An infrared surrounding heating type hot pot frying equipment

An infrared heating technology, applied to heating devices, cooking utensils, household appliances, etc., can solve the problems of large heat loss, slow heating, high production cost, etc., to achieve improved speed and quality, uniform heat distribution, and small heat loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

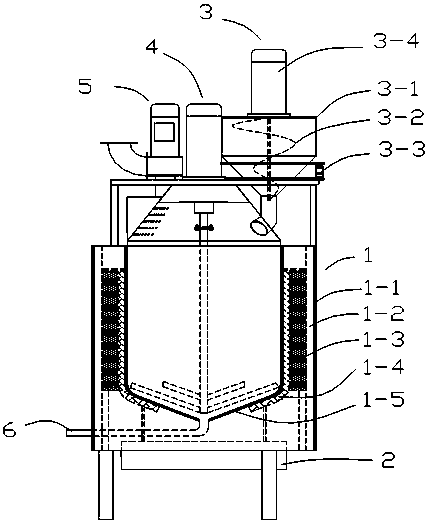

[0024] This embodiment provides a kind of equipment for hot pot stir-frying with infrared surrounding heating, which includes a pot body 1, and the bottom end of the pot body 1 is provided with a gas infrared stove plate 2, and the pot body 1 includes an inner tank 1-5, The outside of the bladder 1-5 is provided with a heat conducting structure 1-4, the outside of the heat conducting structure 1-4 is wrapped with an insulation layer 1-3, the outside of the insulation layer 1-3 is provided with an outer shell 1-1, and the inner tank 1-5 is The wall thickness is 4mm.

[0025] In the present embodiment, the wall thickness of the inner container 1-5 is greater than 4mm. If the power of the gas infrared stove pan is increased while increasing the wall thickness, it can also reach the requirement of the temperature of the frying material, but this wastes energy; such as the inner container 1-5 wall If the thickness is less than 4mm, there will be uneven heat transfer, which will cau...

Embodiment 2

[0027] This embodiment provides a kind of equipment for hot pot stir-frying with infrared surrounding heating, which includes a pot body 1, and the bottom end of the pot body 1 is provided with a gas infrared stove plate 2, and the pot body 1 includes an inner tank 1-5, The outside of the bladder 1-5 is provided with a heat conducting structure 1-4, the outside of the heat conducting structure 1-4 is wrapped with an insulation layer 1-3, the outside of the insulation layer 1-3 is provided with an outer shell 1-1, and the inner tank 1-5 is The wall thickness is 4mm.

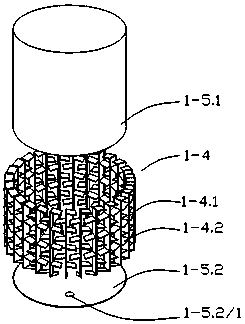

[0028] The inner tank 1-5 includes an inner tank cylinder 1-5.1, an inner tank cone 1-5.2 connected to the bottom of the inner tank cylinder 1-5.1, and the bottom of the inner tank cone 1-5.2 has an inlet and outlet hole 1 -5.2 / 1, inlet and outlet material hole 1-5.2 / 1 is connected with inlet and outlet material pipe 6.

[0029] The inner tank cylinder 1-5.1 and the inner tank cone 1-5.2 are connected by welding,...

Embodiment 3

[0031] This embodiment provides a kind of equipment for hot pot stir-frying with infrared surrounding heating, which includes a pot body 1, and the bottom end of the pot body 1 is provided with a gas infrared stove plate 2, and the pot body 1 includes an inner tank 1-5, The outside of the bladder 1-5 is provided with a heat conducting structure 1-4, the outside of the heat conducting structure 1-4 is wrapped with an insulation layer 1-3, the outside of the insulation layer 1-3 is provided with an outer shell 1-1, and the inner tank 1-5 is The wall thickness is 4mm.

[0032] The inner tank 1-5 includes an inner tank cylinder 1-5.1, an inner tank cone 1-5.2 connected to the bottom of the inner tank cylinder 1-5.1, and the bottom of the inner tank cone 1-5.2 has an inlet and outlet hole 1 -5.2 / 1, inlet and outlet material hole 1-5.2 / 1 is connected with inlet and outlet material pipe 6.

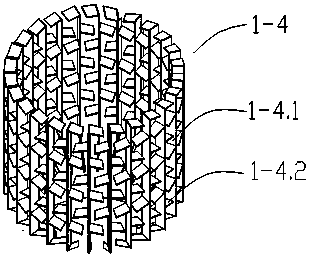

[0033] The heat conduction structure 1-4 includes a number of thermal energy passage columns...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com