Insulation layer thermal-shrinkage furnace for capacitor

A heat shrinkable furnace and insulating layer technology, applied in capacitors, capacitor manufacturing, circuits, etc., can solve the problems of poor heat shrinkage performance, low yield, poor appearance, etc., and achieve the effect of uniform heat shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

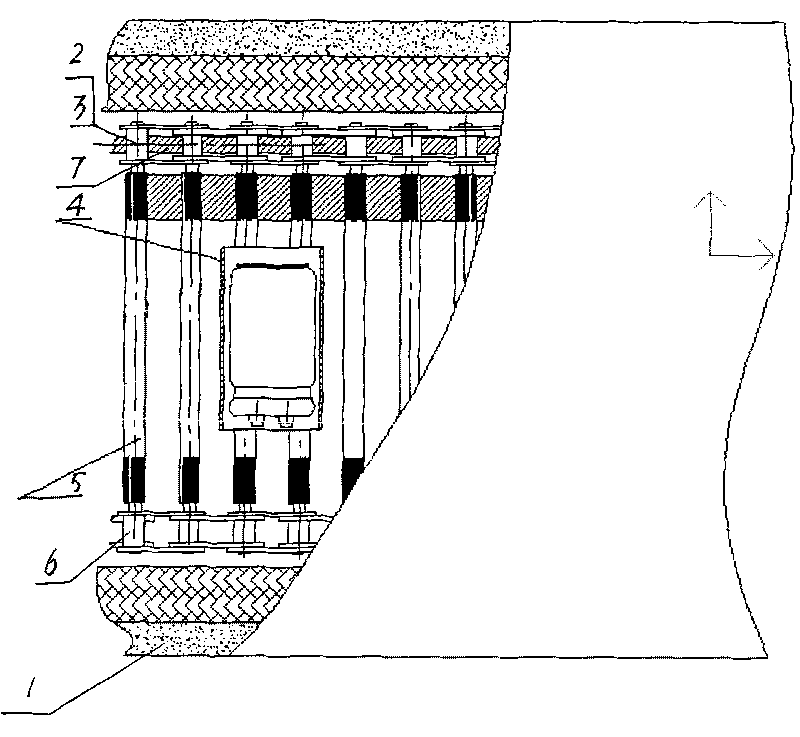

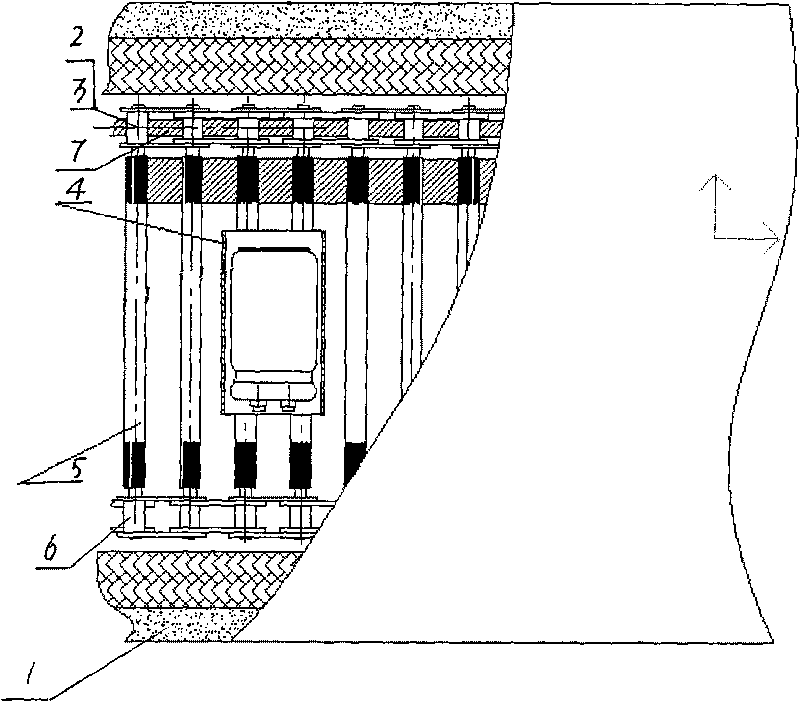

[0009] exist figure 1 Among them, the shrinking furnace is sealed by the insulation layer cover 1, the mesh conveyor belt 4 is dragged by the motor 2, the mesh conveyor belt 4 passes through the chains 3 on both sides, and each section of the chains 3 on both sides is connected by the long axis 5, and the upper half of the chain 3 The lower part has a support block 7 to ensure that the upper half of the chain 3 is always on a plane. The capacitor covered with the insulating protective layer is placed on the long axis and can be moved and rotated. Temperature 120℃-240℃, flow rate 20-60m 3 The hot gas per hour is surrounded by the hot gas that flows reasonably and shrinks evenly to achieve a good shrinkage effect. It is especially used in capacitors with a diameter of 35mm and a height of 60mm or more. It can shrink materials with environmental protection requirements well, significantly improve the appearance and reduce Rework rate, reduce manufacturing cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com