Metallized film capacitor core heat treatment processing technology

A technology of metallized film and processing technology, which is applied in the field of capacitors, can solve the problems of low efficiency and low heat treatment stability, and achieve the effects of reducing energy consumption, maintaining thermal shrinkage balance, and improving heat treatment efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

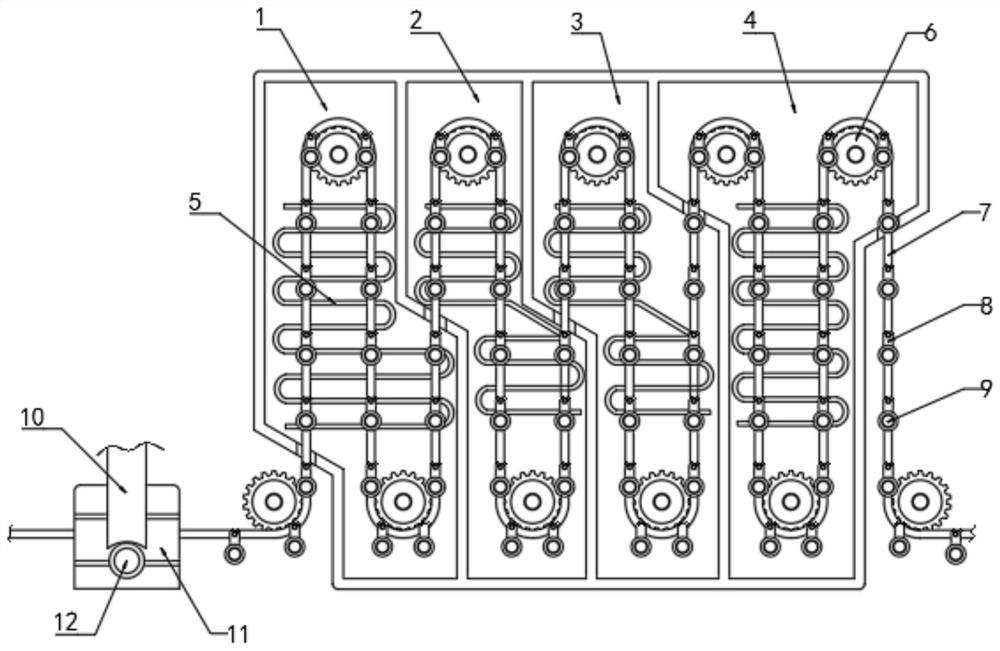

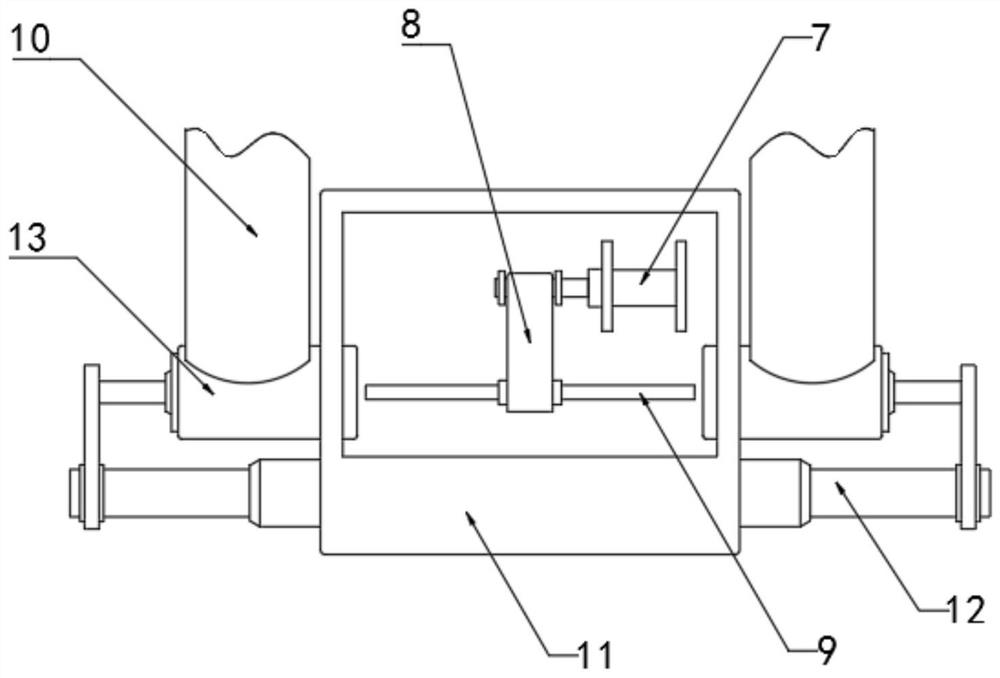

[0029] see Figure 1-3 , a metallized film capacitor core heat treatment process, comprising the steps of:

[0030] Step 1: The neatly arranged capacitor cores are conveyed to the positioning pipe 13 through the feeding pipe 10, and the electric telescopic rods 12 on both sides of the horizontal side of the feeding box 11 are started to move simultaneously, and the output end linkage piston pushes the capacitor cores, Thus, the capacitor core is slid onto the insertion rod 9, and the insertion rod 9 is made of copper material with good heat conduction;

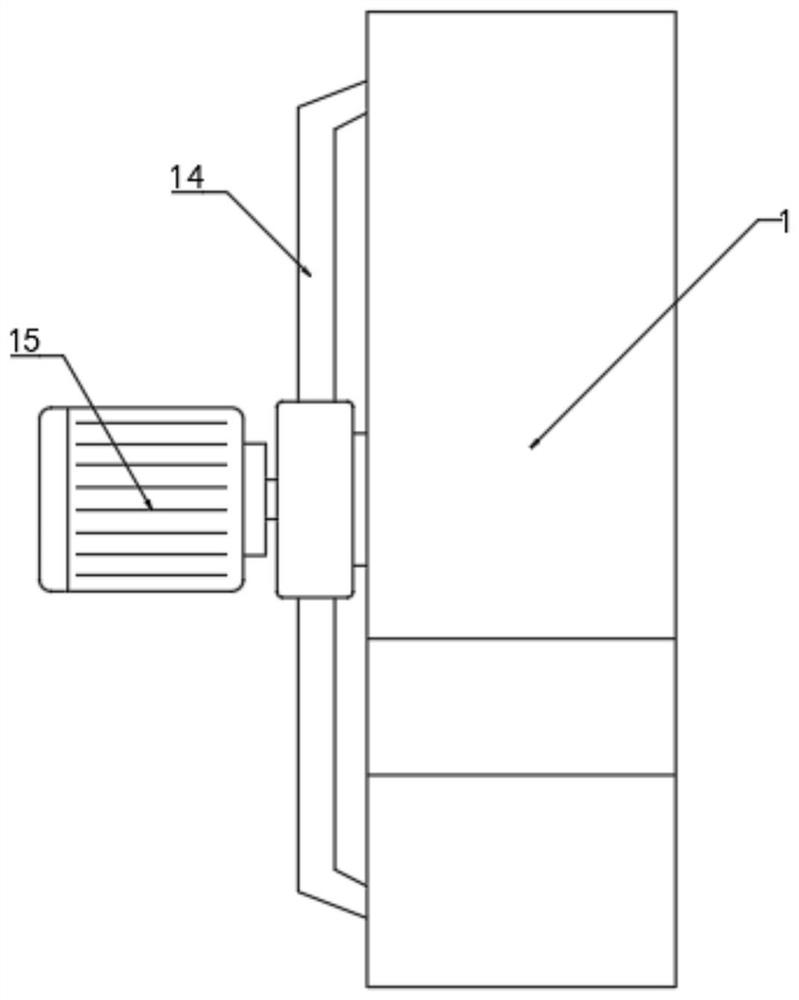

[0031] Step 2: Start the external drive mechanism to operate, and the chain 7 is driven and turned through the gear plate 6. Through the operation of the electric control box, the movement speed of the chain 7 is adjusted, and the chain 7 and the insertion rod 9 are always kept in a horizontal state. Because the total length of the chain 7 arranged inside the first heating box 1, the second heating box 3, the first incubating...

Embodiment 2

[0038] see Figure 1-3 , a metallized film capacitor core heat treatment process, comprising the steps of:

[0039] Step 1: The neatly arranged capacitor cores are conveyed to the positioning pipe 13 through the feeding pipe 10, and the electric telescopic rods 12 on both sides of the horizontal side of the feeding box 11 are started to move simultaneously, and the output end linkage piston pushes the capacitor cores, Thus, the capacitor core is slid onto the insertion rod 9;

[0040] Step 2: Start the external drive mechanism to operate, and the chain 7 is driven and turned through the gear plate 6. Through the operation of the electric control box, the movement speed of the chain 7 is adjusted, and the chain 7 and the insertion rod 9 are always kept in a horizontal state. Because the total length of the chain 7 arranged inside the first heating box 1, the second heating box 3, the first incubating box 2 and the second incubating box 4 is different, thereby realizing that th...

Embodiment 3

[0047] The heating tubes 5 inside the first heating box 1, the second heating box 3, the first incubating box 2 and the second incubating box 4 have different powers. The heating temperature of the heating tubes 5 in the first heating box 1 is 90°C. The temperature of the heating pipe 5 in the box 2 is 95°C, the temperature of the heating pipe 5 in the second heating box 3 is 120°C, the temperature of the heating pipe 5 in the second incubator 4 is 125°C, the first heating box 1 and the second heating box 3 The middle chain 7 has the same length, the length of the chain 7 in the first incubator 2 is less than the length of the chain 7 in the second incubator 4, the running time of the chain 7 in the first heating box 1 and the second heating box 3 is 3.5h, and the first incubator The running time in 2 is 3.5 hours, and the running time in the second incubator 4 is 4 hours.

[0048]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com