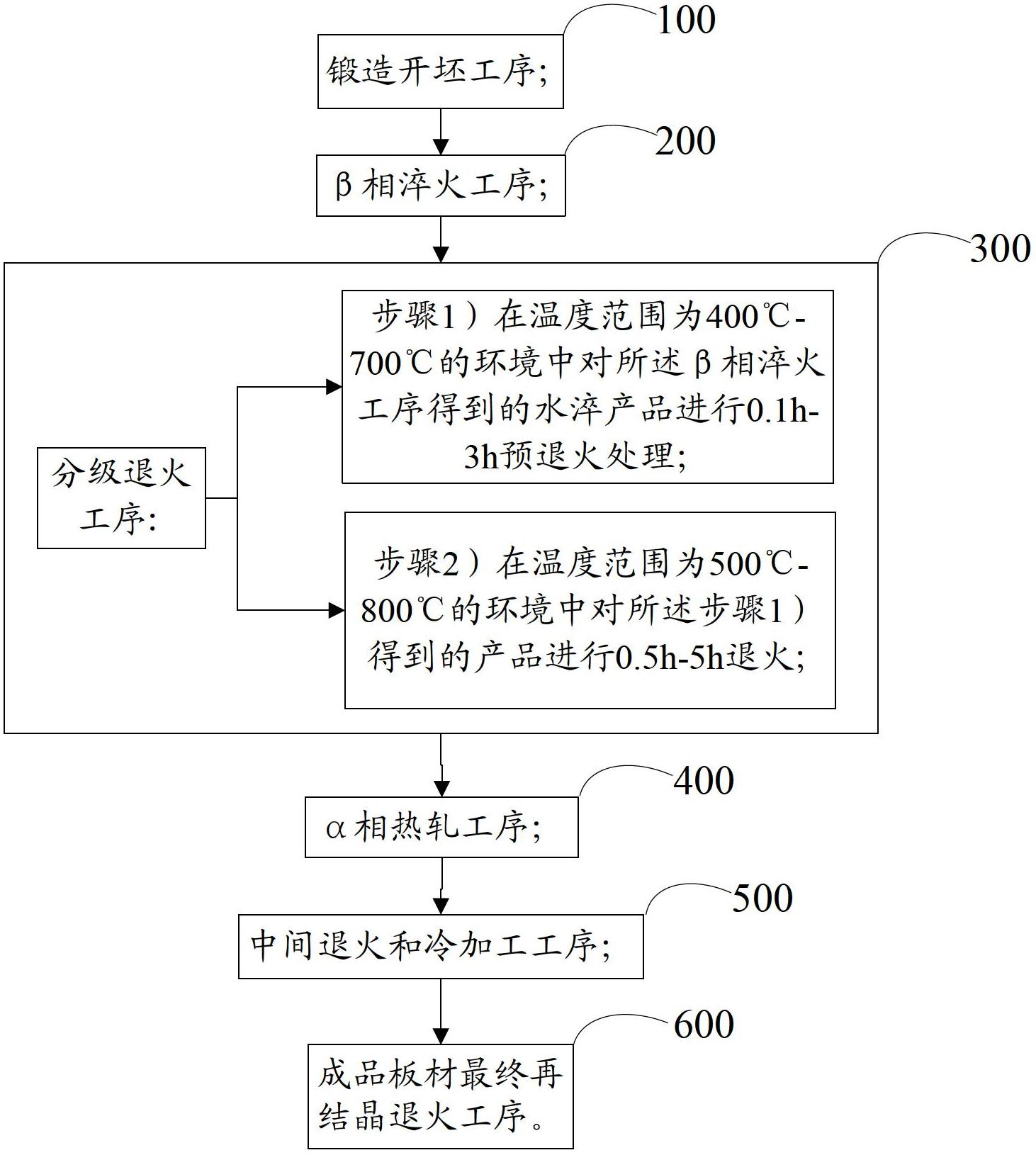

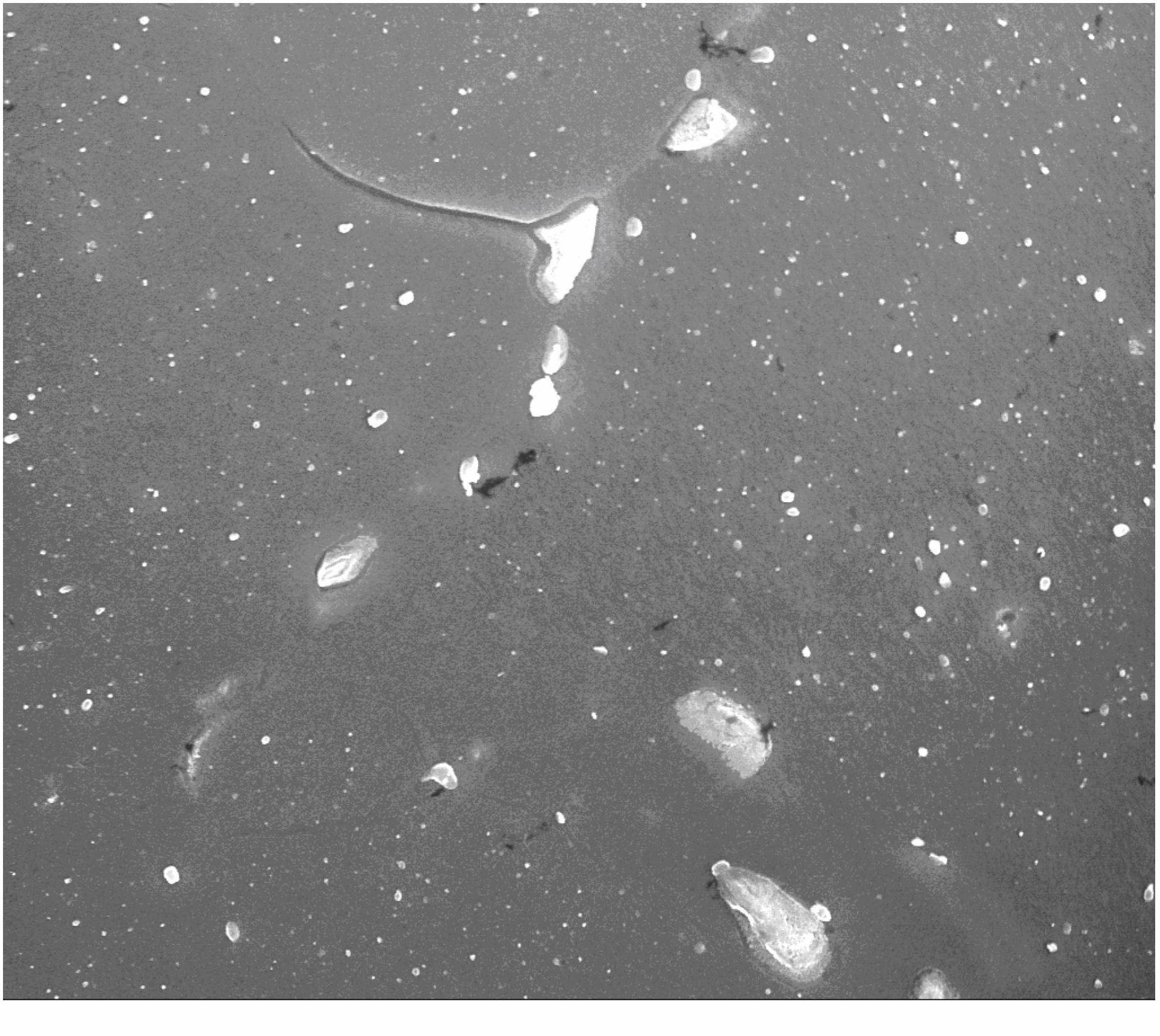

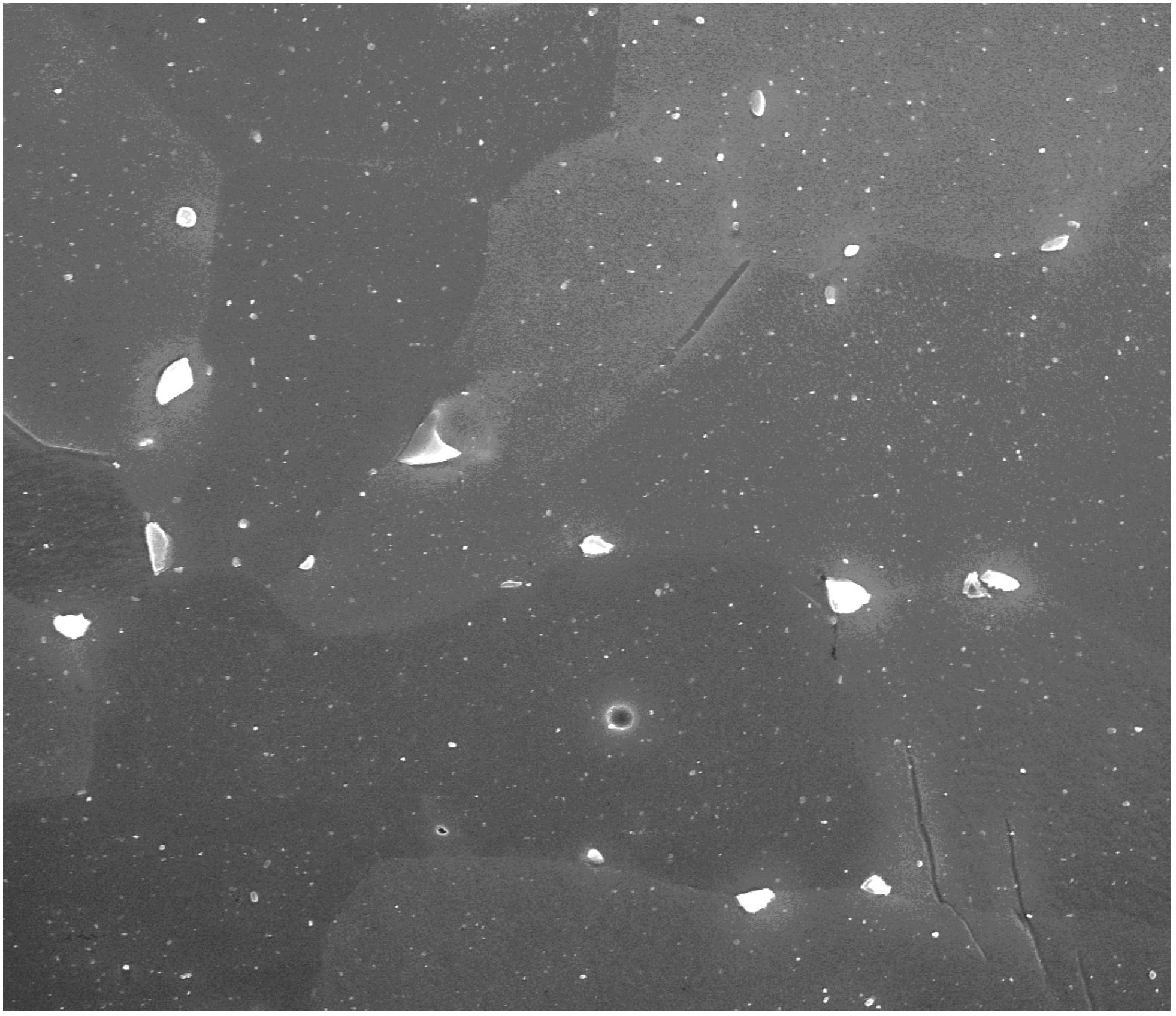

Machining process for zirconium alloy

InactiveCN102660719AImprove plastic deformation abilityTo achieve the effect of graded insulationNuclear reactorBeta phase

The invention discloses a machining process for a zirconium alloy. The machining processing comprises the following sequential steps of: a hammer cogging working procedure, a beta-phase quenching working procedure, a graded annealing working procedure, an alpha-phase hot rolling working procedure, a middle annealing and cold machining working procedure, and a final finished-product board re-crystallizing and annealing working procedure, wherein the graded annealing working procedure comprises pre-annealing treatment; the re-annealing treatment specifically comprises the following steps of: carrying out the pre-annealing treatment on a water quenched product obtained by the beta-phase quenching working procedure under the environment in a temperature range of 400-700 DEG C for 0.1-3 hours; and carrying out annealing and heat preservation on a product obtained by the pre-annealing treatment under the environment in a temperature range of 500-800 DEG C for 0.5-5 hours. The machining process for the zirconium alloy disclosed by the invention enables second-phase grains in the zirconium alloy to be dispersed and distributed, so as to improve the plastic deformation capability of the zirconium alloy and improve the plastic machining capability of the zirconium alloy; and meanwhile, the machining process for the zirconium alloy further can improve the corrosion resistance of a core structural material prepared by the zirconium alloy in a nuclear reactor.

Owner:CHONGQING UNIV

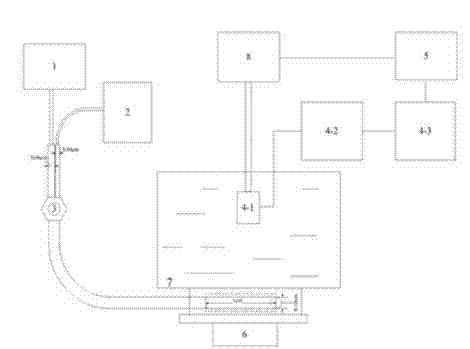

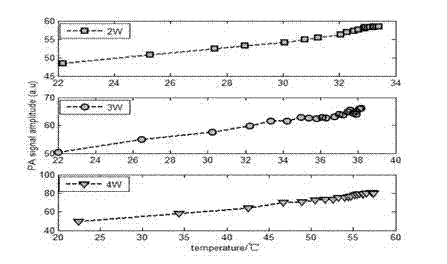

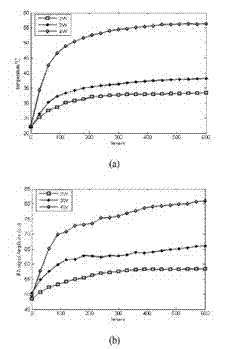

Photothermal effect tissue treatment optimizing and monitoring method and device

InactiveCN103919607AMonitor temperature changesGood photothermal effectSurgical instrument detailsDiagnostic recording/measuringMonitoring methodsMaterials science

The invention relates to a photothermal effect tissue treatment optimizing and monitoring method and device. Continuous intensive laser and pulse laser are transmitted through a flexible diffusion end multimode fiber which is inserted into tissue in a minimal invasion manner, and the same area of the tissue can be irradiated. The continuous intensive laser mainly produces the photothermal effect to cause tissue temperature to change; the pulse laser mainly produces photoacoustic signals, temperature changes of the tissue being monitored are changed according to the strength of the photoacoustic signals, dosage and irradiation time of the continuous intensity laser are regulated in time as required, and optimized photothermal effect is achieved.

Owner:李志芳

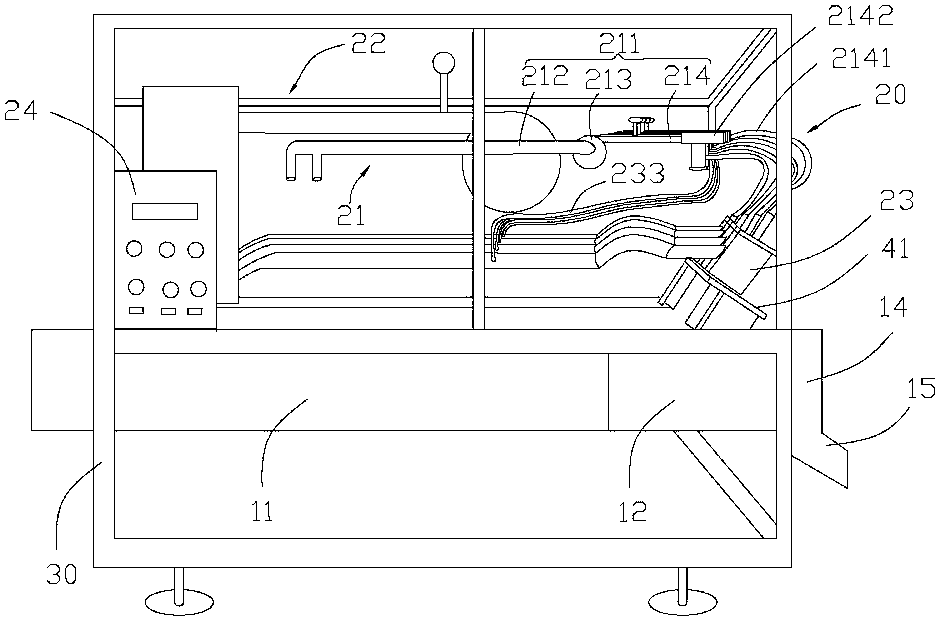

Continuous forging heating furnace

ActiveCN103302223AMeet the temperature requirementsEasy to saveForge furnacesAcute angleHeating furnace

The invention provides a continuous forging heating furnace which comprises a furnace body, a heating mechanism and a machine frame; the furnace body and the heating mechanism is arranged on the machine body; the furnace body comprises a furnace chamber which runs through the furnace body; a furnace wall as well as the feeding end and the discharging end of the furnace body are correspondingly formed; a guide groove is formed in the furnace chamber; the heating mechanism comprises a plurality of burners; the burners are installed at the discharging end close to the furnace body and the top part of the furnace body, and enter into the furnace chamber through the furnace wall in a way that acute angles are formed between the directions of the burners and the material guiding direction. The continuous forging heating furnace can fully preheat materials and facilitates heat energy conservation and utilization.

Owner:彭亦楚

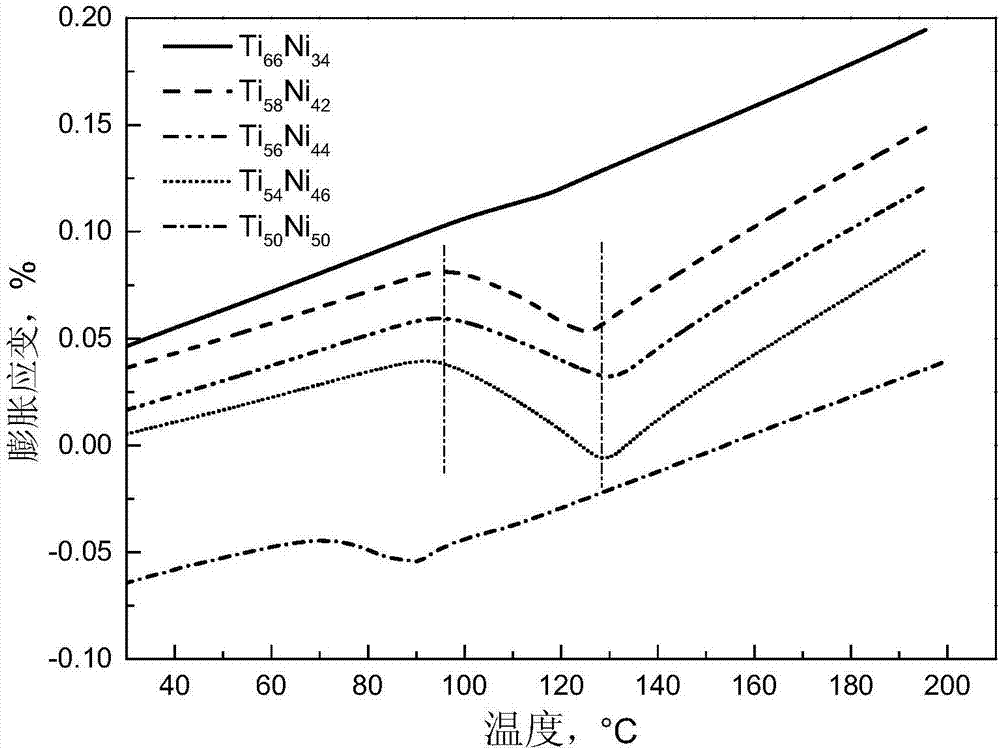

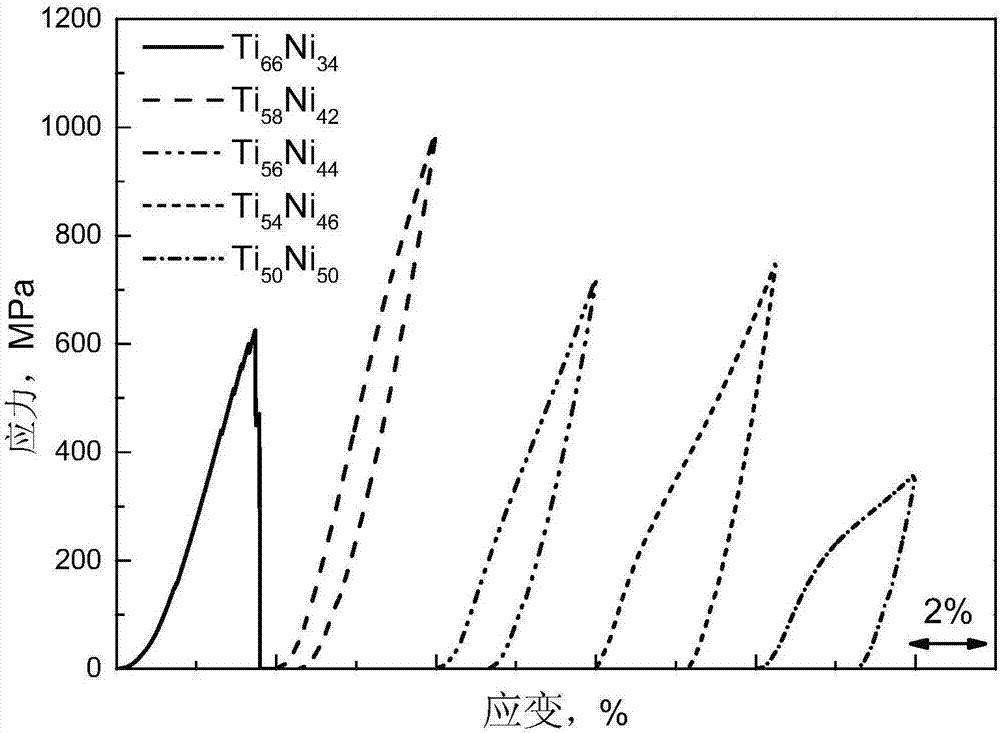

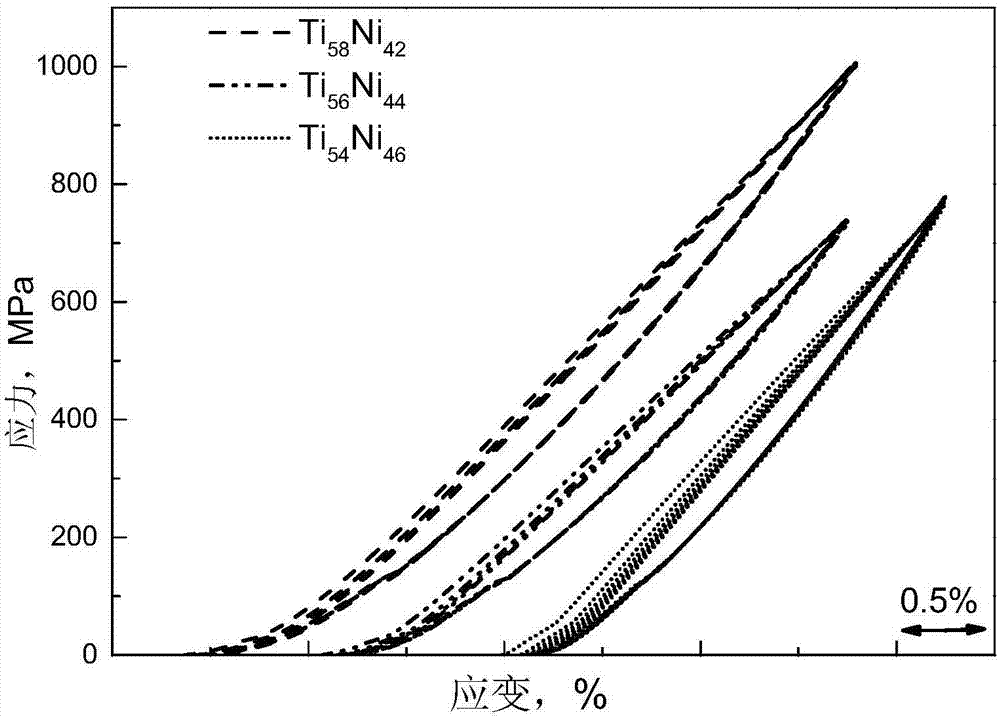

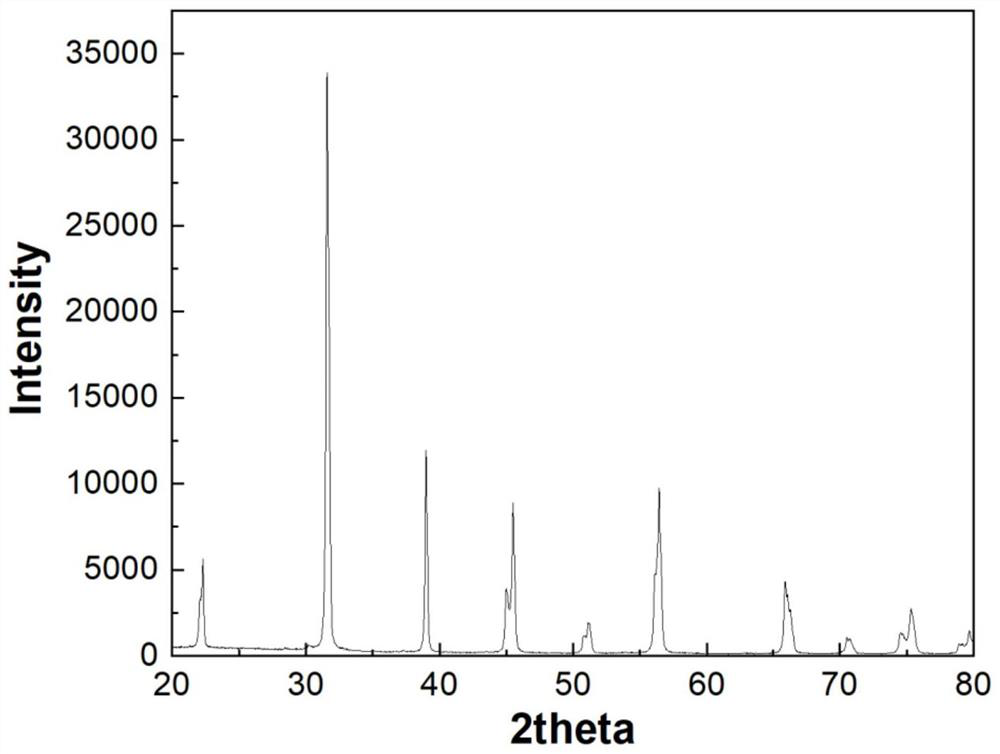

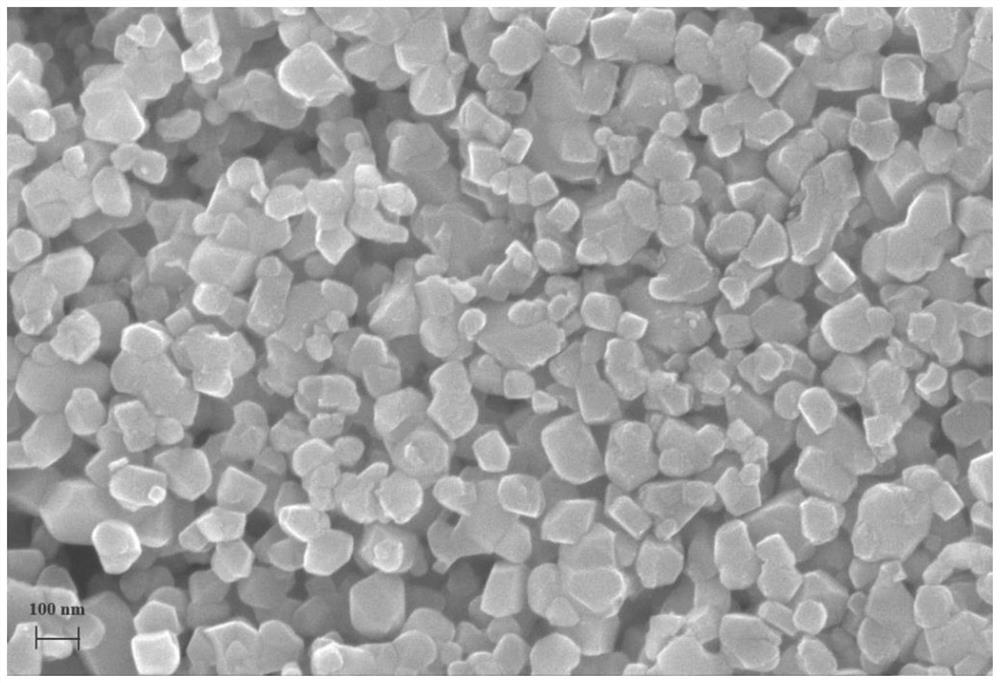

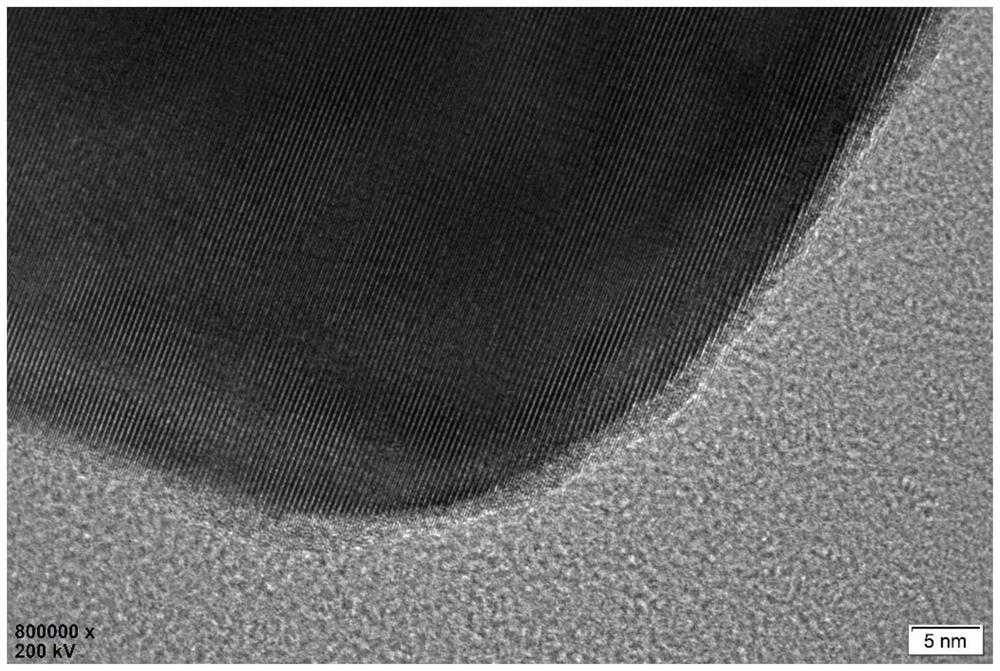

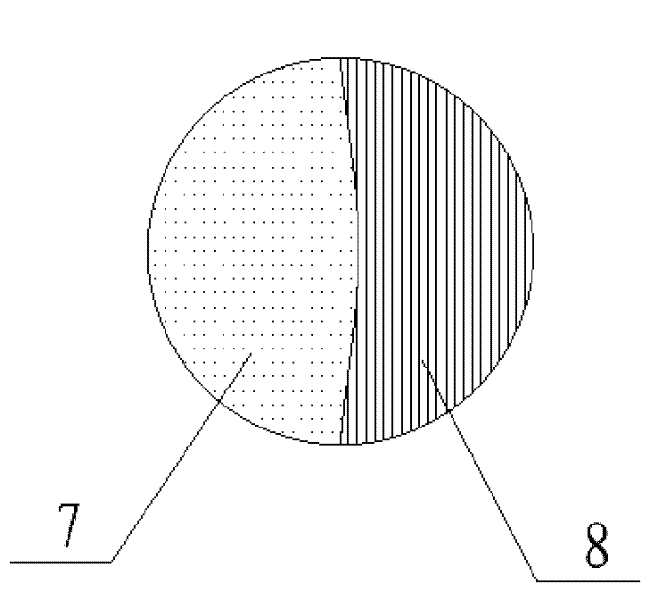

Titanium-rich titanium nickel alloy with negative heat expansion performance and preparation method thereof

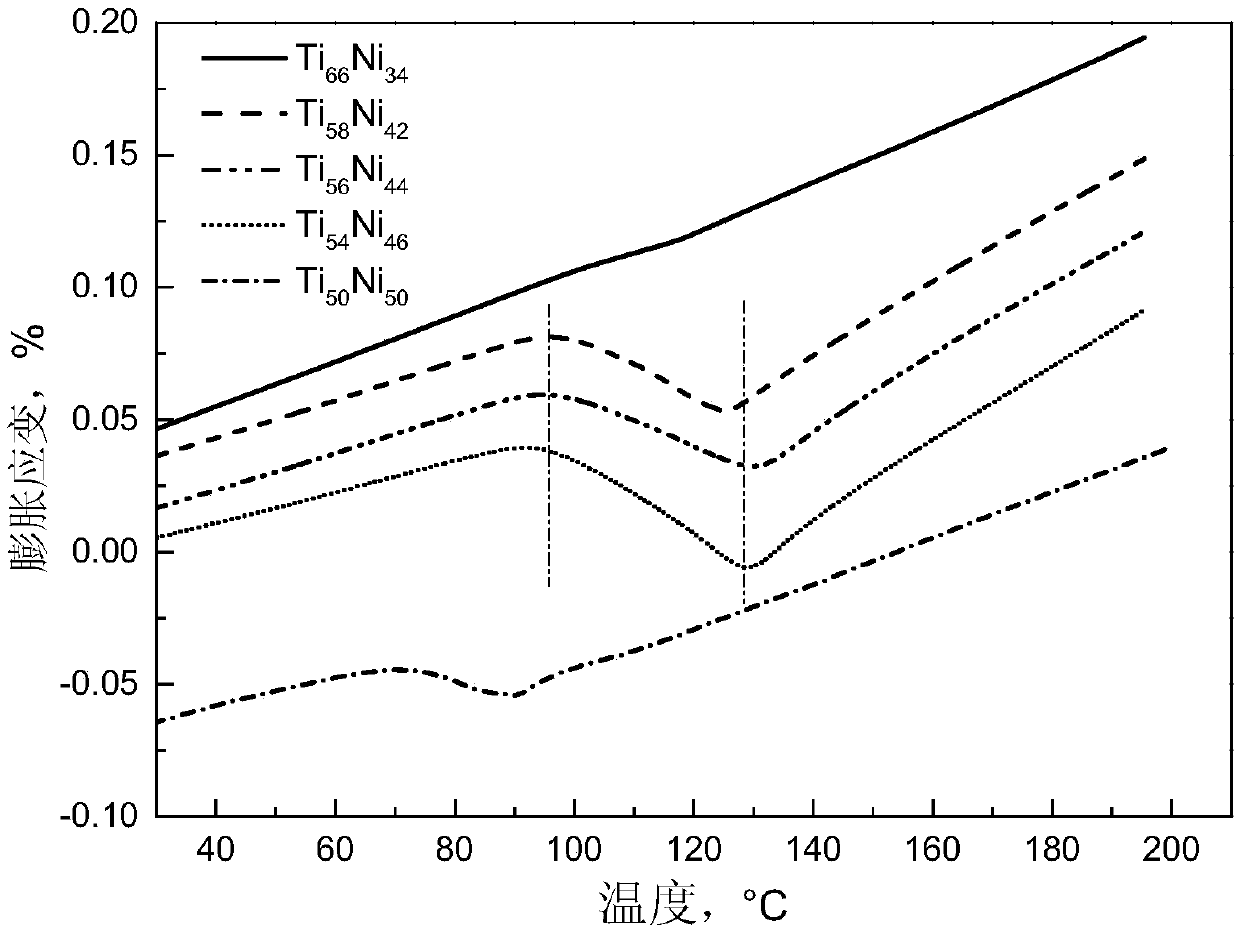

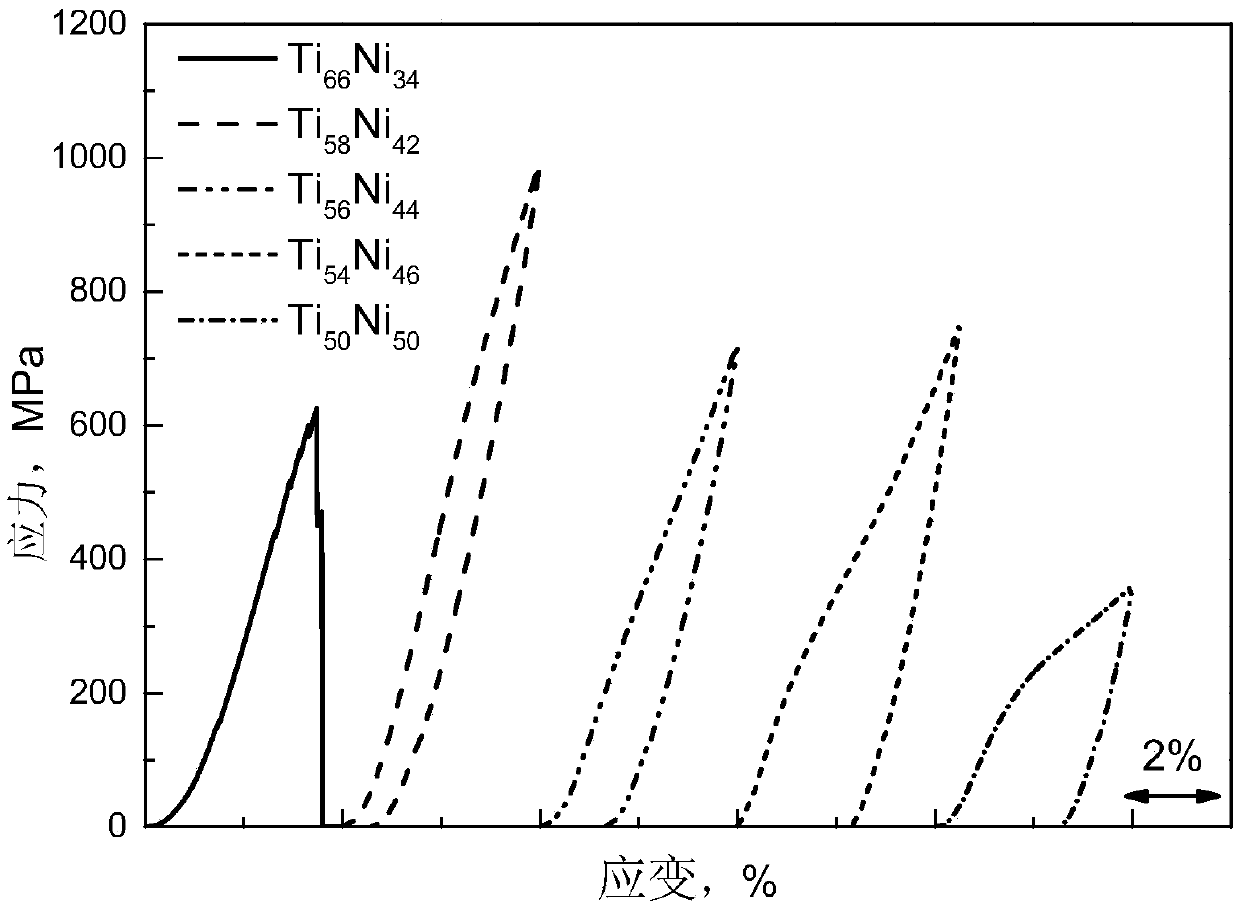

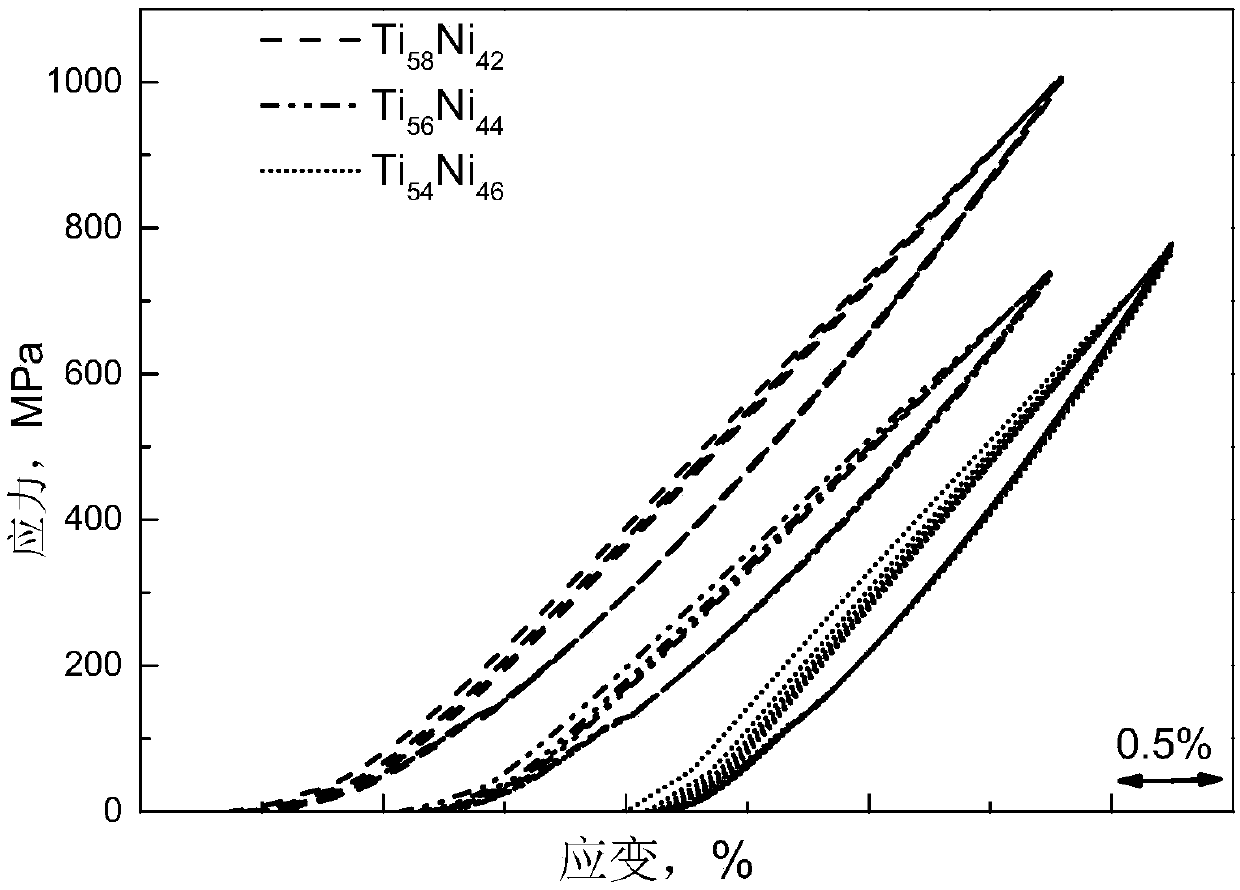

ActiveCN107164653AStable negative thermal expansion propertiesGood thermal expansion matching characteristicsTitaniumNegative thermal expansion

The invention discloses a titanium-rich titanium nickel alloy with negative heat expansion performance and a preparation method thereof. The general formula of the titanium-rich titanium nickel alloy is Ti(100-x)Nix, wherein x is the atomic percentage and meets the relation of x=42.0-46.0. In preparation, electrolytic nickel and sponge titanium serve as raw materials and are placed into a copper crucible, with circulating water led in for cooling, of a vacuum electric-arc smelting furnace after dosing is conducted in proportion, and repeated smelting is conducted under protection of inert gas; a smelted button-shaped mother alloy is placed into a suction-casting copper crucible and heated for remelting, an alloy melt is suctioned into a suction-casting copper mould with circulating water led in for cooling under the vacuum negative-pressure effect, and an alloy with a needed shape is obtained through quick solidification; and after annealing treatment is conducted at the temperature of 800-900 DEG C, a titanium nickel alloy material with a stable negative heat expansion response temperature interval is prepared, and high strength and excellent linear superelasticity are simultaneously achieved. The titanium nickel alloy material is suitable for being compounded with a positive heat expansion material.

Owner:SOUTH CHINA UNIV OF TECH

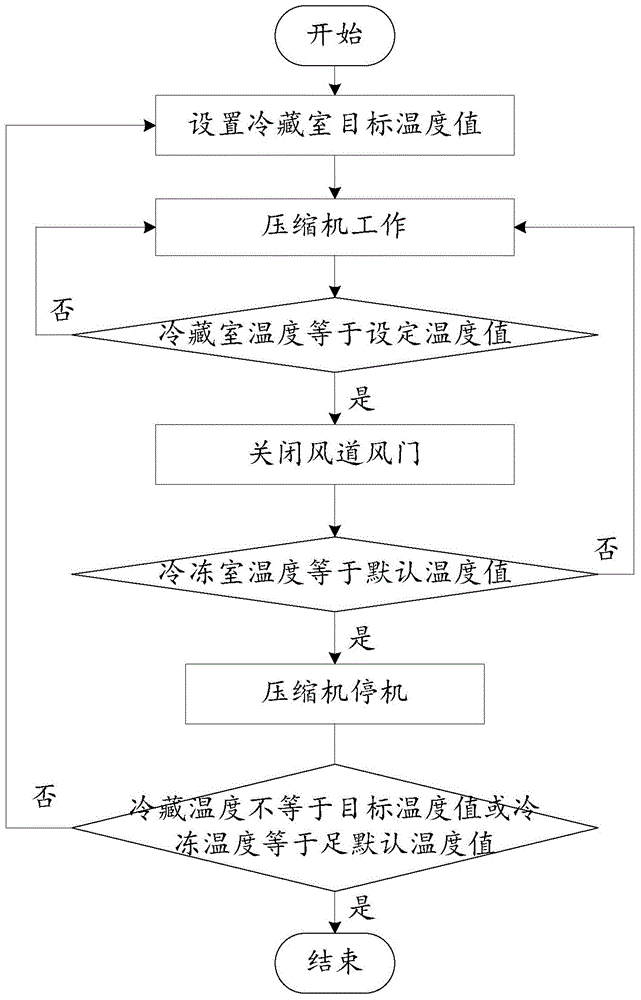

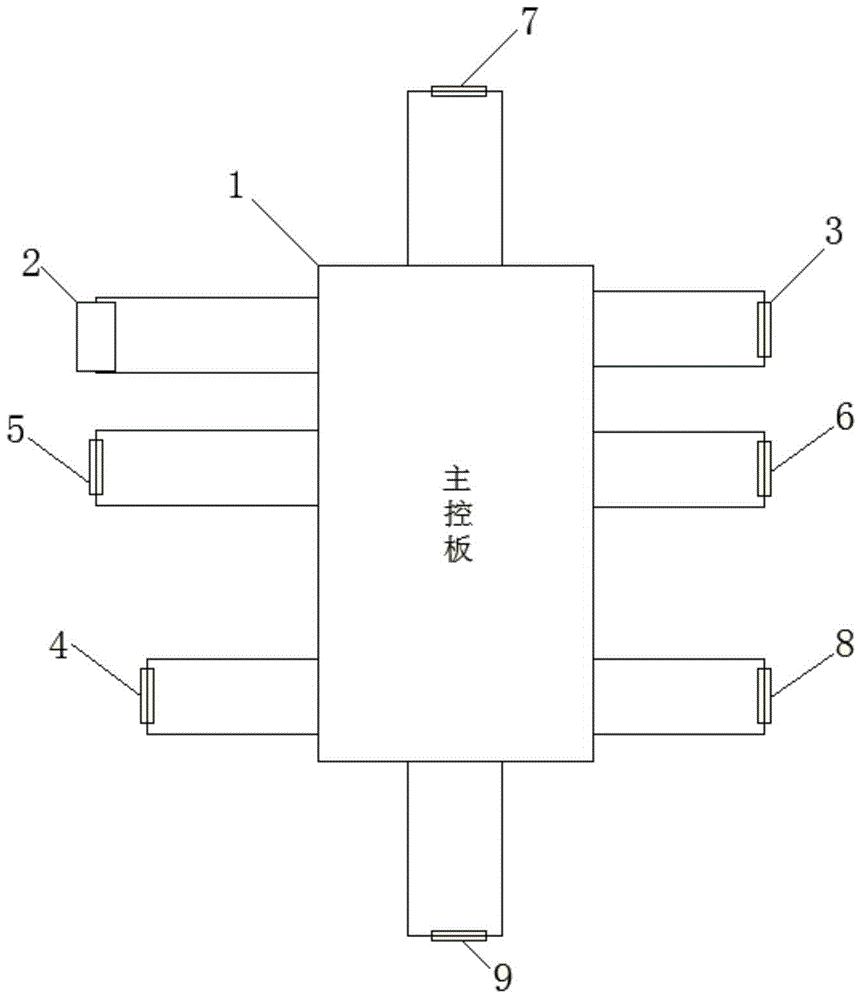

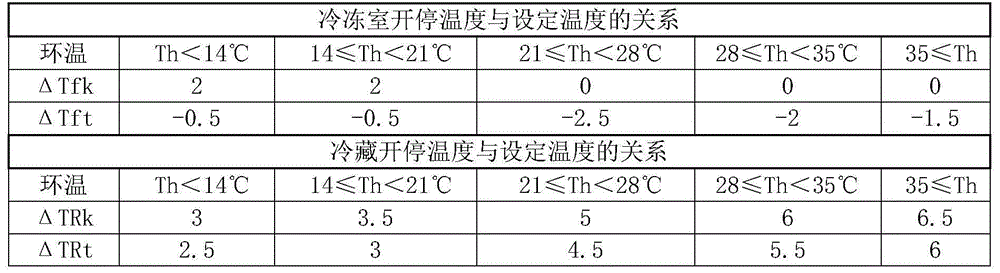

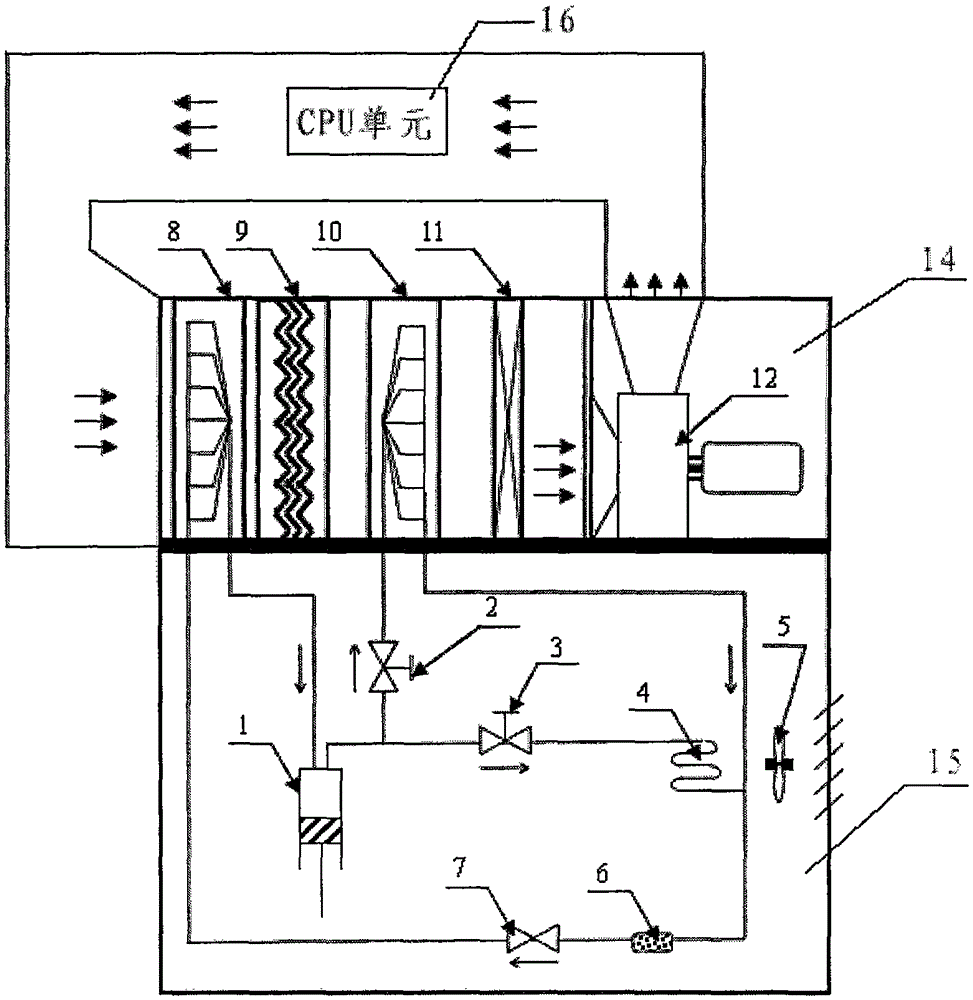

Air-cooled refrigerator temperature control method and system and air-cooled refrigerator

InactiveCN104930813AMeet the temperature requirementsNo need for manual adjustment controlRefrigeration safety arrangementCooling fluid circulationStopped workTemperature control

The invention relates to an air-cooled refrigerator temperature control method and system. The method comprises the steps that a target temperature value of a refrigerator refrigerating chamber is set, and a compressor is controlled to start; the real-time temperature of the refrigerating chamber and the real-time temperature of a freezing chamber are acquired; the acquired real-time temperature of the refrigerating chamber is compared with the target temperature value of the refrigerating chamber; when the real-time temperature of the refrigerating chamber is equal to the target temperature value of the refrigerating chamber, the acquired real-time temperature of the freezing chamber is compared with a default temperature of the freezing chamber; when the real-time temperature of the freezing chamber is equal to the default temperature of the freezing chamber, the compressor is controlled to stop working. According to the air-cooled refrigerator temperature control method and system, only the temperature of the refrigerating chamber needs to be adjusted, the temperature of the freezing chamber is controlled full-automatically, the design requirements for food storage in the freezing chamber are met, the system can automatically run a program without manual adjustment and control, operation is easy, cost is low, the requirement for the use temperature of a refrigerating system and the requirement for the use temperature of a freezing system can be met separately, the phenomenon that only the refrigerating temperature of a mechanical refrigerator can be controlled, and the temperature of a freezing chamber cannot be controlled is avoided, and the requirement for energy conservation is met.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Fully-closed intelligent electric control cabinet cooling system

InactiveCN105407688AMeet the temperature requirementsMeet humidity requirementsSpace heating and ventilation safety systemsLighting and heating apparatusEvaporationElectric control

The invention discloses a fully-closed intelligent electric control cabinet cooling system, which comprises a compressor, a condensation heat recovery adjustment valve, a heat recovery coil, an electric valve, a condensation coil, a condensation fan, a dry filter, a throttle valve, an evaporation coil, a baffle board, an electric heater, a circulating fan and a case. The cooling capacity for cooling each electronic and electric module inside the electric control cabinet is from the refrigerating capacity generated by a vapor compression refrigeration system at the evaporation coil, a constant dew point temperature mode enables the temperature and the humidity of the circulating cooling air to be controlled precisely, and due to the condensation heat recovery design, the cooling system is energy-saving and environmental friendly. The defects that the cooling mode of the cooling fan is largely influenced by interference of the surrounding air environment, and only insufficient cooling effects can be provided can be overcome.

Owner:WUXI INST OF COMMERCE

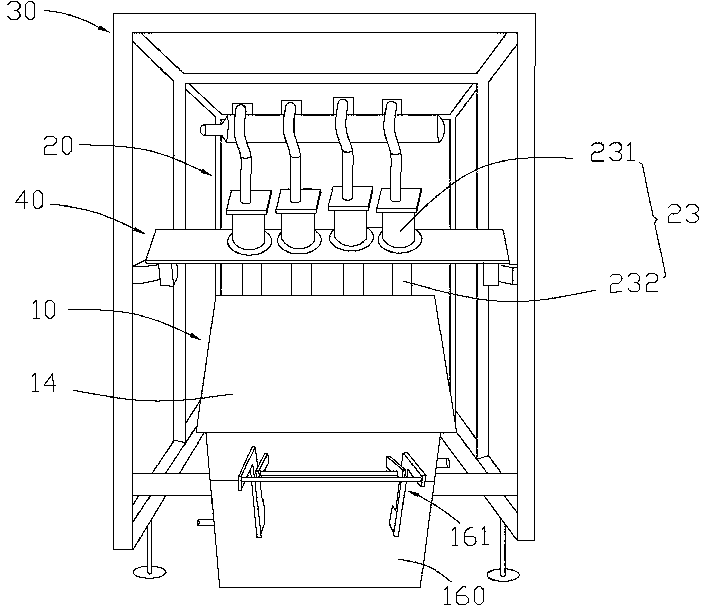

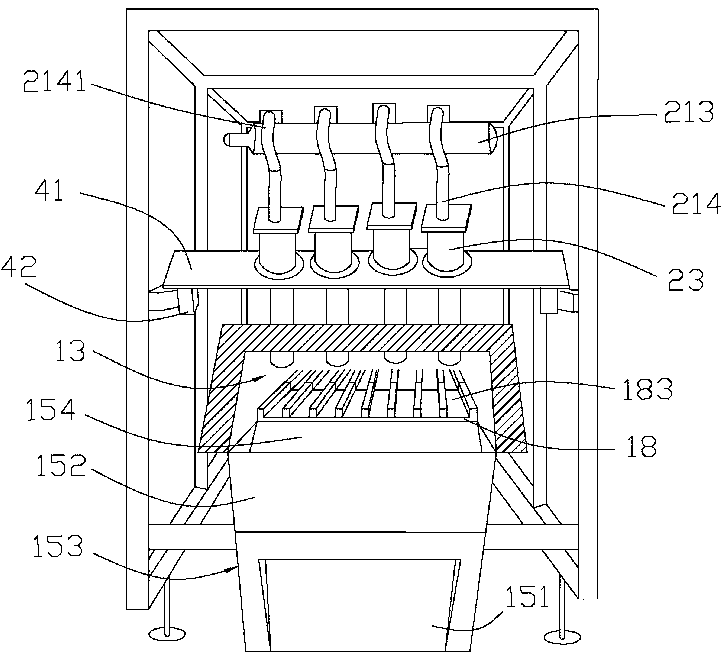

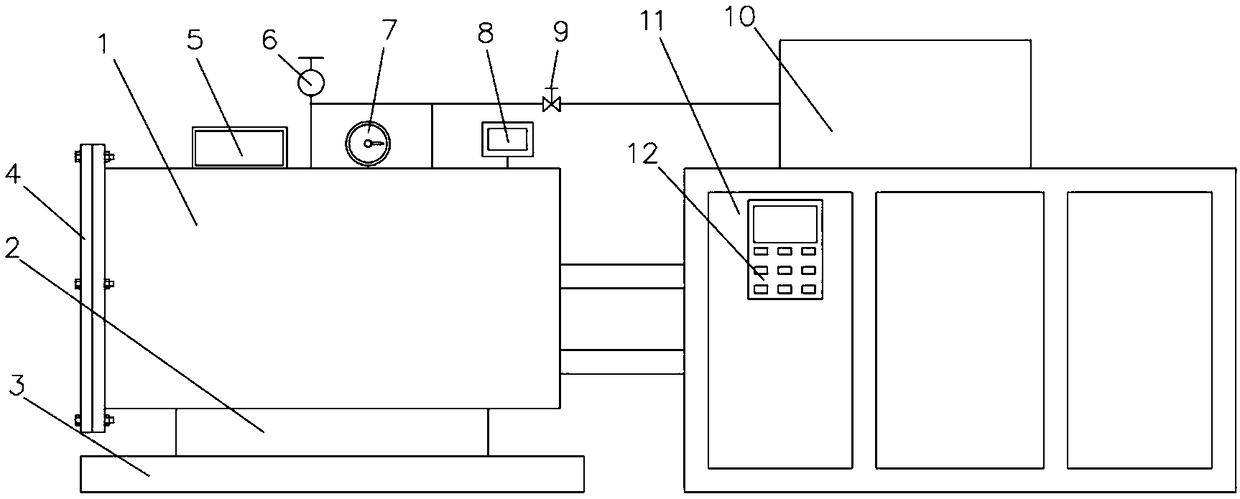

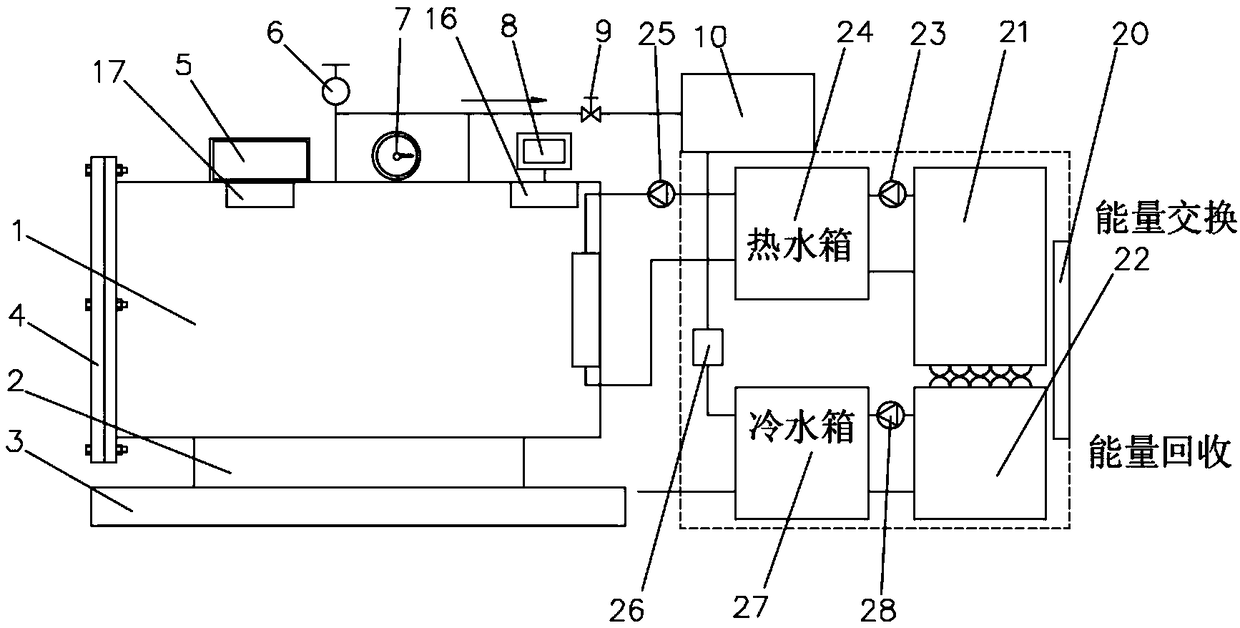

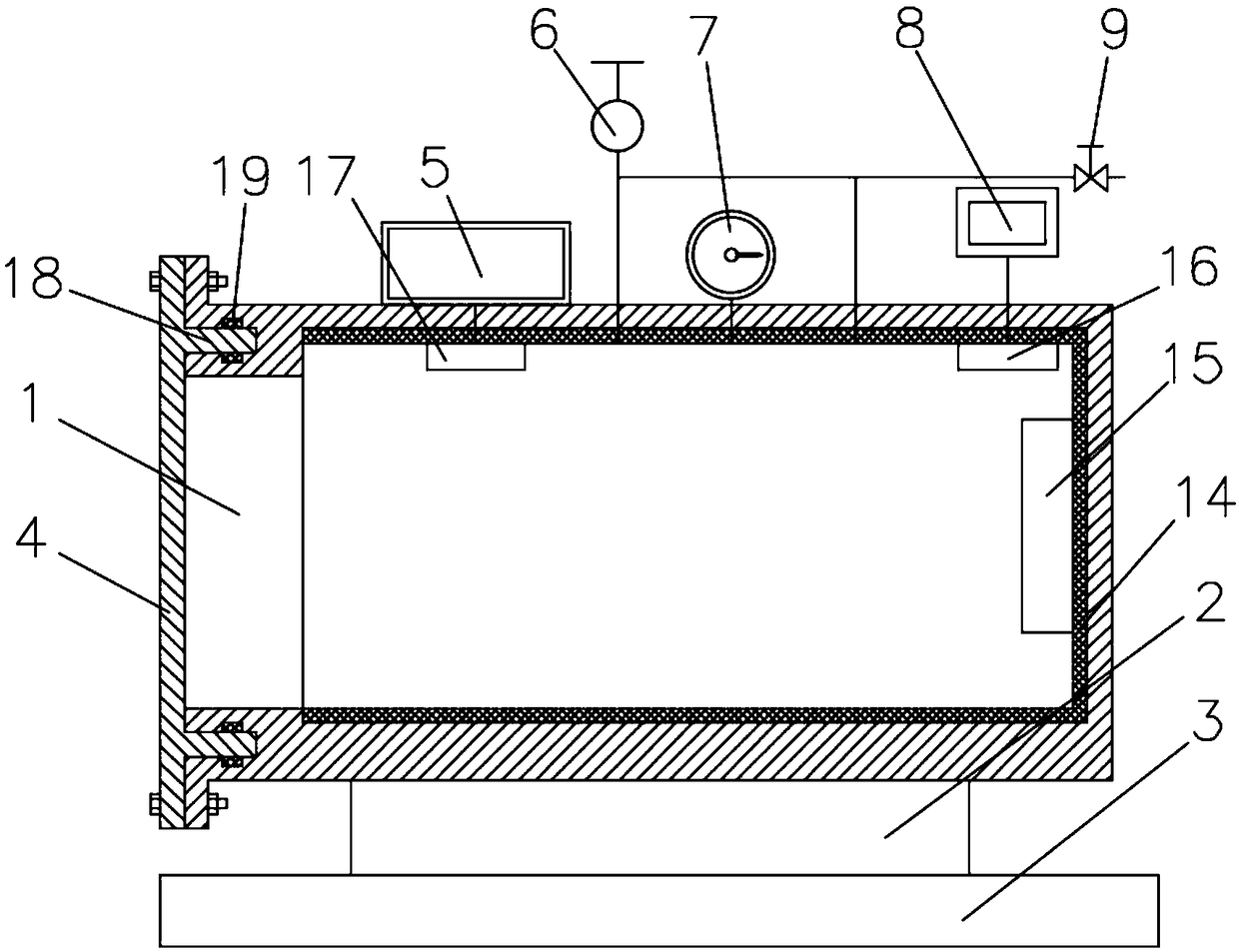

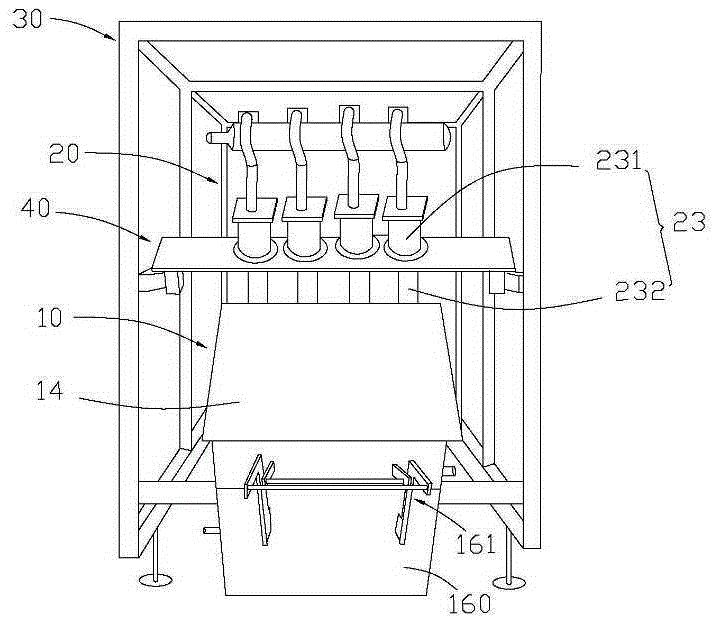

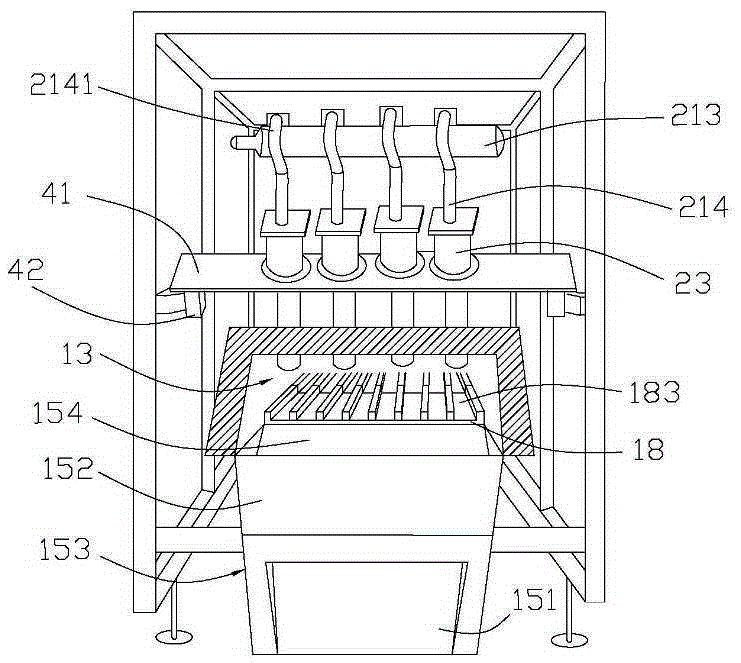

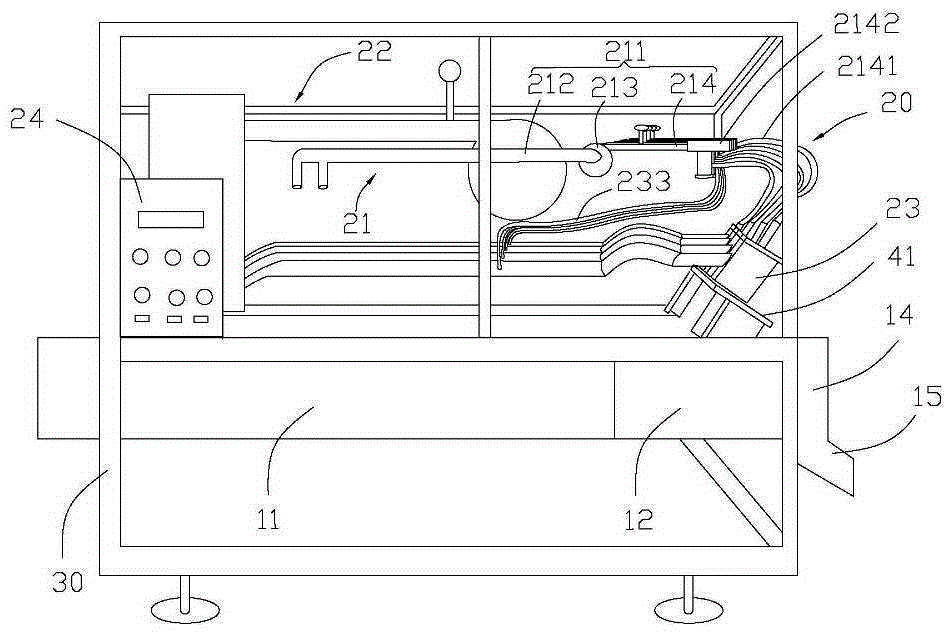

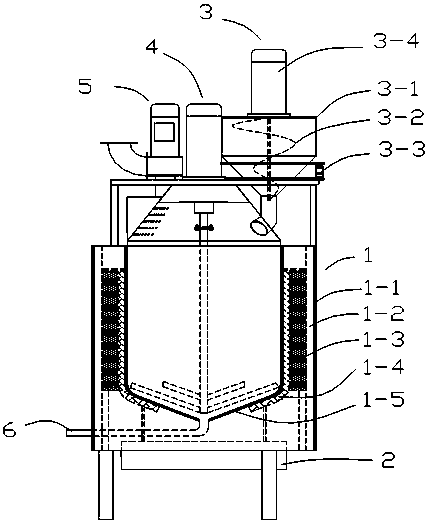

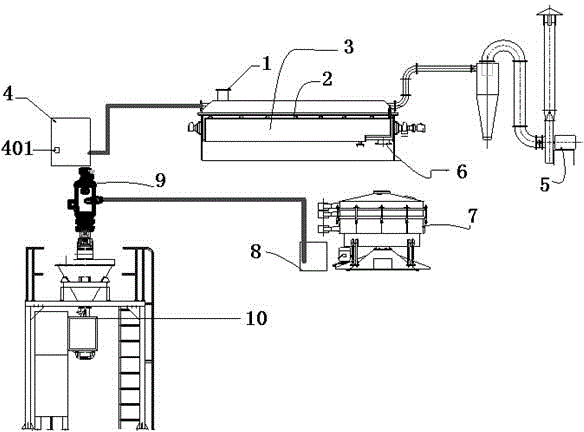

Alkali-free wolfberry drying machine

PendingCN108826859AOvercome oxidationOvercoming the Weakness of DeteriorationDrying solid materials without heatDrying machines with local agitationAlkali freePulp and paper industry

The invention relates to the technical field of wolfberry drying devices, in particular to an alkali-free wolfberry drying machine. The alkali-free wolfberry drying machine comprises a machine box with a cuboid structure, a controller, a drying chamber with a cylindrical structure, an energy exchanger, an energy recycling machine, a cold water tank, a hot water tank and a roots vacuum pump, wherein the energy exchanger, the energy recycling machine, the cold water tank, the hot water tank and the roots vacuum pump are arranged inside the machine box, the energy exchanger and the energy recycling machine are mutually connected through a heat exchanger, an electric auxiliary heating device used for adjusting the heat quantity inside a box body is fixedly arranged on the right side wall of the inner cavity of the machine box, a disc-shaped end cover is arranged at the left end opening of the drying chamber in a matched mode, a connecting ring with an annular structure is arranged on the inner side surface of the end cover, connecting flanges are arranged on the outer edge of the end cover and the outer edge of the left end opening of the drying chamber in a matched mode, the end coverand the drying chamber are fixed in the mode that a bolt penetrates through the connecting flanges, and the threaded section of the bolt is fixed in a matched mode through a nut. The alkali-free wolfberry drying machine is high in practicability, good in wolfberry drying effect and relatively good in popularization value.

Owner:宁夏链杞智汇科技有限公司

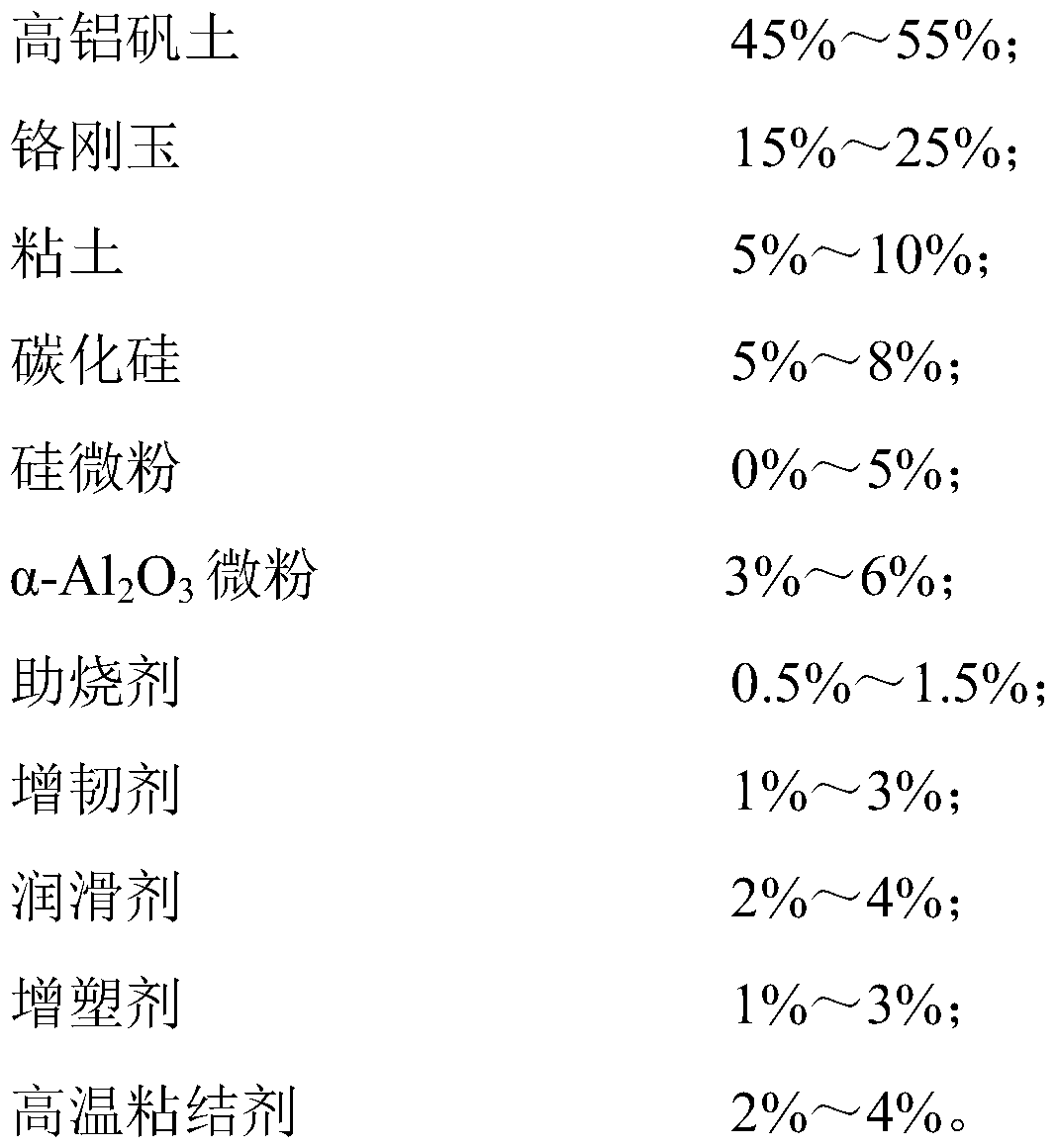

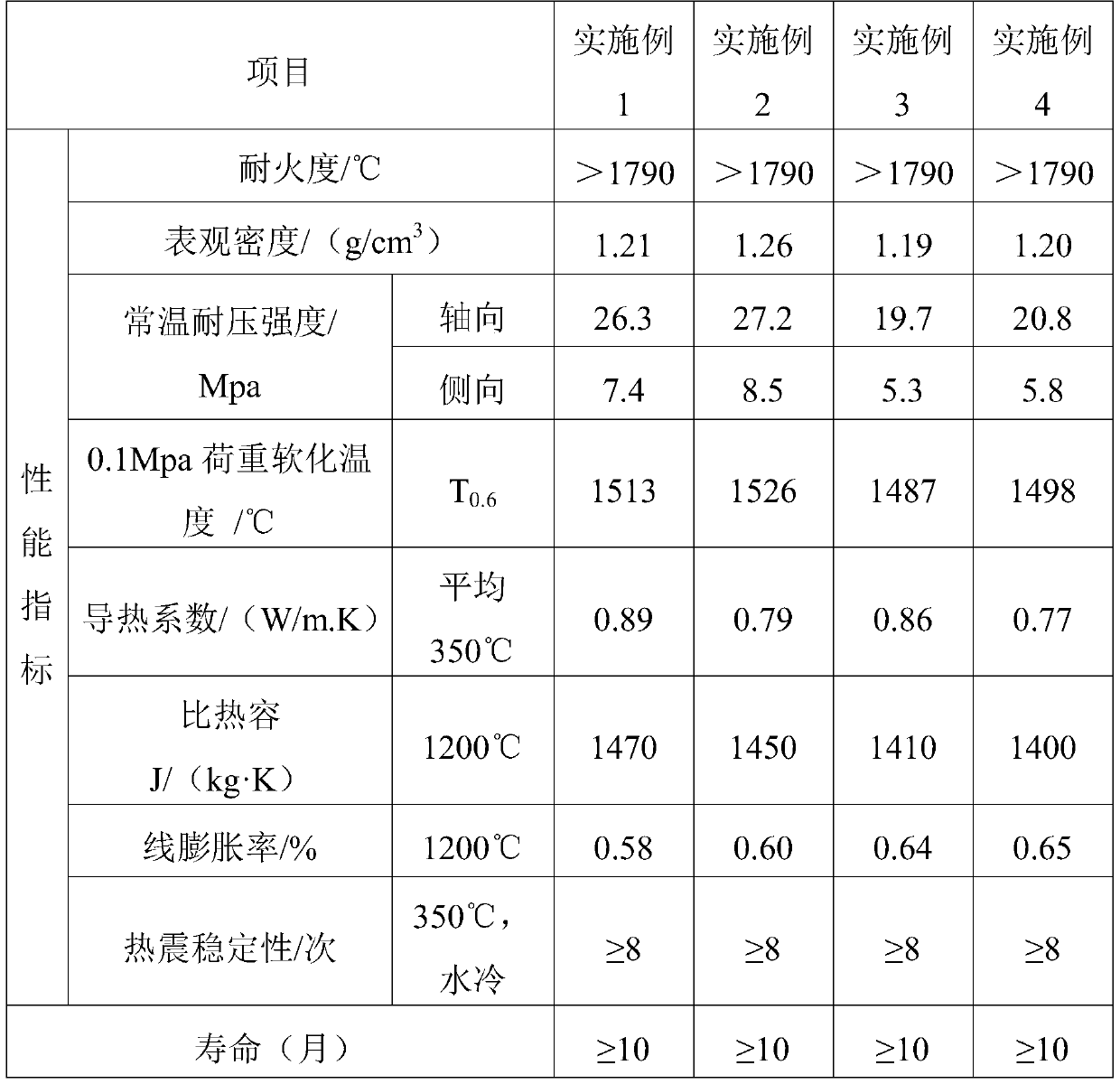

Honeycomb body used for regenerative heating furnace and production method of honeycomb body used for regenerative heating furnace

InactiveCN110372343AMeet the temperature requirementsHigh refractorinessCeramicwareCombustionPlasticizer

The invention discloses a honeycomb body used for a regenerative heating furnace and a production method of the honeycomb body used for the regenerative heating furnace. According to the honeycomb body, high bauxite and pink funsed alumina are adopted as main components, clay is adopted as a binder, silicon carbide, silica powder and alpha-Al2O3 powder are added, a sintering aid, a toughener, a lubricant, a plasticizer and a high-temperature binder are added at the same time, and through technology steps of mixing, vacuum pugging, extrusion, forming drying, firing and the like, the honeycomb body used for the regenerative heating furnace is produced. The honeycomb body meets the technology requirements of a regenerative combustion technology, has performance of large heat storage capacity,stable high-temperature performance, high heat exchange efficiency and a long service life, the number of times of blowing out due to replacement of honeycomb bodies of a steel plant can be decreased, the production operation rate of the heating furnace is improved, the equipment maintenance cost is reduced, and effects of increasing production and practising economy are truly achieved, so that the honeycomb body used for the regenerative heating furnace has obvious economic benefits and very wide use prospects.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

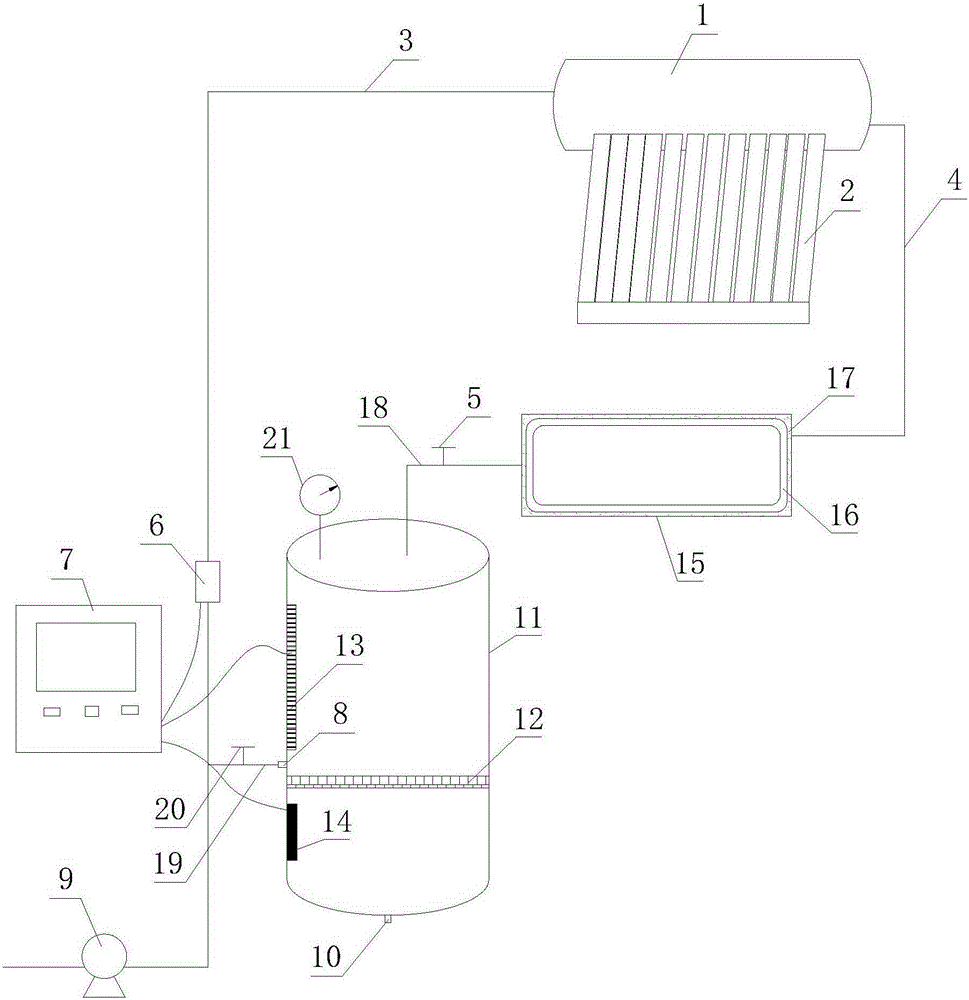

Temperature-adjustable solar hot water supply system

InactiveCN105241097ACause wasteMeet the temperature requirementsSolar heat devicesSolar thermal energy generationWater pipeWater storage tank

The invention discloses a temperature-adjustable solar hot water supply system which comprises a solar water heater, a water storage tank, a controller and a heat preservation case device. The solar water heater is composed of a water tank and solar heat collecting pipes mounted on the water tank. An inlet of the water tank is connected with a cold water pipe, and an outlet of the water tank is communicated with an inlet of the heat preservation case device through a hot water pipe A. An outlet of the heat preservation case device is communicated with the water storage tank through a hot water pipe B, and the cold water pipe is provided with an electromagnetic valve which is connected with the controller through a wire. A water outlet in the water storage tank is communicated with the cold water pipe through a cold-hot water communicating pipe, a cold water control valve is arranged on the cold-hot water communicating pipe, a hot water control valve is arranged on the hot water pipe B, and a thermometer is further arranged on the top of the water storage tank. According to the temperature-adjustable solar hot water supply system, the water temperature can be adjusted conveniently and rapidly and can be adjusted according to needs, water resource waste caused by overhigh or ultralow water temperature is avoided, electric energy consumed by hot water boiling can be saved, and the purpose of saving energy is achieved.

Owner:广西大美节能设备有限公司

Continuous Forging Furnace

ActiveCN103302223BMeet the temperature requirementsEasy to saveForge furnacesAcute angleHeating furnace

The invention provides a continuous forging heating furnace which comprises a furnace body, a heating mechanism and a machine frame; the furnace body and the heating mechanism is arranged on the machine body; the furnace body comprises a furnace chamber which runs through the furnace body; a furnace wall as well as the feeding end and the discharging end of the furnace body are correspondingly formed; a guide groove is formed in the furnace chamber; the heating mechanism comprises a plurality of burners; the burners are installed at the discharging end close to the furnace body and the top part of the furnace body, and enter into the furnace chamber through the furnace wall in a way that acute angles are formed between the directions of the burners and the material guiding direction. The continuous forging heating furnace can fully preheat materials and facilitates heat energy conservation and utilization.

Owner:彭亦楚

Tyre burst detection method and tyre burst sensor

ActiveCN105628292AReduce weightReduce manufacturing costInflated body pressure measurementGramEngineering

The invention designs a tyre burst detection method and a tyre burst sensor and provides a technical scheme aiming at solving the problems of leakage-free catastrophic failures, long-time pressing fatigues of a sensitive element and a switch and inner atmosphere pollution of a tyre. With the adoption of the technical scheme provided by the invention, the tyre burst sensor has a small size, and the increased weight is not more than 3 grams; the switch is not pressed by the sensitive element under most conditions and is pressed only if inner air pressure of the sensitive element is higher than external air pressure and a tyre burst signal needs to be output; and the tyre burst detection method meets actual requirements on detection of tyre burst.

Owner:GUILIN SICHAO AUTO TECH

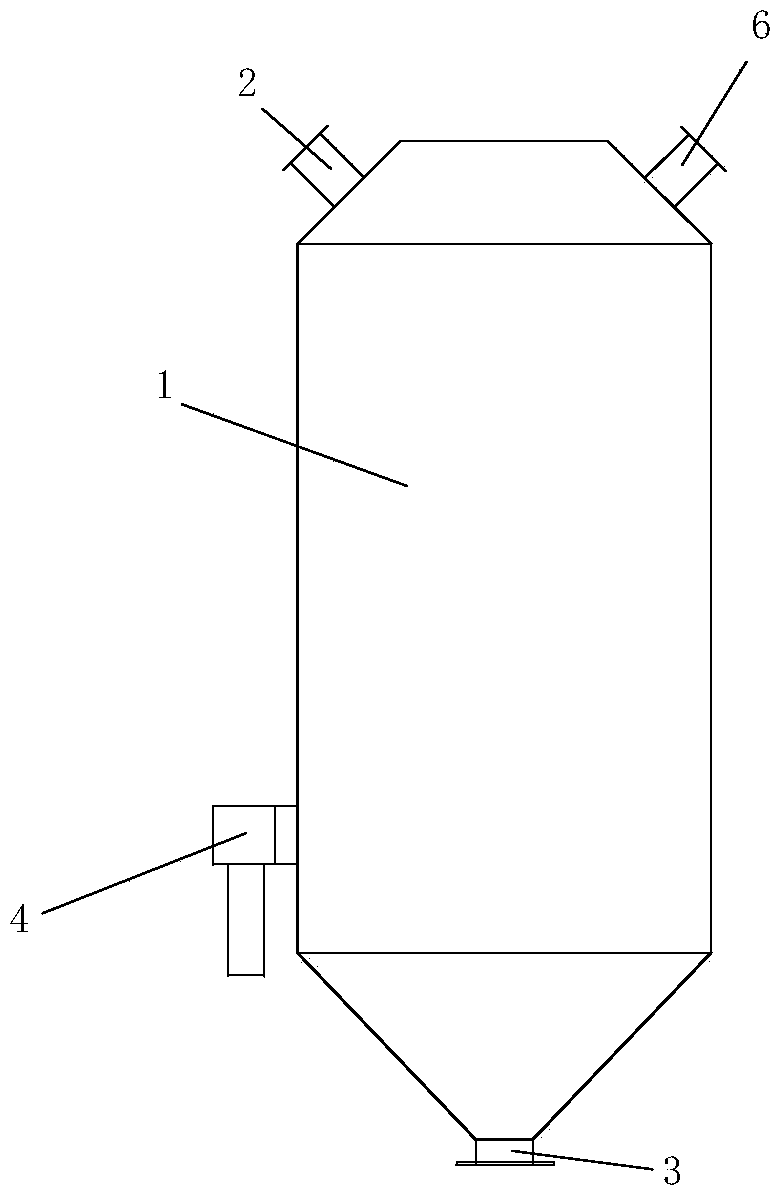

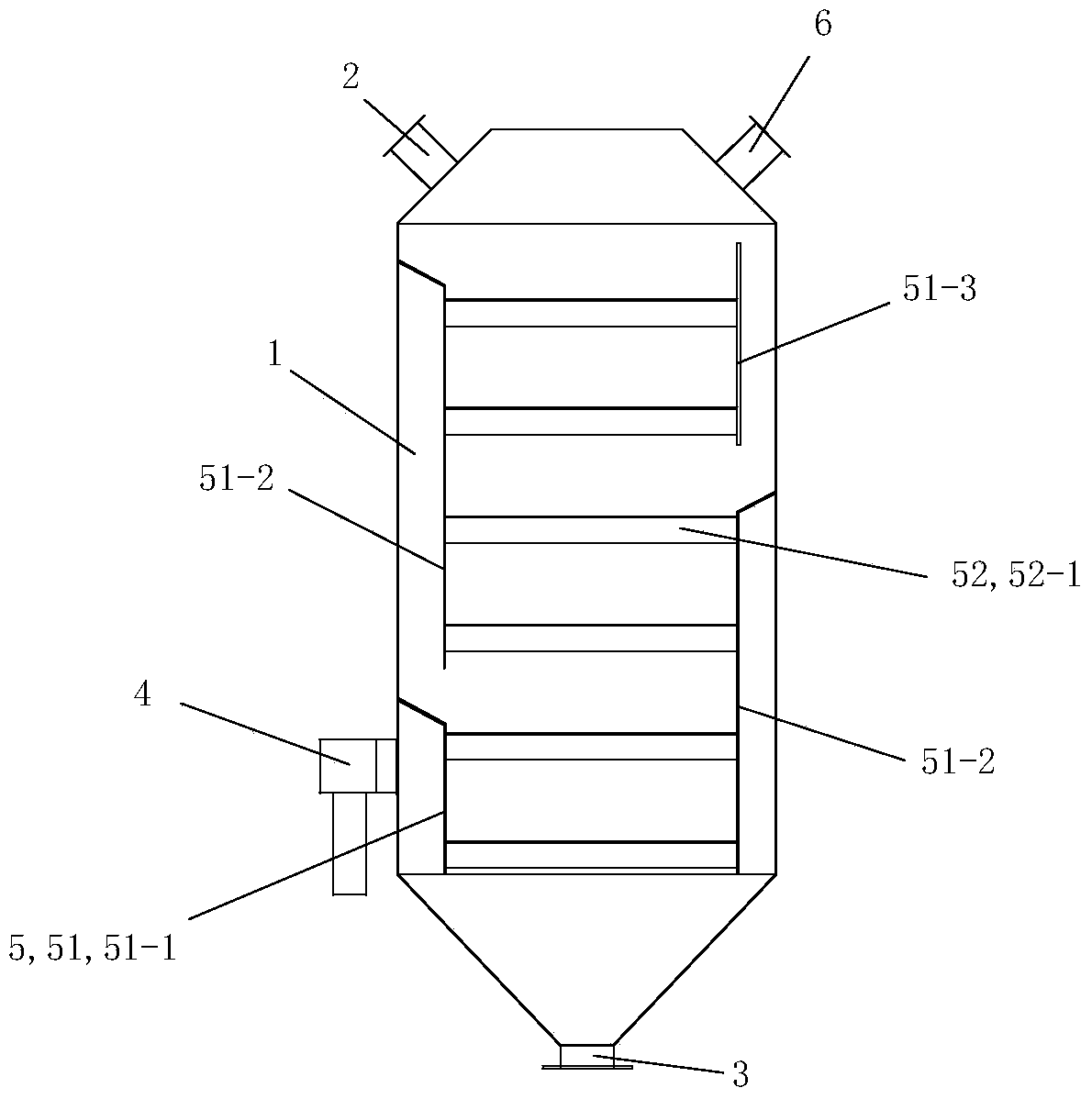

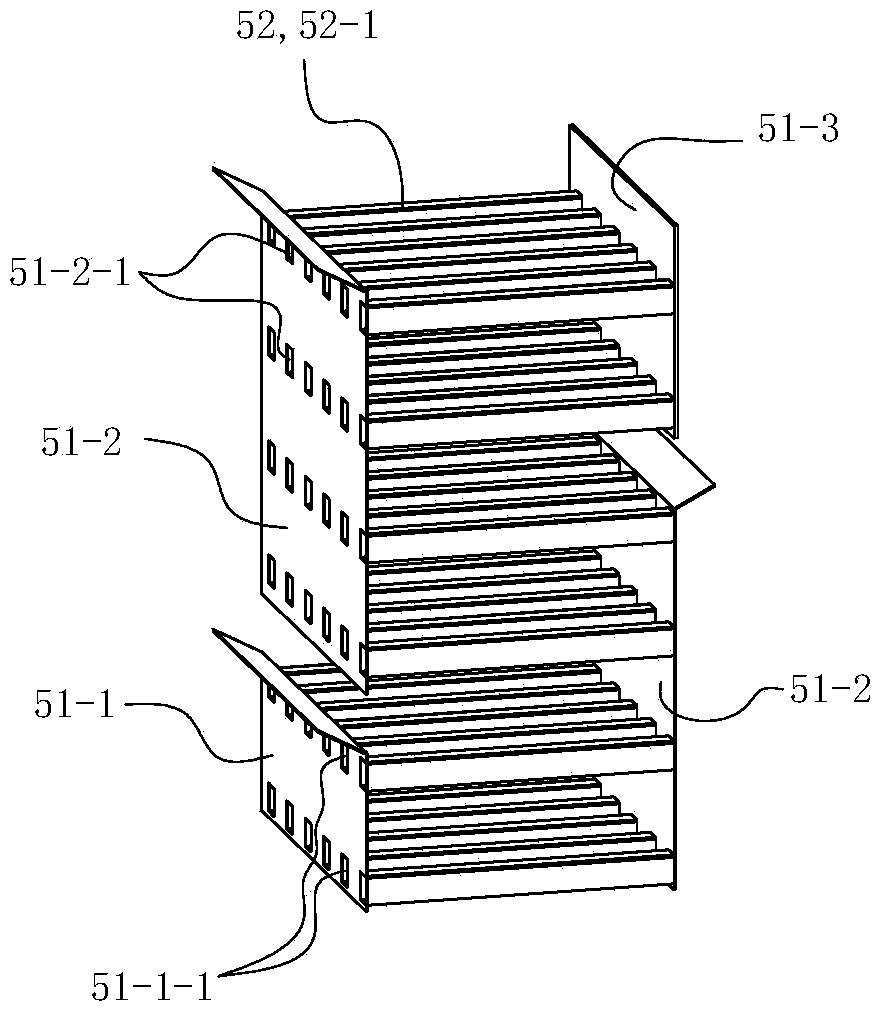

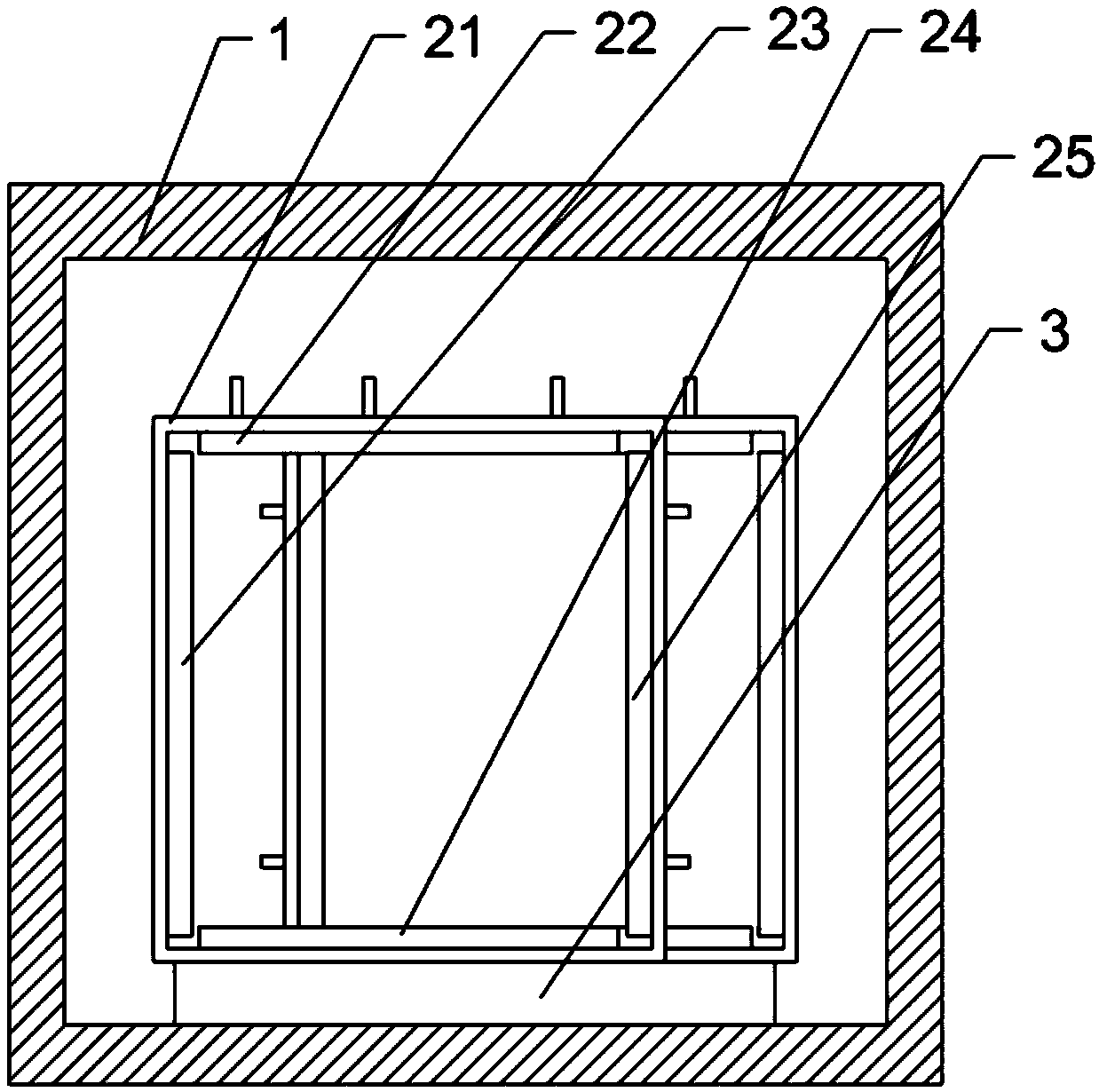

Sand cooling apparatus

ActiveCN104107877ASimple structureLow retrofit costMould handling/dressing devicesEngineeringAirflow

The invention discloses a sand cooling apparatus. The sand cooling apparatus comprises a vertical casing, a material inlet and a material outlet. The apparatus also comprises a gas inlet, a guiding device and a gas outlet. The lower portion of the casing plate of the vertical casing is provided with gas inlet holes. The gas inlet is arranged outside the lower portion of the vertical casing, completely covers the gas inlet holes, and has a closed connection with the outer wall of the vertical casing. The upper right portion of the gas outlet is fixedly connected to the right side of the upper portion of the vertical casing in a closed manner, and is connected with the internal of the vertical casing. The guiding device is arranged in the vertical casing, the guiding device, the vertical casing and molding sand in the vertical casing form an S-shaped gas channel, and the gas channel connects the gas inlet with the gas outlet.

Owner:常州市姚氏铸造材料有限公司

Formaldehyde detection device for building material

ActiveCN109490485AFacilitated DiffusionSpread evenlyTesting manufactured objectsMaterial analysisCentral symmetryBuilding material

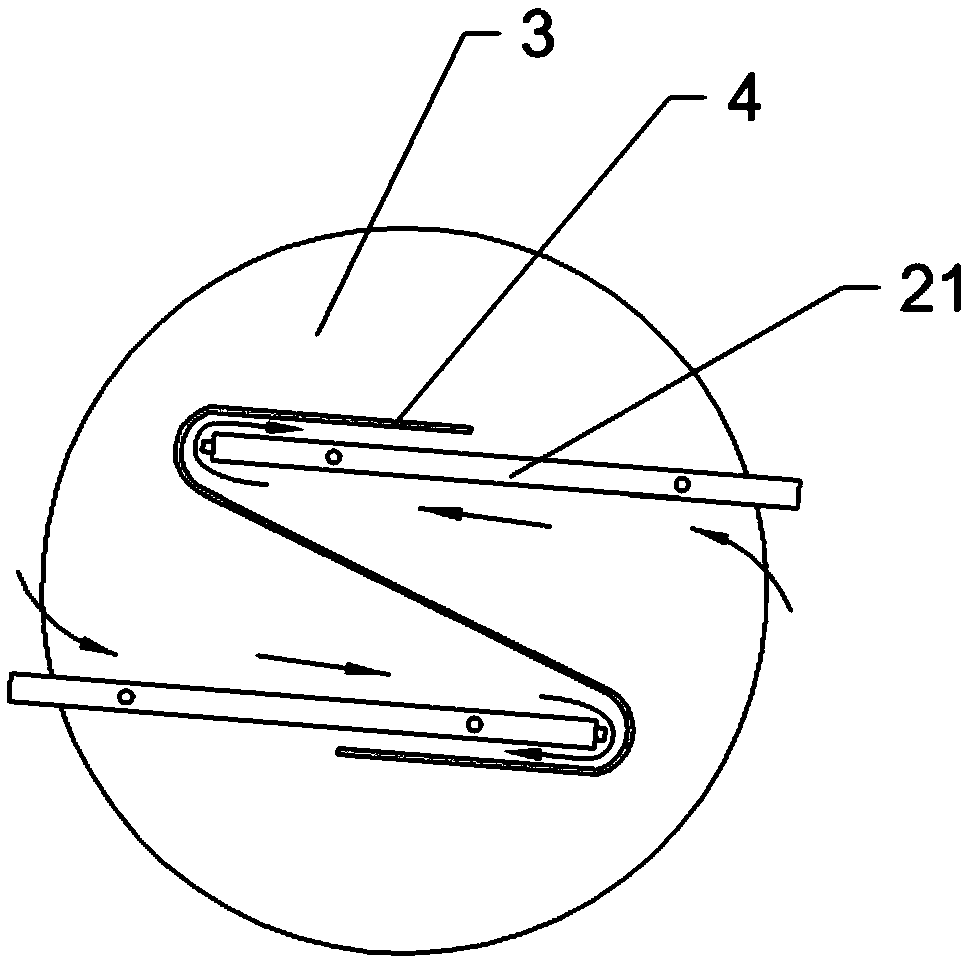

The invention relates to the technical field of detection equipment of materials, in particular to a formaldehyde detection device for a building material. The device comprises a detection box, wherein a rotary disc rotating along the horizontal plane is rotatably connected in the detection box, two fixing mechanisms for fixing panels vertically are fixedly arranged on the rotary disc, the two fixing mechanisms are arranged in a staggered manner and are in central symmetry by taking the rotary axis of the rotary disc as a center axis, a sealing part for sealing the edge of the panel is arranged on each fixing mechanism, a V-shaped guide plate is arranged at the end, close to the rotary axis, of each fixing mechanism, the air guide plate is fixedly connected to the rotary disc, and a driving mechanism for driving the rotary disc to rotate is arranged on the detection box. The scheme solves the problem in the prior art that vibration and noises are relatively great as relatively more mechanisms of the formaldehyde detection device are arranged.

Owner:ZUNYI NORMAL COLLEGE

A titanium-nickel alloy with rich titanium content and a preparation method thereof with negative thermal expansion properties

ActiveCN107164653BMeet the temperature requirementsStable negative thermal expansion propertiesCrucibleTitanium

The invention discloses a titanium-rich titanium nickel alloy with negative heat expansion performance and a preparation method thereof. The general formula of the titanium-rich titanium nickel alloy is Ti(100-x)Nix, wherein x is the atomic percentage and meets the relation of x=42.0-46.0. In preparation, electrolytic nickel and sponge titanium serve as raw materials and are placed into a copper crucible, with circulating water led in for cooling, of a vacuum electric-arc smelting furnace after dosing is conducted in proportion, and repeated smelting is conducted under protection of inert gas; a smelted button-shaped mother alloy is placed into a suction-casting copper crucible and heated for remelting, an alloy melt is suctioned into a suction-casting copper mould with circulating water led in for cooling under the vacuum negative-pressure effect, and an alloy with a needed shape is obtained through quick solidification; and after annealing treatment is conducted at the temperature of 800-900 DEG C, a titanium nickel alloy material with a stable negative heat expansion response temperature interval is prepared, and high strength and excellent linear superelasticity are simultaneously achieved. The titanium nickel alloy material is suitable for being compounded with a positive heat expansion material.

Owner:SOUTH CHINA UNIV OF TECH

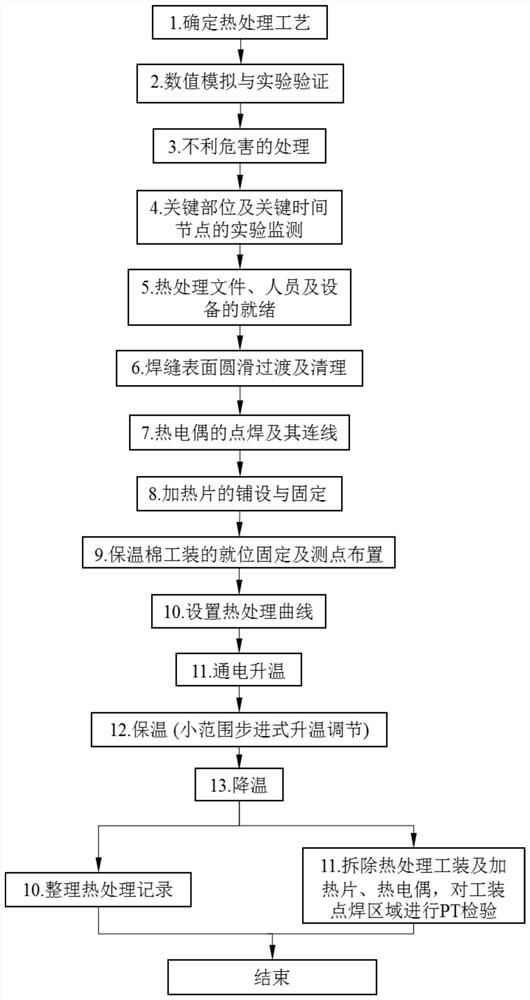

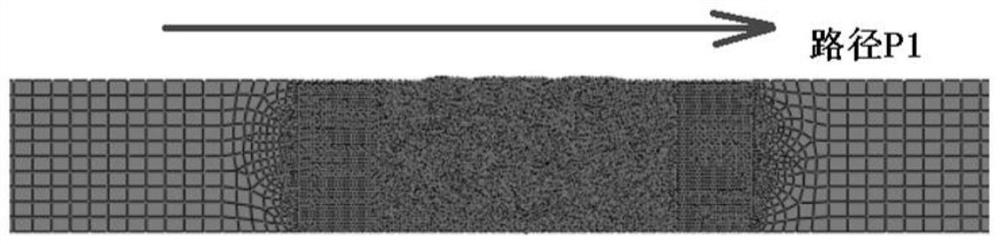

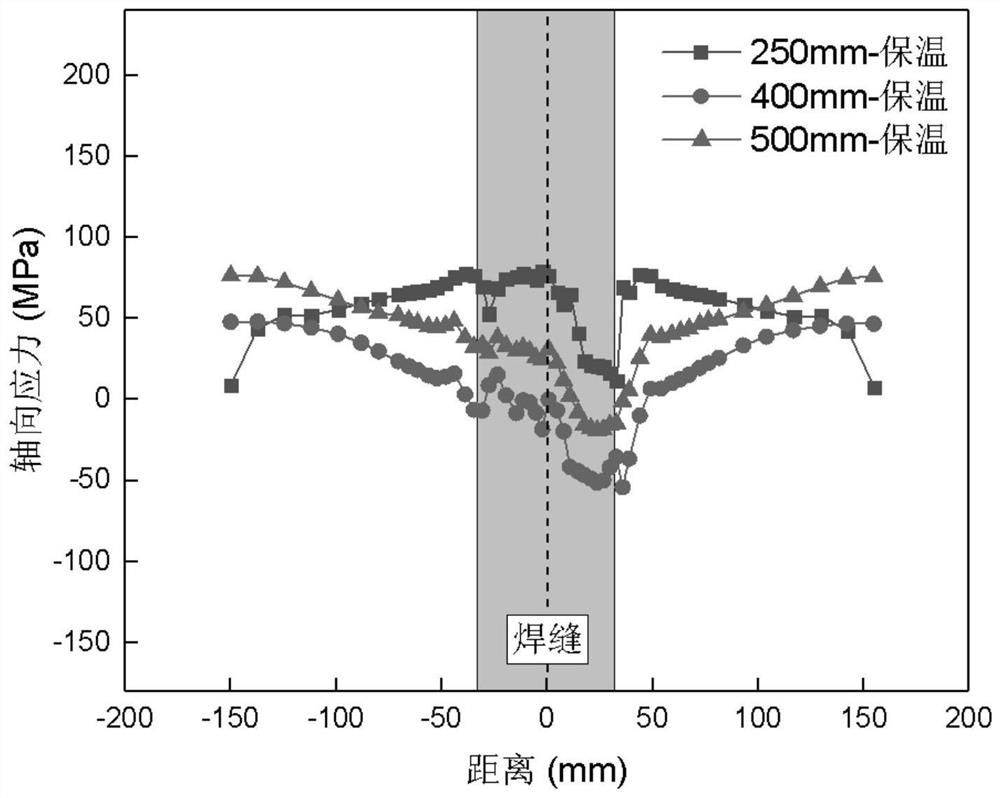

Stabilizing heat treatment method for TP347 thick-wall pipeline

InactiveCN112176175AReduce residual stressMeet the temperature requirementsFurnace typesHeat treatment process controlThermodynamicsProcess engineering

The invention discloses a stabilizing heat treatment method for a TP347 thick-wall pipeline. The stabilizing heat treatment method comprises the following steps of determining a heat treatment process; according to the determined heat treatment process, analyzing the causes of cracking in the stabilizing heat treatment; and carrying out heat treatment construction, including treatment before heattreatment and treatment of a heat treatment implementation process. According to the stabilizing heat treatment method for the TP347 thick-wall pipeline provided by the invention, the residual stressis reduced as much as possible on the basis that the stabilizing heat treatment purpose is achieved, and the stabilizing heat treatment method has important significance in industrial production. According to the stabilizing heat treatment method for the TP347 thick-wall pipeline provided by the invention, tp347 stabilizing heat treatment can be realized, and the inner and outer walls meet the temperature requirement. According to the stabilizing heat treatment method for the TP347 thick-wall pipeline provided by the invention, the effects of reducing the stress peak value and homogenizing thestress distribution can be achieved while the requirement of stabilizing heat treatment temperature is met. The method is easy to operate and wide in applicability, and the TP347 stabilizing heat treatment process with different wall thicknesses can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP

Ground spice temperature return device

ActiveCN103416707AIncrease productivityReduce labor intensityFood shapingFood preparationMoisture absorptionHollow core

The invention discloses a ground spice temperature return device which comprises a main body device, a hot water tank and a dehumidifying fan, wherein the main body device comprises a barrel body used for containing materials; a feeding hole and a discharging hole are formed in the barrel body; a hollow clamping sleeve and a hollow spiral device are arranged in the barrel body; the interiors of the hollow clamping sleeve and the hollow spiral device are communicated with the hot water tank through pipelines for providing temperature return heat for the interior of the barrel body; one end of the barrel body is hermetically connected with the dehumidifying fan through a pipeline for removing excess material water from the barrel body. According to the ground spice temperature return device, spice powder is effectively guaranteed to quickly reach a natural temperature, the influence on the quality guarantee period due to moisture absorption of a product is avoided, and the spice powder is guaranteed to be uniformly and timely packaged through a vibration sieve device, a vacuum suction machine and a packaging machine.

Owner:苏州闻达食品配料有限公司

Novel cooling and dedusting device

InactiveCN102913933APlay a diversion roleHeating up fastSolid fuel combustionCombustion apparatusEngineeringBiomass

The invention discloses a novel cooling and dedusting device which comprises a furnace body, a hearth, a fire inlet and a fire outlet which are arranged at two ends of the furnace body and are communicated with the hearth, and a filtering plate which is isolated at the upper end of the middle of the hearth and is fixed with the furnace body through a valve, wherein a draft fan is additionally arranged below the fire inlet; the draft fan is arranged outside the furnace body and is communicated with the hearth; and a cooling plate is fixedly arranged on the inner wall of the hearth. With the adoption of the cooling and dedusting device in such a mode, the problem that the service life is shortened due to the fact that the temperature inside the existing dedusting device is high is solved, and the direction of the biomass fire is changed; the device is simple in structure, easy to operate and relatively lower in production cost; and not only is the temperature rising speed in an annealing furnace accelerated, but also the quality of a workpiece machined in the annealing furnace is correspondingly ensured, thus the device has better practicability.

Owner:郭丰亮

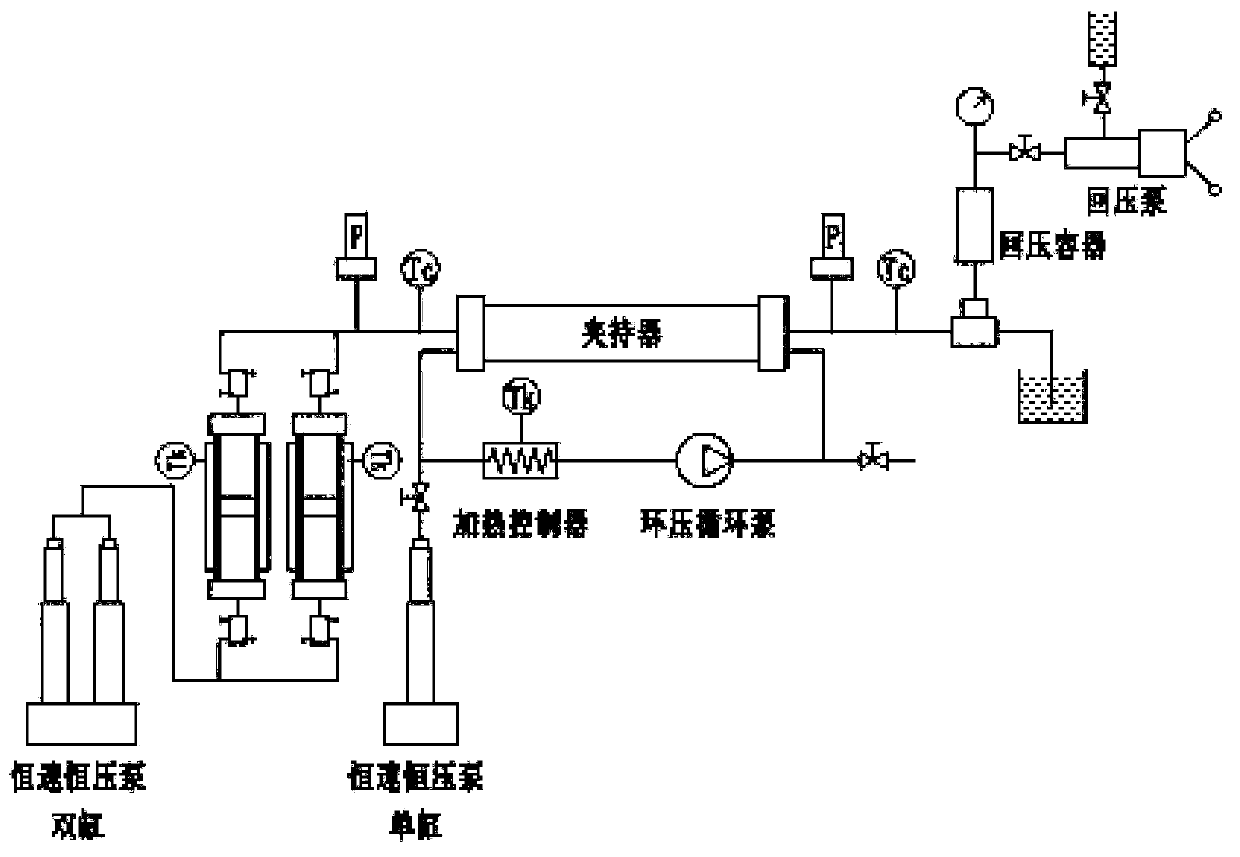

High-temperature and high-pressure circulating displacement system

PendingCN111272984AMeet the temperature requirementsPrecise flowEarth material testingAutomatic controlRock core

The invention discloses a high-temperature and high-pressure circulation displacement system which is composed of an injection system, a high-temperature and high-pressure circulation system, a modelsystem, a back pressure system and a data acquisition and automatic control system. According to the high-temperature and high-pressure circulation displacement system, liquid in a buffer container ispumped into a rock core holder through a double-cylinder constant-speed constant-pressure pump; an annular pressure tracking pump is used for loading tracking annular pressure to an annular cavity ofthe rock core holder, the rock core holder is circularly heated through the heating temperature controller and the annular pressure circulating pump; the temperature requirement of the multifunctional rock core displacement experiment is met; the outlet pressure of the rock core holder is controlled by the back pressure system; data such as experimental temperature and pressure can be acquired and controlled by a computer, the double-cylinder constant-speed constant-pressure pump provides a power source for a test, and the constant-speed constant-pressure pump adopts a digital positioning monitoring servo control circuit, so that a solution can accurately flow under any pressure condition, and the solution can stably flow at a high speed and continuously operate at a constant speed without pulse.

Owner:JIANGSU TUOCHUANG SCI INSTR CO LTD

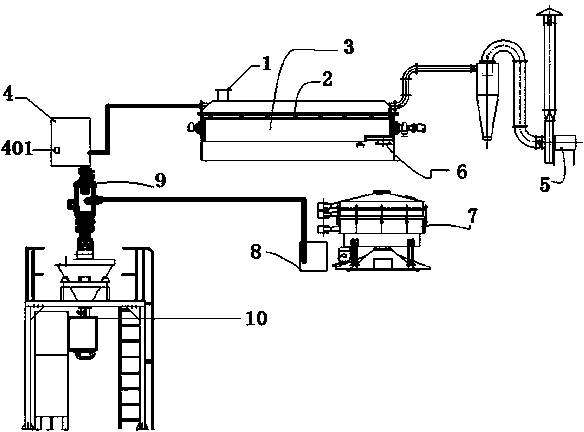

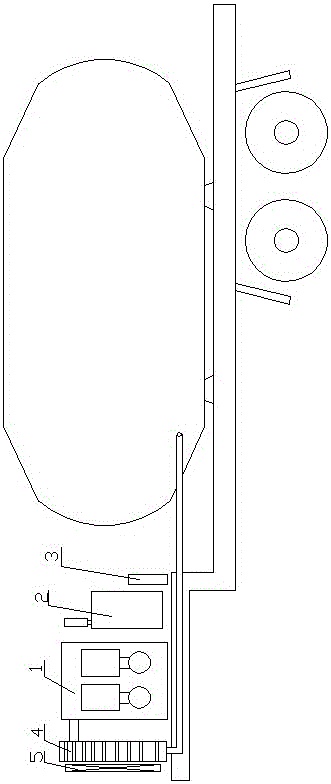

Discharging air source device for combustible powdery material transporting tank truck

InactiveCN106476673AReduce the temperatureMeet temperature requirementsTank vehiclesLoading/unloading vehicle arrangmentGas compressorTank truck

A discharging air source device for a combustible powdery material transporting tank truck comprises a discharging air source device body with an air compressor (1), wherein the discharging air source device body is arranged on a tank truck frame of the powdery material transporting tank truck. Through arrangement of the discharging air source device body on the tank truck frame, the discharging air source device body is not mounted at the lower end of a cab on a traction chassis any more, so that the discharging air source device body is not affected by the heat radiation effect of an engine on the traction chassis any more and the temperature of the discharging airflow is lowered; therefore, a requirement on the temperature of the discharging airflow for a combustible powdery material is met.

Owner:TAIAN XIANGJIE RADIATOR MFG

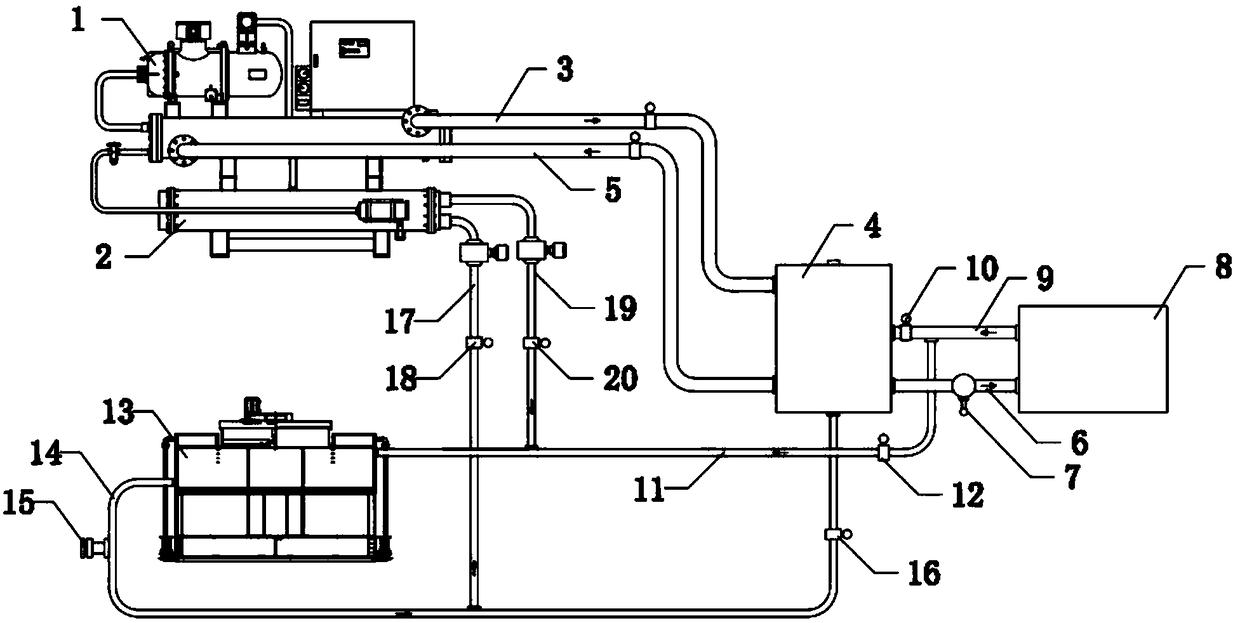

Cooling system for injection molding workshop

ActiveCN108407241AMeet the temperature requirementsSave electricityTemperature differenceEngineering

The invention discloses a cooling system for an injection molding workshop, and belongs to the technical fields of energy saving and environment protection. The cooling system comprises a cold water unit, a freezing water box, injection molding equipment and a cooling water tower, wherein a water inlet of the cold water unit is connected with a water outlet of a condenser through a pipeline; a cold water outlet of the cold water unit is connected with a first water drain pipe through a flange; the right end of the first water drain pipe is connected with a cold water inlet of the freezing water box; a hot water outlet of the freezing water box is connected with a first water intake pipe; the left end of the first water intake pipe is connected with a hot water inlet of the cold water unit;a cold water outlet of the freezing water box is connected with a second water drain pipe through a flange; a temperature detector is arranged on the second water drain pipe. By adopting the scheme,the cooling system has the advantages that the temperature difference conditions in winter and summer are switched on the existing cold water system, the temperature requirement of injection molding technology is met, and the effect of saving electric energy is realized.

Owner:滁州市瑞康塑胶科技有限公司

Dephosphorizing slag pressing agent and method thereof for inhibiting steel slag bubbles

ActiveCN106755739AIncrease FeO contentExtend your lifeManufacturing convertersChemical compositionMoisture

The invention discloses a dephosphorizing slag pressing agent and method thereof for inhibiting steel slag bubble, and belongs to the technical field of steel-making. The dephosphorizing slag pressing agent comprises the following components in mass percent: 45-55% of SiO2, 25-30% of Al2O3, 1.5-3.0% of Fe2O3, 0.5-1.0% of CaO, 2.5-4.5% of MgO, 0.7-1.1% of TiO2, 10-15% of C, less than 5% of total moisture. The slag pressing agent is added after the dephosphorizing blowing is finished, thereby effectively inhibiting the production of the steel slag bubble; the direct tapping can be realized without performing fore-deslagging in dephosphorizing smelting, the smelting period is greatly shortened, the steel and iron consumption can be effectively lowered at the same time, the lining life of a converter is improved, the production target of low cost, high efficiency, energy-conservation and environmental protection of the semi-steel smelting through a dephosphorizing furnace is realized, the environment cannot be influenced, and the chemical component and temperature requirements of the semi-steel are achieved.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

High-pressure and low-humidity air-conditioning device for marine cooling aircraft

ActiveCN104235961BAccurate control precisionAvoid direct coolingCondensate preventionSpace heating and ventilation safety systemsSystems designEvaporation

The invention relates to a high-pressure low-humidity air conditioner device for cooling an aircraft for a boat. The high-pressure low-humidity air conditioner device comprises a box body, wherein one side of the box body is provided with an air inlet, the other end of the box body is provided with an air supply box, a first-stage air conditioning system, an air pressure boosting system and a second-stage air conditioning system are sequentially arranged in the box body in the air supply direction, the air pressure boosting system realizes the air inlet from the first-stage air conditioning system side, in addition, the air is supplied to the second-stage air conditioning system, a bypass air conditioning pipeline is arranged in the box body, one end of the bypass air conditioning pipeline is connected with an air outlet of the air pressure boosting system, the other end of the bypass air conditioning pipeline is connected with an air outlet of the second-stage air conditioning system, and an electric butterfly valve is arranged on the bypass air conditioning pipeline. Coolant water supplied by the boat and a platform is adopted, a fluorine direct evaporation system and the electric heating temperature rise are omitted, the system design complexity is greatly simplified, the potential risk is avoided, and the high-pressure low-humidity air conditioner device has the advantages of high air outlet pressure, precise temperature, low humidity and low energy consumption.

Owner:JIANGSU JOSUN AIR CONDITIONER

X8R type BCZT-based BME-MLCC dielectric material suitable for high voltage resistance and high reliability and preparation method thereof

ActiveCN114057483AMeeting the Needs of Multilayer Ceramic CapacitorsReduce manufacturing costFixed capacitor dielectricStacked capacitorsDielectricCurie temperature

The invention discloses an X8R type BCZT-based BME-MLCC dielectric material suitable for high voltage resistance and high reliability and a preparation method thereof. The molecular formula of the BCZT-based dielectric material is shown as a formula I, in the formula I, in (Ba1-xCax) (Ti1-y-zCayZrz) O3, x represents the mole fraction of Ca in the A site, x is larger than or equal to 0.01 and smaller than or equal to 0.05, y represents the mole fraction of Ca in the B site, y is larger than or equal to 0.01 and smaller than or equal to 0.05, z represents the mole fraction of Zr, and z is larger than or equal to 0.01 and smaller than or equal to 0.05. Compared with BaTiO3 which is widely used, the Curie temperature of the BCZT can reach 125-135 DEG C, the room temperature dielectric constant of the dielectric material can reach 1800-2800 through chemical coating modification, the higher use temperature requirement is met, and then the MLCC anti-reduction dielectric material meeting the X8R characteristic is prepared. The research on the BCZT-based X8R type ultrathin layer BME-MLCC dielectric material with high voltage resistance and high reliability has important practical application significance. (Ba1-xCax) (Ti (1-y-z) CayZrz) O3-MgO-MnO2-BaCO3-SiO2-R2O3 is shown as a formula I in the specification.

Owner:TSINGHUA UNIV

An infrared surrounding heating type hot pot frying equipment

InactiveCN105310459BEvenly heatedMeet the temperature requirementsWarming devicesThermal energyInfrared

The invention discloses a hot pot stir-frying equipment heated around infrared rays, which solves the technical problems of uneven heating of hot pot ingredients, slow heating, easy sticking to the pan, and large heat loss when the bottom of the existing hot pot stir-frying equipment is heated. Body, the bottom of the pot body is provided with a gas infrared stove, the pot body includes an inner tank, a heat conduction structure is arranged outside the inner tank, an insulation layer is wrapped on the outside of the heat conduction structure, and an outer shell is arranged outside the insulation layer. The wall thickness of the inner tank is 4mm, and the invention has the advantages of simple structure, uniform heating, heat transfer block and non-stick pan.

Owner:程铖

Two-step production method for elastic nonwoven material

ActiveCN101691681BUniform heat shrinkageMeet shrinkage requirementsHeating/cooling textile fabricsNon-woven fabricsPolyesterFiber

The invention discloses a two-step production method for elastic nonwoven material. No methods for producing elastic fabric by utilizing non-elastic fiber exist in the prior art. The invention provides the two-step production method for elastic nonwoven material, which comprises the following steps: 1) selecting polyester differential fiber and polyester fiber as raw material, adopting a spun-laced method to process the raw material and obtain a base material, applying antistatic agent mixture solution accounting for 5 to 10 percent of the total weight of the fiber to opened or mixed parts, wherein the antistatic agent mixture solution consists of antistatic agent with the mass percentage between 2 and 3 percent and water; and 2) thermally contracting the obtained base material in a loosestate in a drying room under the conditions of uniform overfeed and no tension and finally obtaining the elastic nonwoven material. The method has the advantage of solving the problem of utilizing non-elastic fabric to produce elastic fabric, and the elastic nonwoven material has the characteristics of softness, comfort, simple production process and low production cost.

Owner:江苏弘正扬瑞新材料有限公司

Ground spice temperature return device

ActiveCN103416707BIncrease productivityReduce labor intensityFood shapingFood preparationEngineeringMoisture absorption

The invention discloses a ground spice temperature return device which comprises a main body device, a hot water tank and a dehumidifying fan, wherein the main body device comprises a barrel body used for containing materials; a feeding hole and a discharging hole are formed in the barrel body; a hollow clamping sleeve and a hollow spiral device are arranged in the barrel body; the interiors of the hollow clamping sleeve and the hollow spiral device are communicated with the hot water tank through pipelines for providing temperature return heat for the interior of the barrel body; one end of the barrel body is hermetically connected with the dehumidifying fan through a pipeline for removing excess material water from the barrel body. According to the ground spice temperature return device, spice powder is effectively guaranteed to quickly reach a natural temperature, the influence on the quality guarantee period due to moisture absorption of a product is avoided, and the spice powder is guaranteed to be uniformly and timely packaged through a vibration sieve device, a vacuum suction machine and a packaging machine.

Owner:苏州闻达食品配料有限公司

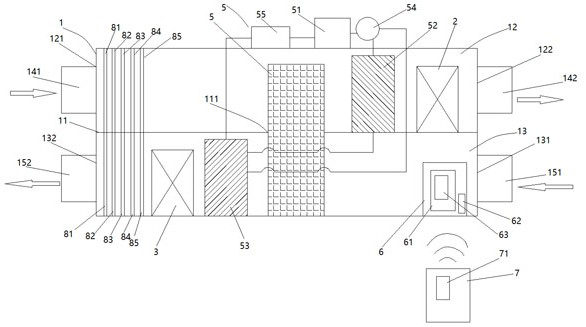

Fresh air ventilation system with heat recovery function

InactiveCN112432271AGuaranteed pureGuaranteed purityEnergy recovery in ventilation and heatingMechanical apparatusAir changeEnergy recycling

The invention provides a fresh air ventilation system with a heat recovery function. The fresh air ventilation system comprises a machine box, a fresh air fan, an exhaust air fan, a heat recovery heatexchanger, a heat pump heat exchanger set, an electric control box and a remote controller, wherein a partition plate is connected into the machine box, a fresh air inlet and a fresh air outlet are formed in two side walls corresponding to a fresh air partition chamber, and an exhaust air inlet and an exhaust air outlet are formed in two side walls corresponding to an exhaust air partition chamber; the fresh air inlet and the fresh air outlet correspondingly form a fresh air channel; the exhaust air inlet and the exhaust air outlet correspondingly form an exhaust air channel; the fresh air fan is erected at the inner side of the fresh air partition chamber; the exhaust air fan is erected at the inner side of the exhaust air partition chamber; the upper portion of the heat recovery heat exchanger is located in the fresh air partition chamber, and the lower portion of the heat recovery heat exchanger is located in the exhaust air partition chamber; and the heat pump heat exchanger set comprises a compressor, and an outlet is sequentially connected with a fresh air heat pump heat exchanger and an exhaust air heat pump heat exchanger through pipelines. According to the fresh air ventilation system, the heat recovery efficiency can reach 80% or above from 50% to the maximum; and meanwhile, through heat recovery of heat pumps, 100% recovery of air conditioner energy in exhaust air can be realized, additional cold and heat capacity can be generated, and the requirement of a user for the fresh air temperature is met.

Owner:SUZHOU HUILIN ENERGY SAVING MATERIALS CO LTD

Large-luminosity-angle spherical bulb with diamond light-emitting surfaces

ActiveCN102128370BAchieve coolingIncrease the light transmission anglePoint-like light sourceLighting heating/cooling arrangementsEngineeringLight head

The invention provides a large-luminosity-angle spherical bulb with diamond light-emitting surfaces, comprising a lamp head insulating body, a lamp body, a lamp shade, a diamond polyhedron and LED (Light-Emitting Diode) light-emitting component and an in-bulb cooling device, wherein the lamp body connects the in-bulb cooling device and the lamp head insulating body; the lamp shade is matched withthe in-bulb cooling device; the diamond polyhedron and LED light-emitting component is arranged near the center in the lamp shade and is combined by substrates, flexible connecting bridges, a diamondpolyhedral heat-conducting installing body; the substrates are provided with LED light sources, and the front surfaces of the substrates are provided with welding points used for connecting; the flexible connecting bridges are connected among the substrates through circuits; the diamond polyhedral heat-conducting installing body is diamond-like and has N sides, can be used for fixing a light-emitting component and can be set into any angle and shape; and the in-bulb cooling device is communicated with the lamp head, the lamp body and the lamp shade to form an airflow inlet and outlet channel.In the large-luminosity-angle spherical bulb provided by the invention, the lamp shade is designed into a shape larger than a hemisphere, which can increase a light-transmitting angle, the LED light-emitting component is made into a diamond structure so as to realize multidirectional positive and negative surface irradiation, and the in-bulb cooling device can carry out forced air-cooling on the in-bulb radiating fins and radiating fins in the lamp body.

Owner:SICHUAN LIANKAI LIGHTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com