Two-step production method for elastic nonwoven material

A non-woven material and stretchable technology, applied in the directions of non-woven fabrics, textiles and papermaking, fabric surface trimming, etc., to achieve the effects of good adhesion, simple production process and improved cosmetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

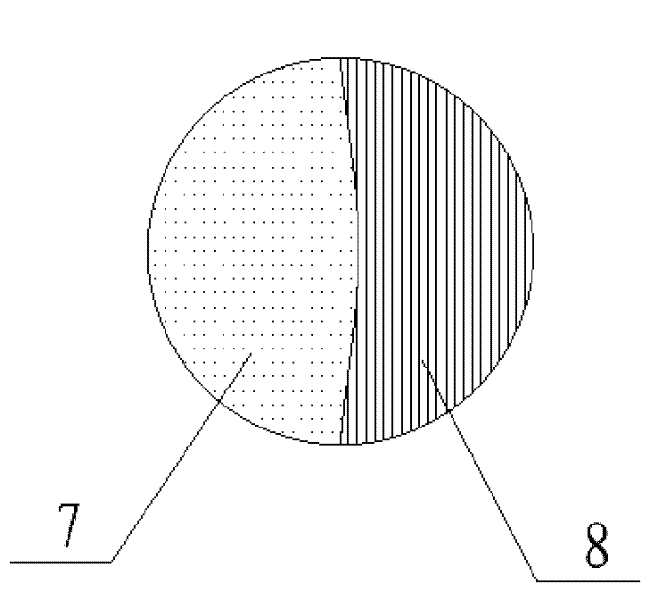

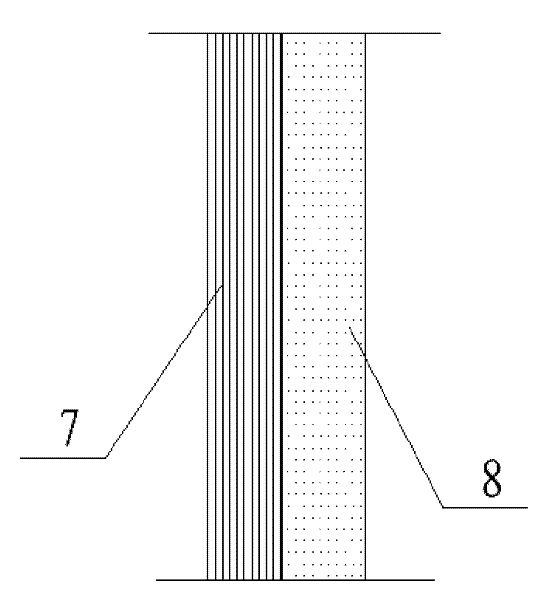

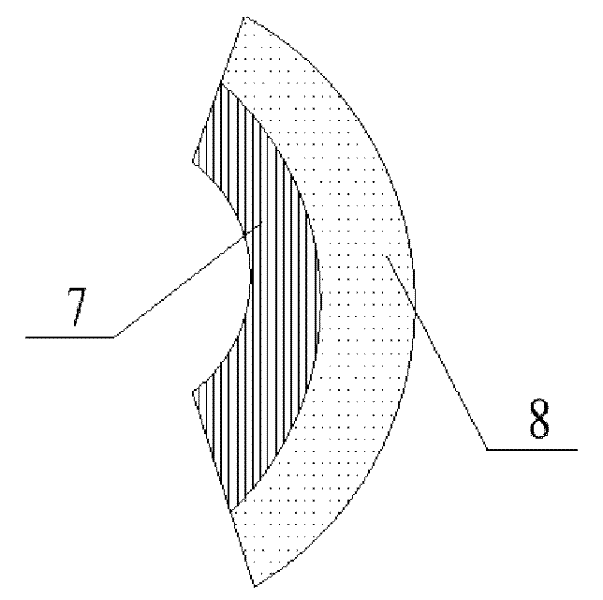

Image

Examples

Embodiment 1

[0029] Embodiment 1: produce 90g / m 2 stretchable material

[0030] The first step of the spunlace nonwoven process to produce the substrate has the following steps:

[0031] Choose a polyester differential fiber with a fineness of 2 deniers and a length of 51 mm and a cross-section composed of two types of fibers (the fiber supplier is Japan Toyobo Industry Co., Ltd., model msw5730), and add 20% polyester differential fiber Weight of 2D*51mm fiber; use two bale opening machines to feed polyester differential fiber and polyester fiber in proportion respectively, and then go through two openings, multi-bin cotton blending, cross-laying, drafting, drum drying, hot air Spunlace nonwoven process of through-drying and functional finishing, apply antistatic oil and water at the opening or mixing place according to 8% of the total fiber weight, and the antistatic agent mixture consists of 3% antistatic agent and 97% water Composition to improve fiber carding. The main process of th...

Embodiment 2

[0037] Embodiment 2: produce 110g / m 2 The product

[0038] The first step of the spunlace nonwoven process to produce the substrate has the following steps:

[0039] Choose a polyester differential fiber with a fineness of 2 deniers and a length of 51 mm and a cross-section composed of two types of fibers (the fiber supplier is Japan Toyobo Industry Co., Ltd., model msw5730), and add 15% polyester differential fiber The weight of 2D*51mm polyester fiber; two bale opening machines are used to feed the polyester differential fiber and polyester fiber in proportion, and then go through two openings, multi-bin cotton blending, cross-laying, drafting, drum drying and The spunlace nonwoven process of hot air penetration drying, antistatic oil and water is applied at the opening or mixing place according to 10% of the total fiber weight, and the antistatic agent mixture is composed of 2% antistatic agent and 98% water. To improve the carding effect of fibers.

[0040] The main tec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com