X8R type BCZT-based BME-MLCC dielectric material suitable for high voltage resistance and high reliability and preparation method thereof

A technology of dielectric materials and quality, applied in the field of materials, can solve problems such as disadvantages, reduce the cost of MLCC, cannot meet the dielectric of ultra-thin layer ceramic capacitors, etc., and achieve the effect of increasing resistivity and reducing production costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] (Ba prepared in this embodiment 1-x Ca x )(Ti 1-y-z Ca y Zr z )O 3 The molecular formula of the base metal internal electrode multilayer ceramic capacitor dielectric material is as follows:

[0055] 100mol% (Ba 0.95 Ca 0.05 )(Ti 0.96 Ca 0.02 Zr 0.02 )O 3 -2mol%MgO-1mol%MnO 2 -1mol% BaCO 3 -1mol% SiO 2 -1mol%Y 2 o 3 -1mol%Yb 2 o 3 Formula Ⅰ-1

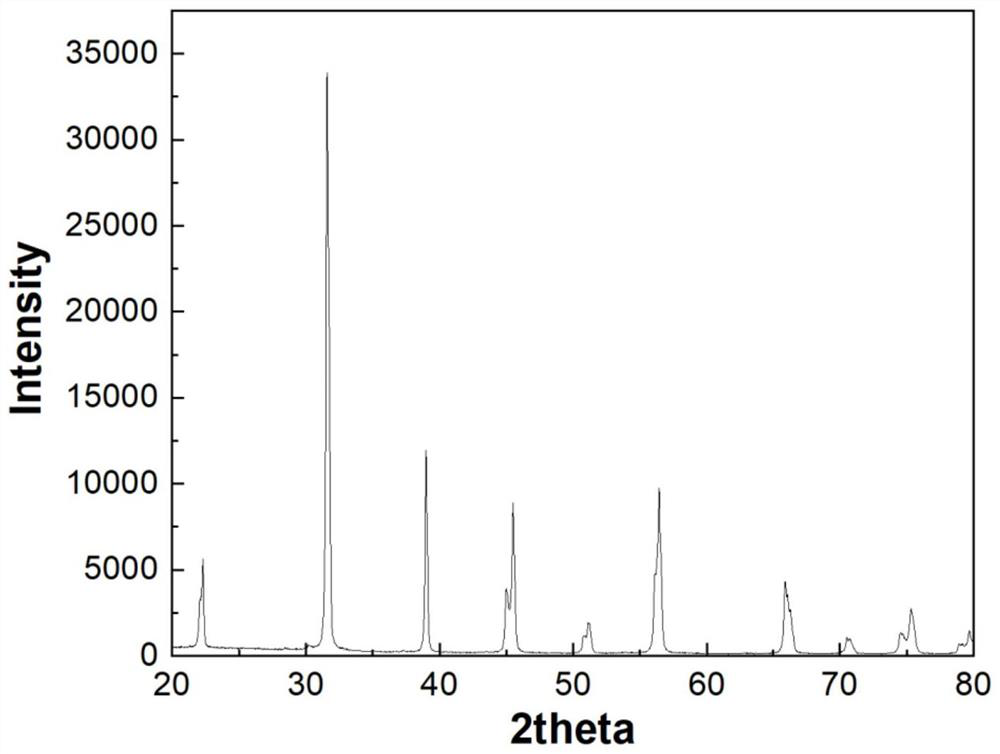

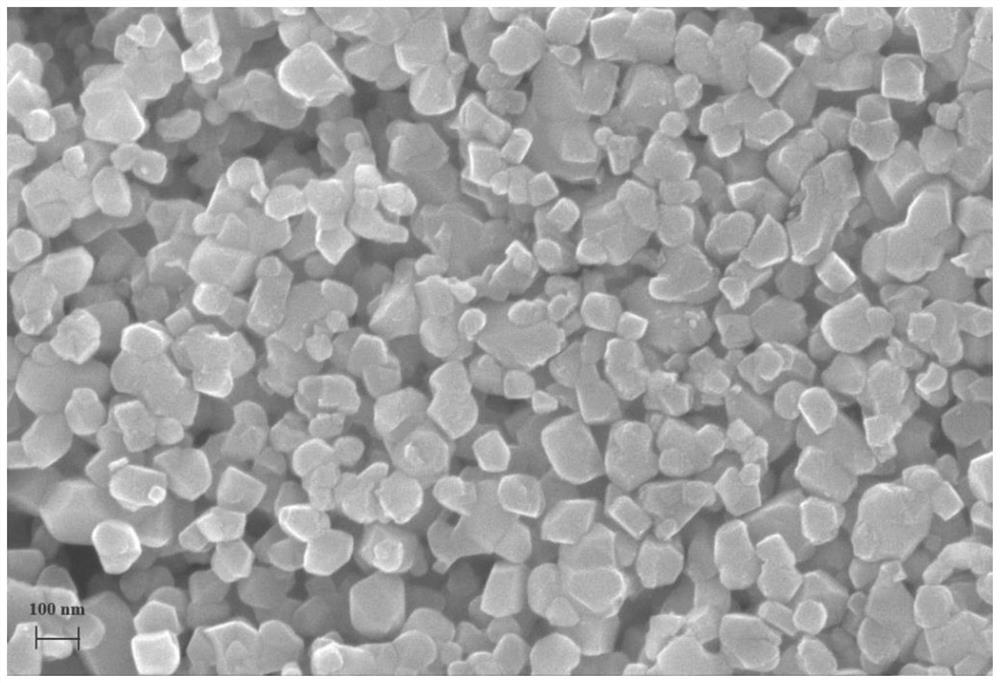

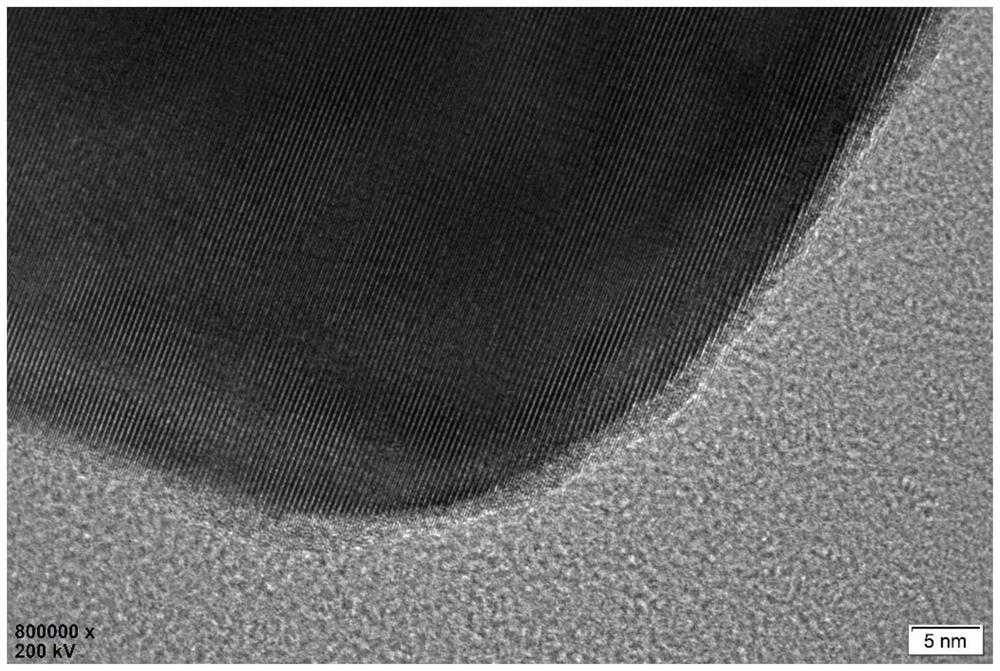

[0056] figure 1 and figure 2 Adopted for this embodiment (Ba 1-x Ca x )(Ti 1-y-z Ca y Zr z )O 3 From the X-ray diffraction images and SEM images of the matrix powder, it can be seen that the BCZT matrix powder has no impurity phase, the grain size distribution is uniform, and the average grain size is about 160nm.

[0057] Prepare as follows:

[0058] According to the stoichiometric ratio of the above chemical formula, using 160nm (Ba 0.95 Ca 0.05 )(Ti 0.96 Ca 0.02 Zr 0.02 )O 3 As the base powder, isopropanol (about 10 times the mass of the powder) was used as the dispersion medium, ball milled f...

Embodiment 2

[0073] (Ba prepared in this embodiment 1-x Ca x )(Ti 1-y-z Ca y Zr z )O 3 The molecular formula of the base metal internal electrode multilayer ceramic capacitor dielectric material is as follows:

[0074] 100mol% (Ba 0.95 Ca 0.05 )(Ti 0.97 Ca 0.02 Zr 0.01 )O 3 -2mol%MgO-1mol%MnO 2 -1mol% BaCO 3 -1mol% SiO 2 -xmol%Ho 2 o 3 -xmol%Dy 2 o 3 Formula Ⅰ-2

[0075] Prepare as follows:

[0076] According to the stoichiometric ratio of the above chemical formula, using 120nm (Ba 0.95 Ca 0.05 )(Ti 0.97 Ca 0.02 Zr 0.01 )O 3 The powder is used as the matrix powder, using deionized water as the dispersion medium, adding a certain amount of dispersing aid, ball milling for 6 hours, and then transferred to a measuring cup for stirring.

[0077] The soluble metal salt Mg(NO 3 ) 2 ·6H 2 O, Mn(CH 3 COOH) 2 4H 2 O, (CH 3 COOH) 2 Ba,Dy(NO 3 ) 3 ·6H 2 O and Ho(NO 3 ) 3 ·6H 2 O is dissolved in a certain amount of deionized water to form a metal salt solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| Curie point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com