Tyre burst detection method and tyre burst sensor

A tire puncture sensor and tire puncture technology are applied in the field of tire puncture detection, which can solve the problems of small size of the tire puncture sensor, pollution of tire atmosphere, and fatigue of sensitive components and switches after long-term contact pressure, achieving small size and conforming to real-time performance , to meet the effect of long-term low power consumption and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

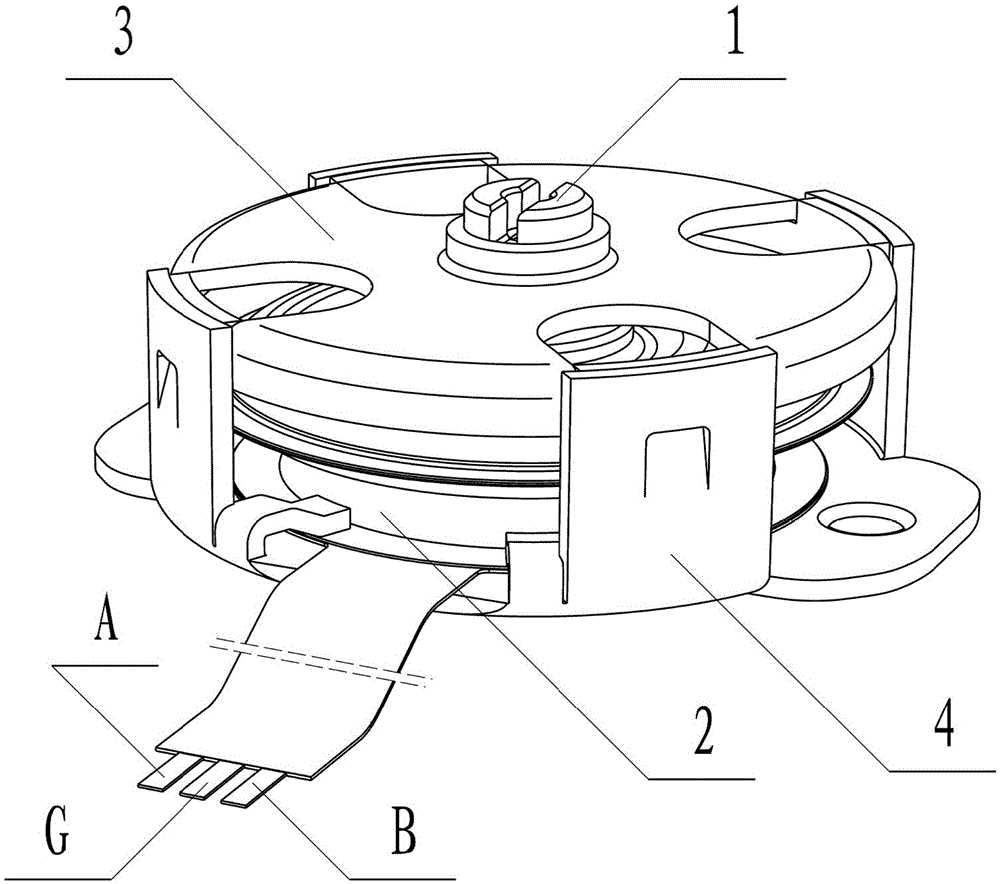

[0023] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Embodiment 1 of the present invention, a tire blowout sensor with an independent structure, is described in detail.

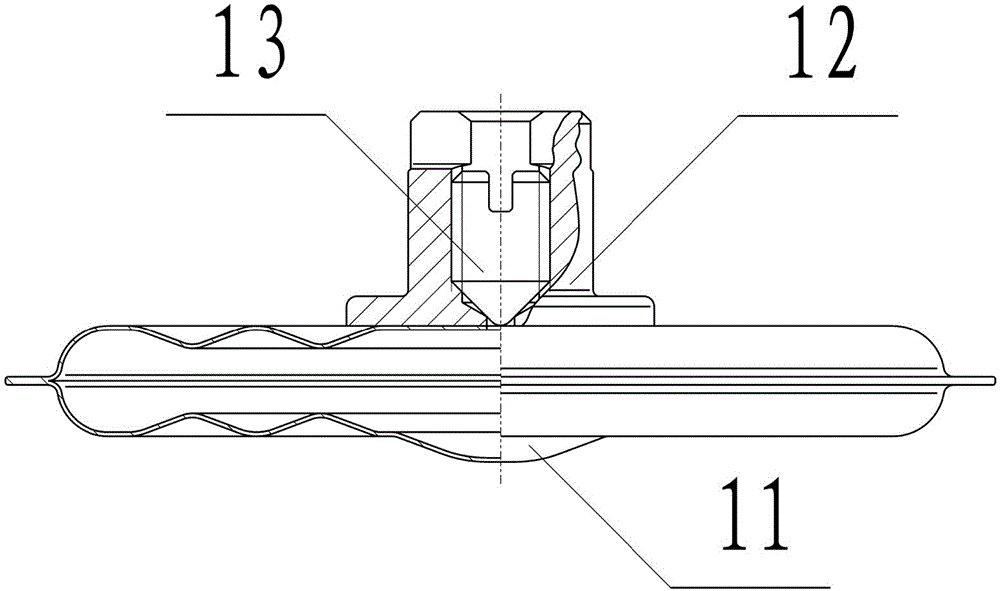

[0024] A tire burst sensor with an independent structure, consisting of a metal corrugated diaphragm box (1), a light touch switch assembly (2), a bracket (3) and a base (4); one side of the metal corrugated diaphragm case (1) is welded with a threaded film The box handle (12), the end of the threaded bellows handle (12) is provided with a structure adapted to the adjustment tool, along the central axis of the threaded bellows handle (12), there is a threaded hole and a cone head that can adjust the flow rate of the filling and discharging gas The screw (13), the bottom of the threaded hole is provided with a tapered hole to communicate with the cavity of the metal corrugated membrane box (1), and the corrugated center on the other side of the metal corrugated membrane box (1) is p...

Embodiment 2

[0030] Combine below figure 1 , figure 2 , image 3 , Figure 4 , Figure 6 , Embodiment 2 of the present invention, a tire blowout sensor with a non-independent structure, is described in detail.

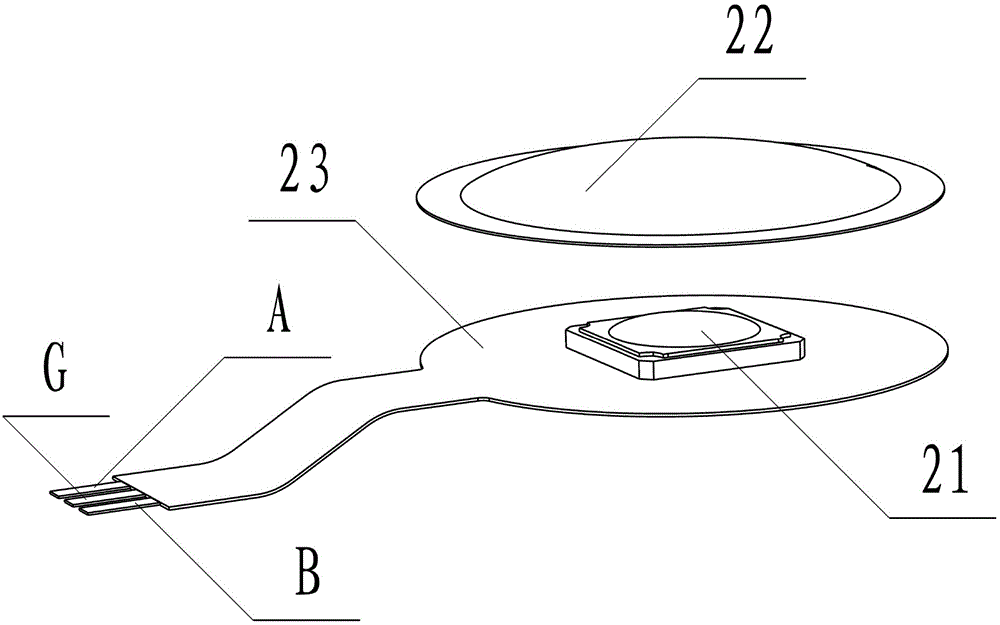

[0031] As a change, the PCB of the tire blowout and tire pressure monitoring remote module replaces the independent structure of the tire blowout sensor base function, and the metal corrugated bellows (1) is installed on the metal bracket (3') through the threaded bellows handle (12). The threaded holes are installed on the PCB of the remote module for tire blowout and tire pressure monitoring through screws; The connection between the tire output circuit and the circuit of the tire blowout and tire pressure monitoring remote module; the PCB of the tire blowout and tire pressure monitoring remote module is provided with via holes for welding mounting claws (4'), and the protective diaphragm (22) is provided with holes for installation The through hole where the claw (4') pene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com