Copper bar heat shrinkable sleeve mounting device with uniform heating function

A heat-shrinkable sleeve and uniform heating technology, which is applied in the field of copper bars, can solve the problems of insufficient shrinkage, uneven heating of the heat-shrinkable sleeve, and affecting the performance of protection, so as to avoid air bubbles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

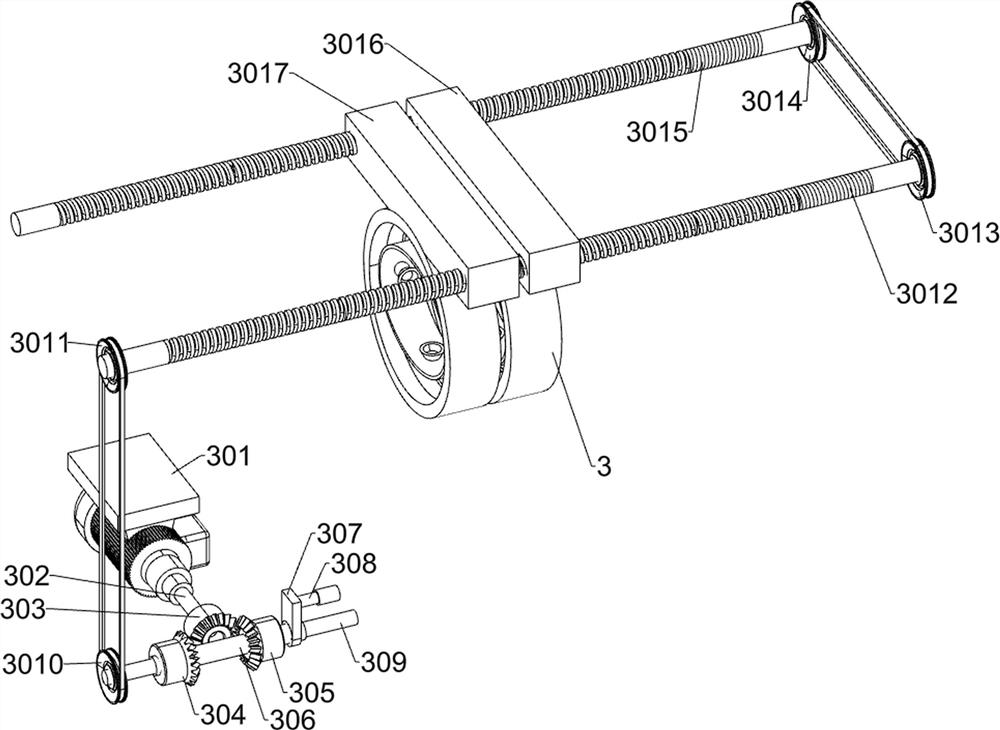

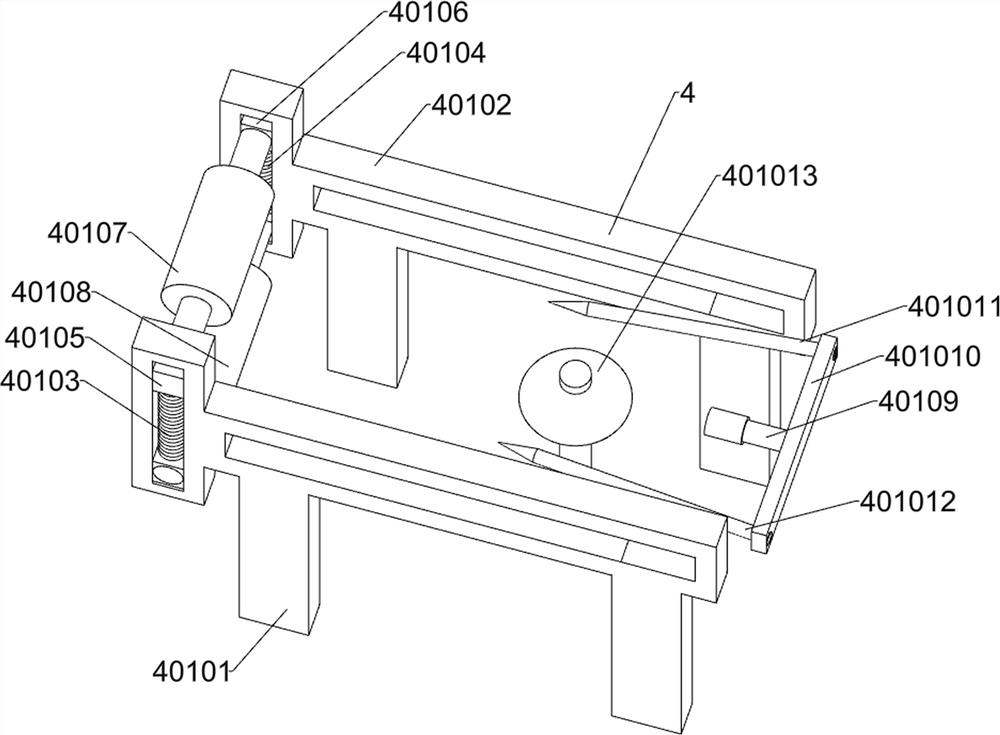

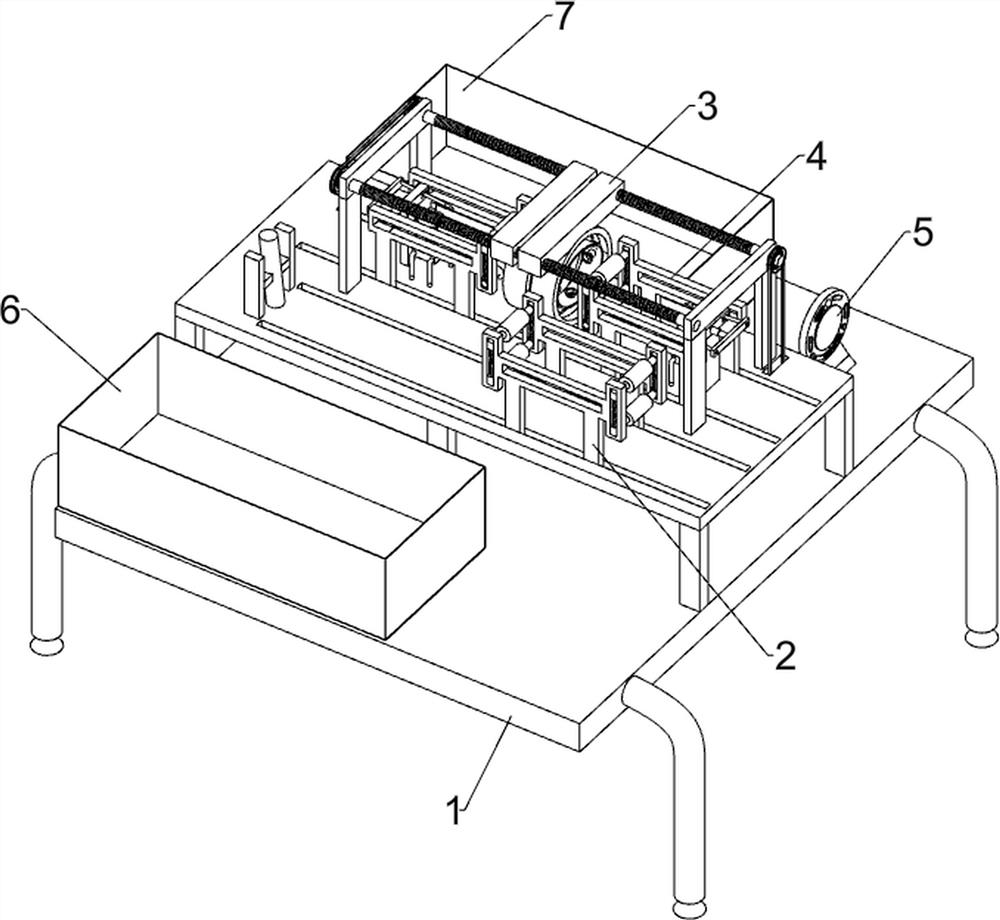

[0028] A uniformly heated copper row heat shrinkable sleeve installation device, such as Figure 1-7 As shown, it includes a chassis 1, a pre-casing unit 2, a heating and shrinking unit 3, a pre-pressing unit 4, a control panel 5, a first collection box 6 and a second collection box 7; the chassis 1 is connected to the pre-casing unit 2 The bottom frame 1 is connected with the heating shrinkage unit 3; the bottom frame 1 is connected with the pre-pressing unit 4; the bottom frame 1 is connected with the control panel 5; The two collection boxes 7 are connected.

[0029] When in use, first place the evenly heated heat-shrinkable copper tube installation device at the position to be used, then connect the external power supply, and start the device through the control panel 5; firstly, the staff will take out the copper bar from the first collection box 6 and fix it On the pre-casing unit 2, there is also a pre-cut heat-shrinkable sleeve of an appropriate length and fixed on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com