Patents

Literature

191results about "Testing manufactured objects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of calibrating a detector and calibration sphere for the same

InactiveUS20050172695A1Minimize image distortionMinimize distortionImage analysisWave based measurement systemsDistortionOptics

A method of calibrating a detector using a calibration object having a rounded surface and indicia is disclosed. The calibration object, when coupled with a detector and analyzer, assists in minimizing image distortion caused by misalignment of the detector relative to the calibration object. A calibration object is also disclosed.

Owner:ACUSHNET CO

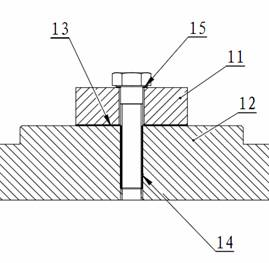

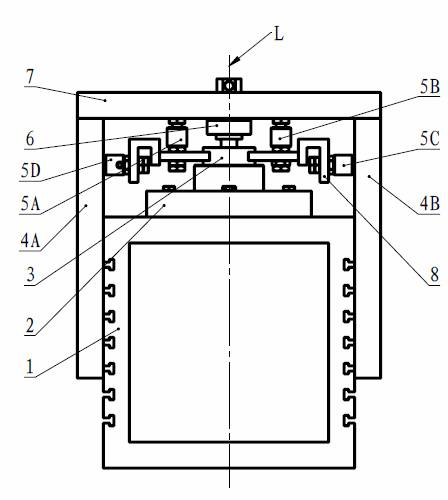

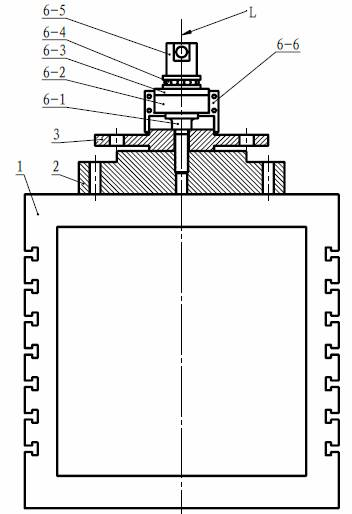

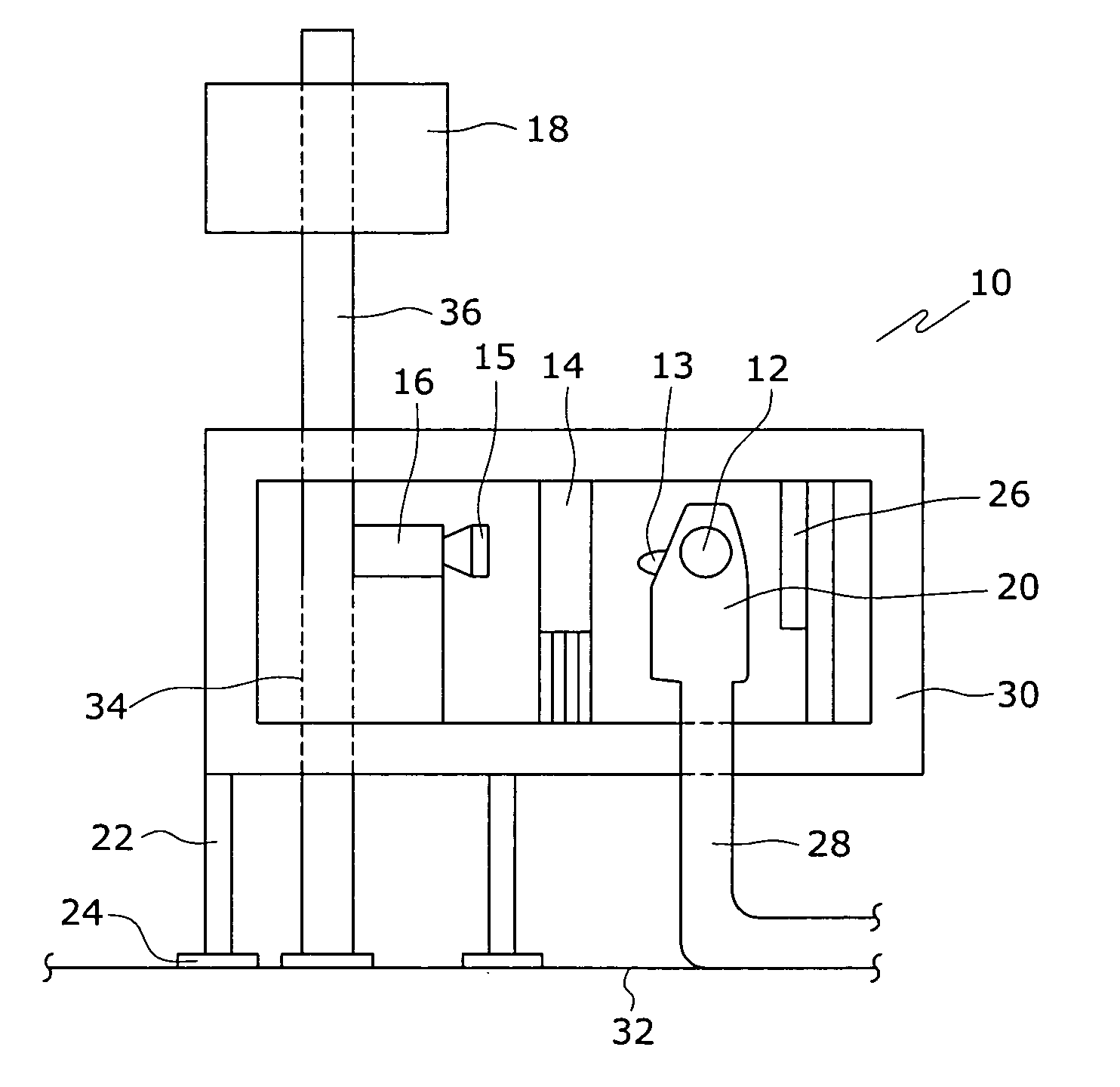

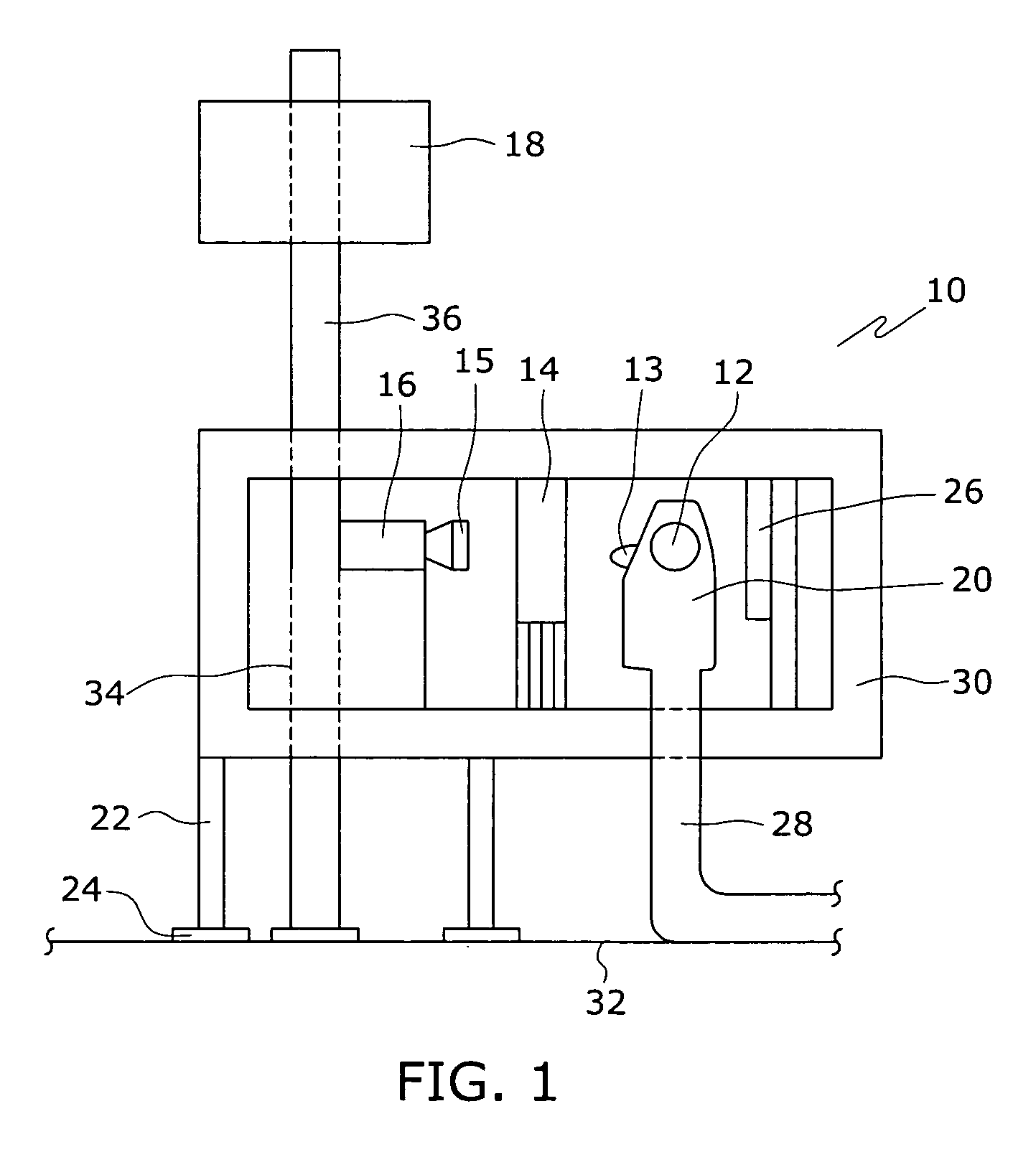

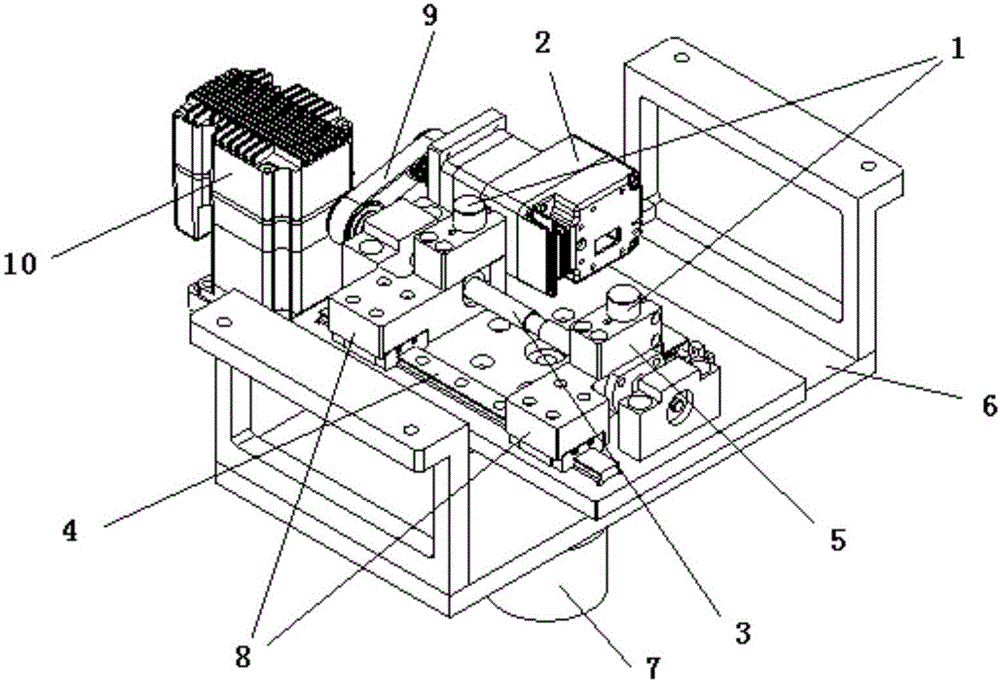

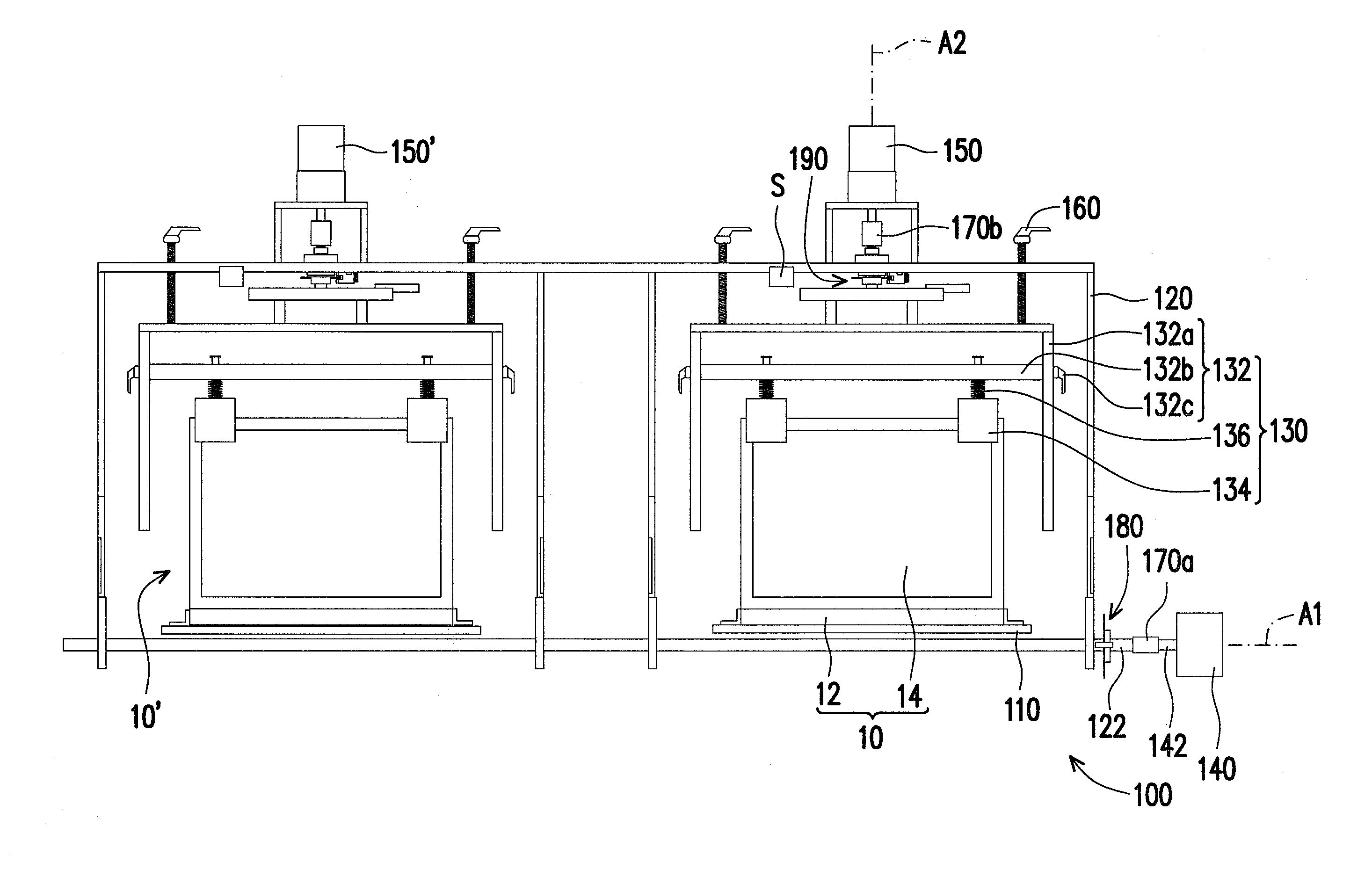

Full-load static characteristic test device and test method of bolt joint surface unit

InactiveCN101886961ARealize comprehensive static characteristic testMeasurement of torque/twisting force while tighteningTesting manufactured objectsEngineeringVertical load

The invention relates to a full-load static characteristic test device of a bolt joint surface unit, comprising a box body, wherein a transverse beam is arranged above the box body; the transverse beam is fixedly connected with the box body through a left upright post and a right upright post; a lower test piece is arranged on the table surface of the box body; an upper test piece is arranged on the lower test piece; a preloaded assembly is arranged between the upper part of the upper test piece and the transverse beam; the upper test piece is connected with the lower test piece through the preloaded assembly; cantilevers at the two ends of the upper test piece are respectively provided with a vertical load applying assembly; each load applying assembly is respectively connected with the transverse beam upwards; cantilever end heads at the two ends of the upper test piece are respectively provided with a connecting piece; and a horizontal load applying assembly is respectively arranged between each connecting piece and right upright post of the transverse beam as well as between each connecting piece and the left upright post of the transverse beam. The full-load static characteristic test method of the bolt joint surface unit of the invention can be used for carrying out a pre-tightening force test, a normal operating load static characteristic test, a tangential operating load static characteristic test, a bending moment operating load static characteristic test and a torque operating load static characteristic test of the bolt joint surface unit by utilizing the test device according to the different structural combinations.

Owner:XIAN UNIV OF TECH

Turf test apparatus

InactiveUS6925858B2Reduce resistanceEarth material testingTesting manufactured objectsAccelerometerDrop tests

Owner:TESTING SERVICES

Testing device for an electronic device having two pivot points

InactiveUS8302488B2Digital data processing detailsStructural/machines measurementEngineeringElectric equipment

Owner:INVENTEC CORP

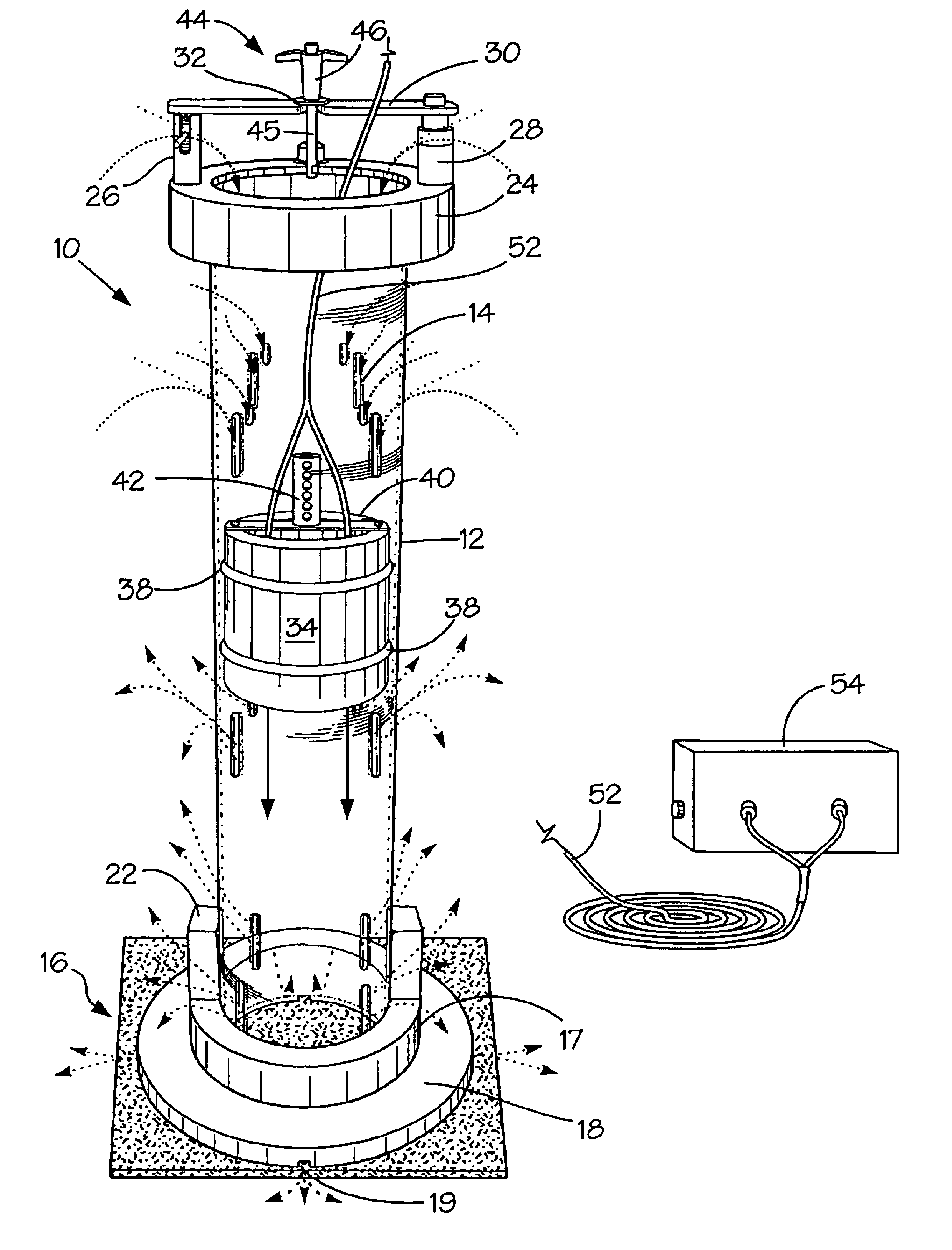

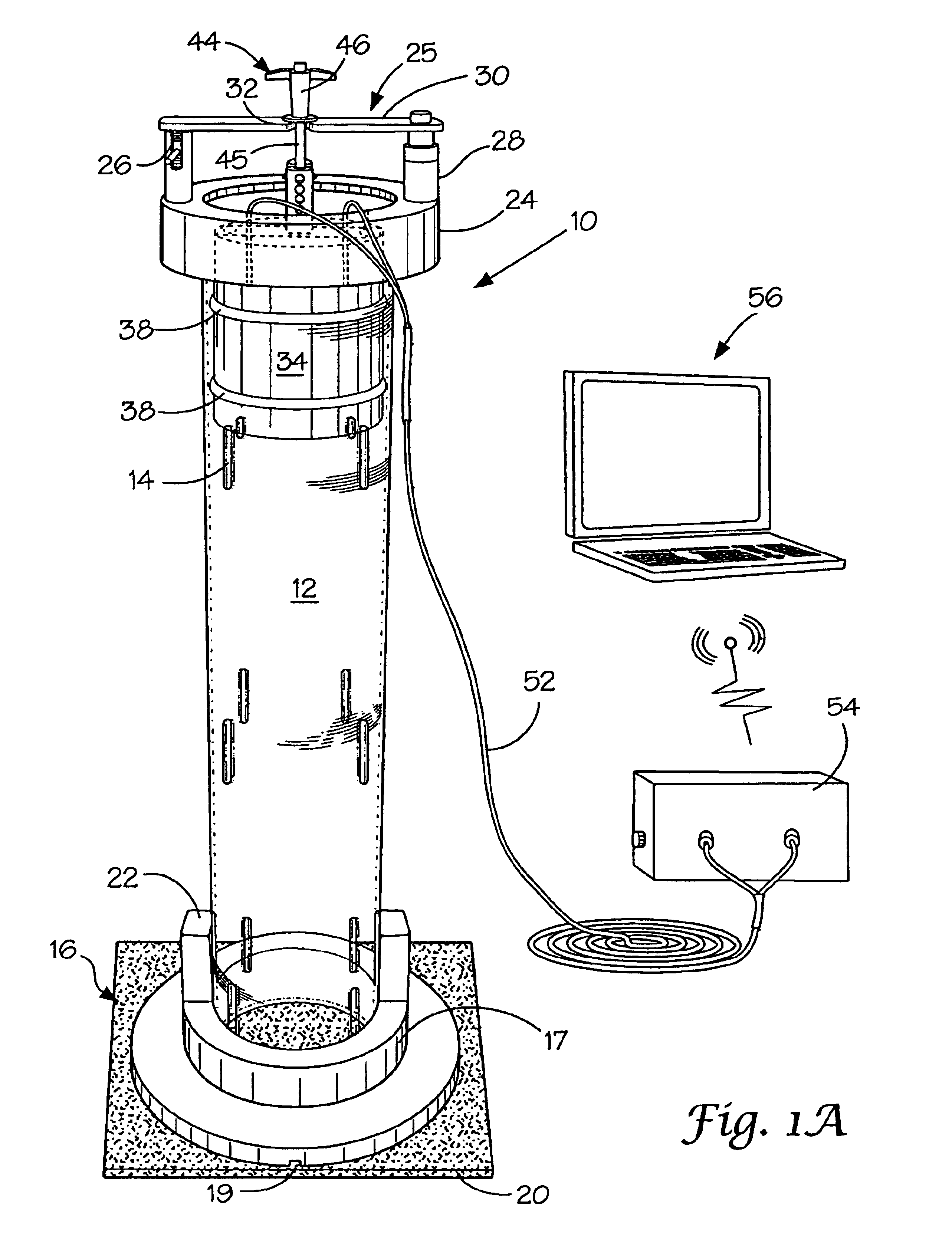

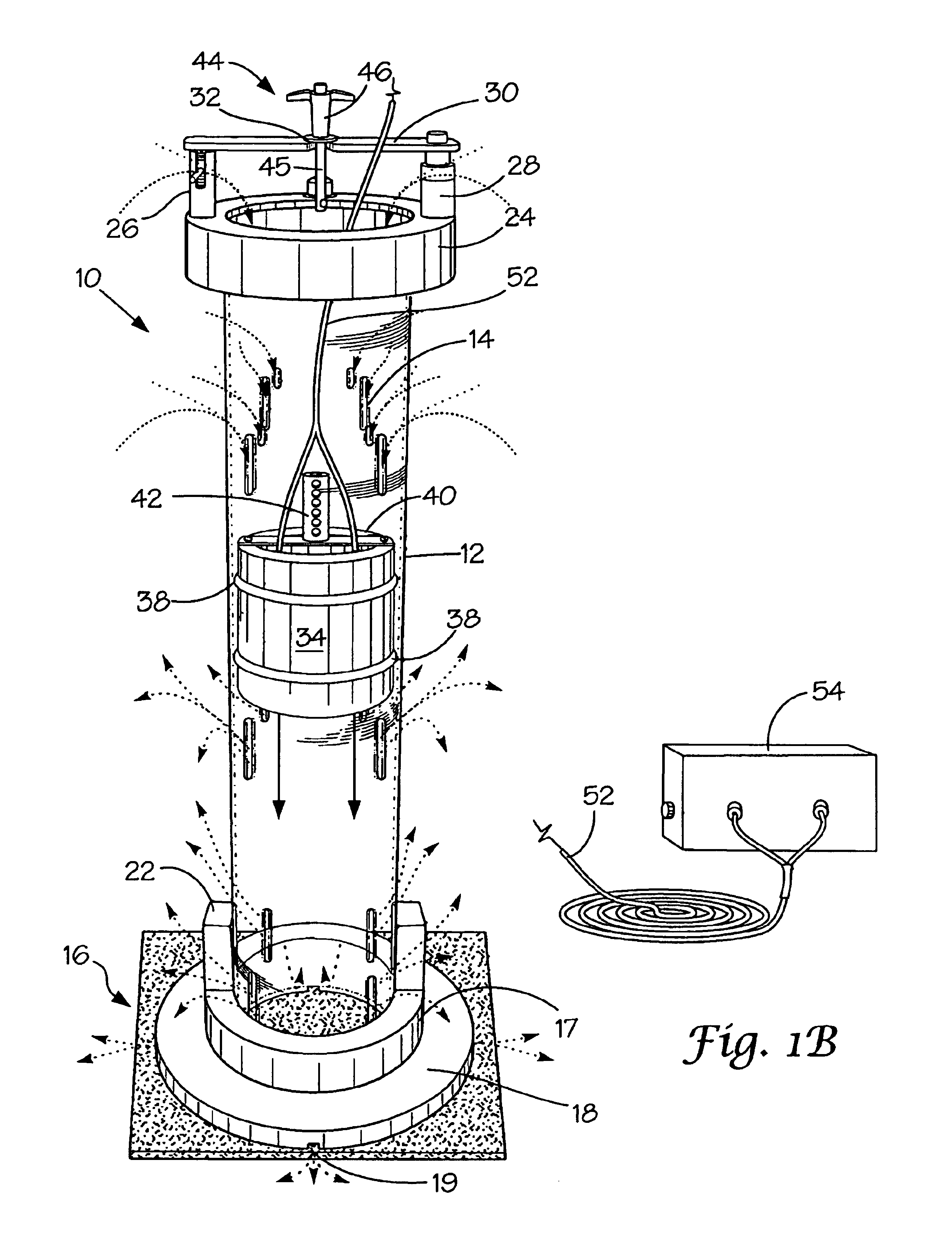

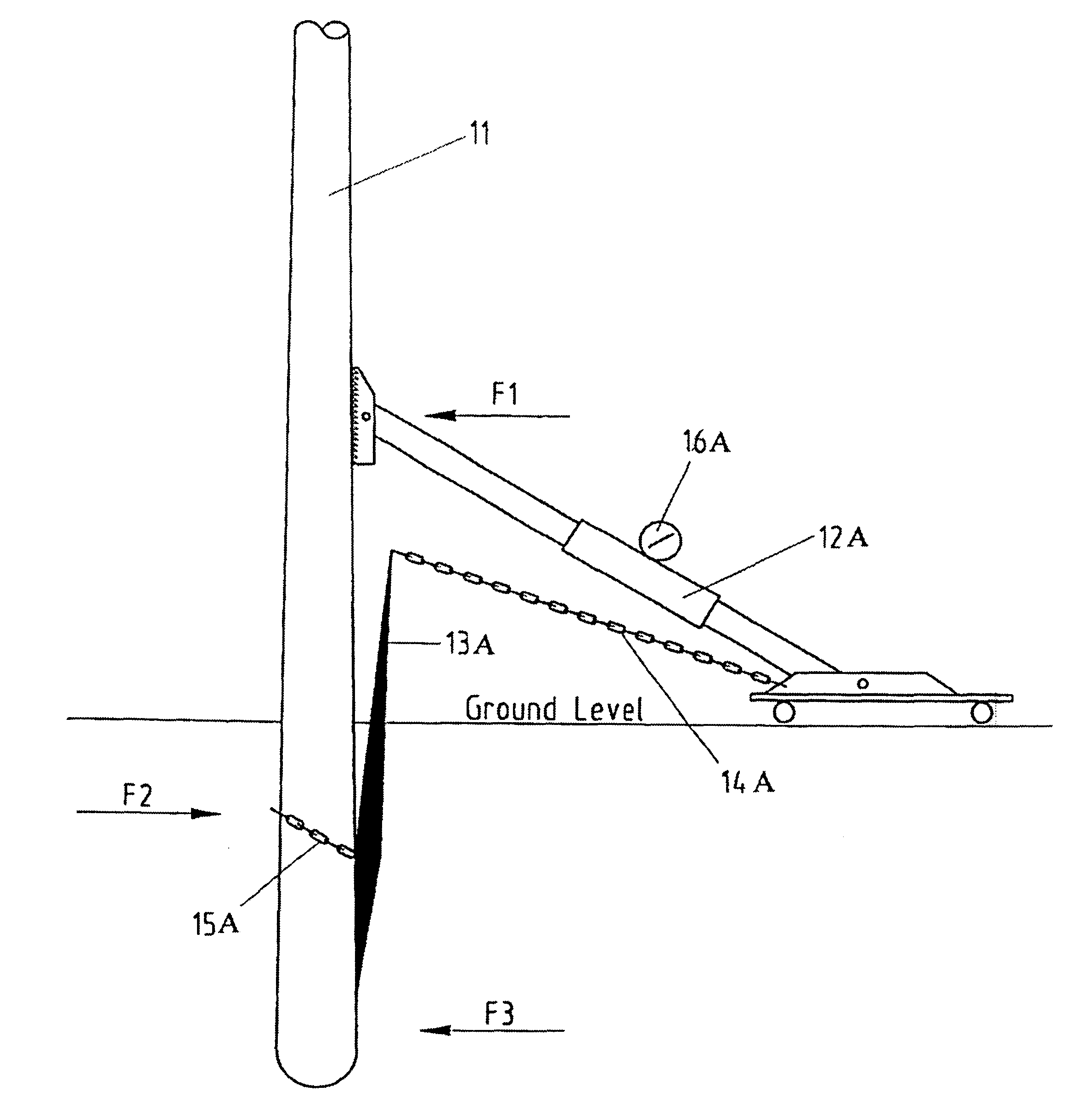

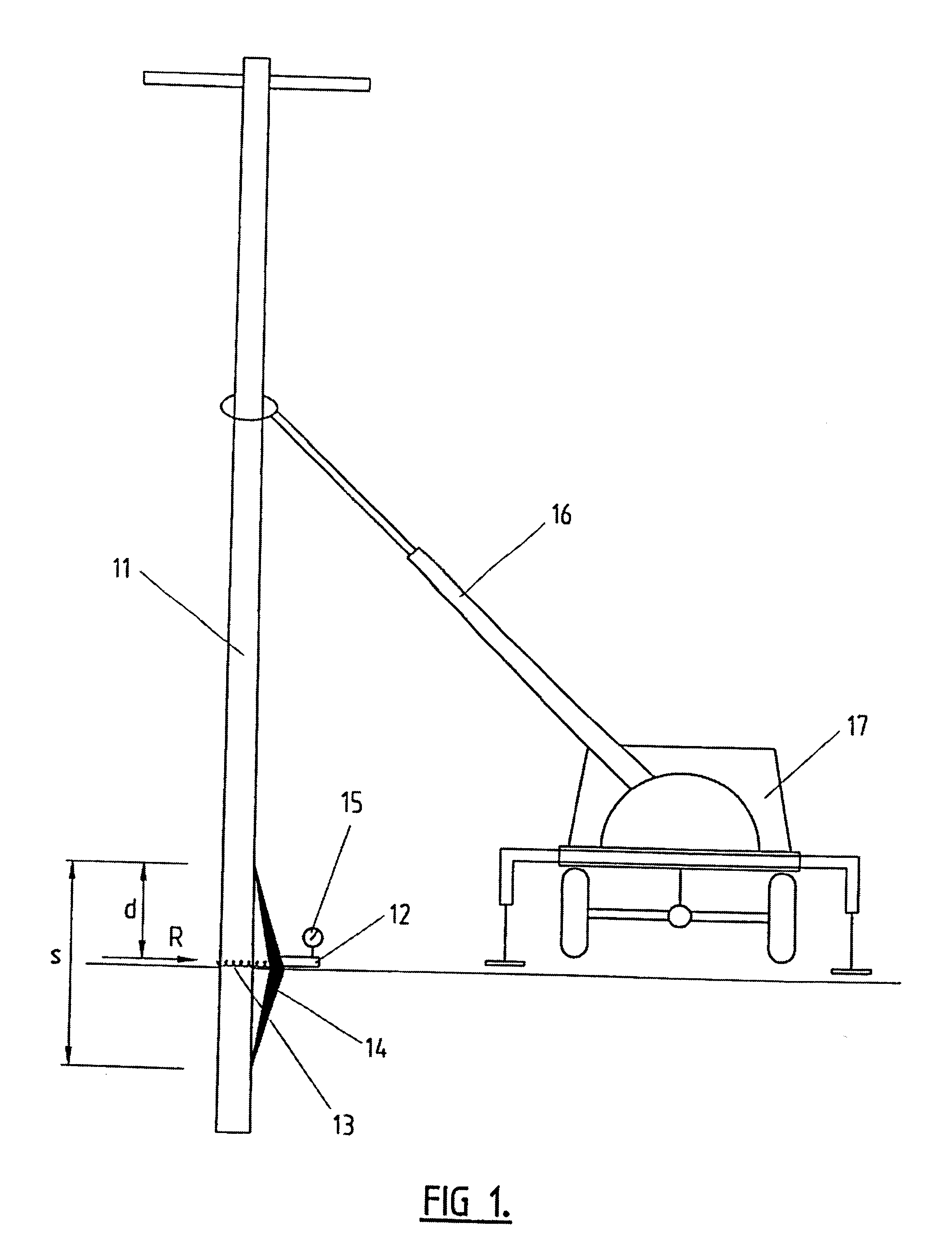

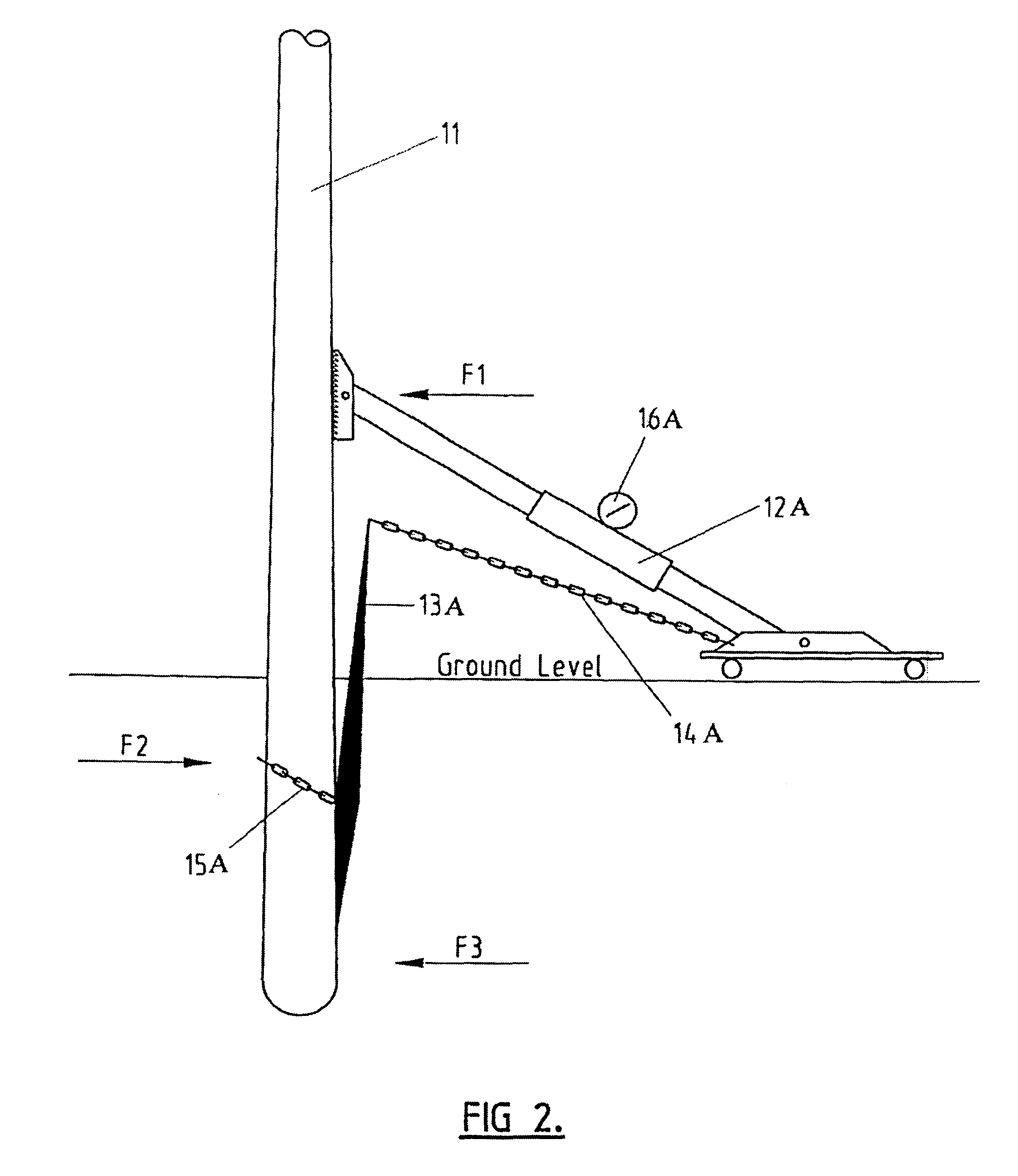

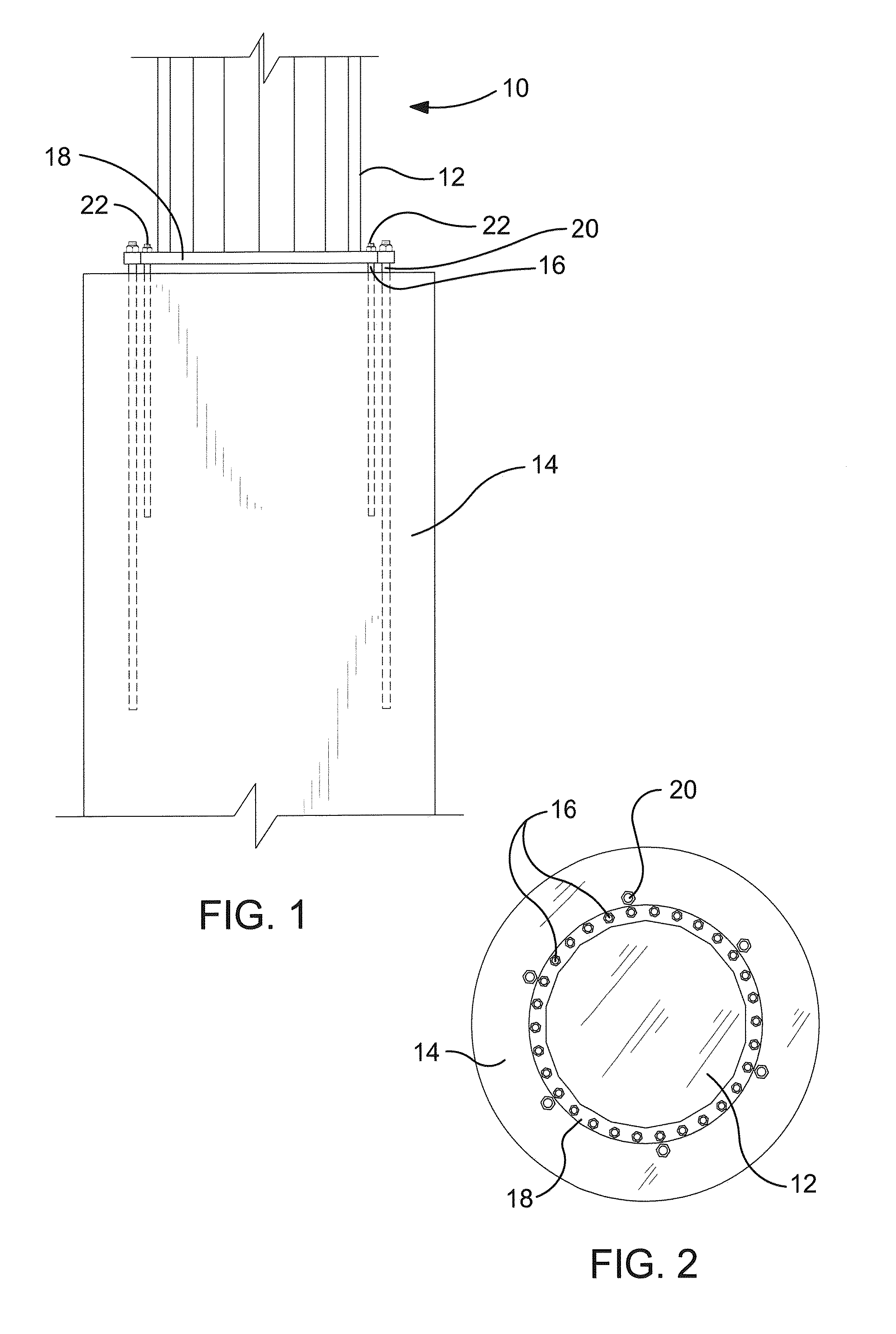

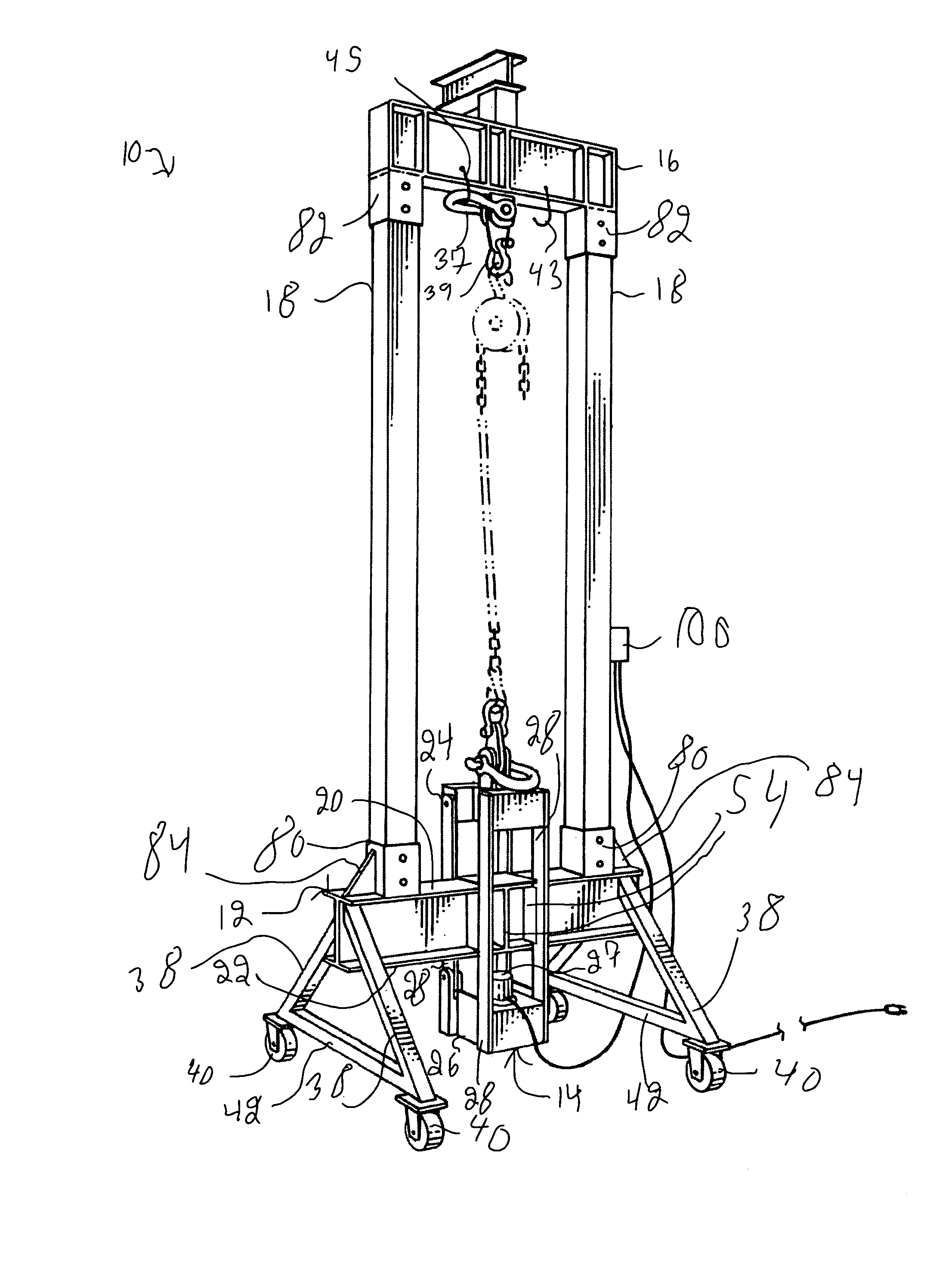

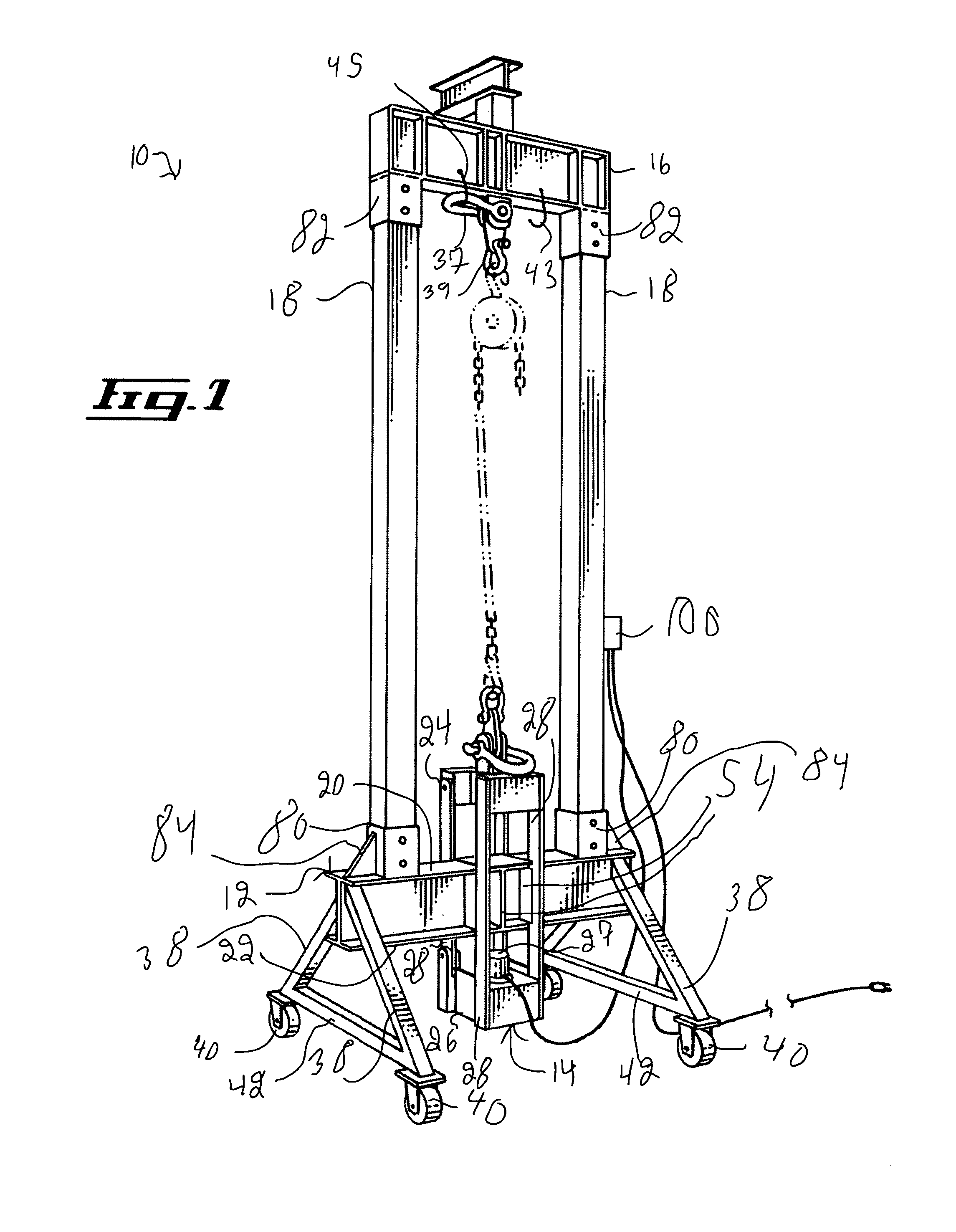

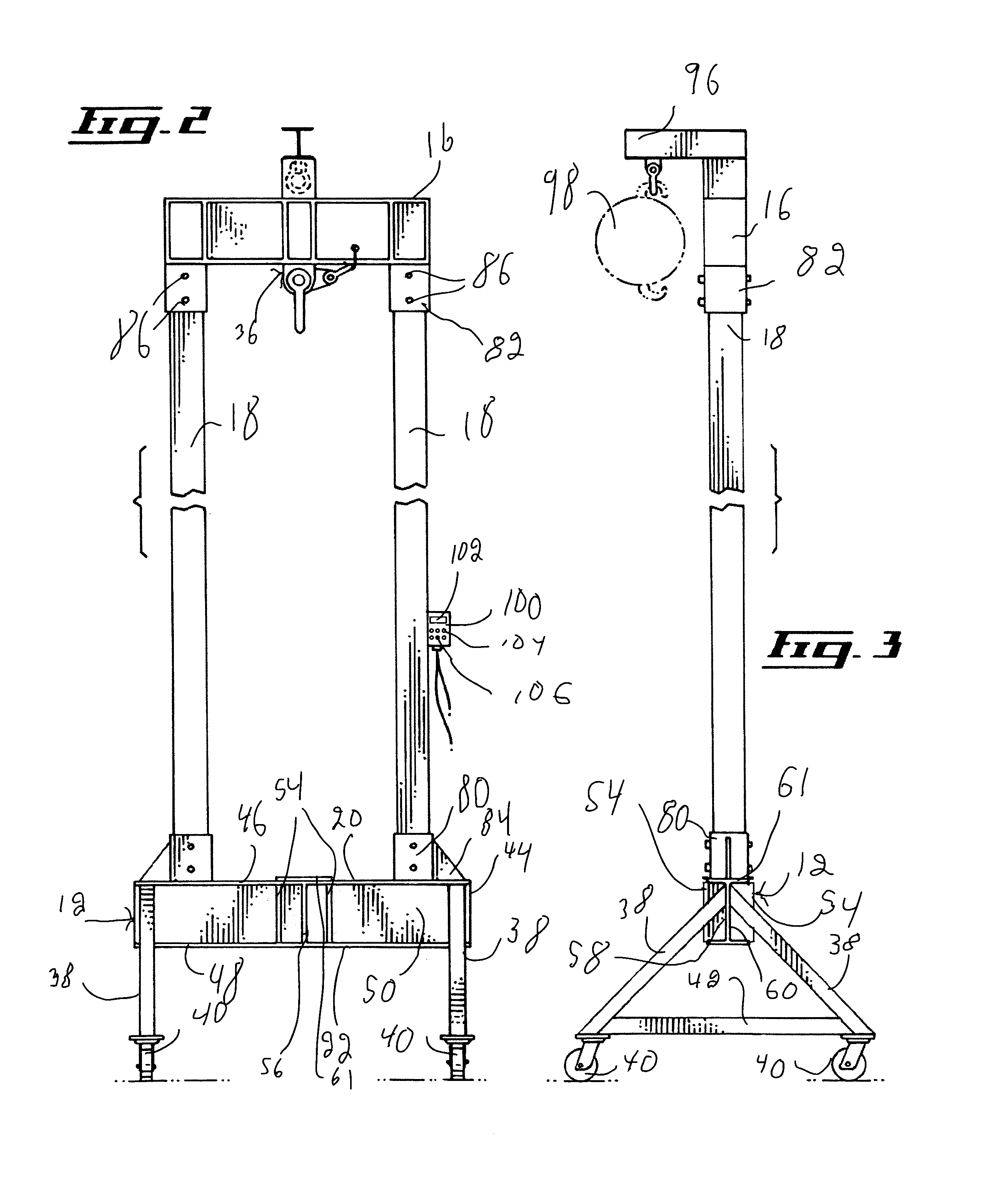

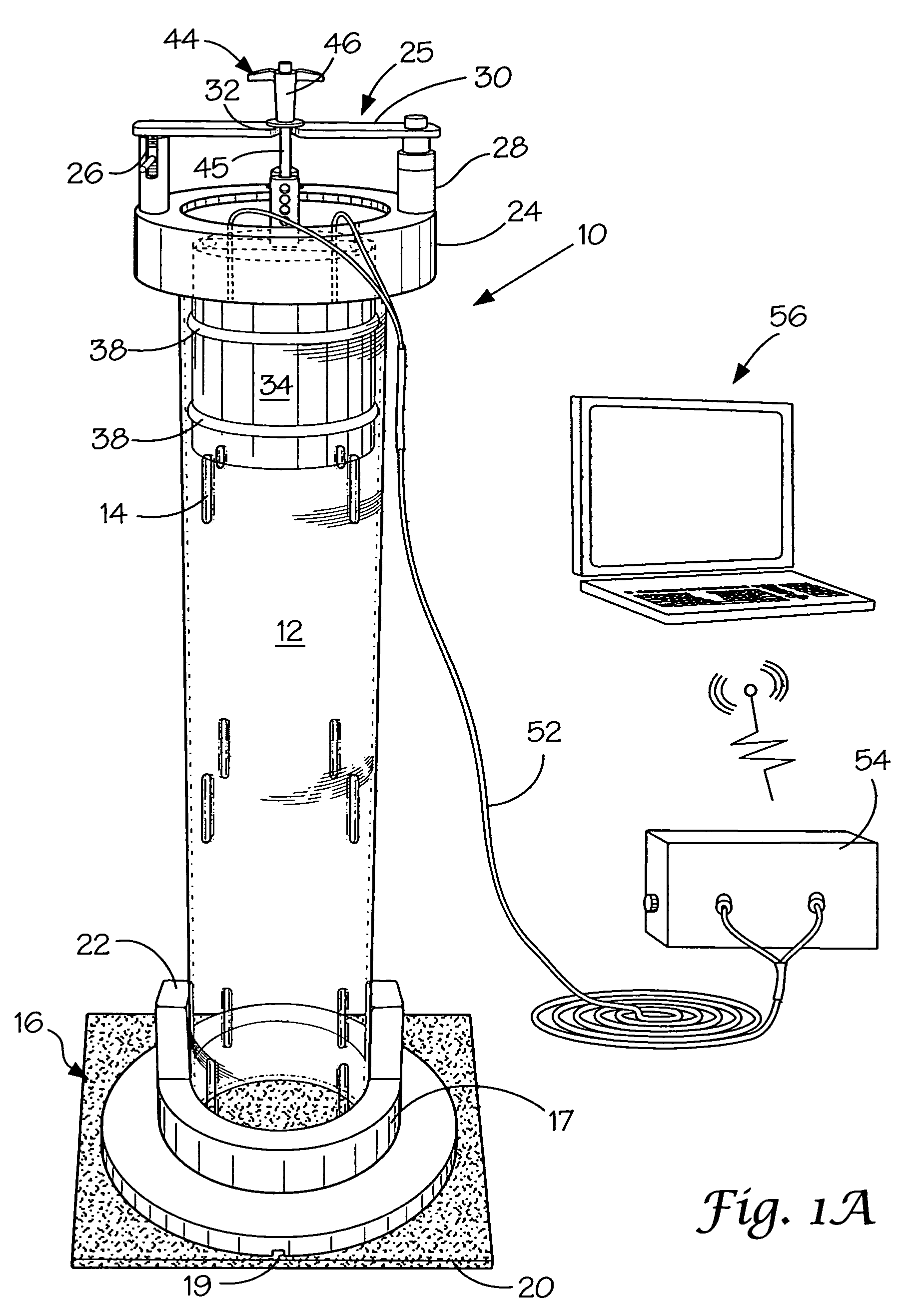

Method, apparatus and support for testing poles

InactiveUS6647801B1Improve abilitiesIncrease stiffnessFlow propertiesForce measurementResidual strengthEngineering

A pole support for ground poles, such as telephone poles and power poles, is disclosed. The support can be driven into the ground next to the pole. It has a pair of spaced apart longitudinal end plates which are interconnected intermediate their ends by an intermediate plate. The end plates are spaced apart to allow the ground pole to pass at least partially between the end plates. Each end plate has a front longitudinal edge which, in use, is adjacent to the pole and a rear longitudinal edge which, in use, is directed away from the pole. The pole support has means to reduce sharp edges on the rear longitudinal edges. Also disclosed is a method for testing pole strength which comprises applying a load to the pole and either measuring its displacement or observing if it withstands the load. The amount of load applied to the pole and the degree of displacement is undergoes can be used to calculate the residual strength of the pole.

Owner:DEUAR ANNA TERESA

Testing device and limiting switch thereof

InactiveUS20110239776A1Structural/machines measurementMaterial strength using steady bending forcesFixed frameEngineering

A limiting switch suitable for a testing device is provided. The testing device includes a fixed frame and a clamping element pivoted to each other. The limiting switch includes a first rod, a second rod, a first switching element and a second switching element. The first and second rods are fixed to the clamping element. The first and second switching elements are pivotally connected to the fixed frame. When the clamping element is pivoted along a first direction, the second rod pushes the second switching element to pivot and the first rod is moved to contact with the first switching element. When the clamping element is pivoted along a second direction opposite to the first direction, the first rod pushes the first switching element to pivot and the second rod is moved to contact with the second switching element.

Owner:INVENTEC CORP

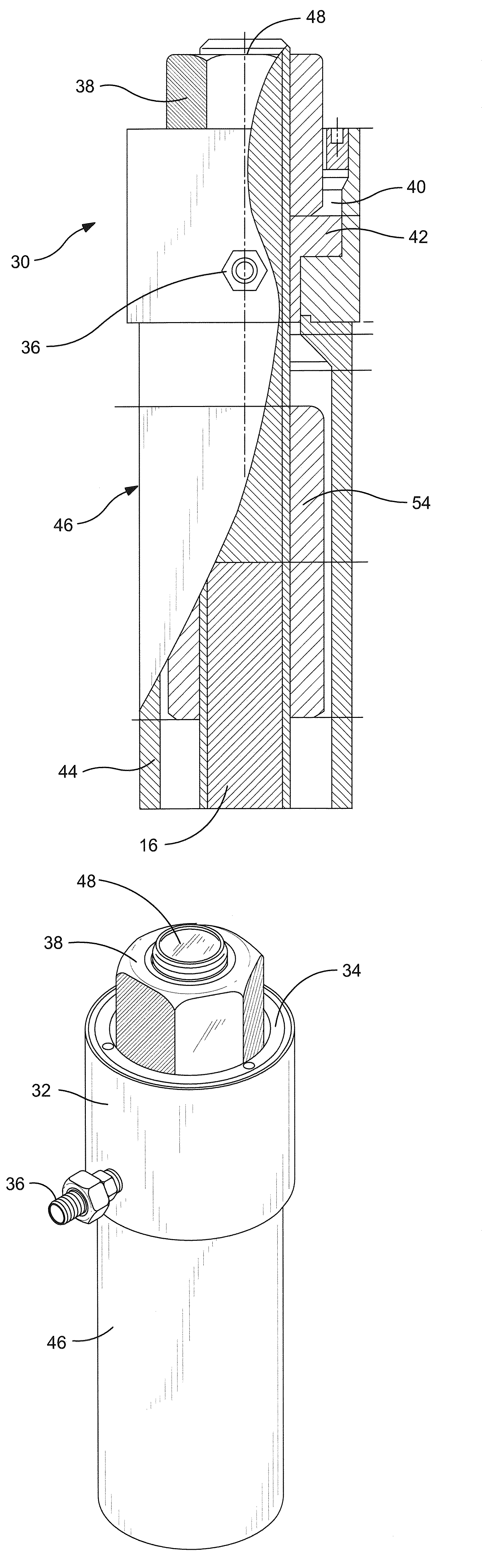

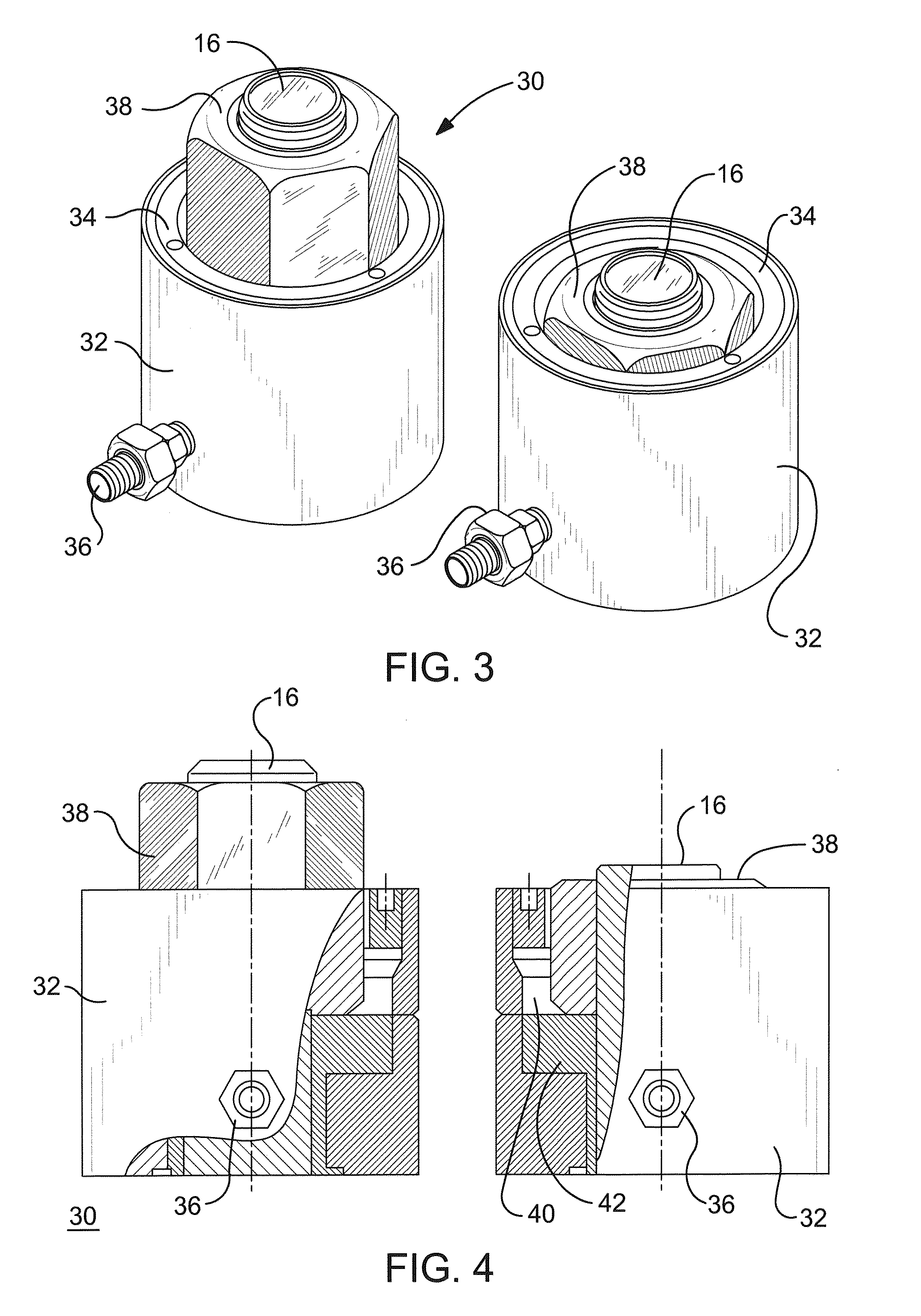

Method and apparatus for testing post-installed anchor rods

InactiveUS20100206089A1Fast timeFoundation testingMaterial strength using tensile/compressive forcesEngineeringActuator

A method is provided for testing a post installed anchor rod to determine the stresses on the anchor rod. The method comprises the steps of providing a linear hydraulic actuator comprising a cylinder, a piston slideable therein in response to a change in hydraulic pressure, and a longitudinal opening formed in the piston for receiving the anchor rod, positioning the anchor rod in the opening, releasably securing a fastener onto the anchor rod to a position in contact with the piston, actuating the linear hydraulic actuator to induce a force on the fastener and thereby a tensional stress on the anchor rod, and measuring elongation of the anchor rod resulting from the tensional stress.

Owner:GRISWOLD JR WILLIAM A

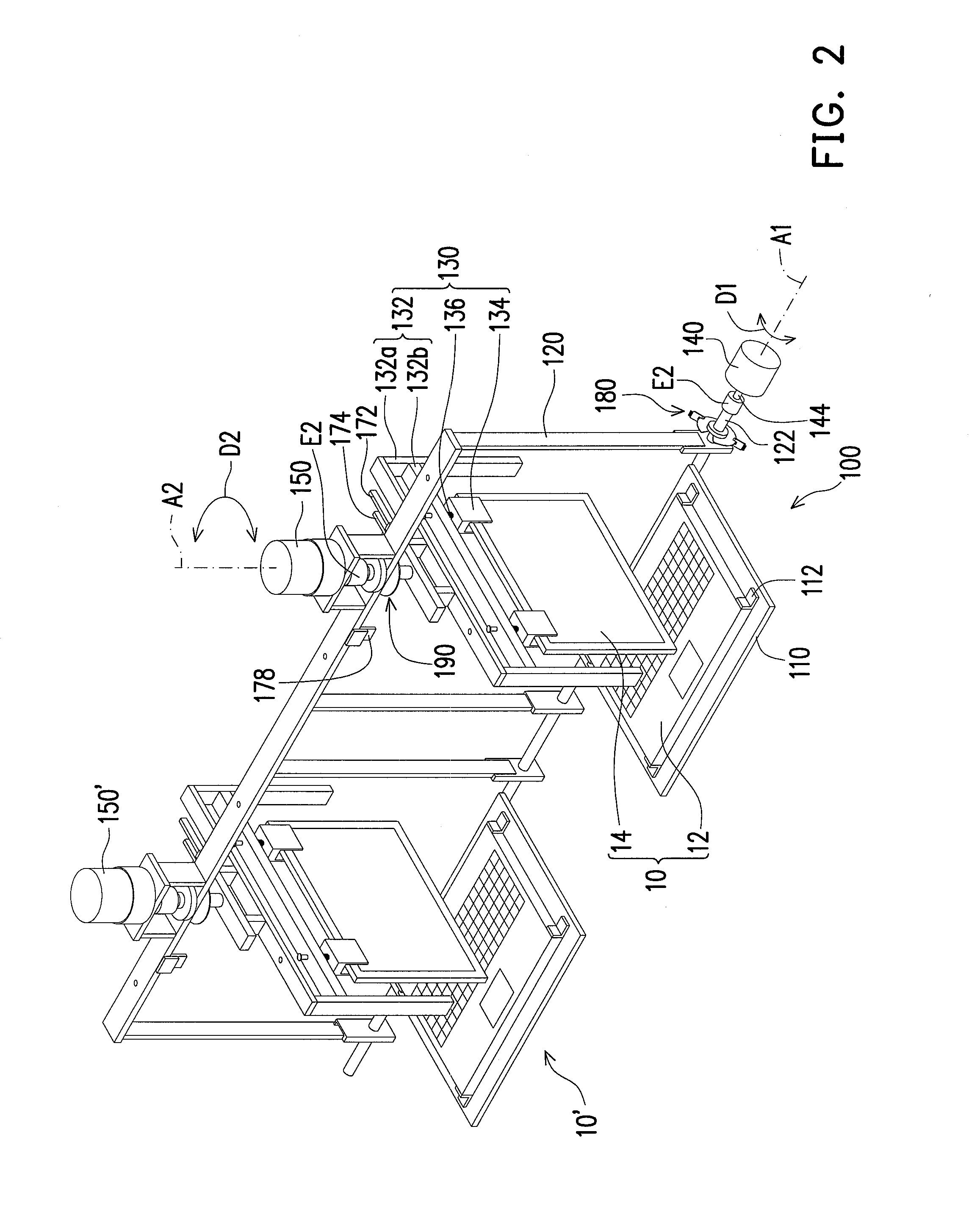

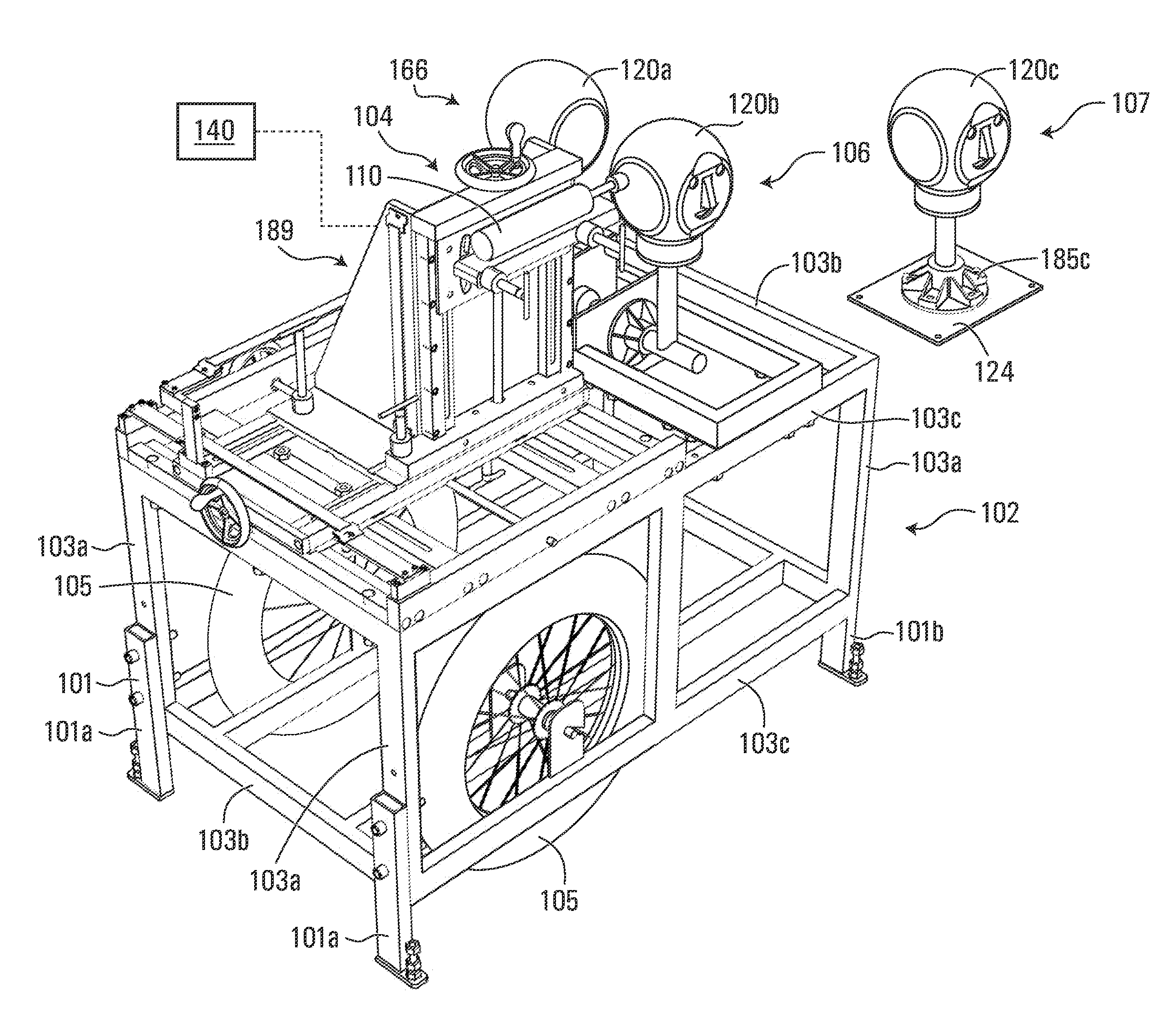

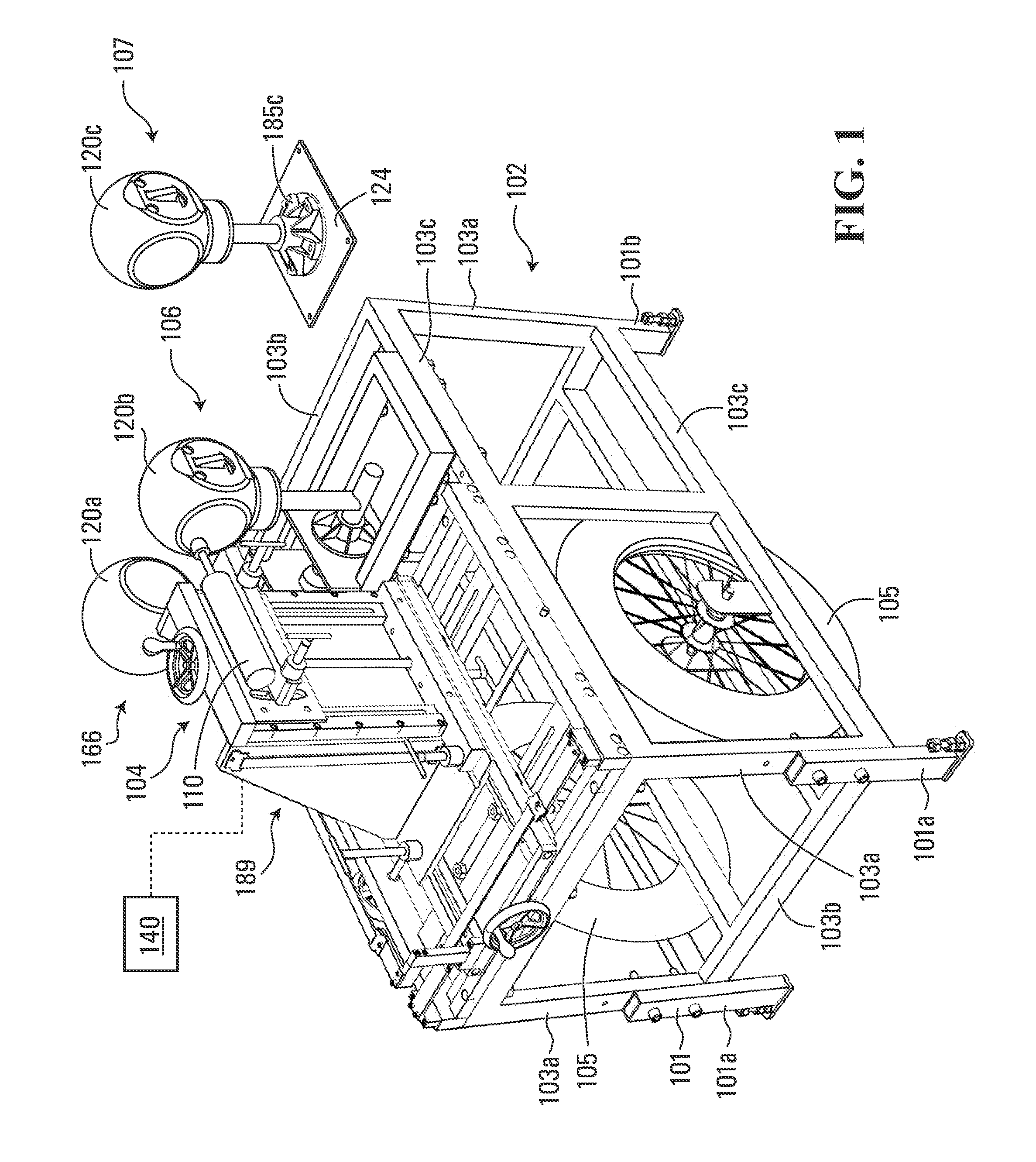

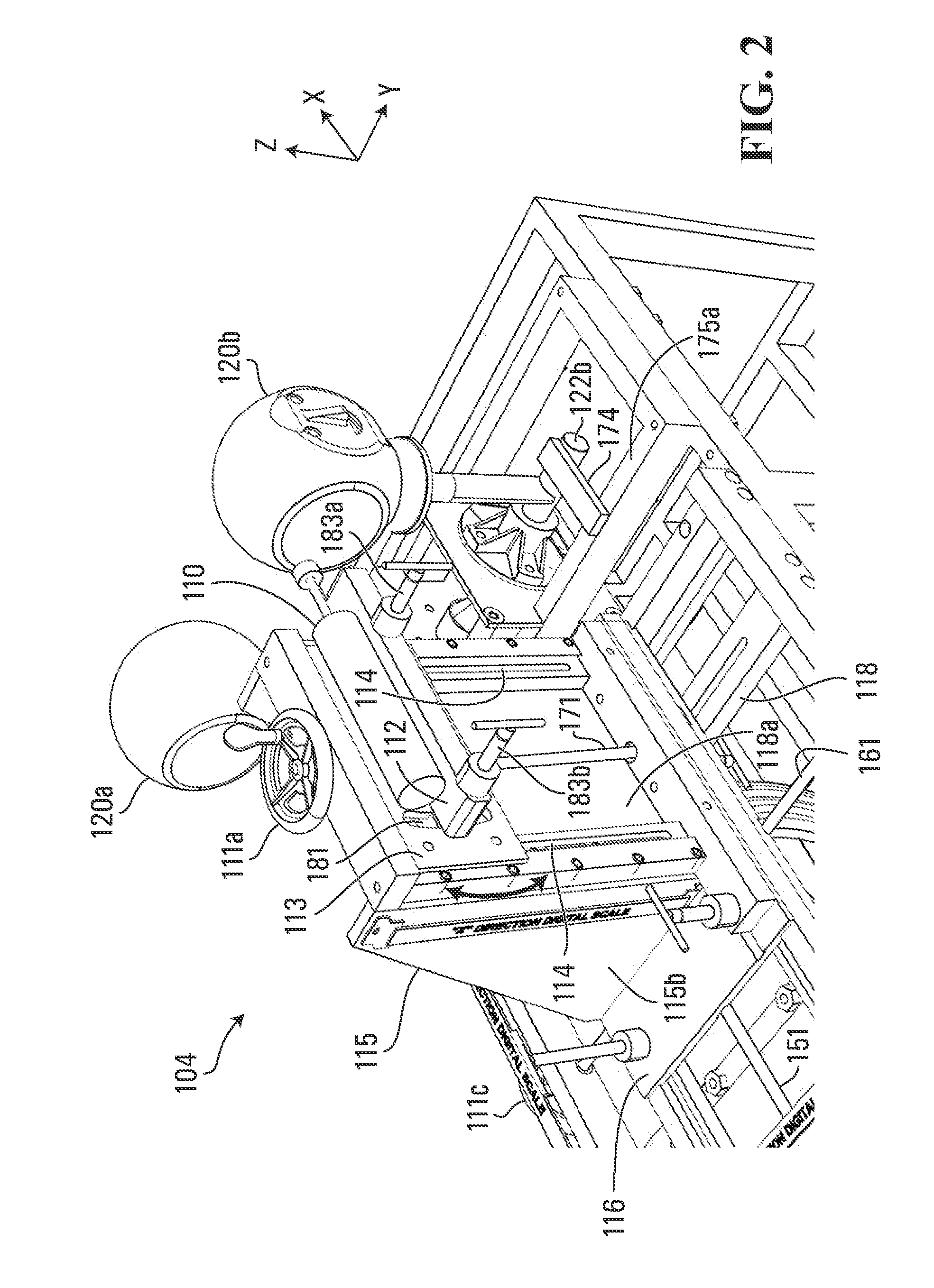

Method and apparatus for simulating head impacts for helmet testing

ActiveUS20120247178A1Testing manufactured objectsMaterial strength using single impulsive forceEngineeringHead shape

An apparatus is disclosed that includes a frame, an impact delivery unit for delivering an impact force and at least one head form. The head form is adapted to be mounted to the frame such that the impact delivery unit can deliver an impact force to a designated location on the head form. The head form is configured to have a helmet installed thereon. The head form is selectively rotatable about each of a plurality of different axes of rotation, wherein movement of the head form is constrained to be able to move only in rotation and in rotation about only one axis of rotation of the plurality of axes at any time. A measuring system provides an indicator of the rotational acceleration of the head form when rotated about each of the plurality of axes. Also disclosed are methods for comparing the degree of protection afforded by first and second helmets.

Owner:KIS JR MIHALY +3

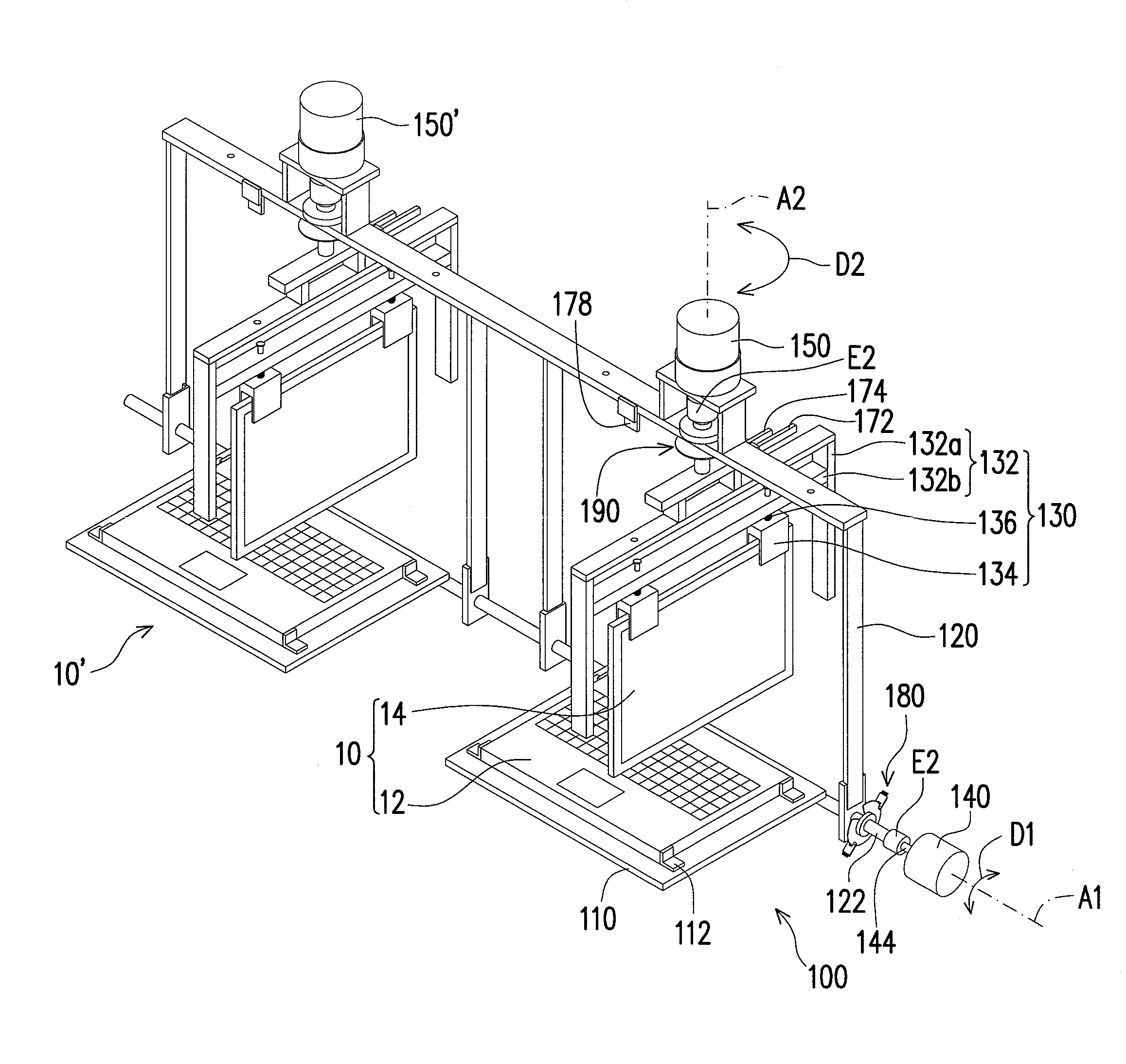

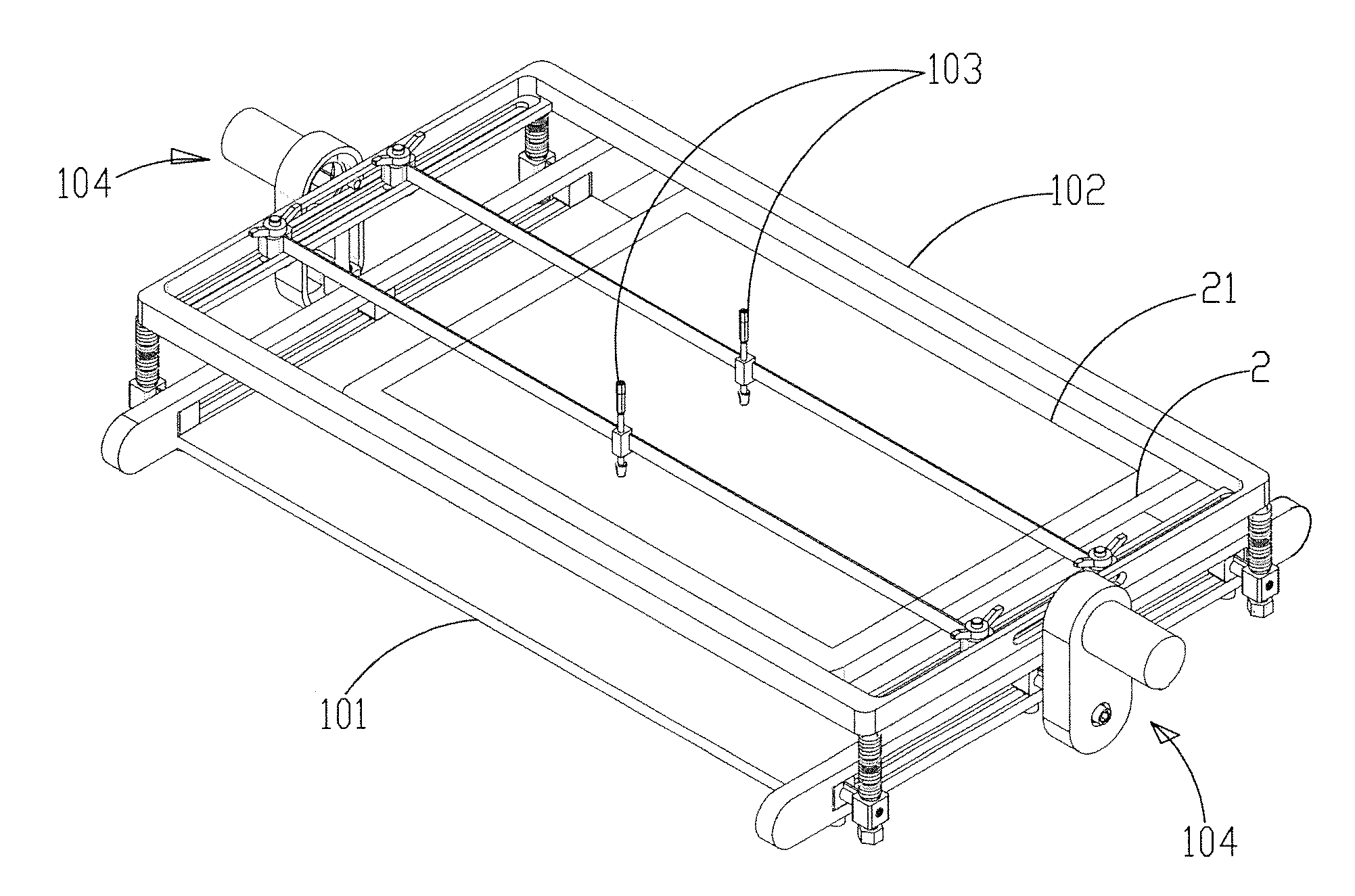

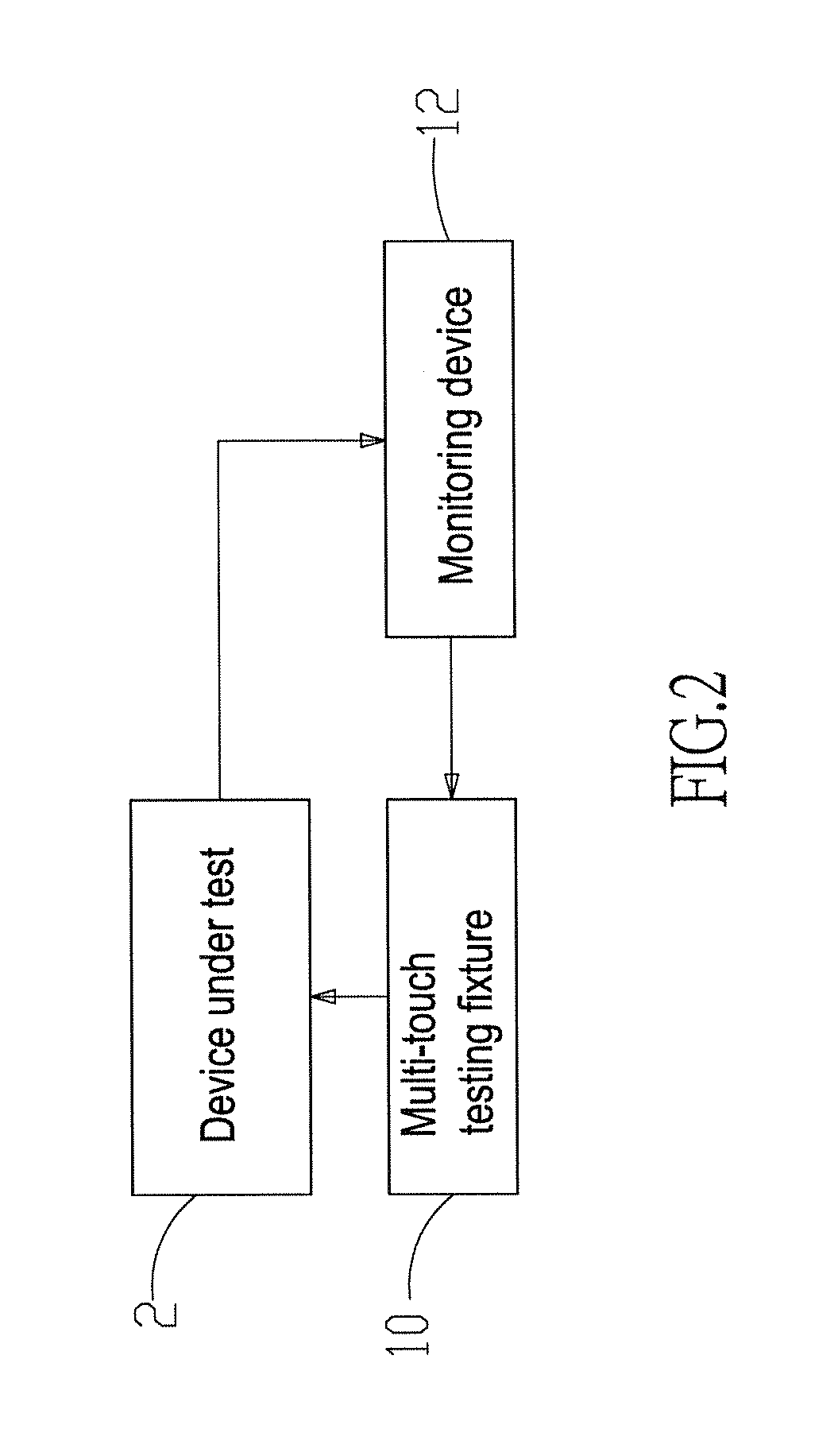

Multi-touch testing system and fixture thereof

InactiveUS20140305224A1Simple structureMaterial strength using tensile/compressive forcesStructural/machines measurementElectricityEngineering

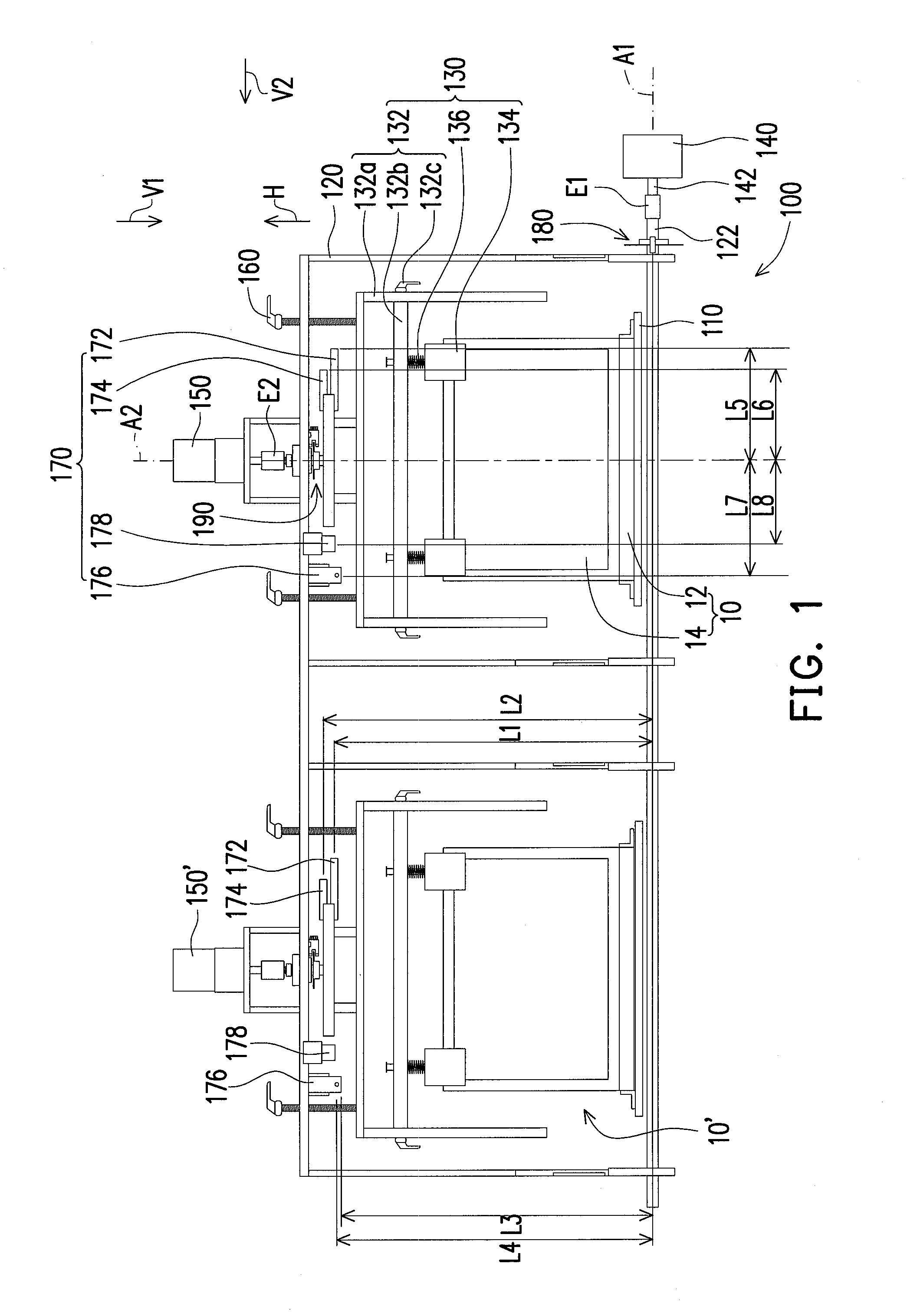

The present disclosure provides a multi-touch testing system and the fixture thereof. The multi-touch testing system comprises a multi-touch testing fixture and a monitoring device. The monitoring device is connected electrically with the multi-touch testing fixture and a device under test disposed at the multi-touch fixture. Thereby, the monitoring device activates the multi-touch testing fixture. The multiple test heads of the multi-touch testing fixture press the device under test simultaneously. Meanwhile, the device under test generates at least a signal. The monitoring device judges if the device under test passes the multi-touch test according to the signal. The pressure of each test head of the multi-touch testing fixture according to the present disclosure is identical to that of any other. In addition, the structure is simplified.

Owner:WISTRON CORP

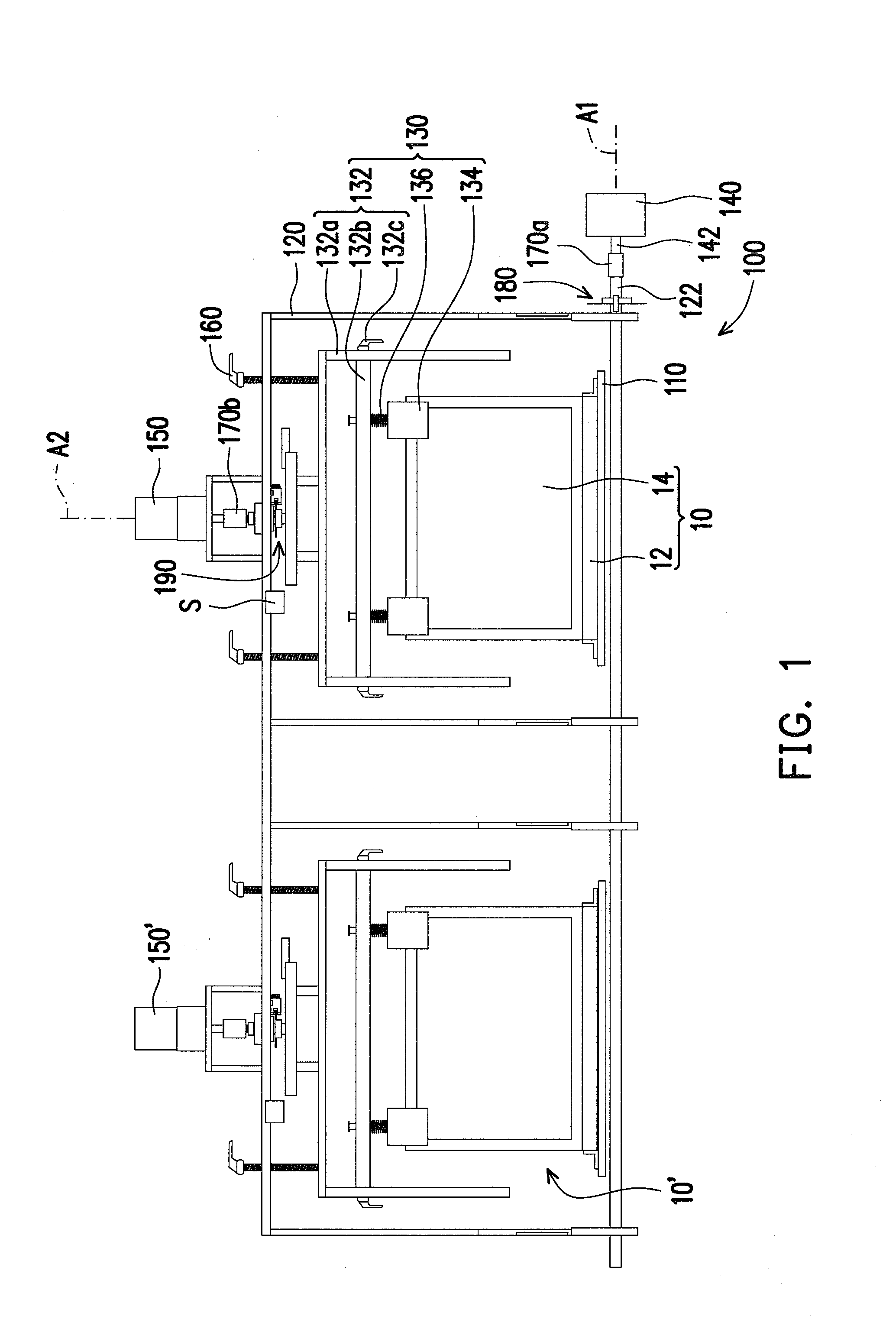

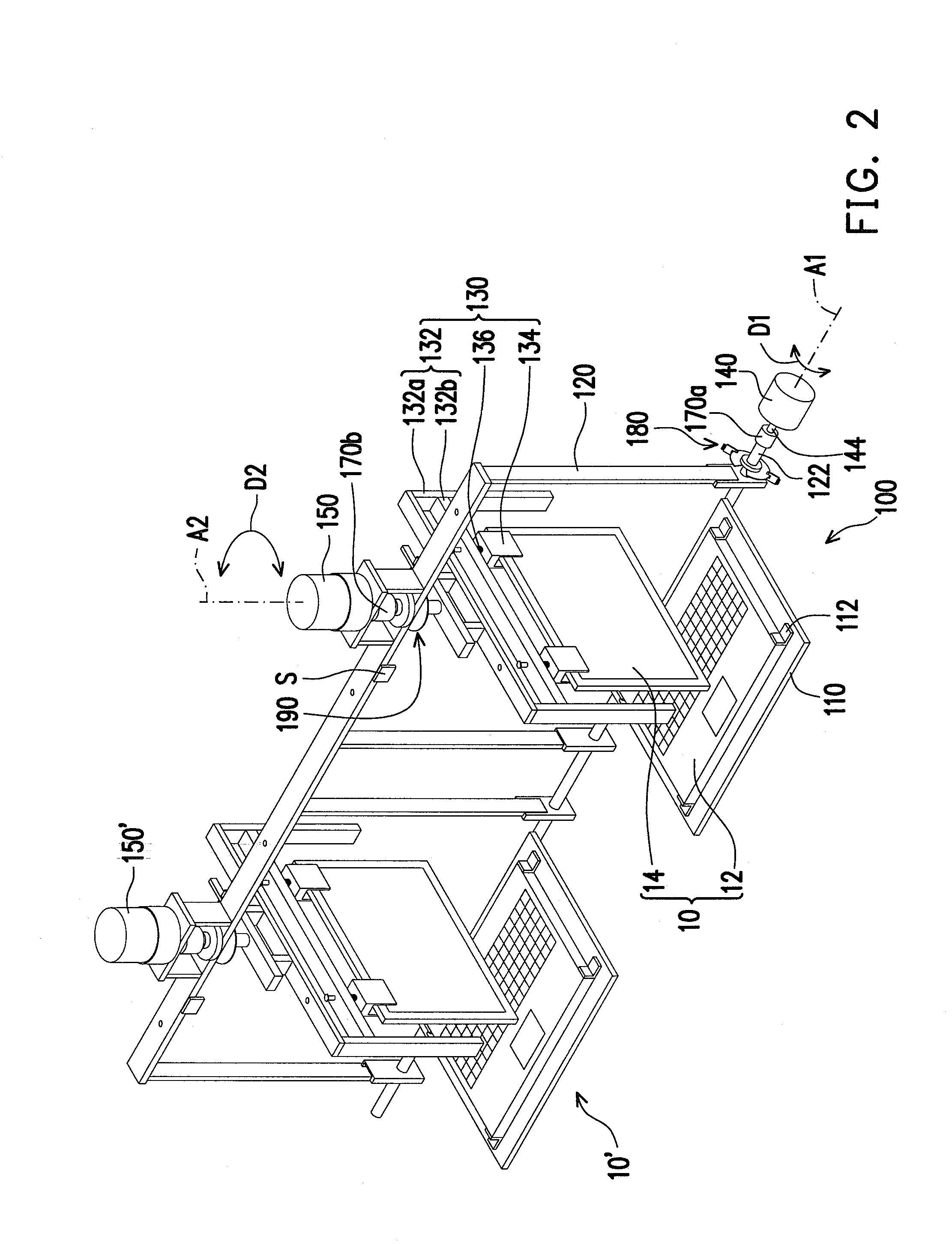

Polyvalent test stand

InactiveUS6912916B1Easy to optimizeEasy to moveStructural/machines measurementTesting manufactured objectsEngineeringMechanical engineering

A test stand for allowing the testing of both a pull-type lifting apparatus and a push-type lifting apparatus. The test stand includes a base and a carriage component, the carriage component including a load transmitting section and a sensor receiving section. The load transmitting section and the sensor receiving section are spaced apart by spacing members. The spacing members are slidably mounted to the base for allowing a sliding movement of the carriage component relative to the base between a retracted configuration and an extended configuration. A load sensor provides a measurement of a force biasing the carriage component towards the extended configuration. The carriage component is configured and sized for allowing the push-type lifting apparatus to be inserted between the base and the load transmitting section so as to bias the carriage component towards the extended configuration and for allowing the attachment of the pull-type lifting apparatus to the load transmitting section so as to bias the carriage component towards the extended configuration.

Owner:INNOVATIONS INDS JOUBERT

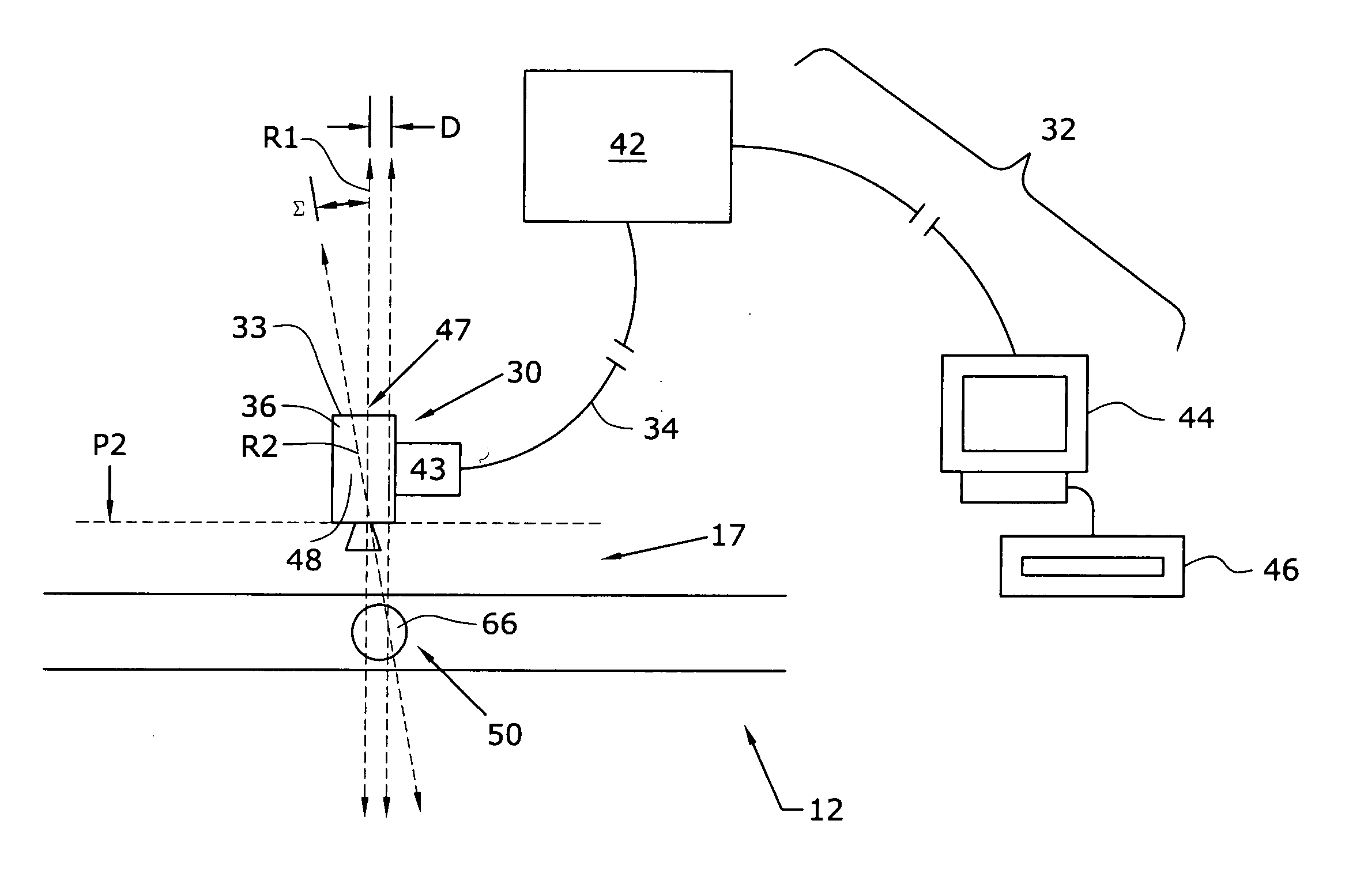

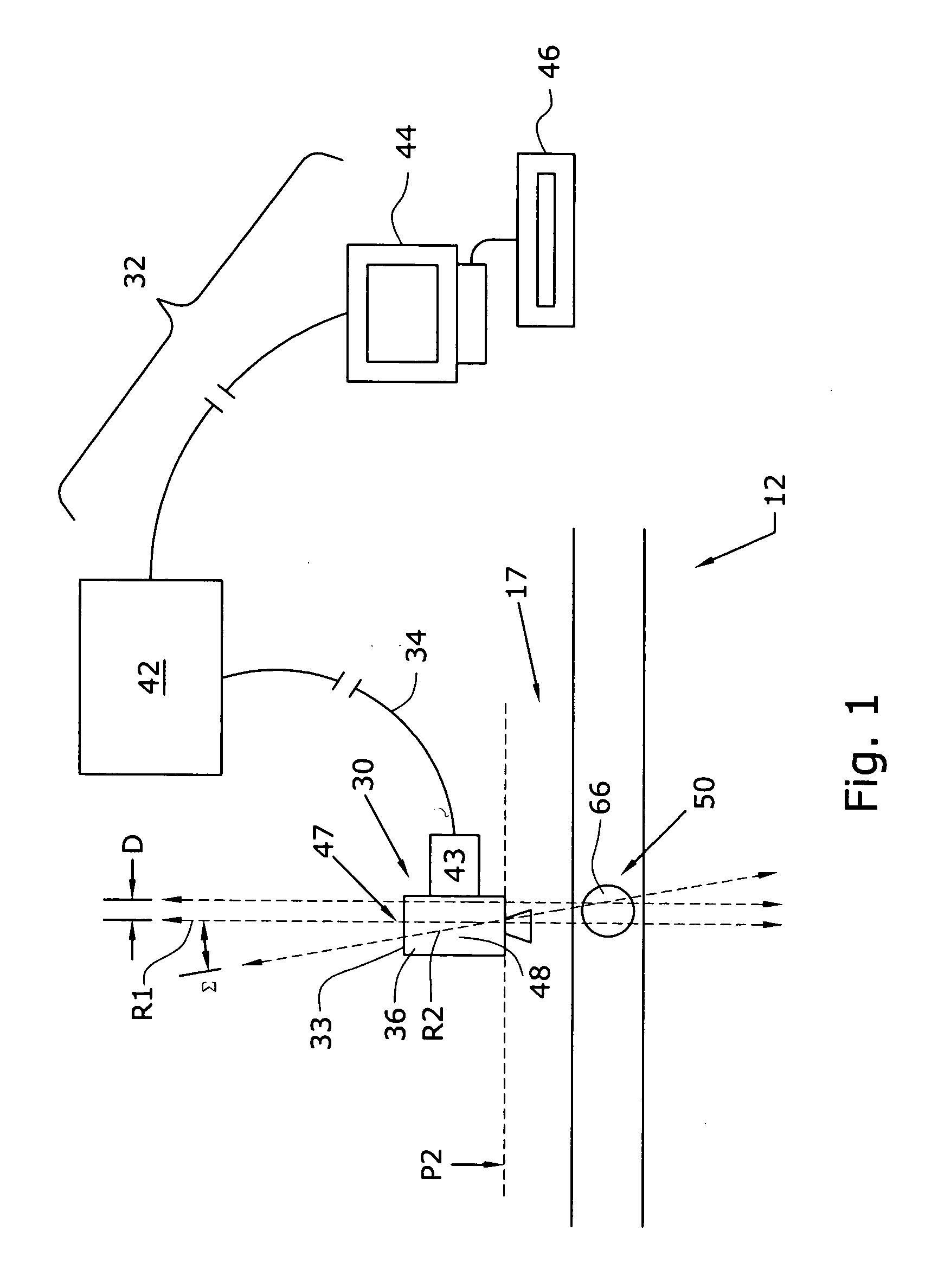

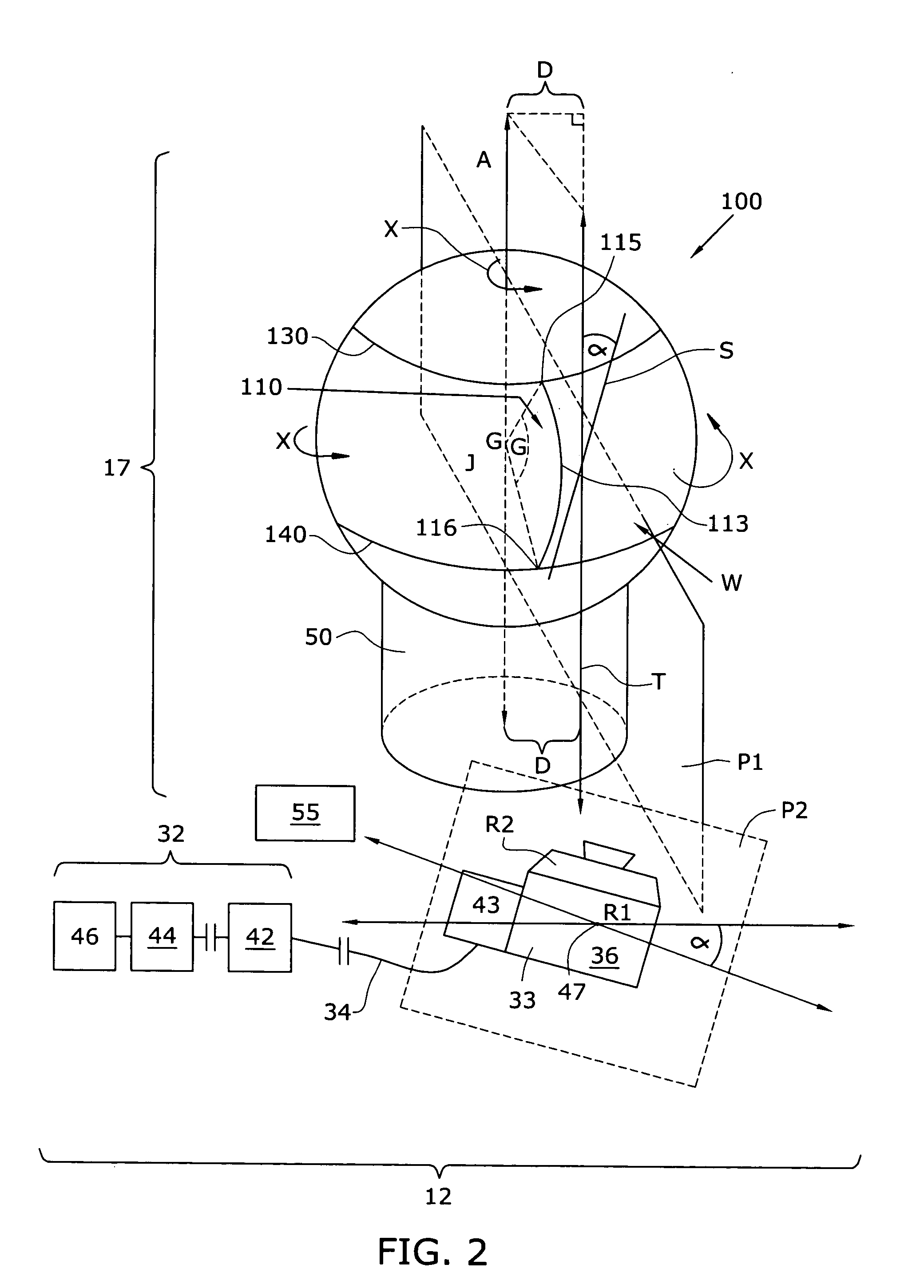

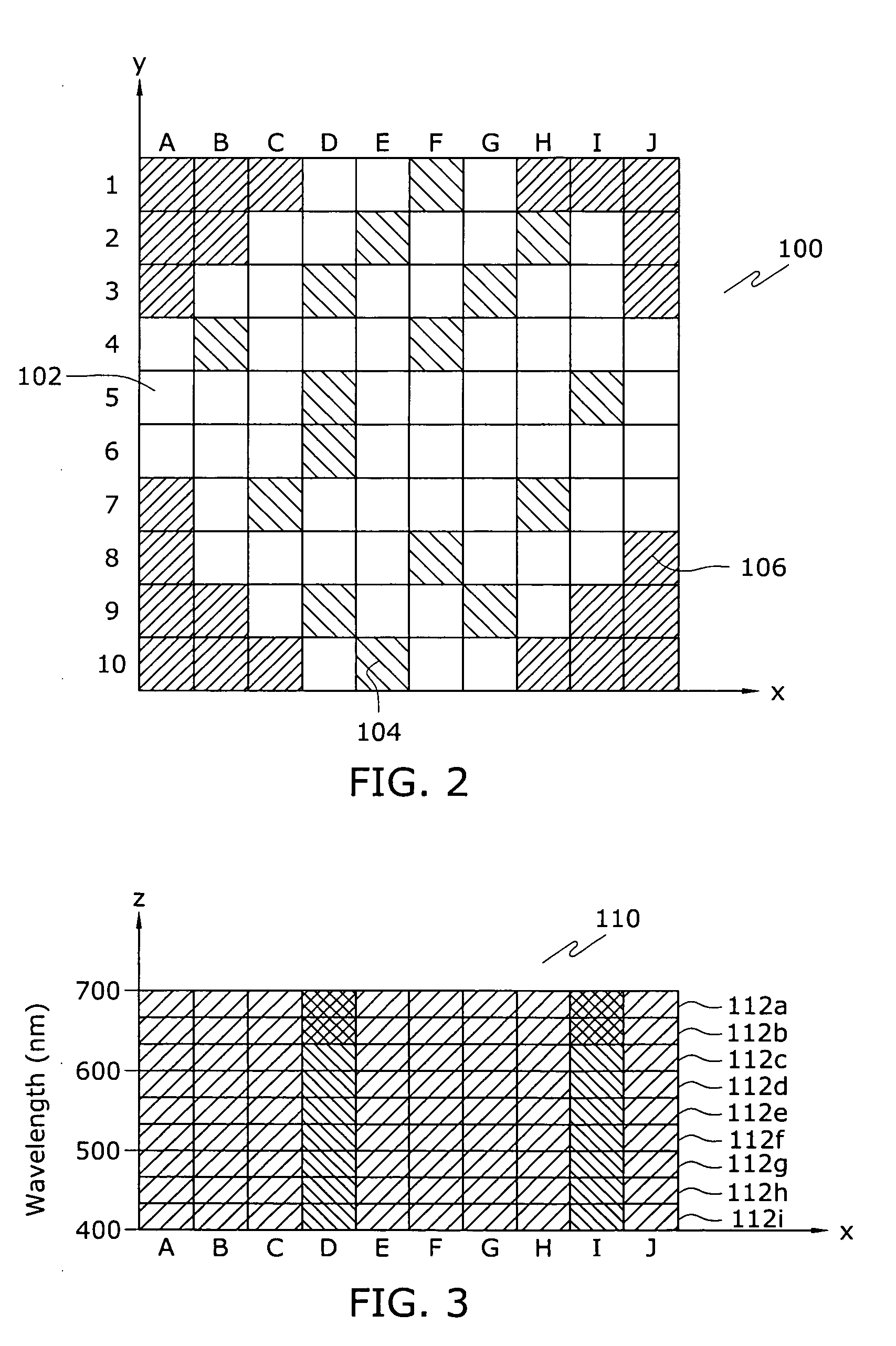

Apparatus and method for inspecting golf balls using spectral analysis

A method for inspecting golf balls is disclosed. An imager such as a camera captures a spectral image of the golf ball. The spectral image is captured line-by-line as the golf ball rotates. The lines are then packed together to form a three-dimensional spectral image of the golf ball showing full spectral information for every pixel. The resultant three-dimensional spectral image is then analyzed, such as using a pattern matching or threshold analysis tool. If a golf ball passes the inspection, it is permitted to advance in the processing. If the golf ball does not pass the inspection, it may be diverted. This inspection system is capable of detecting very subtle color differences, so the system is particularly applicable for use in inspecting primer coat coverage.

Owner:ACUSHNET CO

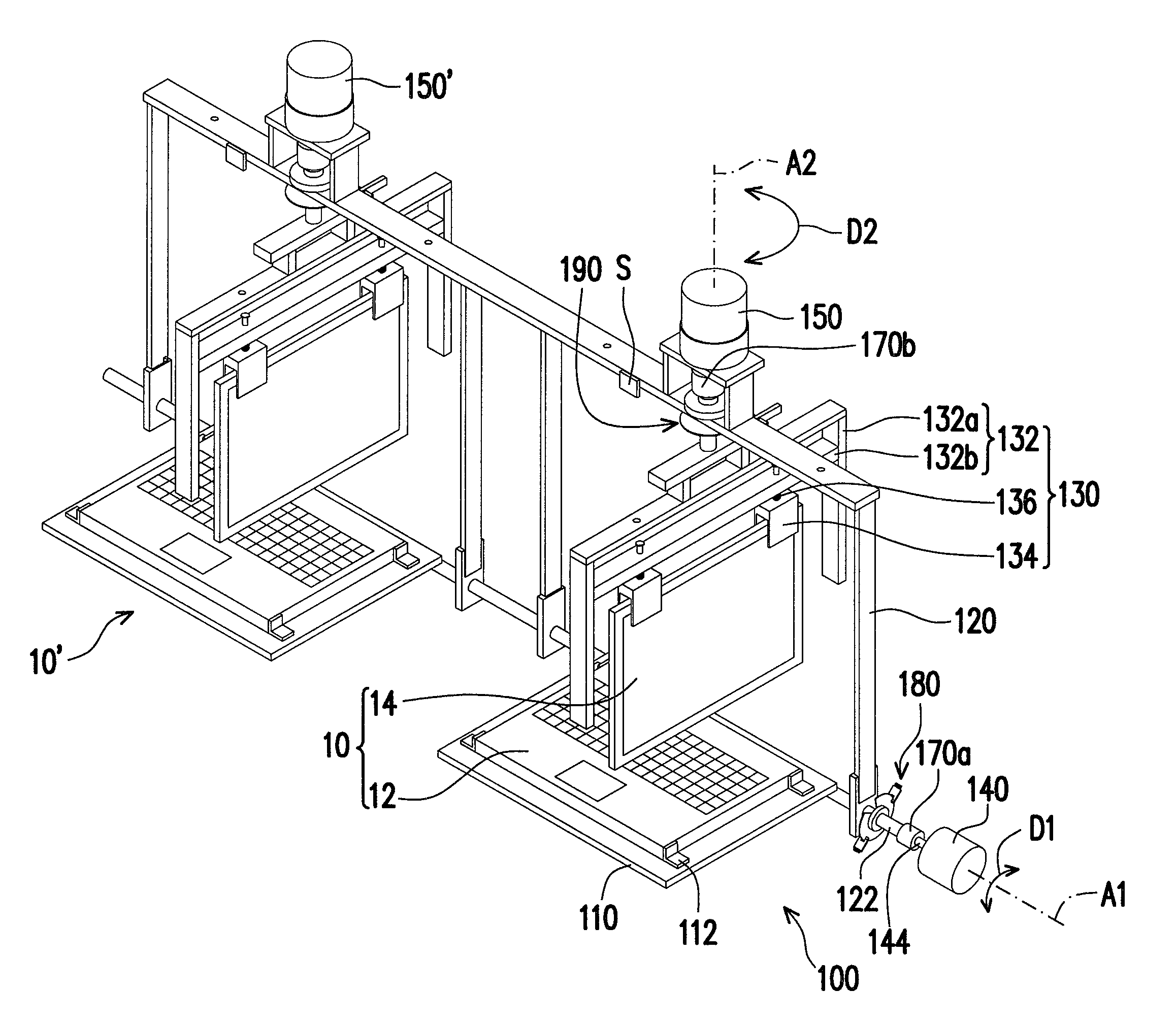

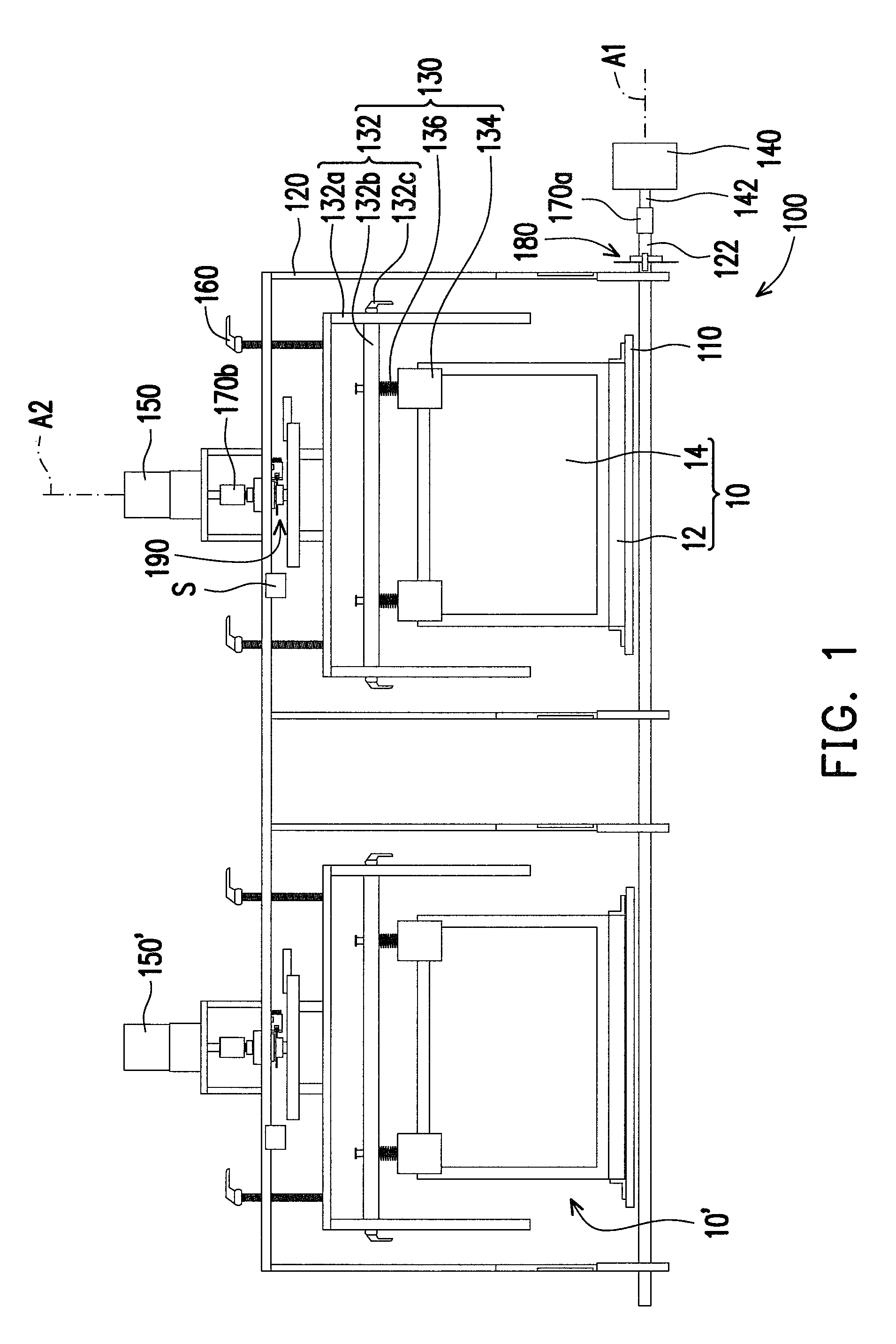

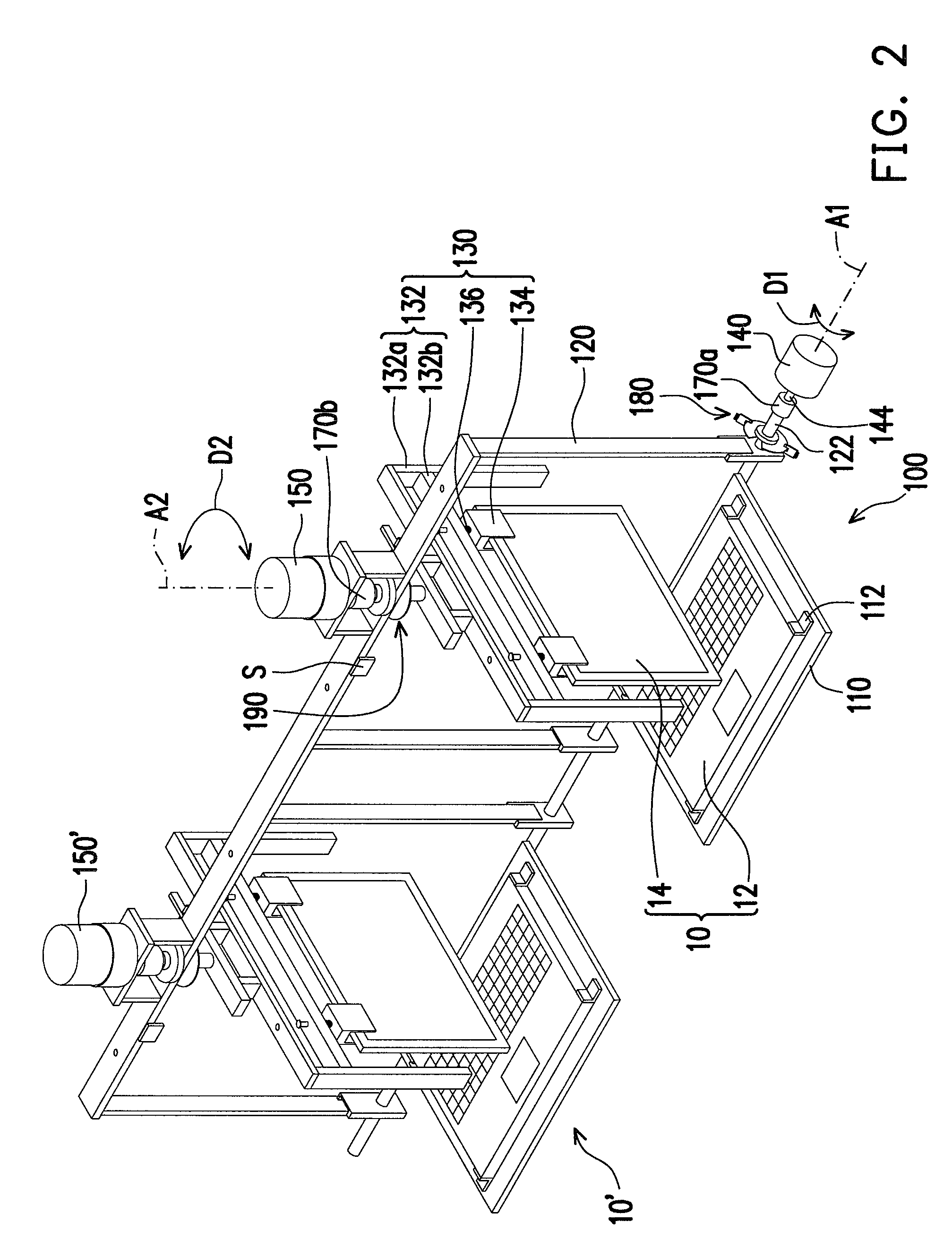

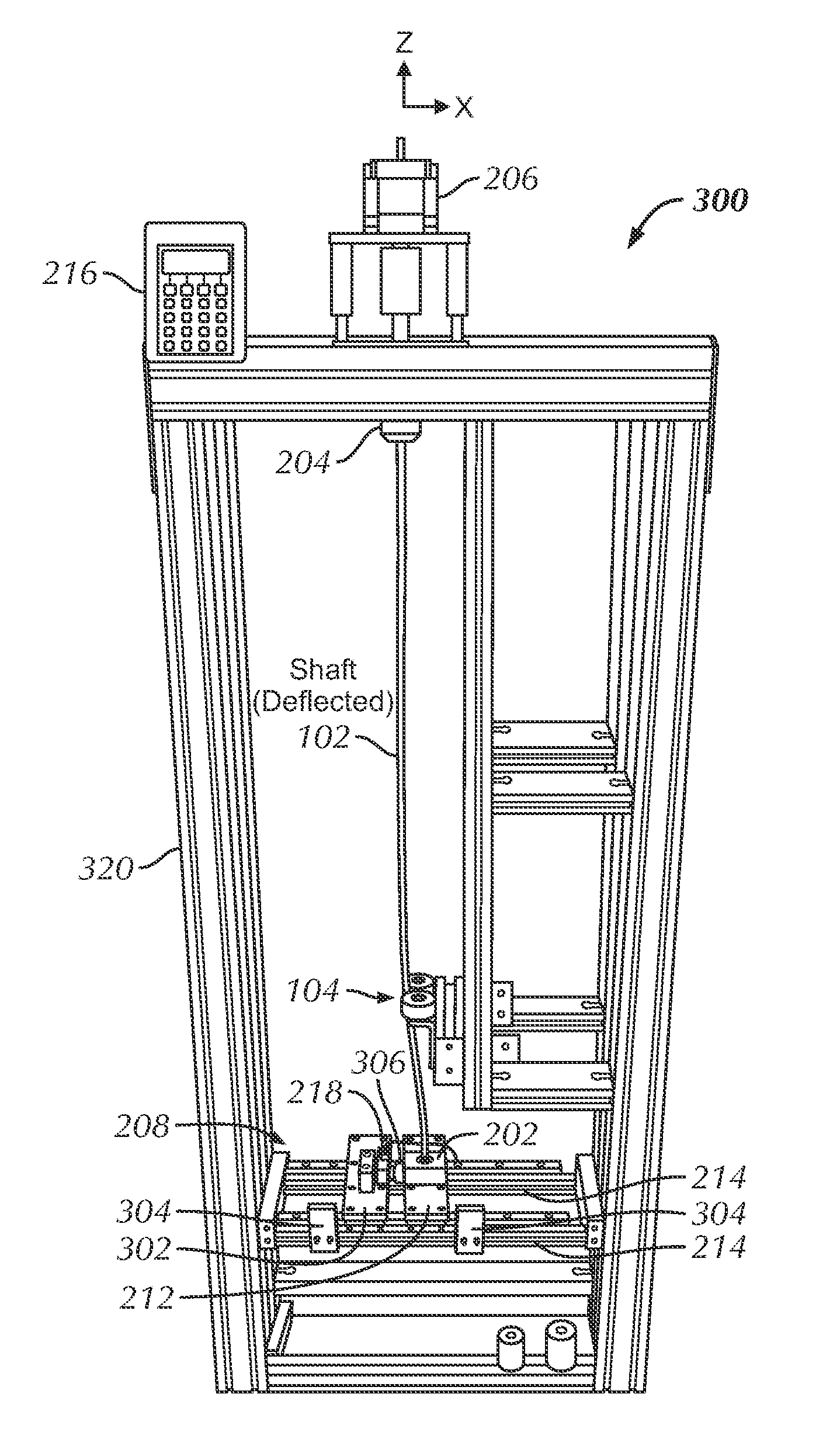

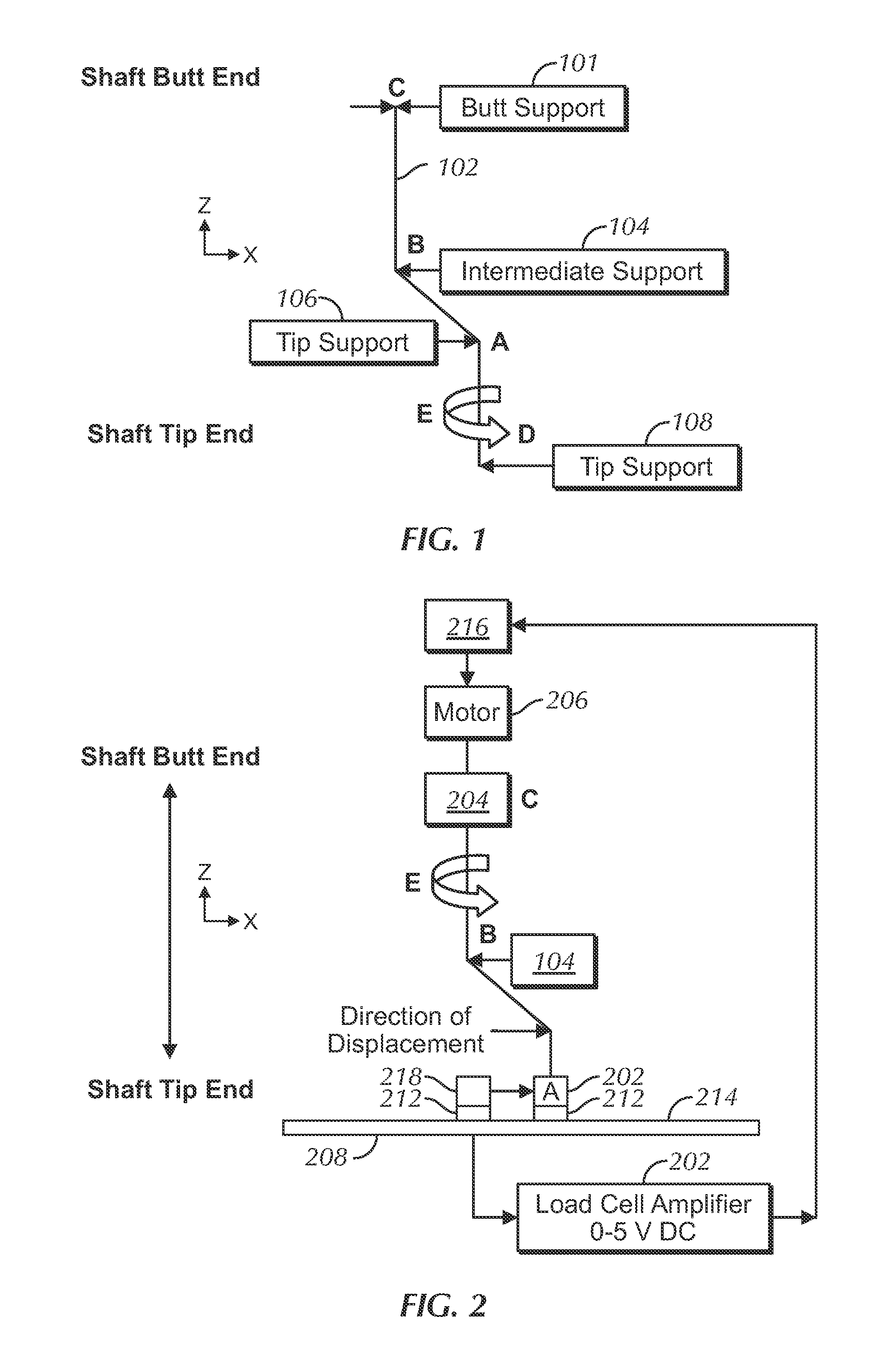

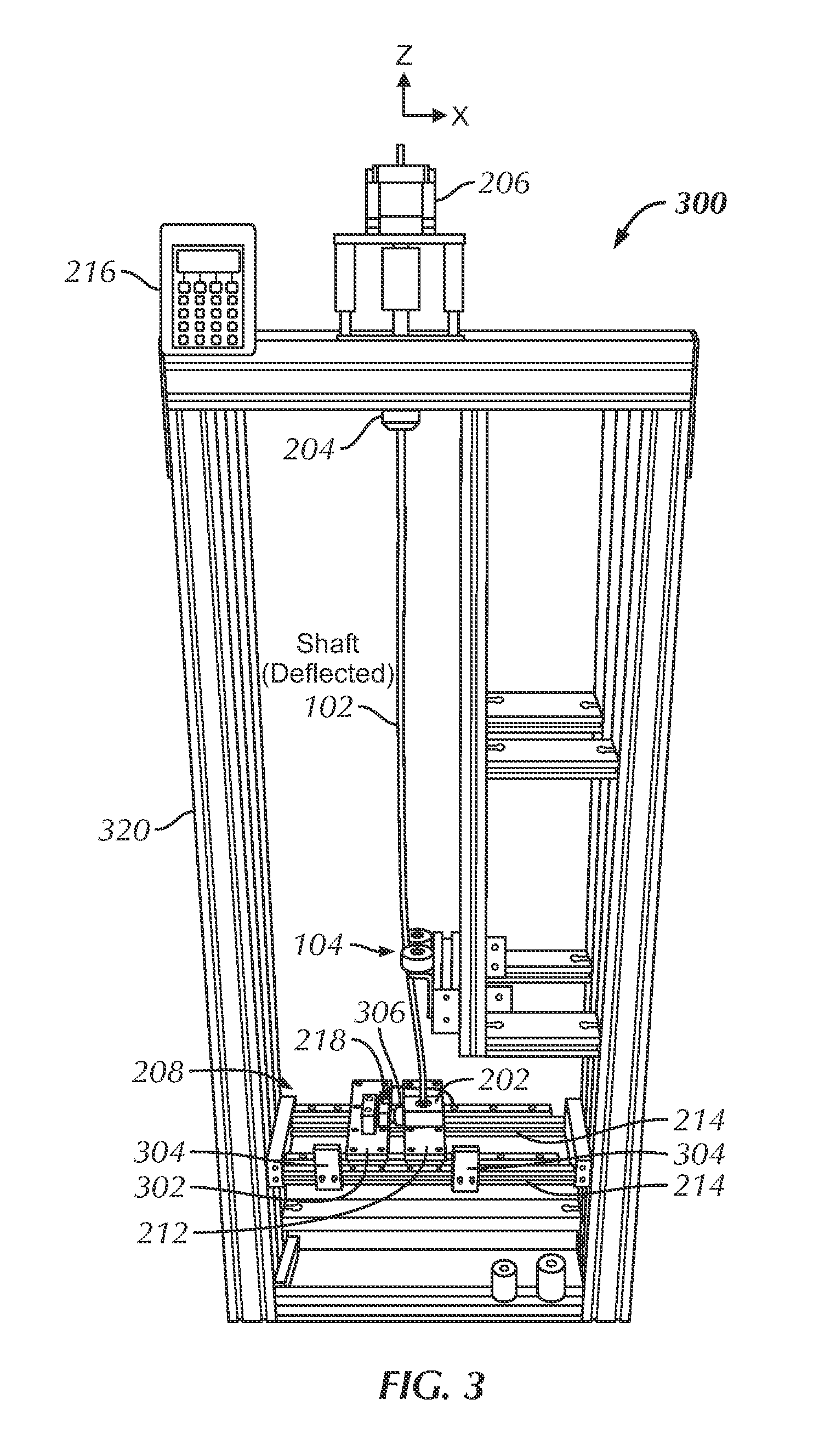

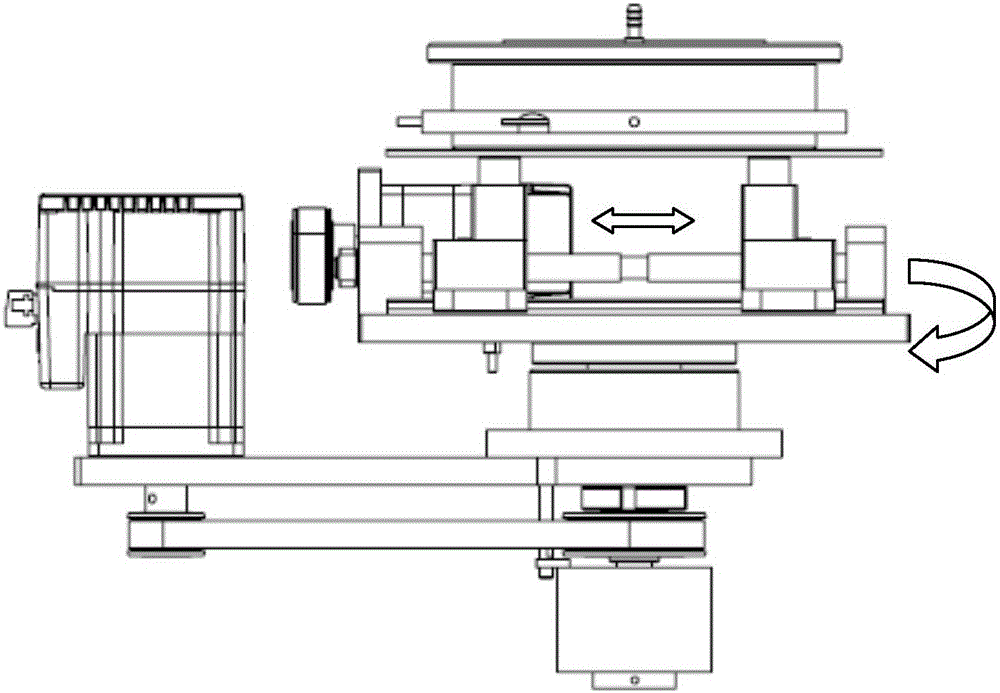

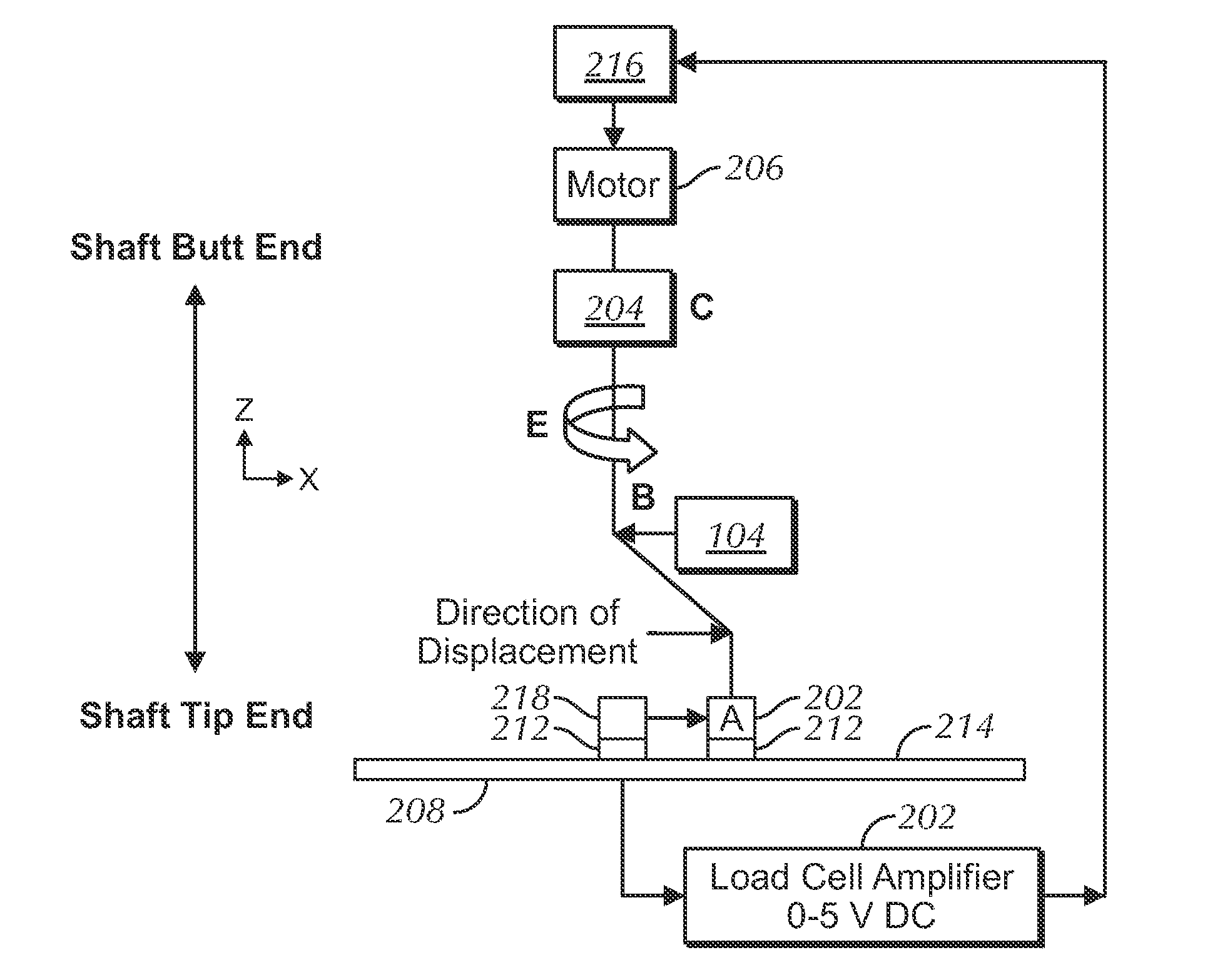

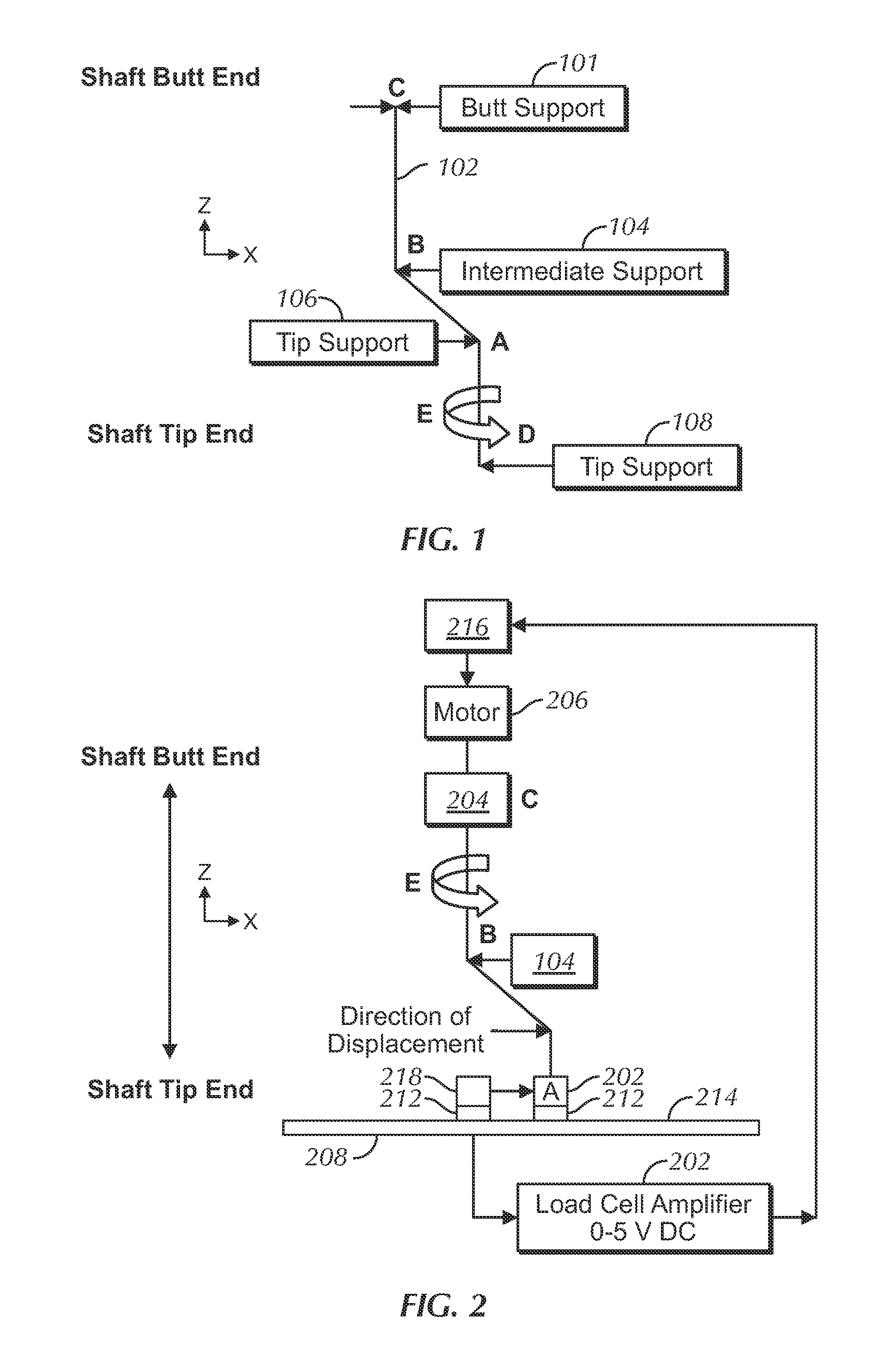

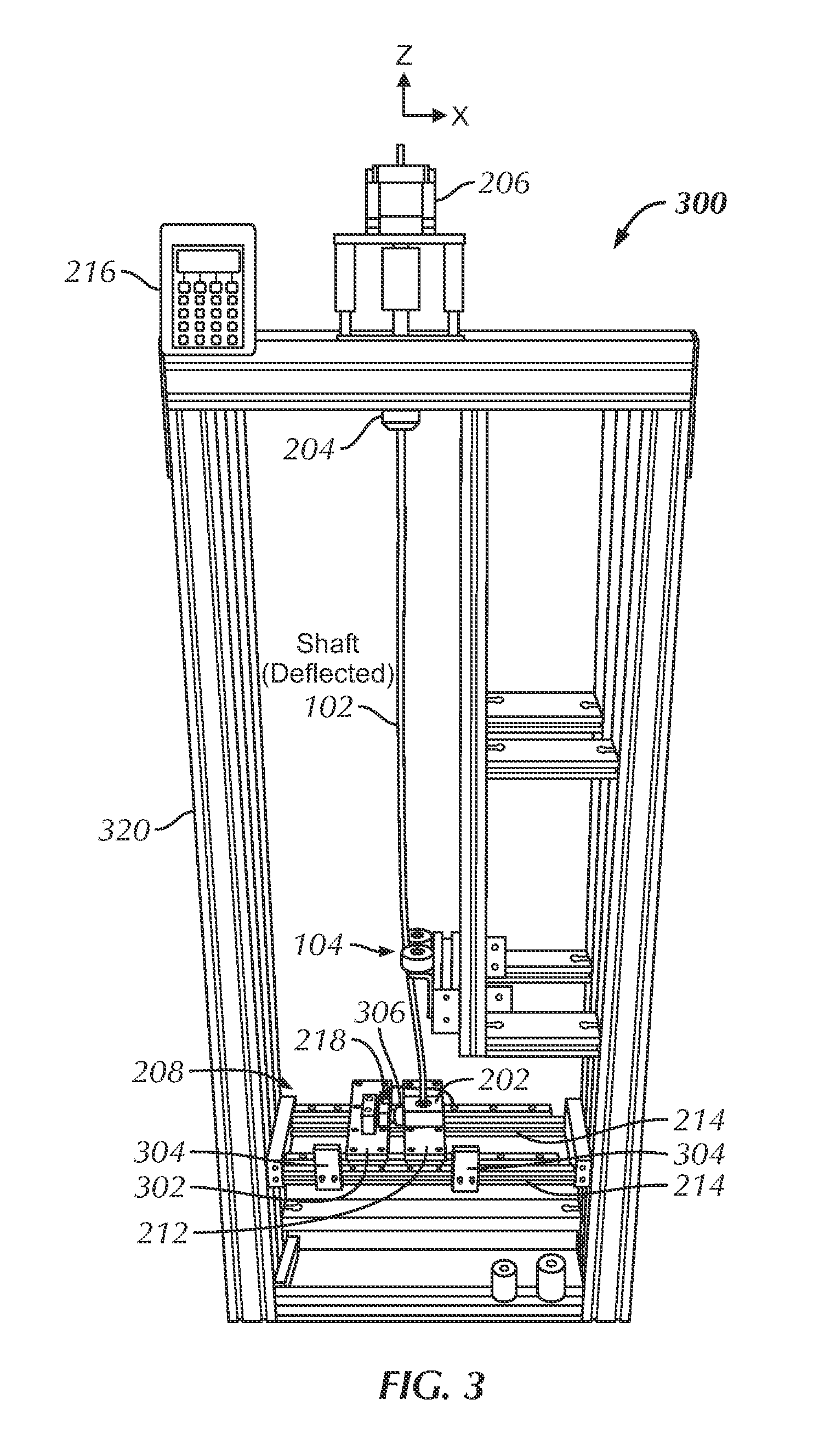

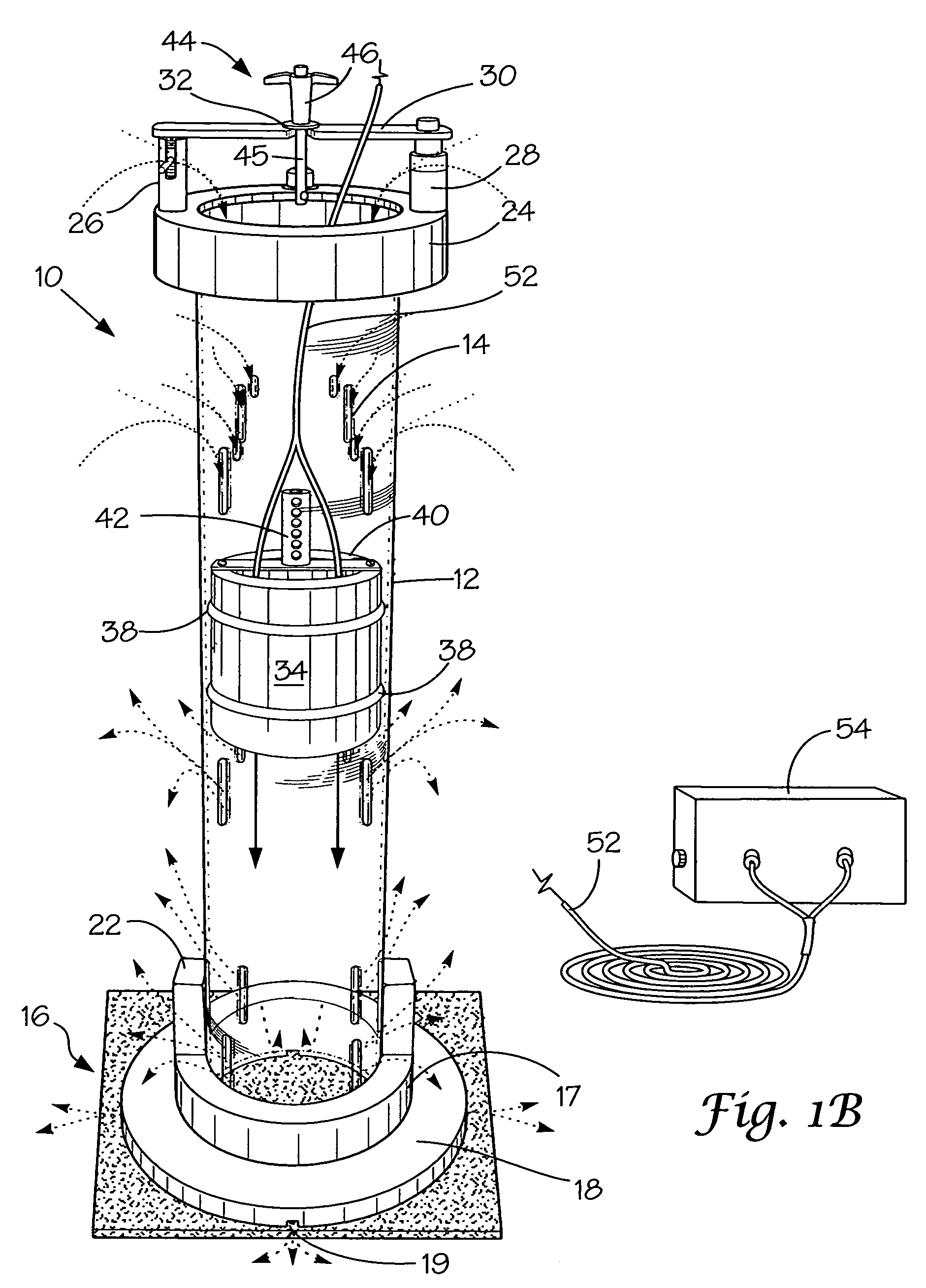

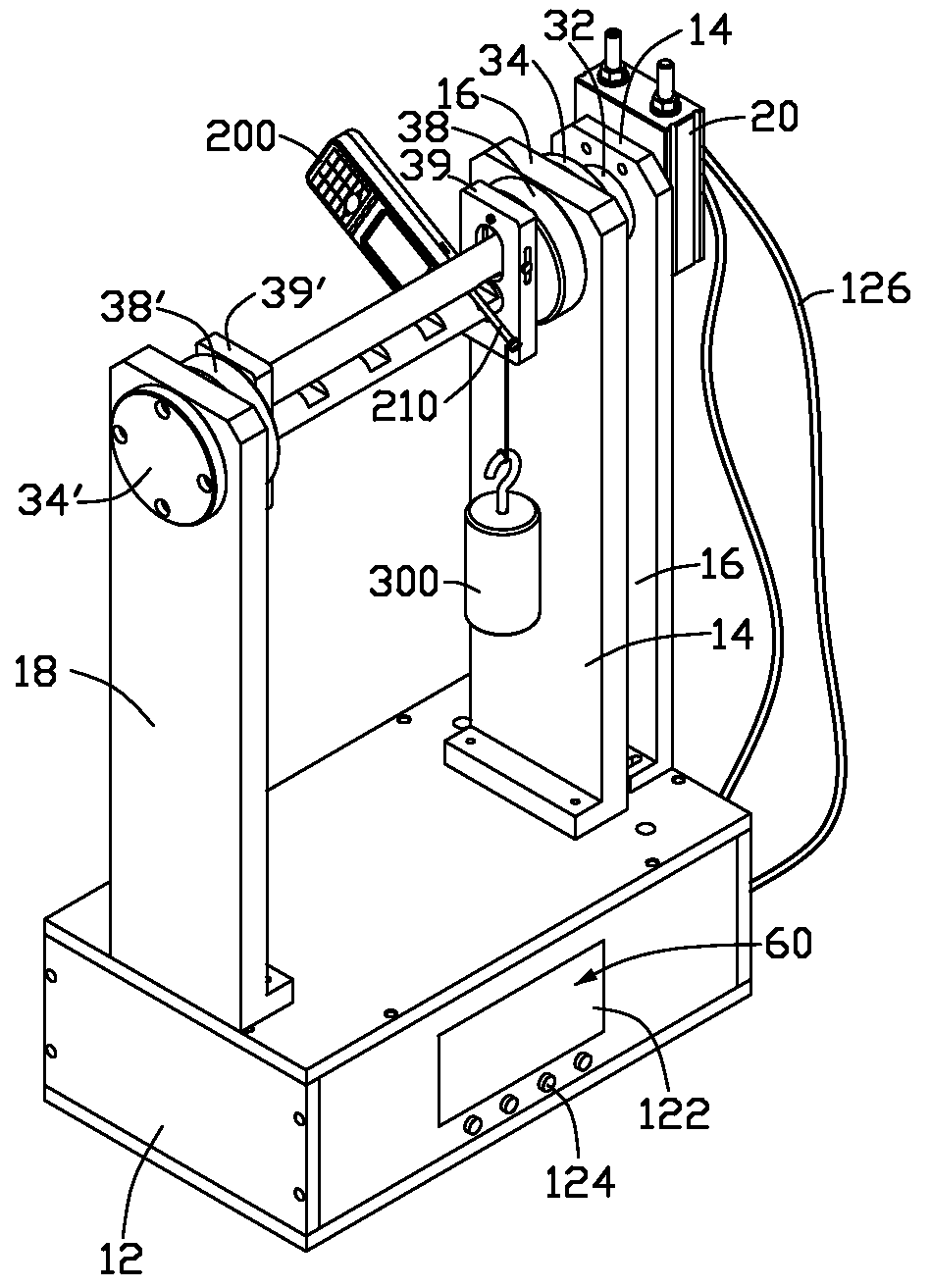

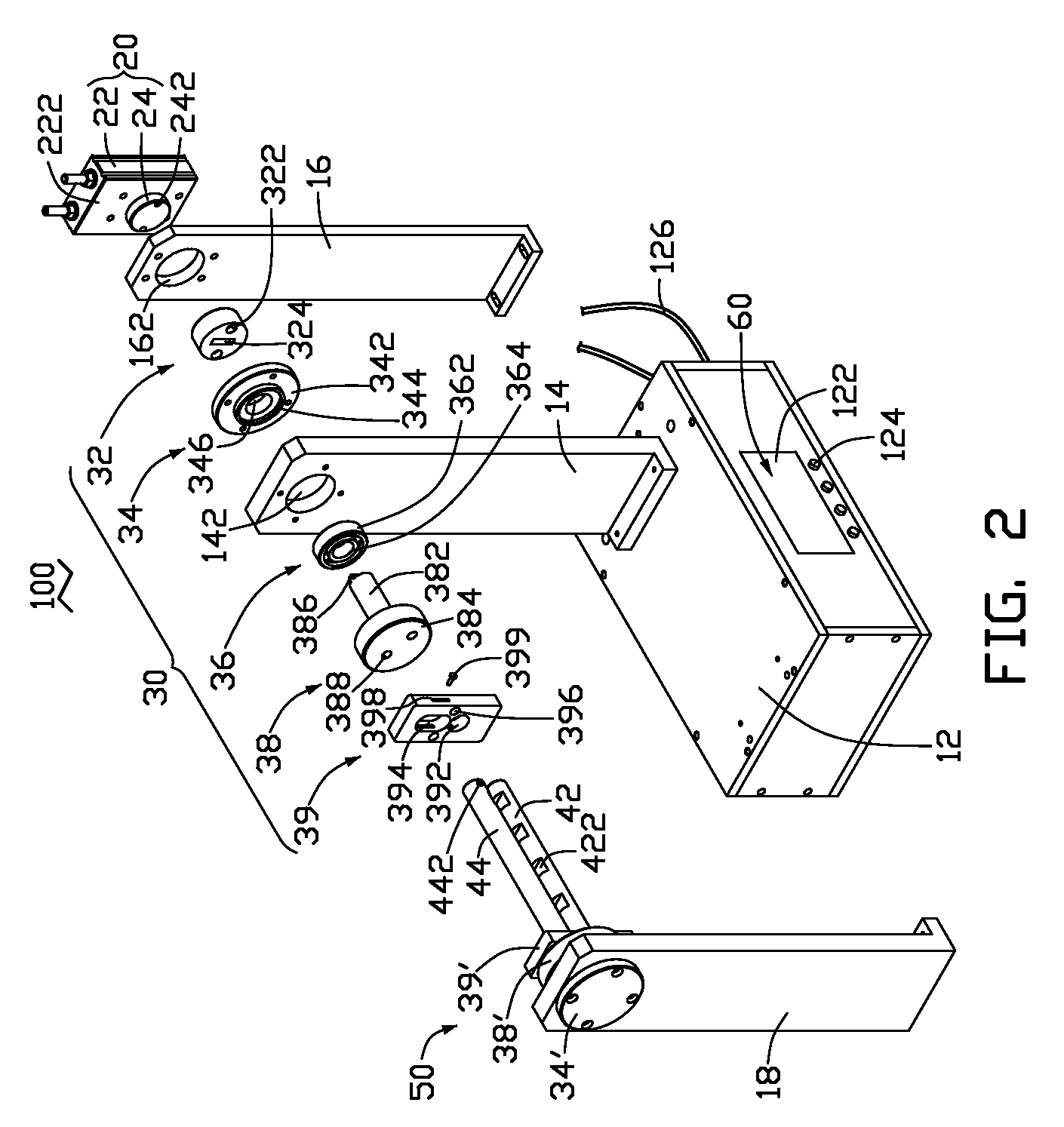

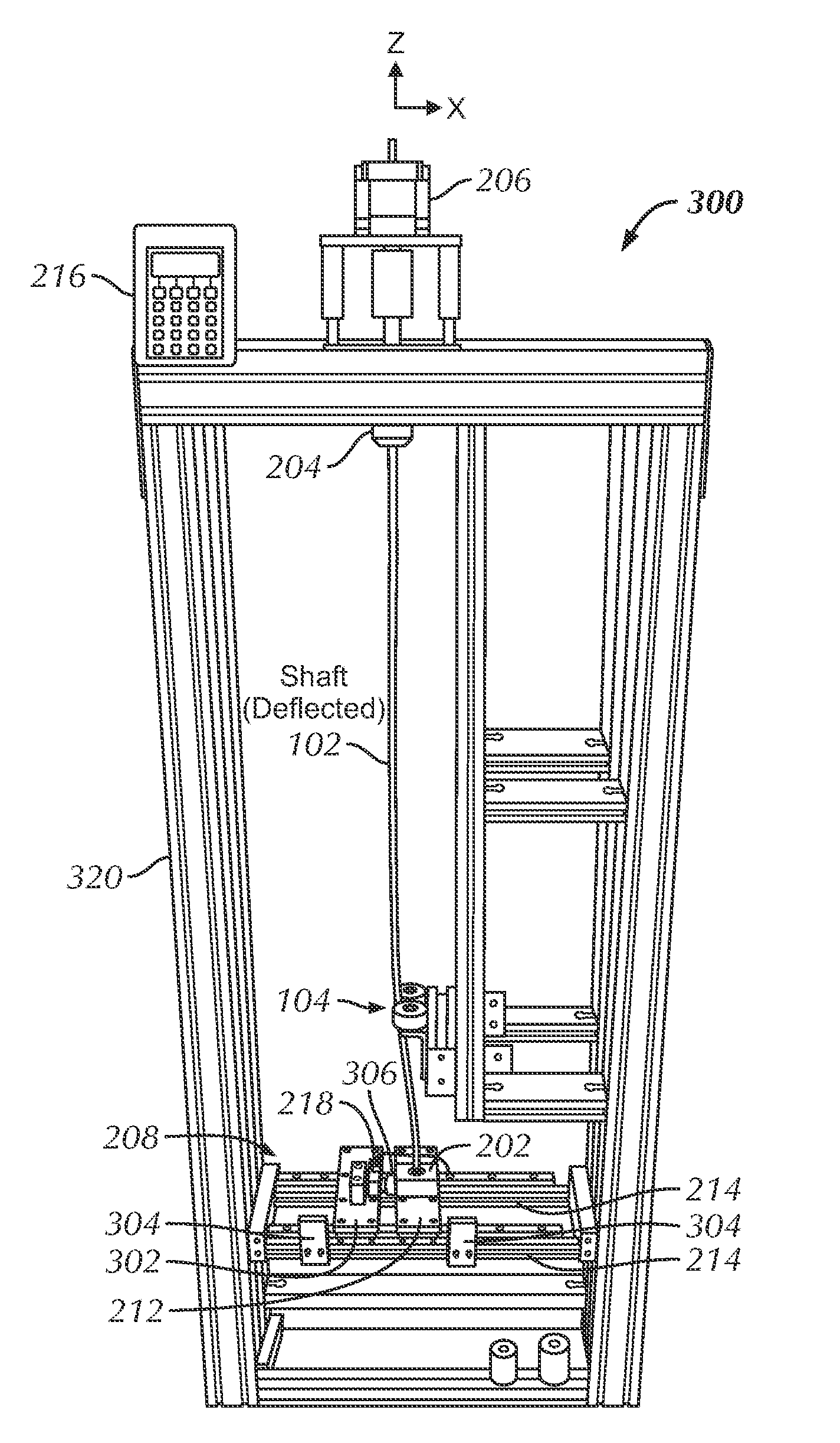

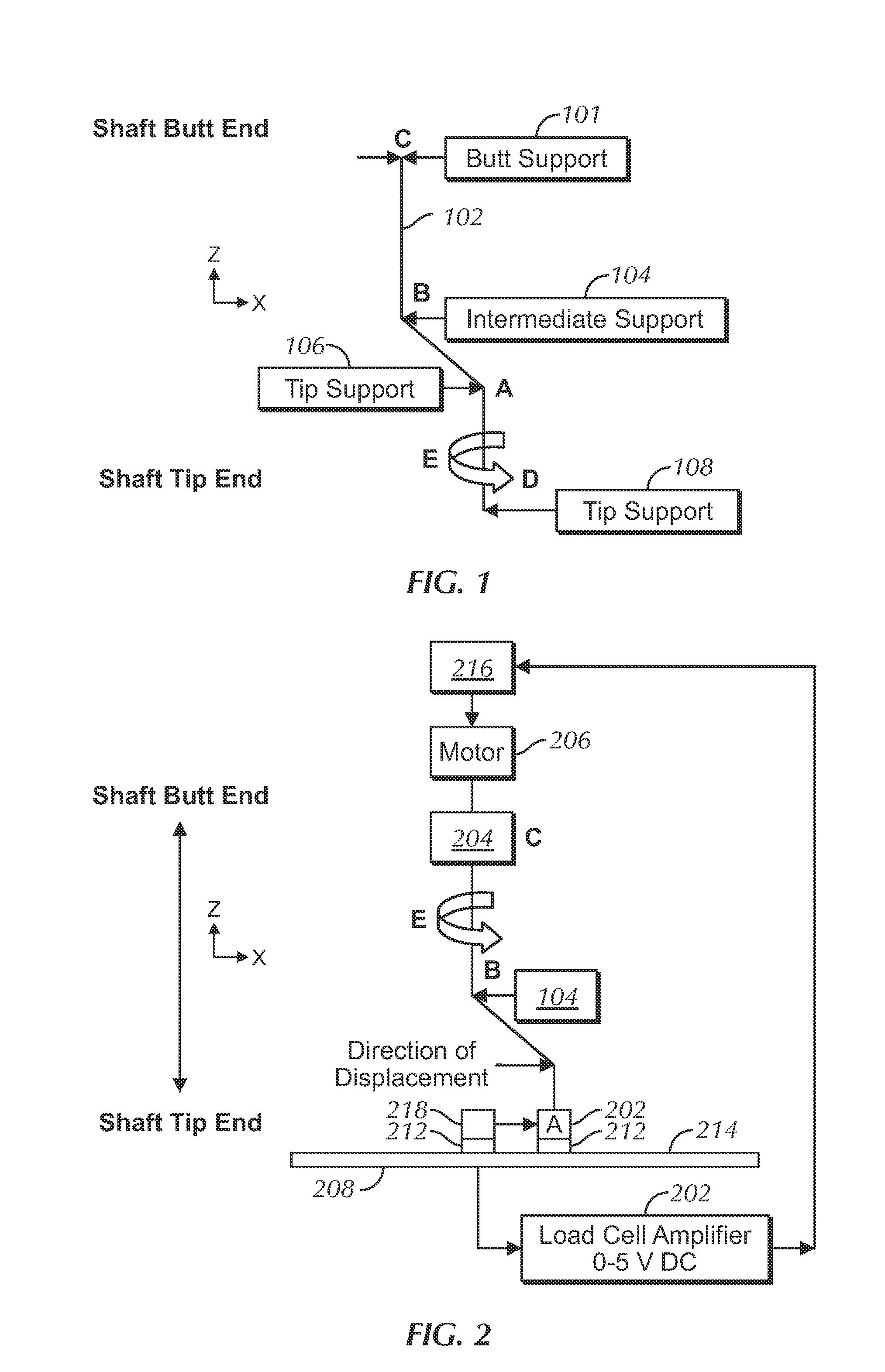

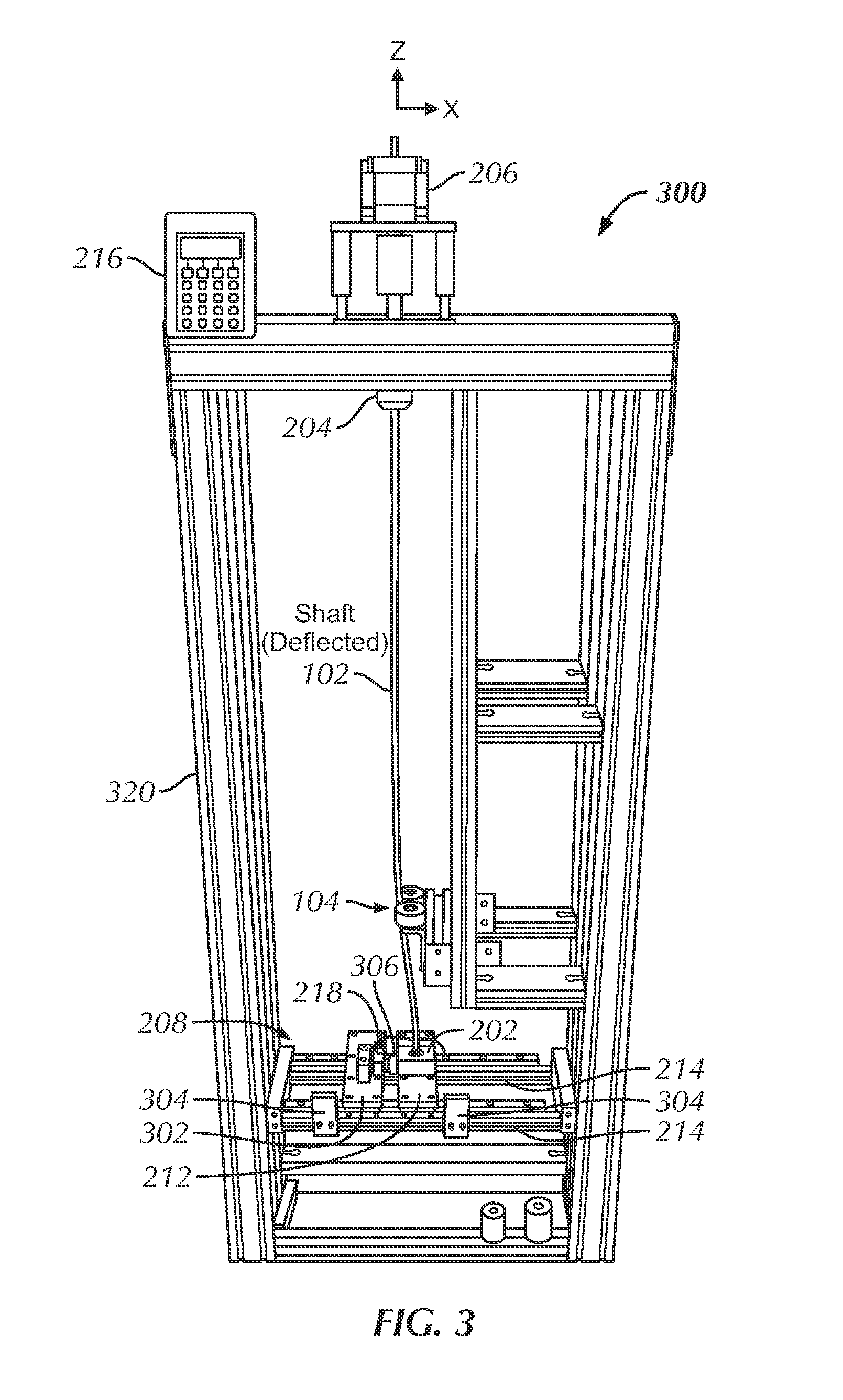

Method and Apparatus for Testing Shafts

ActiveUS20080264179A1Force measurementMaterial strength using steady bending forcesActuatorGolf Ball

Methods and apparatus are provided for testing shafts, such as golf club shafts. In one embodiment, the invention can be characterized as a shaft tester comprising: a frame; a first shaft support supporting a first portion of a shaft at a first fixed position; a second shaft support supporting a second portion of the shaft at a second fixed position; and a third shaft support supporting a third portion of the shaft at a third fixed position. An actuator couples to the third shaft support to displace the third portion relative to the first and second portions to deflect the shaft. A sensor couples to one of the first, second and third supports outputting a signal corresponding to a force exerted by the shaft due. A controller controls displacement of the shaft. In some embodiments, the shaft is rotated while being deflected.

Owner:FUJIKURA COMPOSITE AMERICA

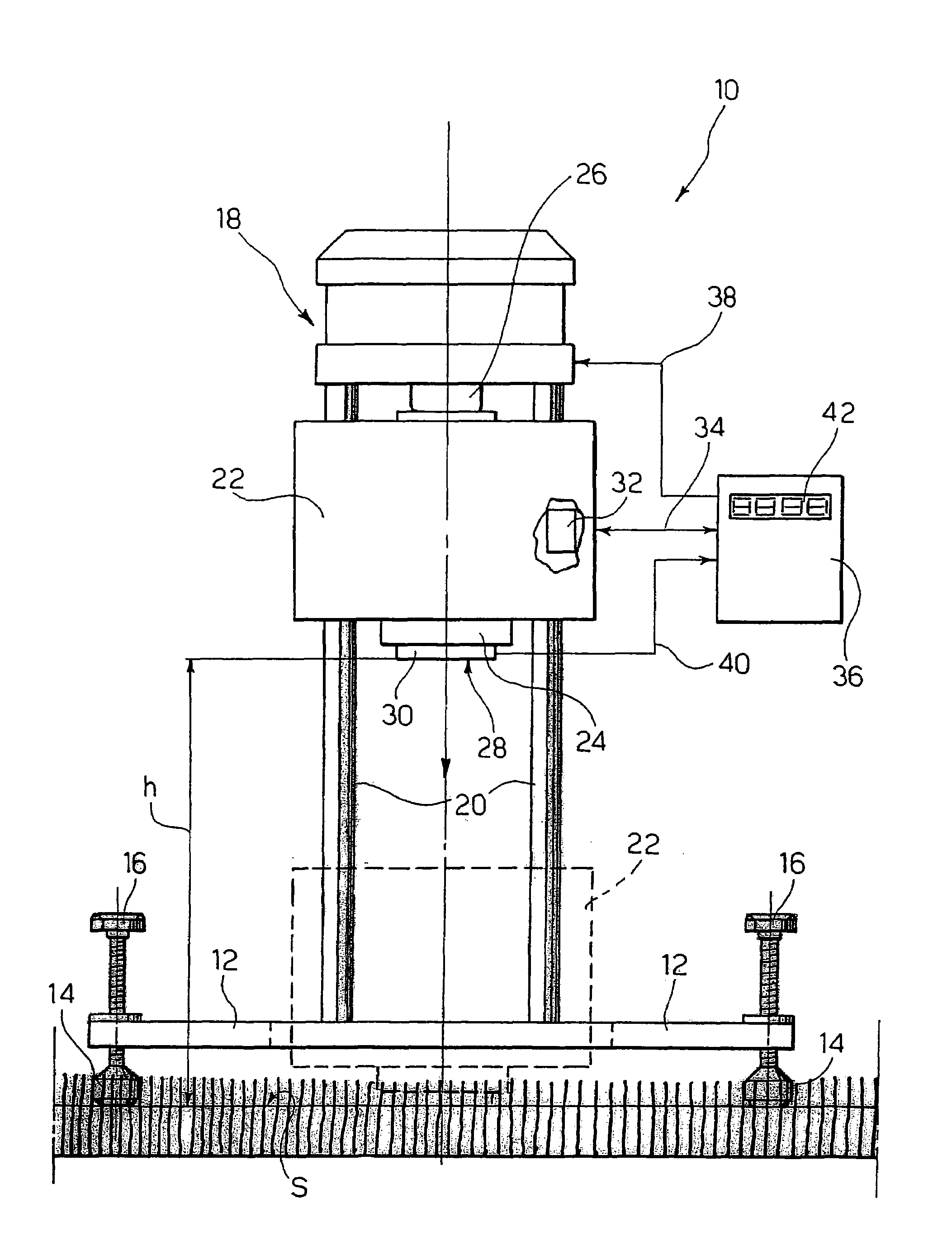

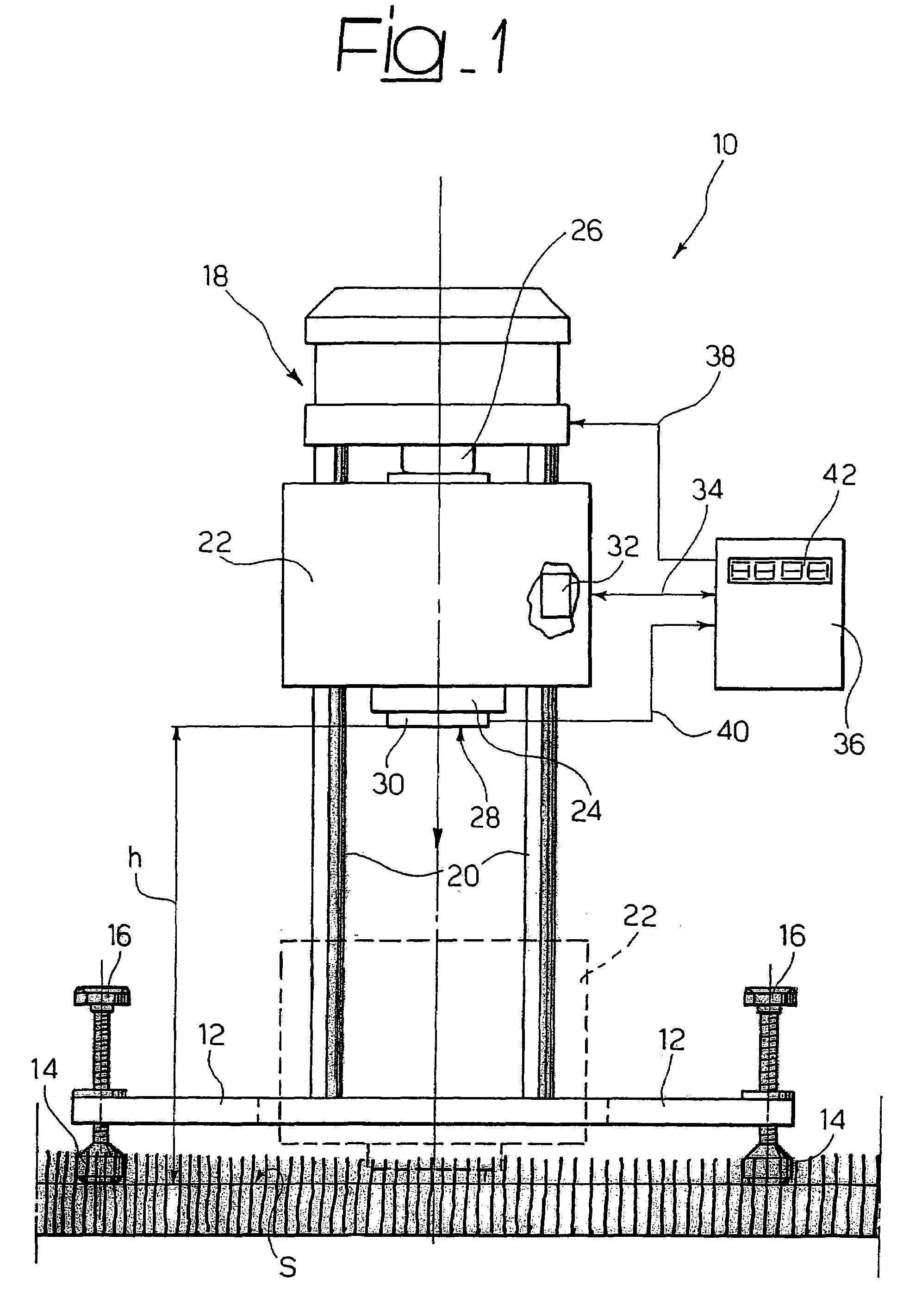

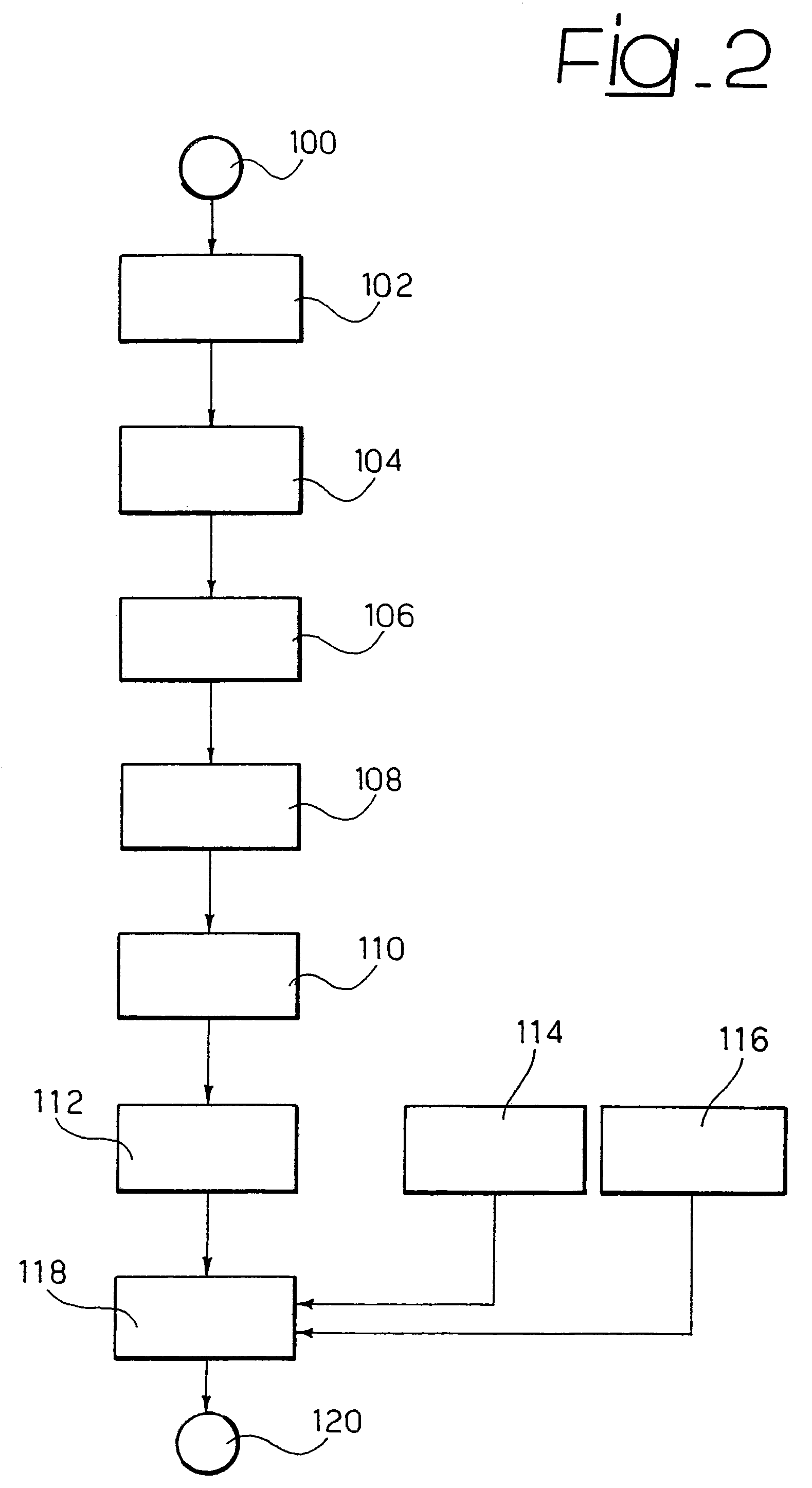

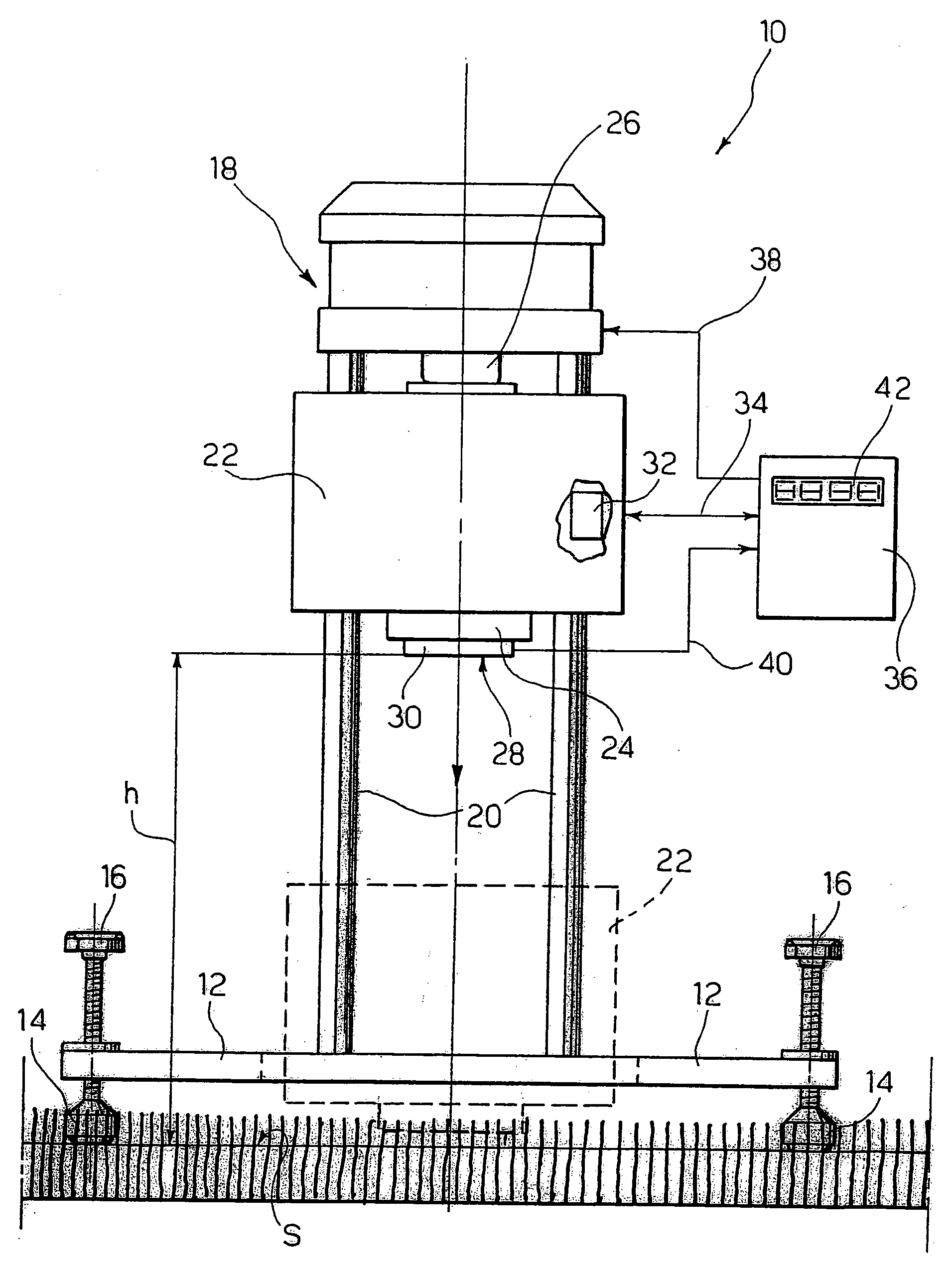

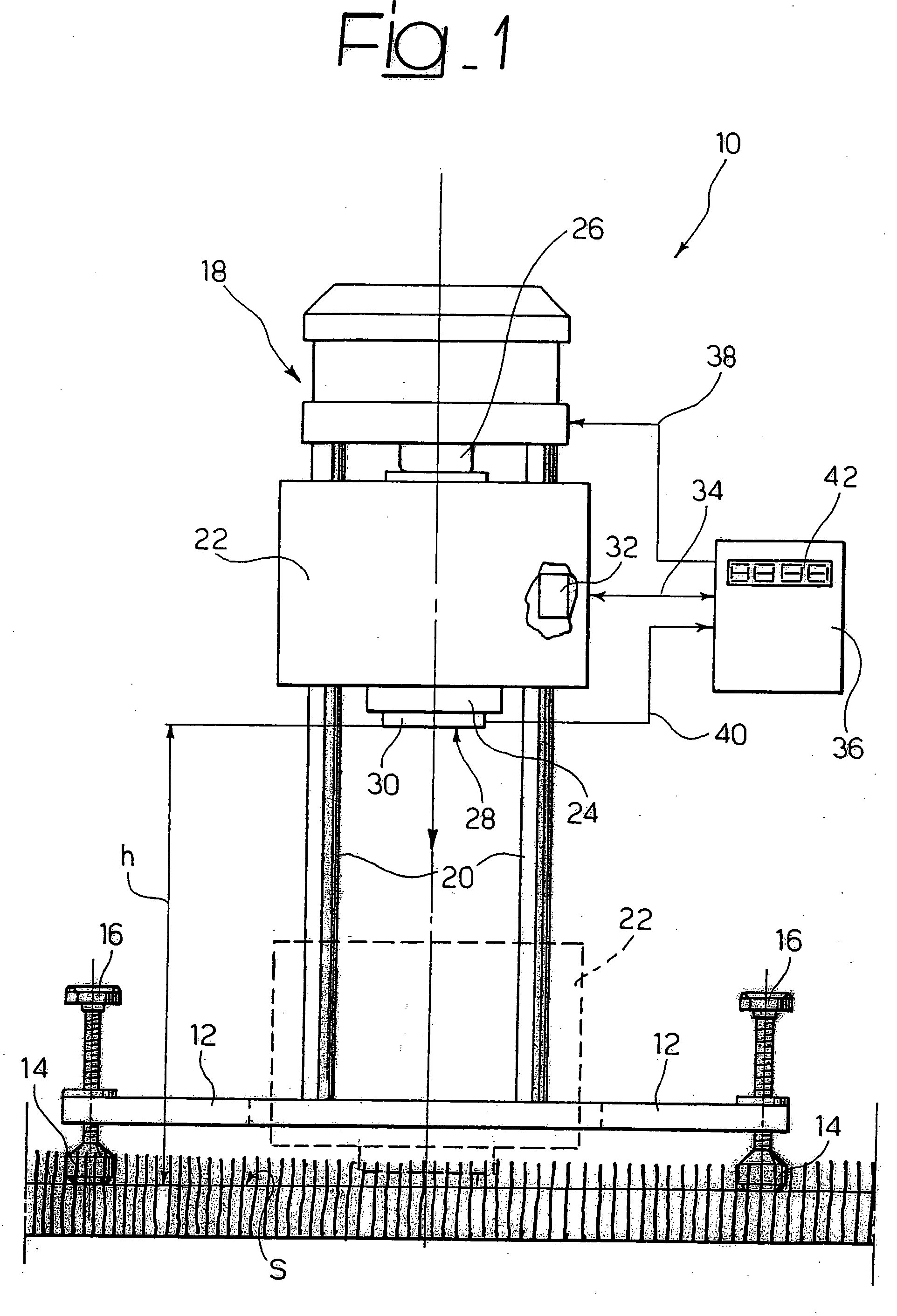

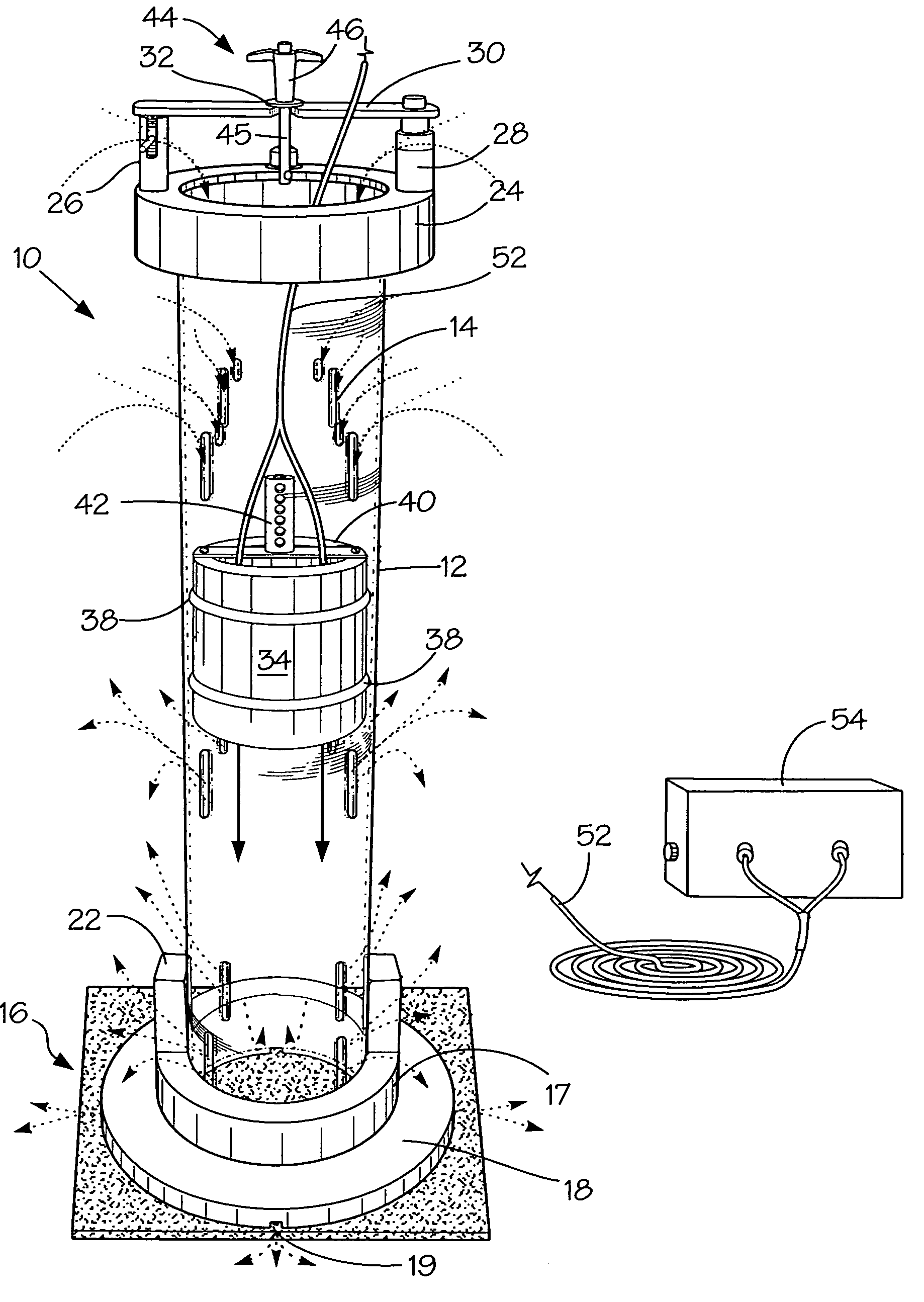

Method and instrument for characterizing treading surfaces, for instance for realizing synthetic turf surfaces

InactiveUS7137285B2Reliable characterizationEarth material testingMaterial strength using tensile/compressive forcesBiomechanicsSurface recovery

An instrument (“artificial athlete”) for characterizing, from the biomechanical standpoint, a treading surface, such as natural grass cover or synthetic grass flooring, is configured for: dropping a weight from a given height on the surface, producing the conversion of kinetic energy of falling of the weight into deformation energy of the surface, the deformation energy being able to be restored by the surface to the weight, bringing about its return / bouncing back upwards; and detecting at least one parameter representing the process of restitution of the deformation energy by the surface to the weight, the parameter identifying the characteristics of tread of the surface.

Owner:MONDO SPA

Method and instrument for characterizing treading surfaces, for instance for realizing synthetic turf surfaces

InactiveUS20050178184A1Reliable characterizationEarth material testingMeasurement/indication equipmentsBiomechanicsSurface recovery

Owner:MONDO

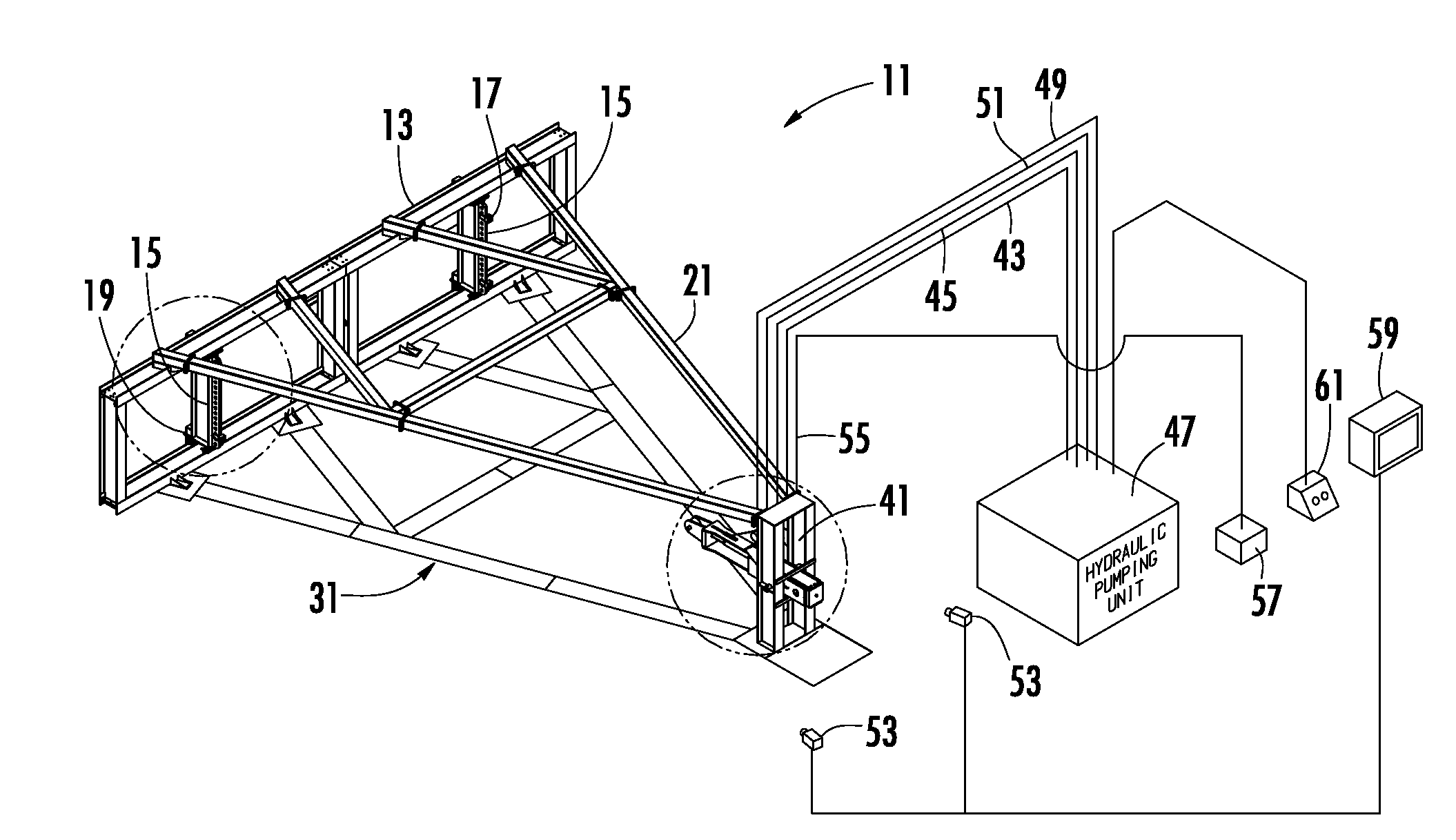

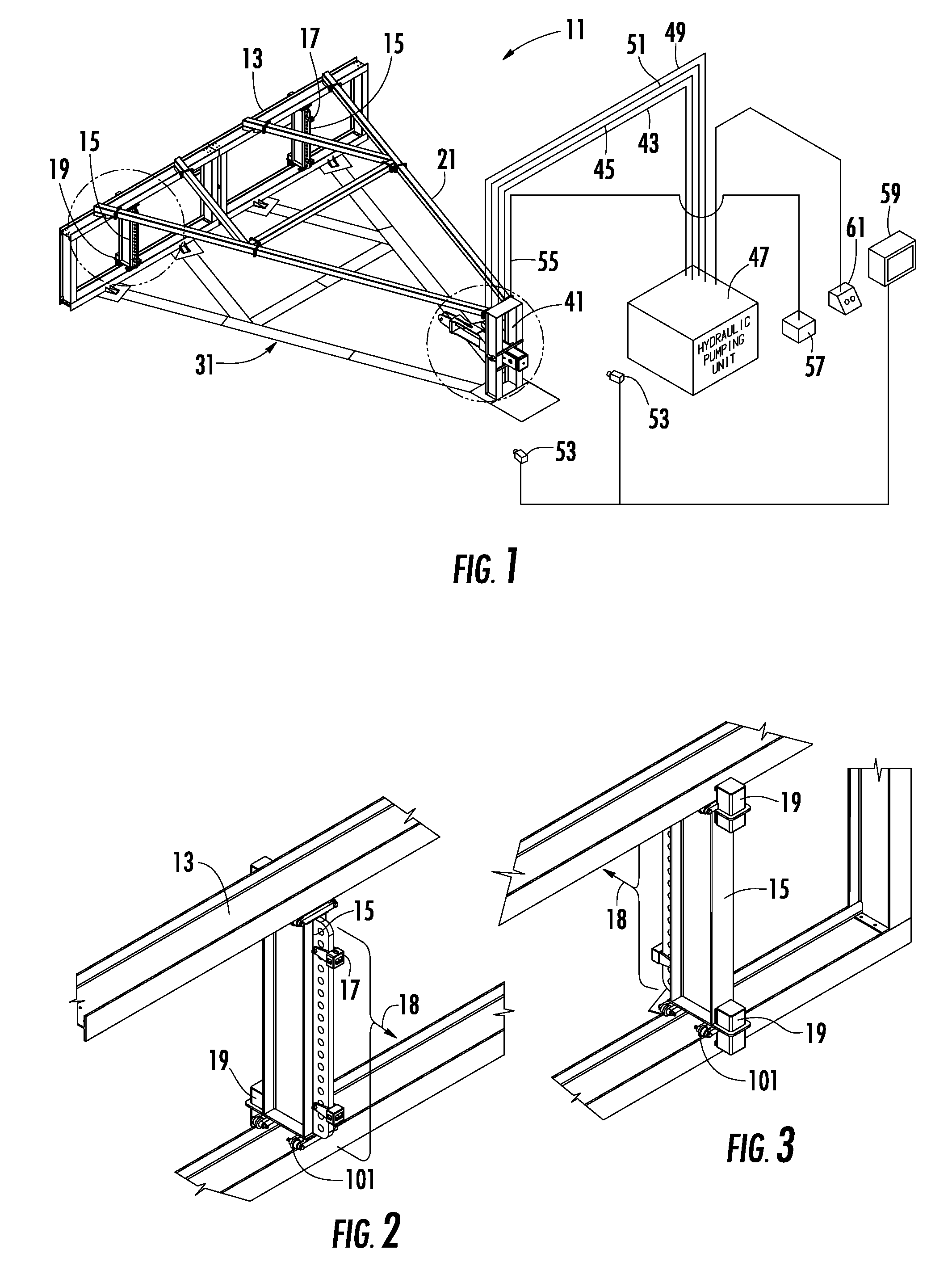

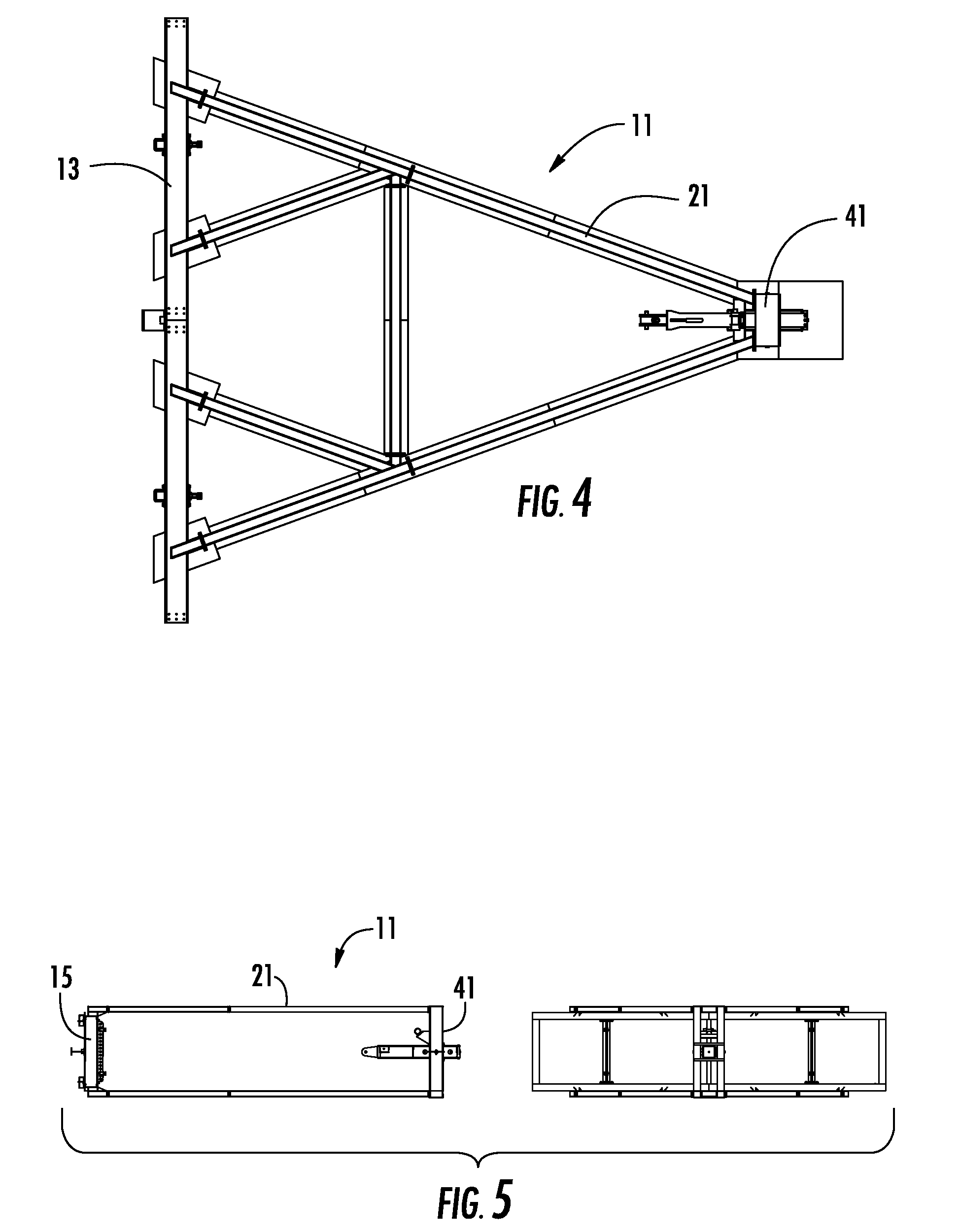

Load test system

ActiveUS20090064793A1Material strength using tensile/compressive forcesTesting manufactured objectsHydraulic cylinderPower station

A load test system includes a test bed frame which extends horizontally along a first axis and includes two rolling beams moveably mounted securely in the test bed frame for being moved to desired position. The rolling beams have plural attachment locations for attaching a test lift device. A hydraulic power station is located spaced perpendicular from the test bed frame along a second axis and includes a hydraulic cylinder with a line connected to the hydraulic cylinder at one end, which is connectable to a test device at another end for applying a load when the test device is attached to the test bed. Beam members connect the hydraulic power station and the test bed frame to form a rigid structure.

Owner:TANDEMLOC

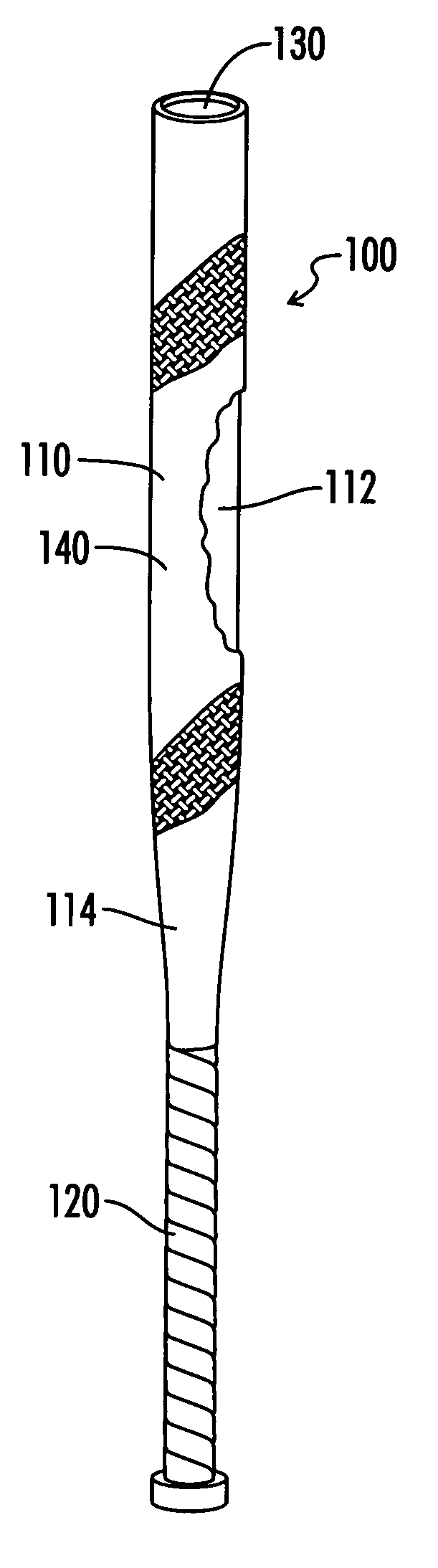

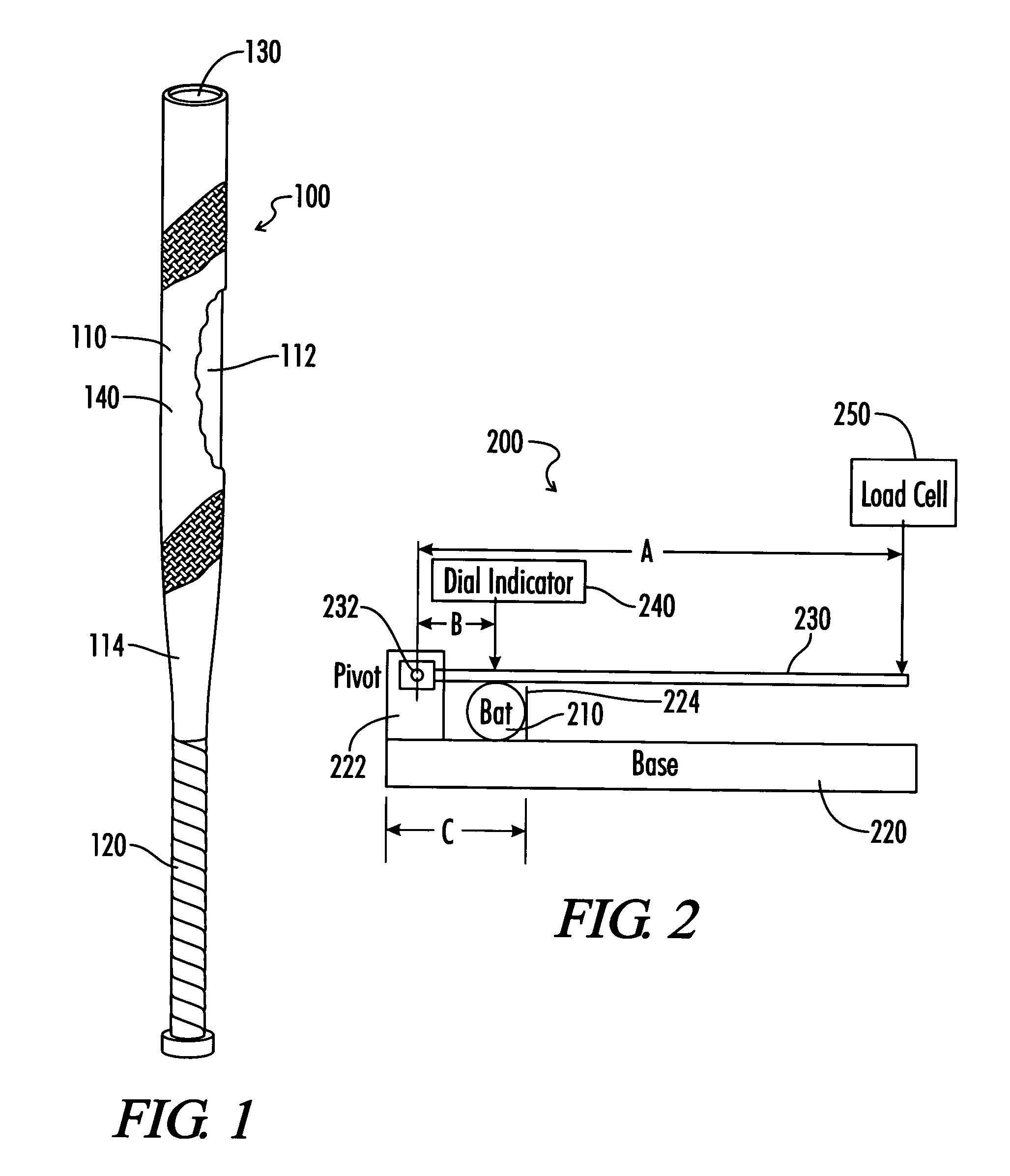

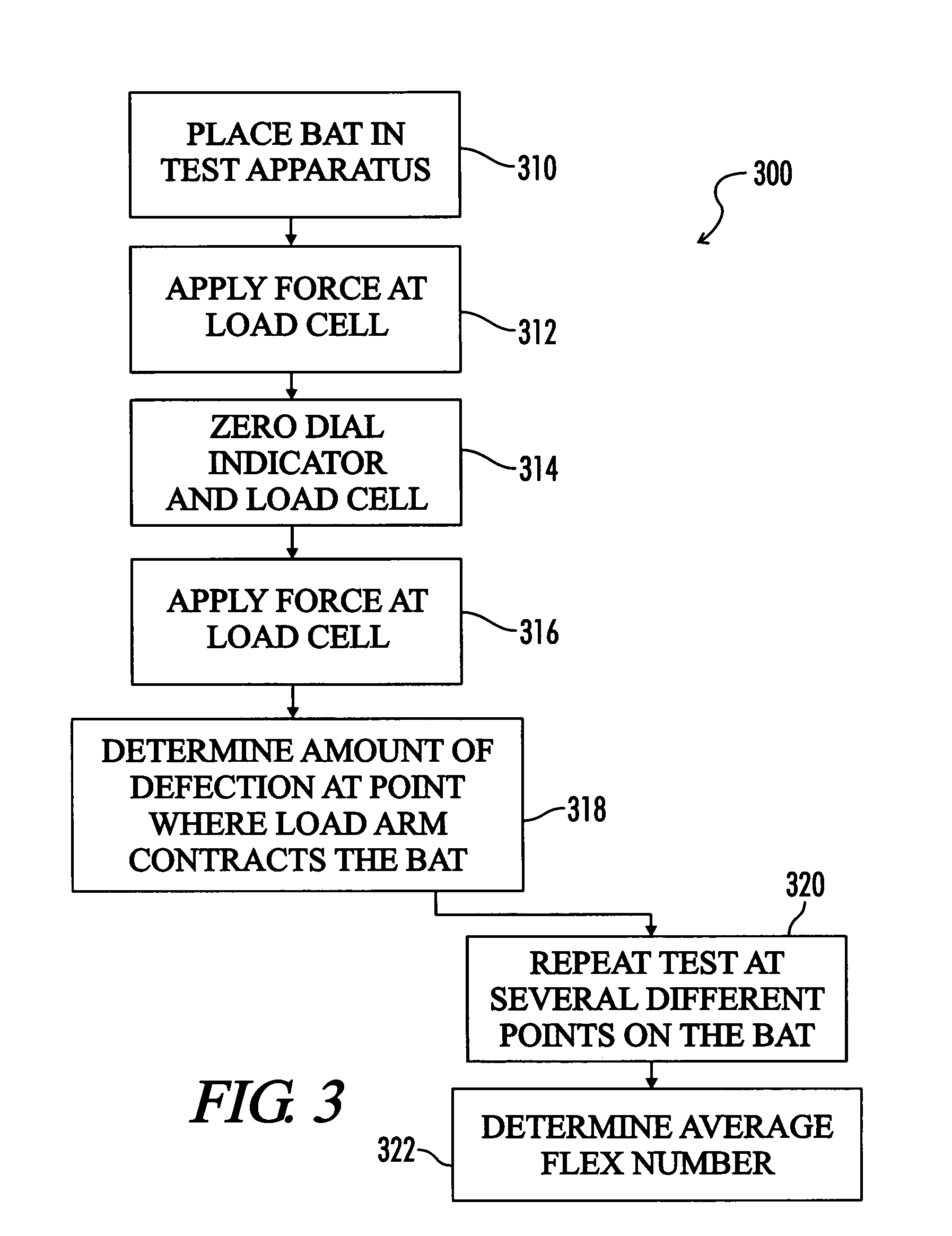

Testing apparatus and method for composite articles

InactiveUS7017427B1Low densityDurableMaterial strength using tensile/compressive forcesTesting manufactured objectsLoad cellForce sensor

A testing apparatus for a composite material includes a base for holding the composite article, a load cell for placing a selected load on a portion of the composite article, and a displacement measuring device for measuring the amount of displacement for a selected load. In operation, a composite article is placed in a testing apparatus, a selected load is placed on the composite article, and the displacement of the composite article is measured.

Owner:MIKEN SPORTS

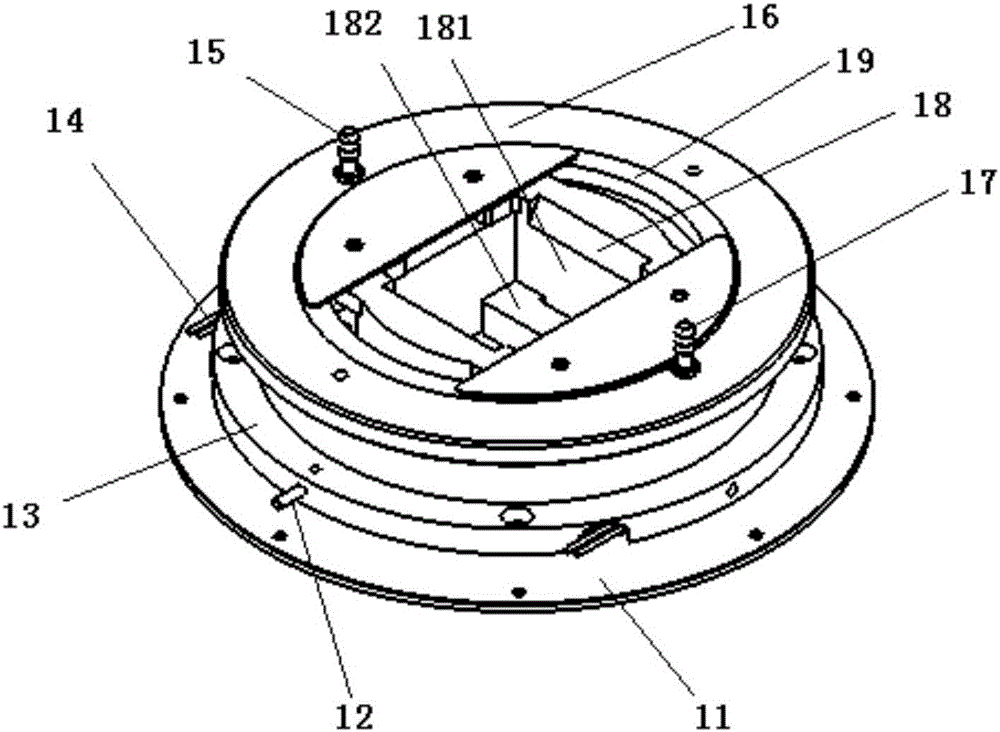

Full simulation chewing machine

ActiveCN106053730AFully fragmented and dissolvedFull dissolution releaseTesting manufactured objectsTesting foodHuman bodyAdditive ingredient

The invention discloses a full simulation chewing machine which comprises a left-and-right opening, closing and rotating assembly, a simulation oral cavity and chewing mechanical teeth. The left-and-right opening, closing and rotating assembly is arranged under the simulation oral cavity, and a first permanent magnet and a second permanent magnet which are arranged in the assembly are arranged to be opposite up and down; the upper chewing tooth (107) of the chewing mechanical teeth is aligned to a solution vessel (16) of the simulation oral cavity, that is to say, the solution vessel (16) serves as the lower chewing tooth (108). The full simulation chewing machine can simulate human body chewing actions such as up-and-down biting, left-and-right grinding, chewable gathering and turning by the cheeks and the tongue, the simulation degree is high, a food sample can be fully fragmented and dissolved, and therefore main ingredients in the food sample are fully dissolved out to be released. The device can be widely applied to research on release behaviors of the main ingredients in food samples.

Owner:CHINA TOBACCO YUNNAN IND +1

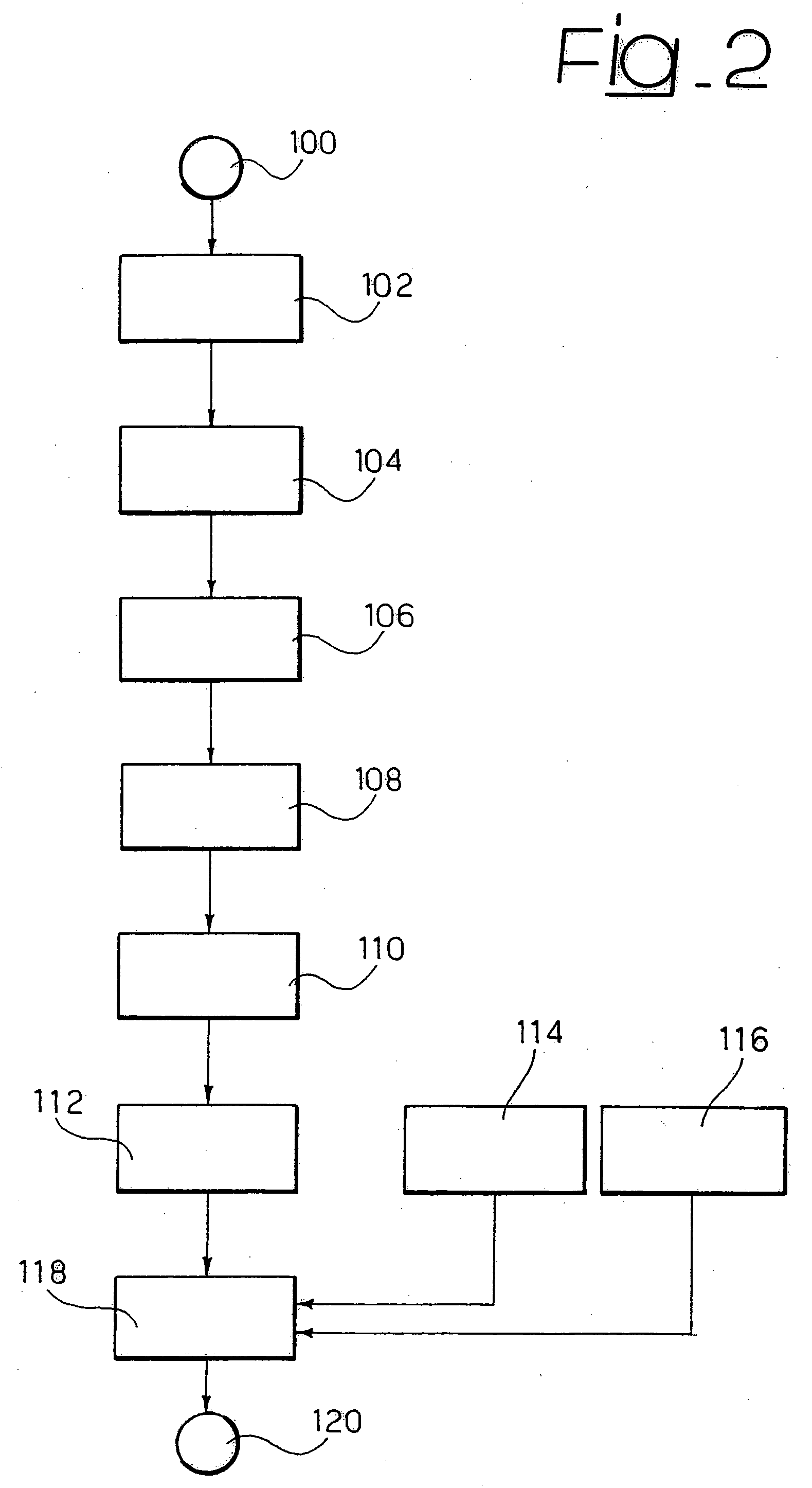

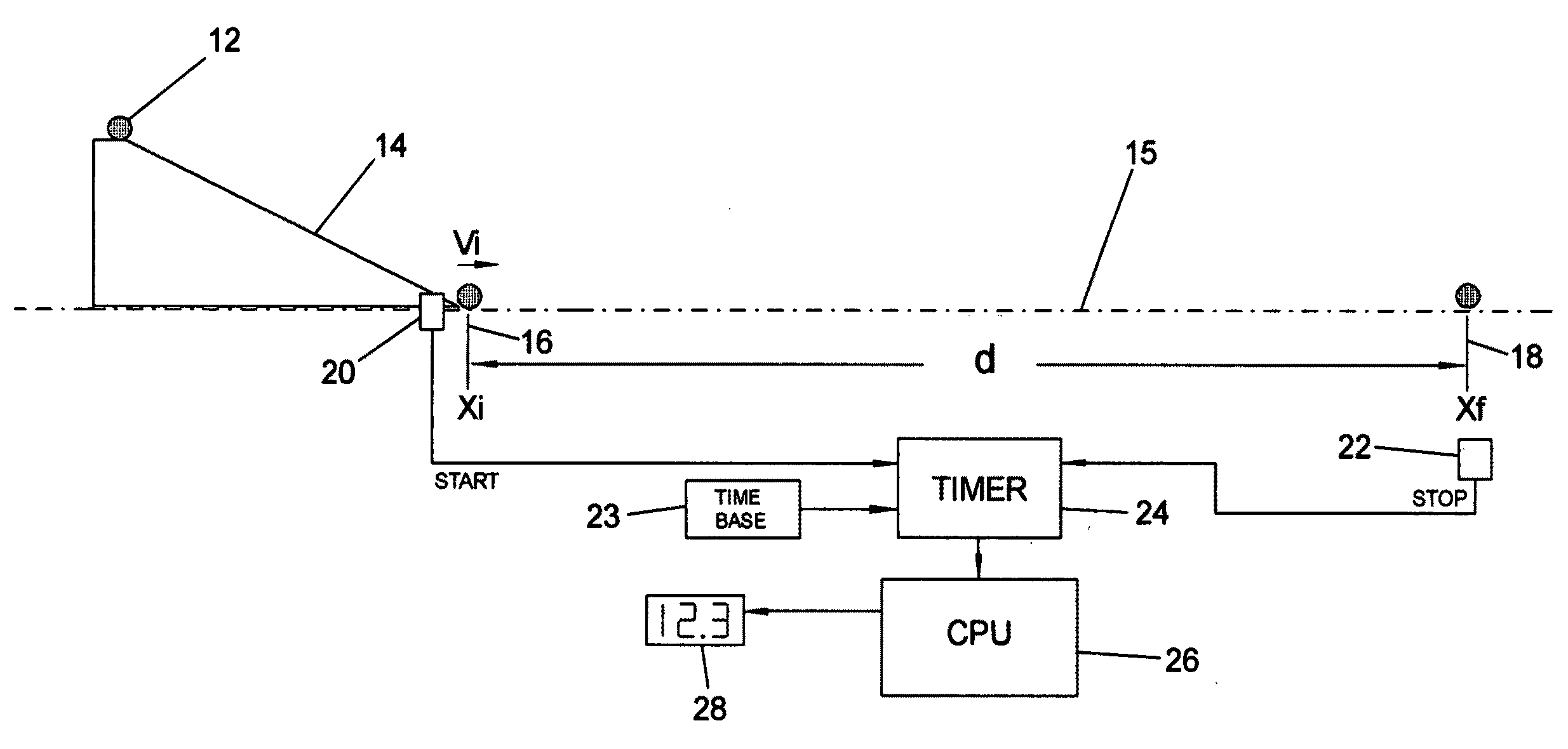

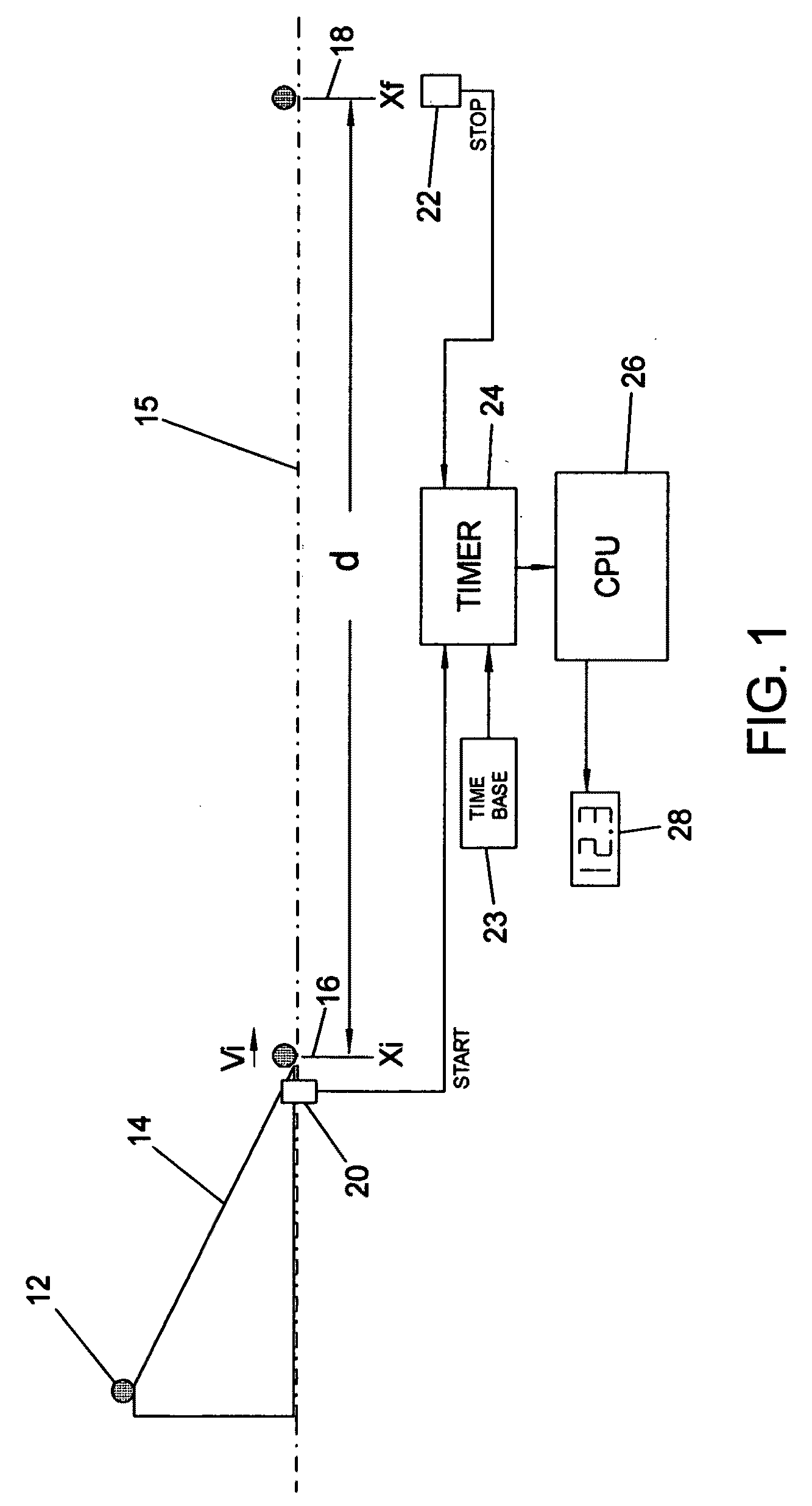

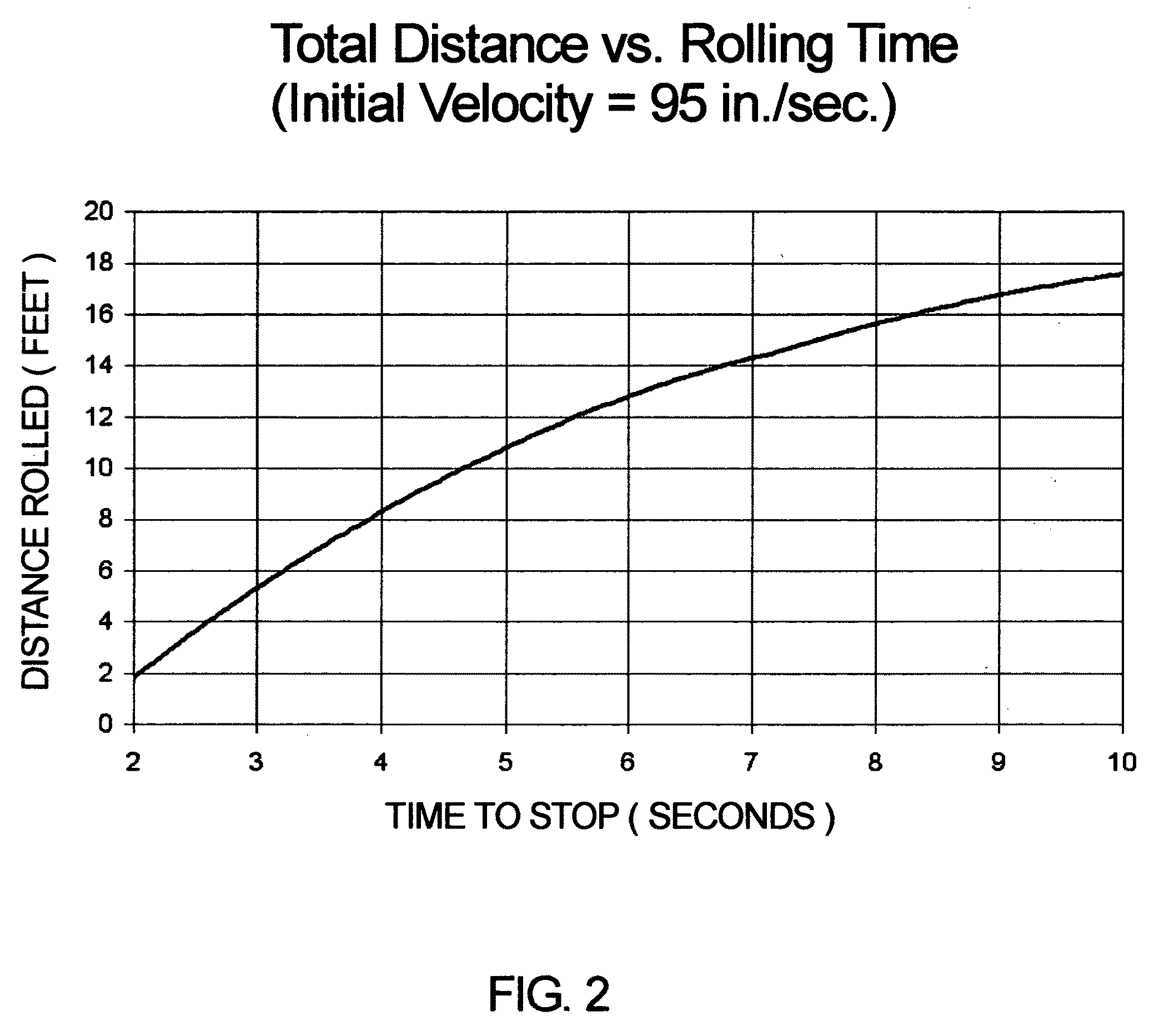

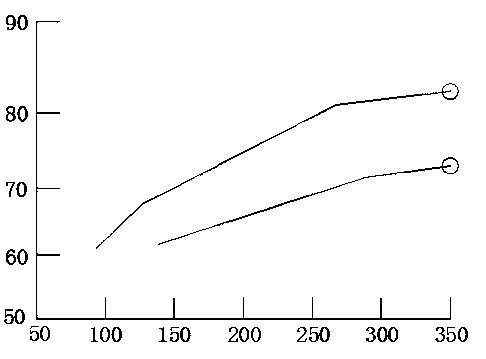

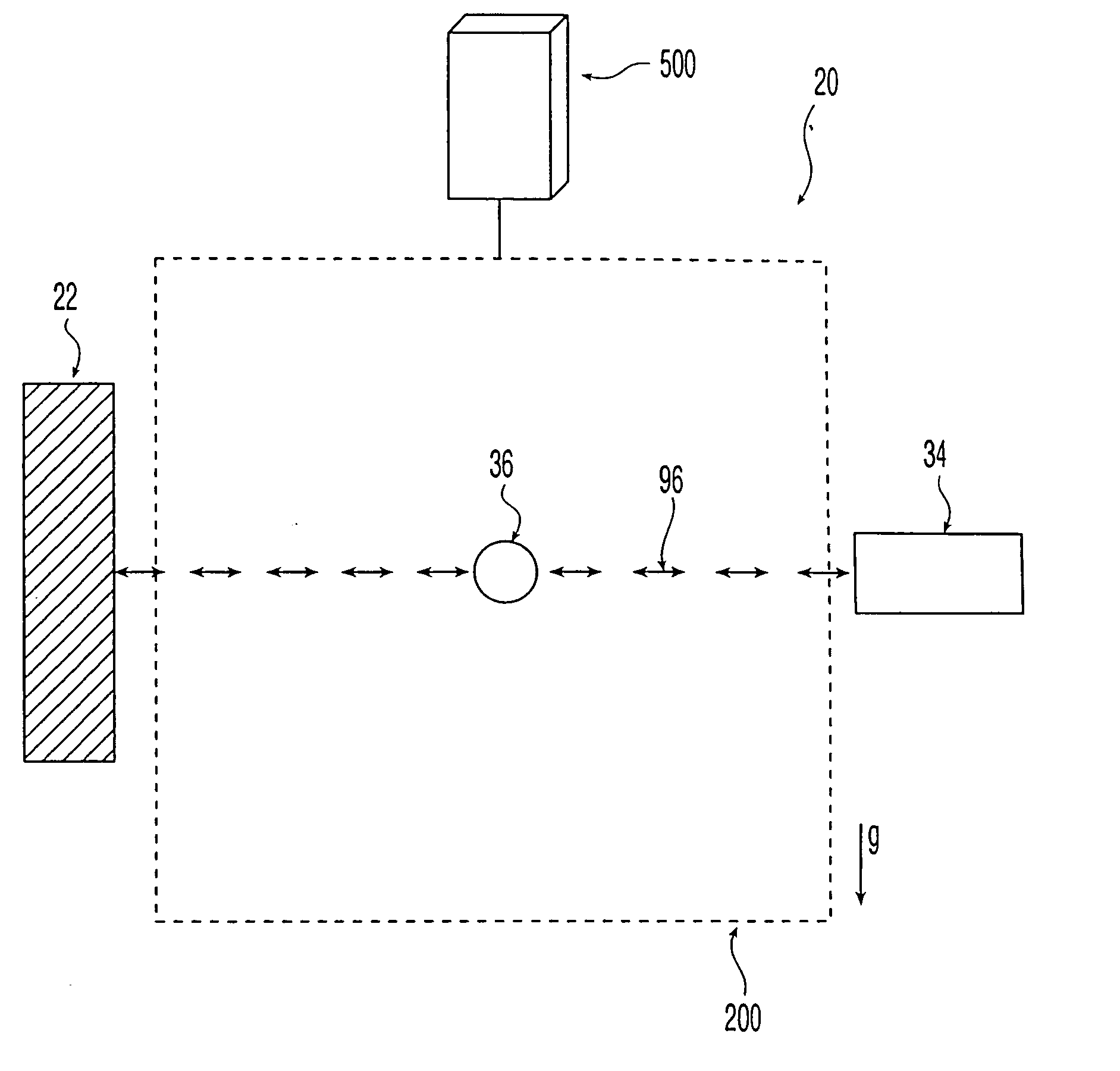

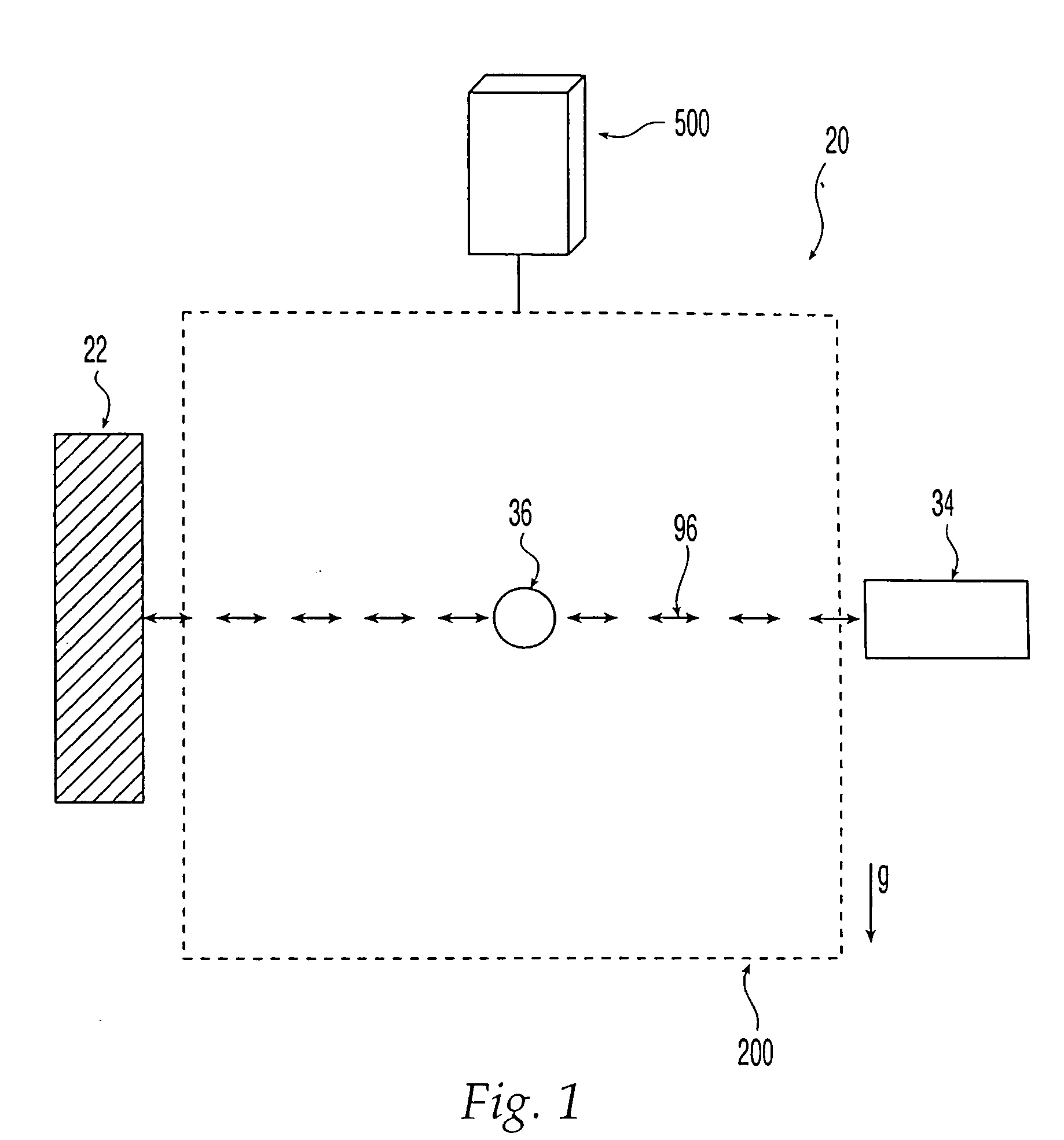

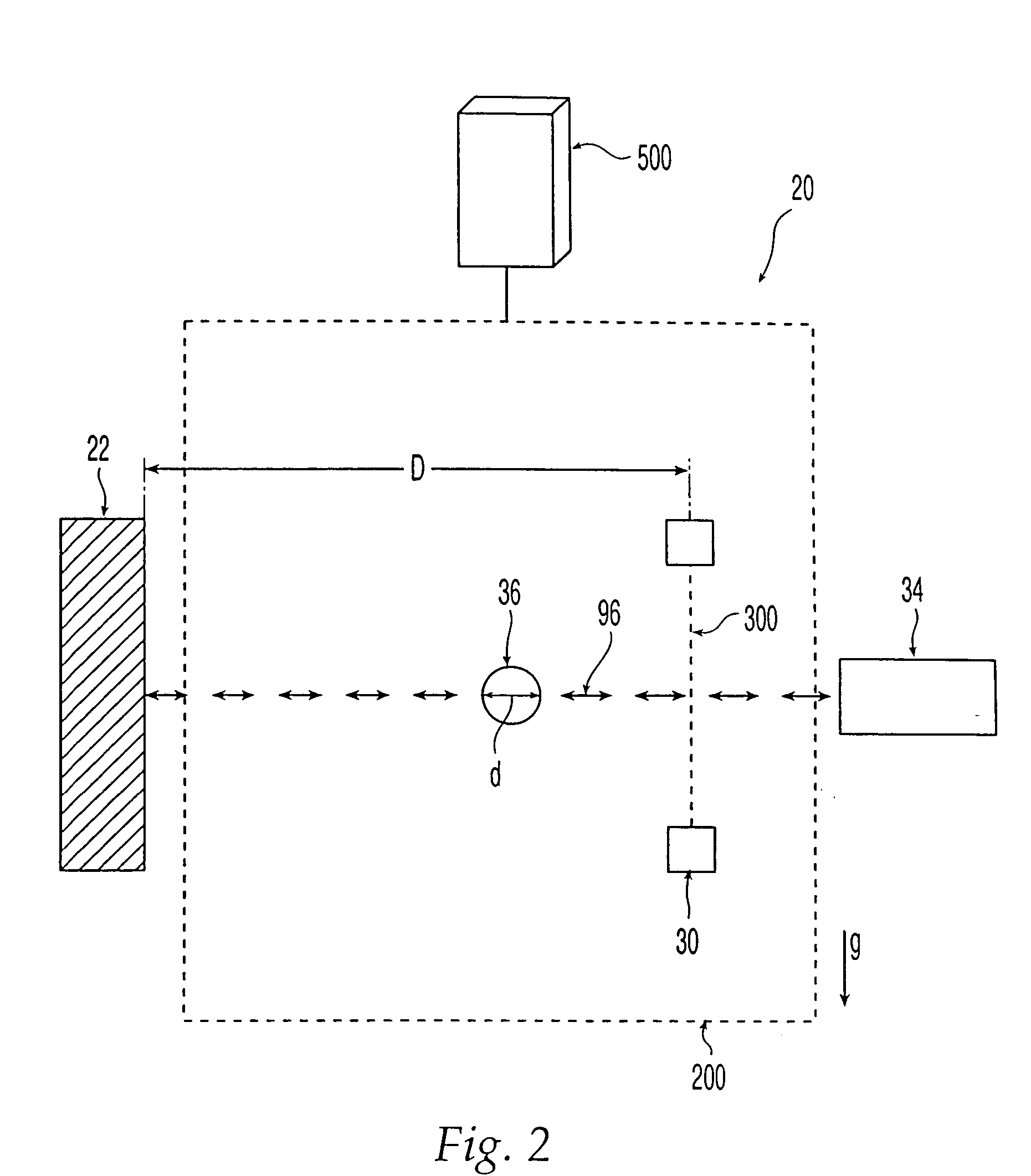

Method and device for automated electronic green speed measurement

InactiveUS20090100928A1Measured rapidly and convenientlyQuickly determining the green speed of the current putting surfaceSpeed measurement using accelerationAcceleration measurementSurface velocityLaws of thermodynamics

Method and apparatus for measuring the coefficient of rolling friction or speed of a horizontal surface over which a round object is rolled such as a putting green encountered in the game of golf. The method includes a device for launching a ball across the surface at a constant and consistent velocity. An included timing device is triggered to start counting the elapsed time when the ball exits the launching device and continues counting until the ball has decelerated to a stop. At the instant the ball ceases moving the timer is triggered to terminate the count. The time required for a body with a specific velocity to come to rest after experiencing constant deceleration is determined by the laws of motion. The coefficient of friction or “speed” of the green which is proportional to the amount of deceleration may then be calculated. This time measurement is therefore sufficient to determine the speed of the green surface which may be reported as an equivalent “stimp” value.

Owner:FRY STEVEN +1

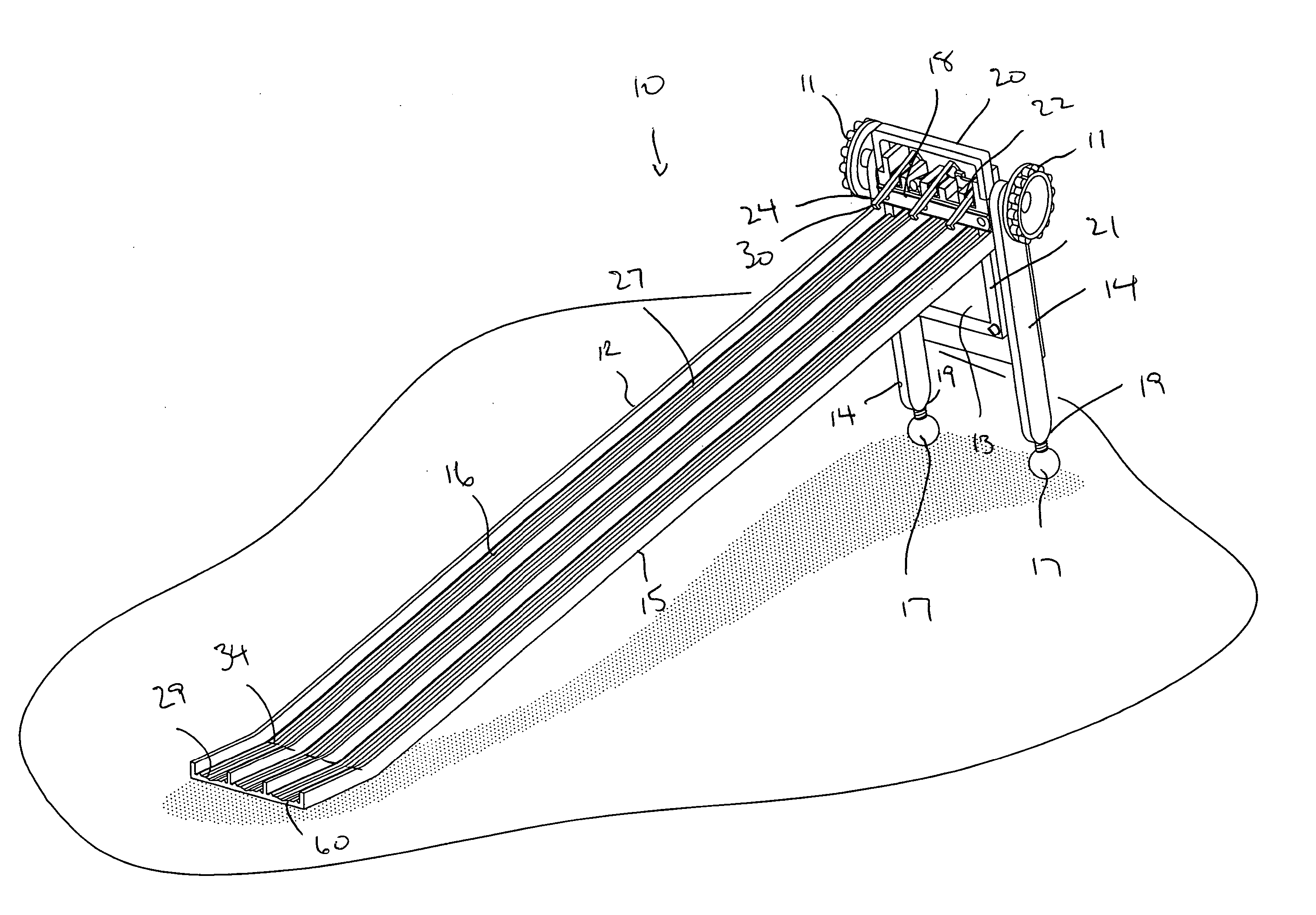

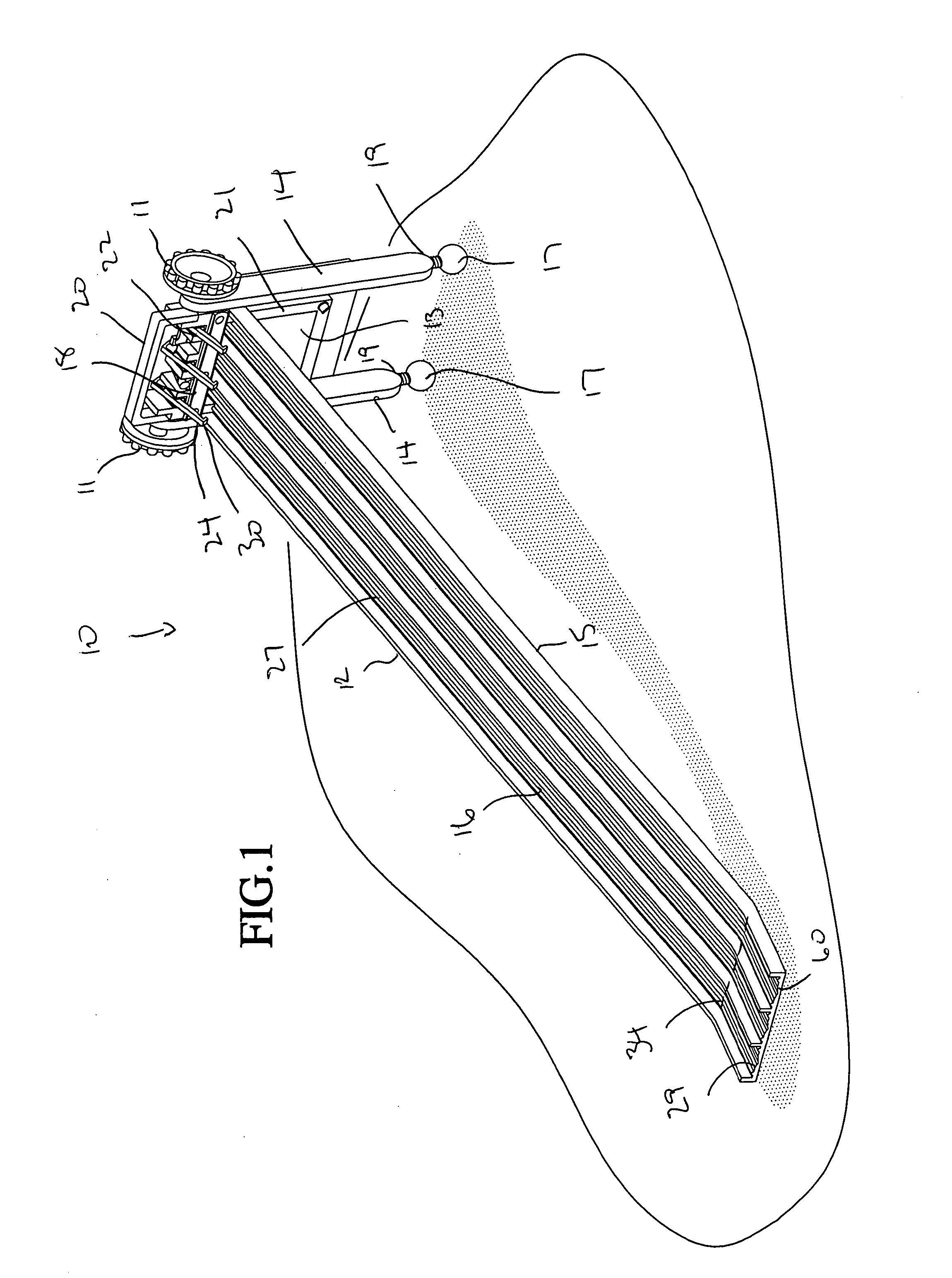

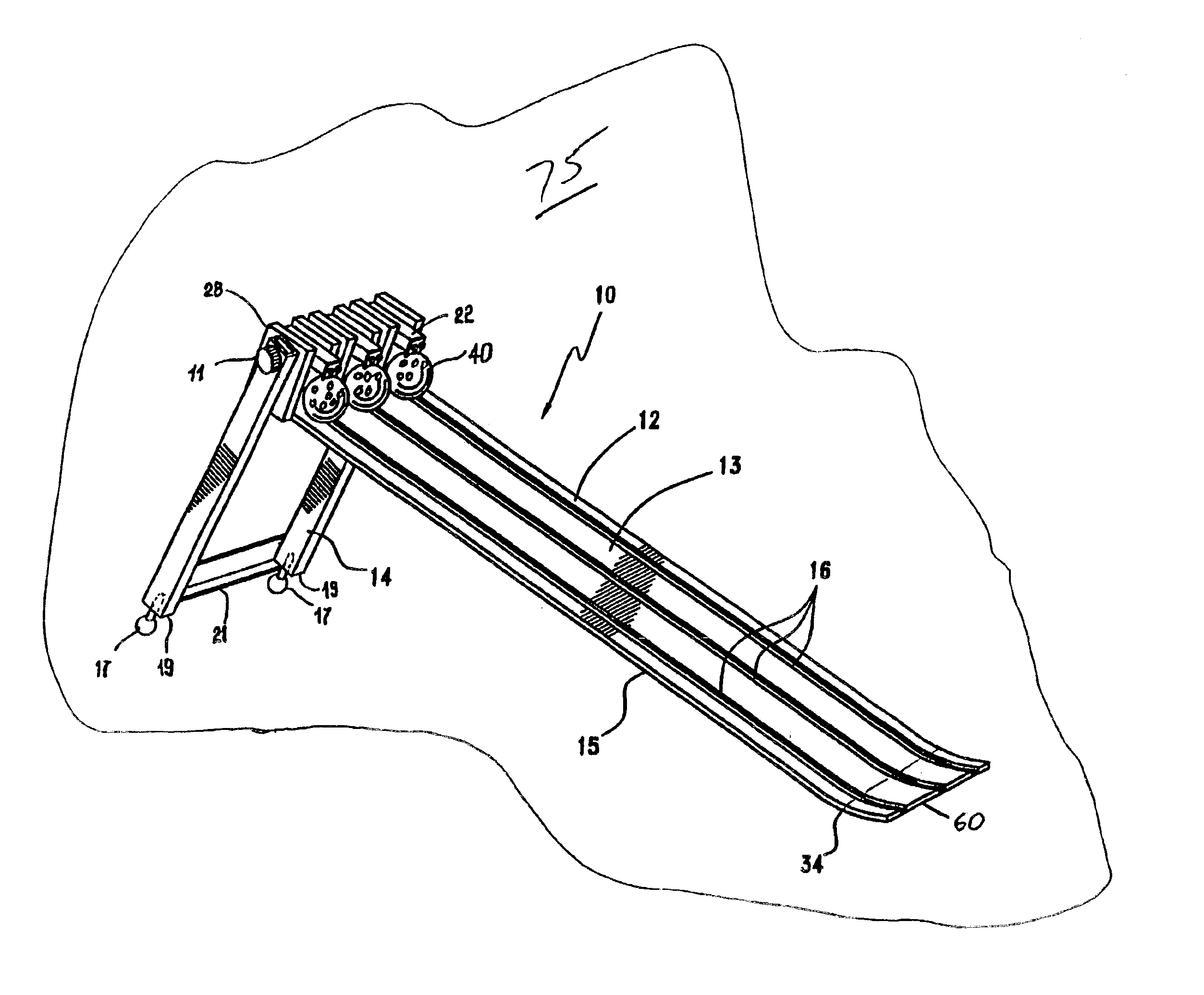

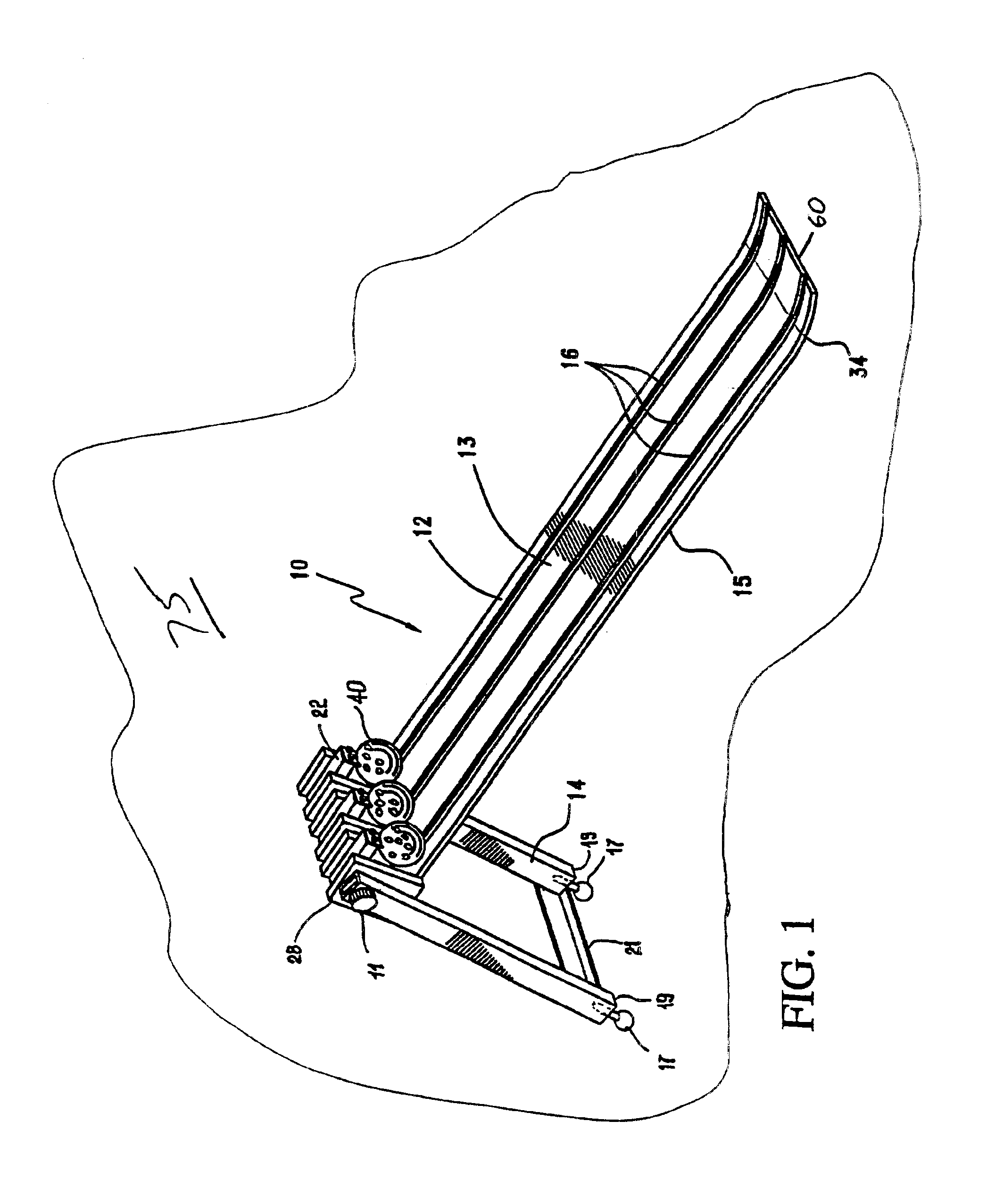

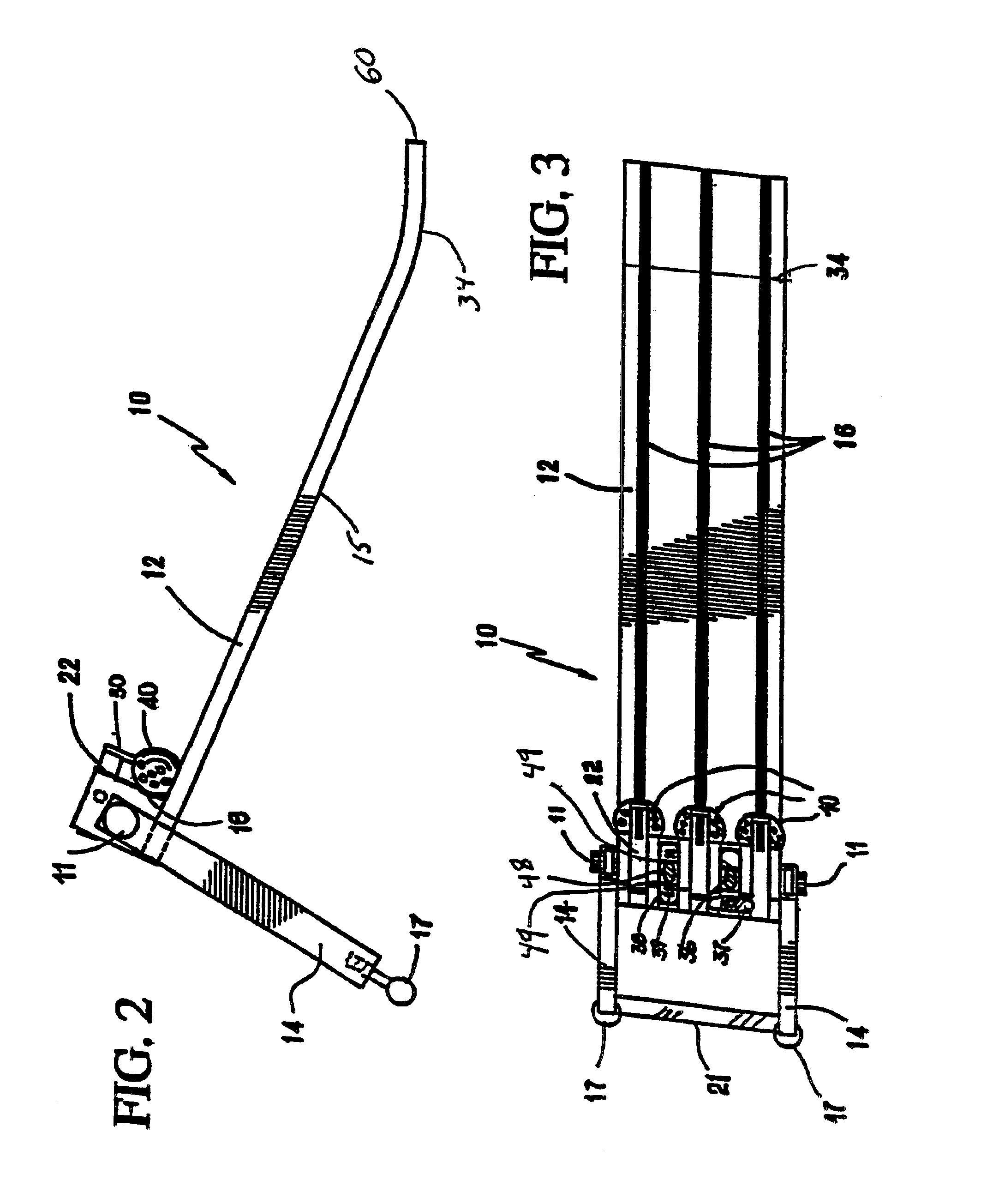

Apparatus for measuring green-speed

InactiveUS20050145011A1Accurate and consistent readingFew errorTesting manufactured objectsUsing mechanical meansGround contactEngineering

A method and apparatus is employed in determining the green-speed of a golf putting green. The method is achieved by selecting a site on a putting green having a relatively flat surface and determining the extent of putting surface available for measurements, setting a green-speed reading apparatus including a ramp, which includes a raised start end and a ground contacting release end with at least one golf ball rolling track thereon, in a first direction whereby the release end of the ramp contacts the putting green surface at the selected site, selecting one of two predetermined start positions for a golf ball based upon the extent of putting surface available for measurements and retaining the golf ball at the selected start position in the track, the start position being at the raised start end of the track, releasing the golf ball from the start position, allowing the golf ball to roll down the track by gravity onto the putting green surface, measuring the distance the golf ball rolls across the putting green from the release end of the ramp, repeating the test with the apparatus facing in the opposite direction at the selected site and measuring the distance the golf ball rolls across the putting green from the release end of the ramp, and calculating the average distance of all the golf balls rolled to determine a value in terms of green-speed.

Owner:PELZ DAVID T

Method and apparatus for testing shafts

Methods and apparatus are provided for testing shafts, such as golf club shafts. In one embodiment, the invention can be characterized as a shaft tester comprising: a frame; a first shaft support supporting a first portion of a shaft at a first fixed position; a second shaft support supporting a second portion of the shaft at a second fixed position; and a third shaft support supporting a third portion of the shaft at a third fixed position. An actuator couples to the third shaft support to displace the third portion relative to the first and second portions to deflect the shaft. A sensor couples to one of the first, second and third supports outputting a signal corresponding to a force exerted by the shaft due. A controller controls displacement of the shaft. In some embodiments, the shaft is rotated while being deflected.

Owner:FUJIKURA COMPOSITE AMERICA

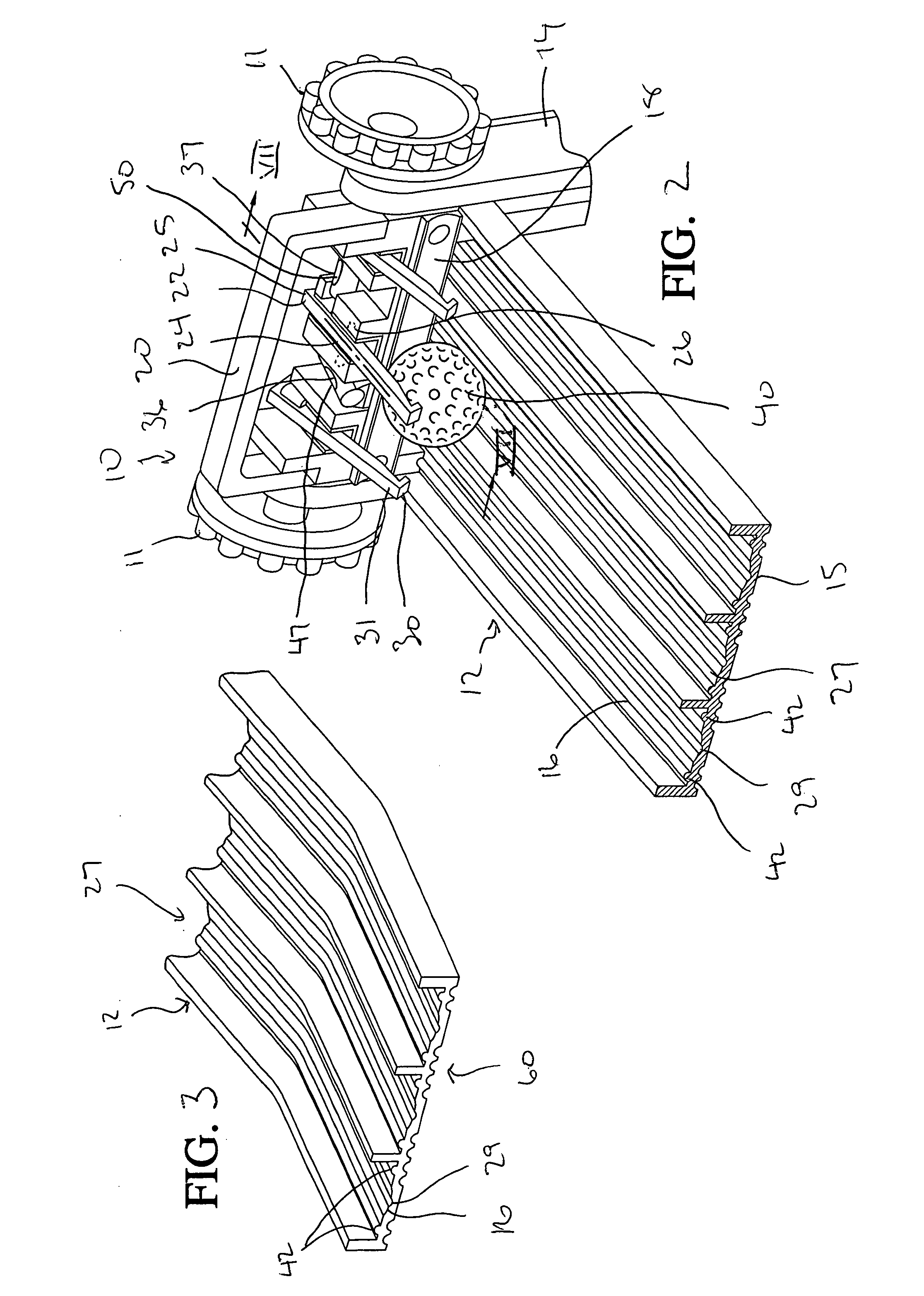

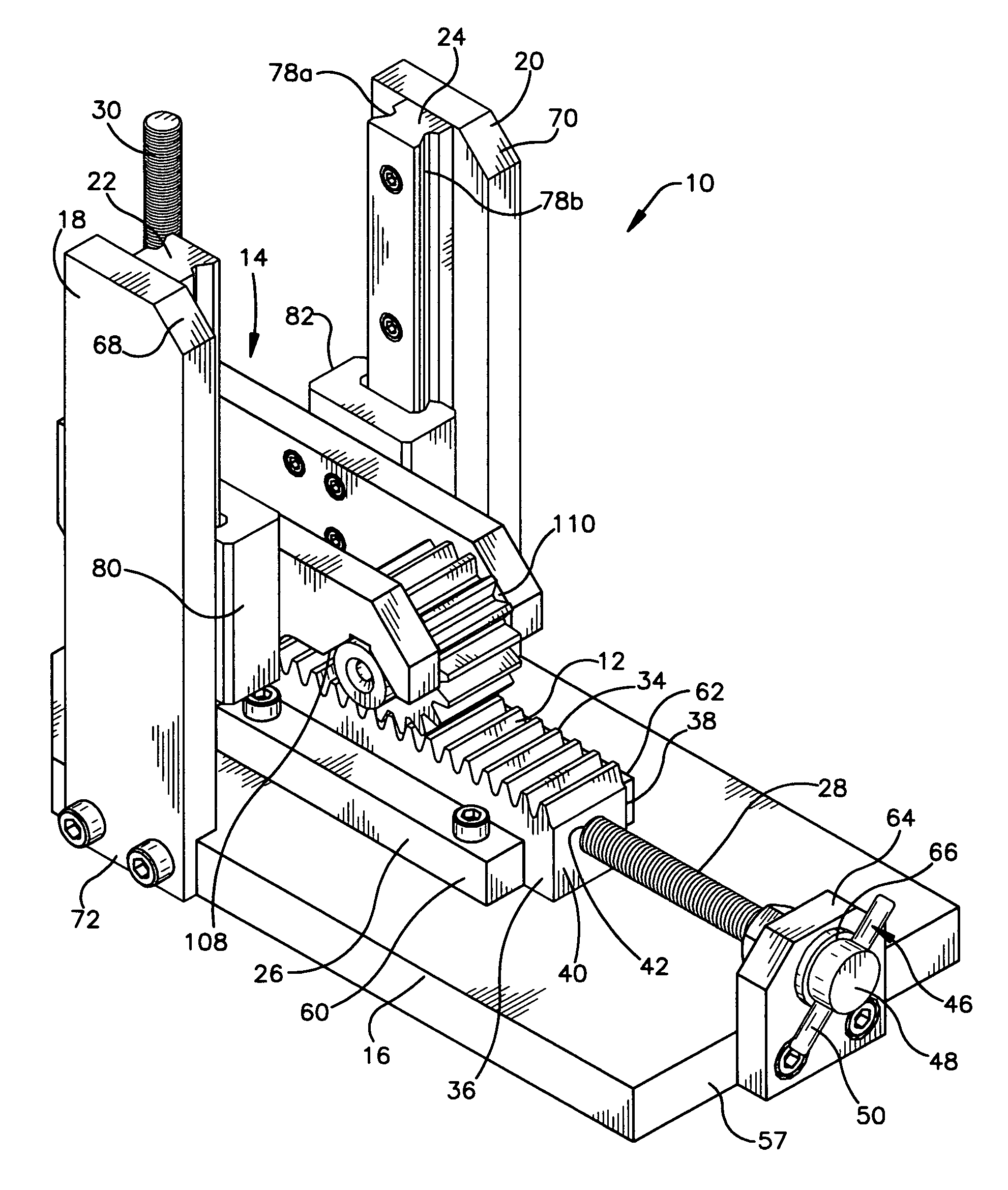

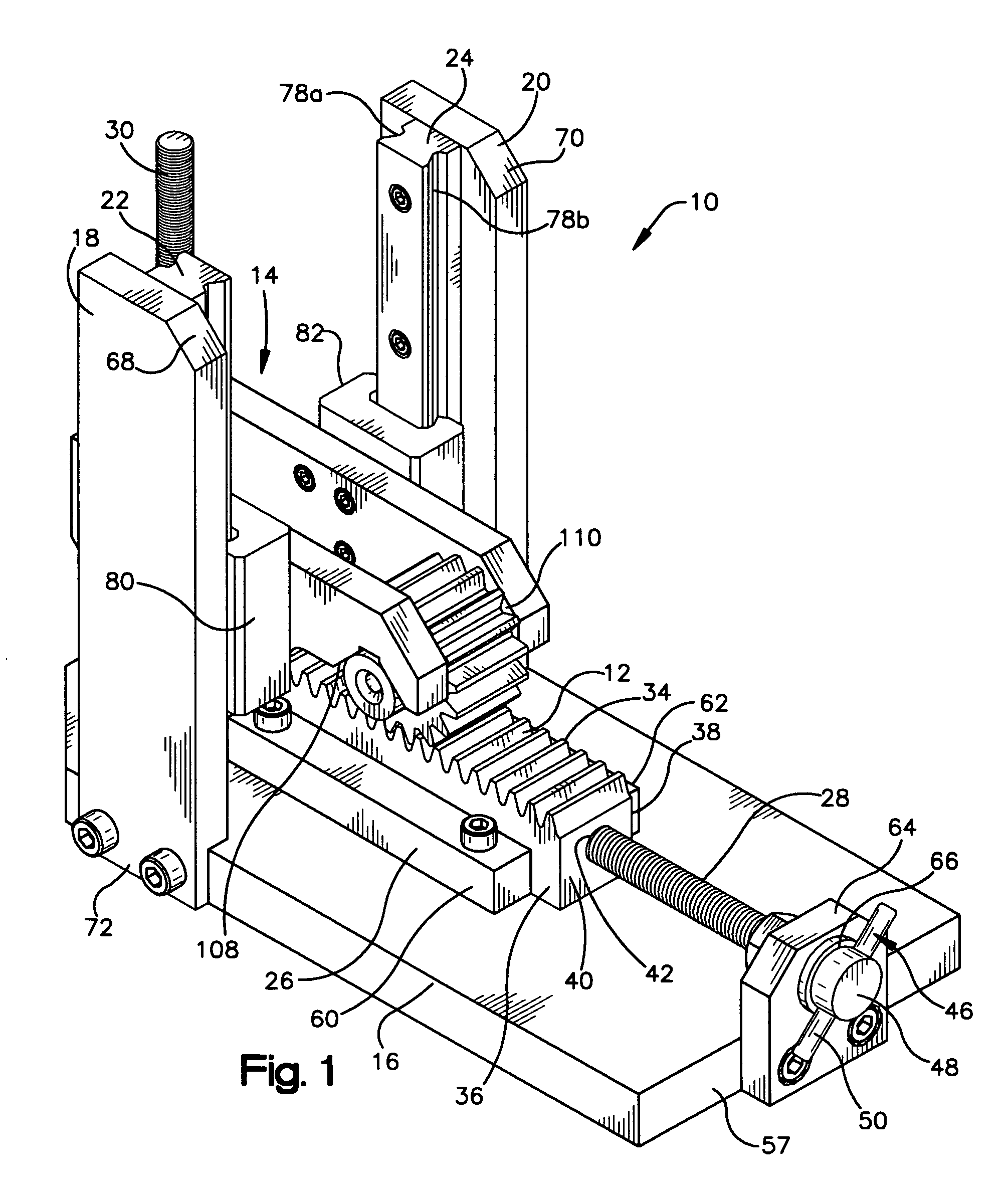

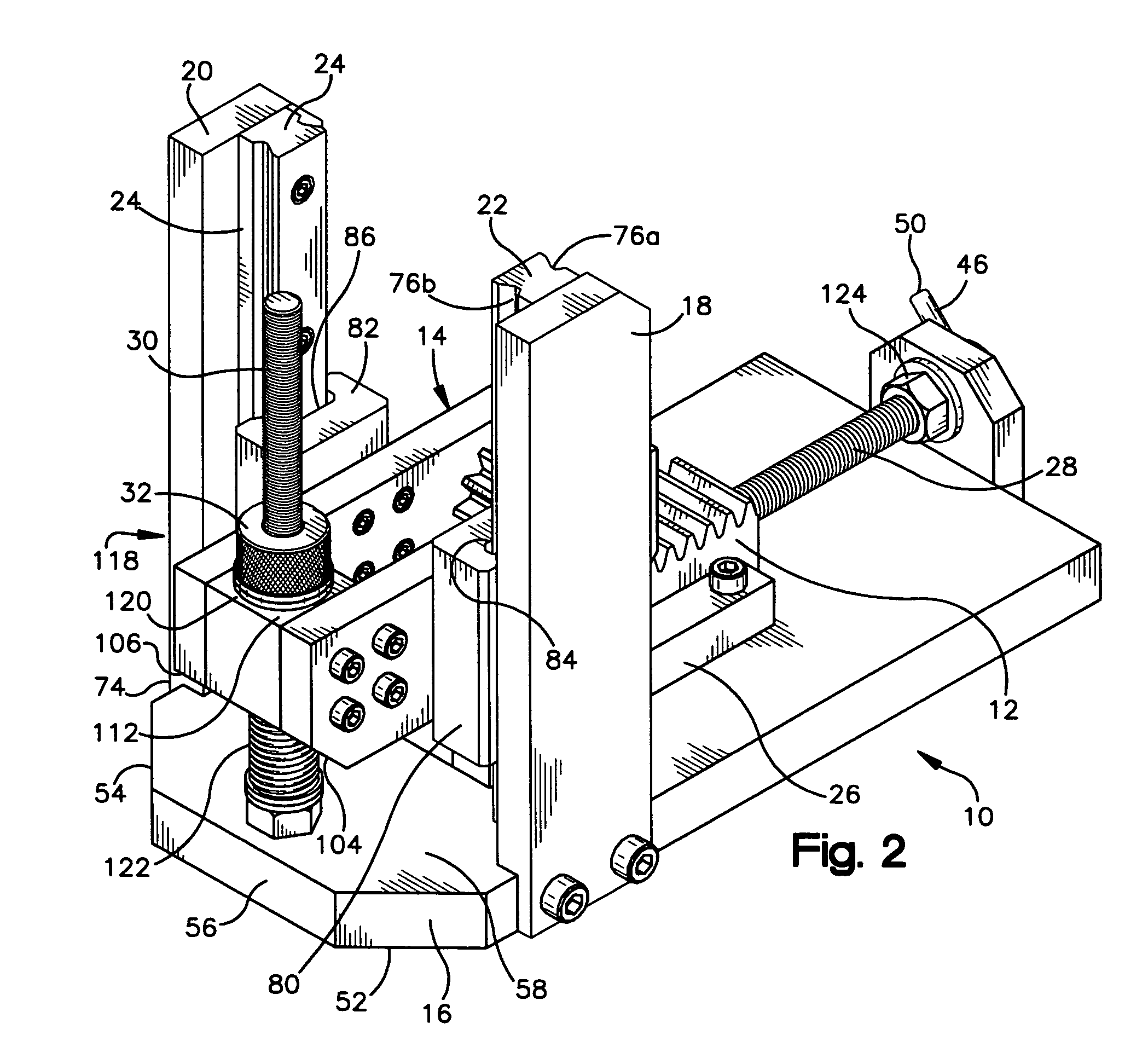

Fixture for holding a gear

InactiveUS7263898B1Easy to adjustOvercome disadvantagesTesting manufactured objectsInvestigating material hardnessGear wheelGear tooth

A gear holding fixture is provided so that the appropriate position upon a gear tooth may be placed in line with an indenting device on testing equipment. The fixture includes a base that supports a movable rack, the rack including a plurality of teeth. The gear being tested is supported upon the movable rack in a way wherein the teeth on the gear intermesh with the teeth on the rack. The fixture also includes a gear axle restraint that is selectively movable depending on whether the gear is being tested or being replaced. The gear axle restraint in a gear testing position abuts an axle that supports the gear and extends along the gear's axis of rotation. This reduces the gear to only rotational movement. Thus, as the rack is moved incrementally along the base, the teeth on the rack drive the teeth of the gear, causing the gear to rotate.

Owner:HONDA MOTOR CO LTD

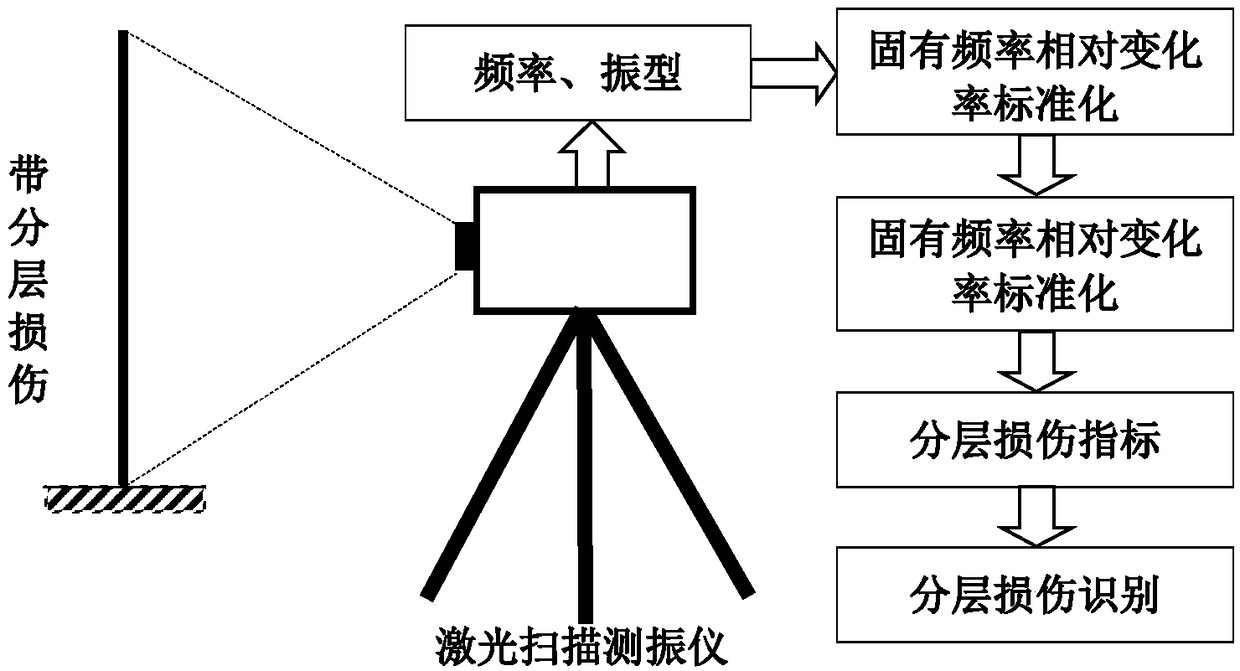

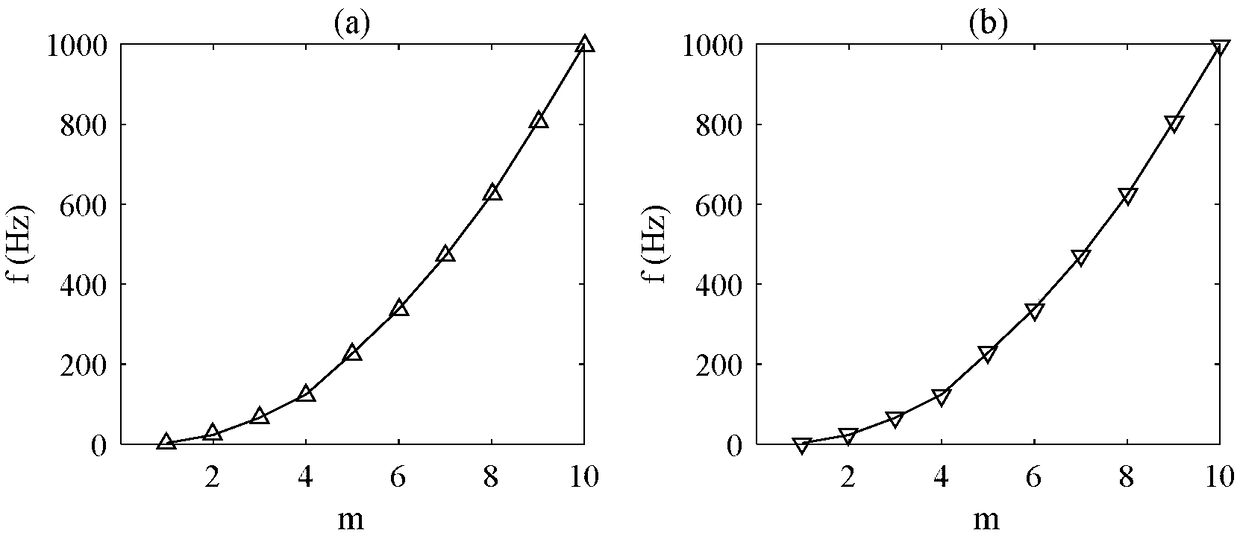

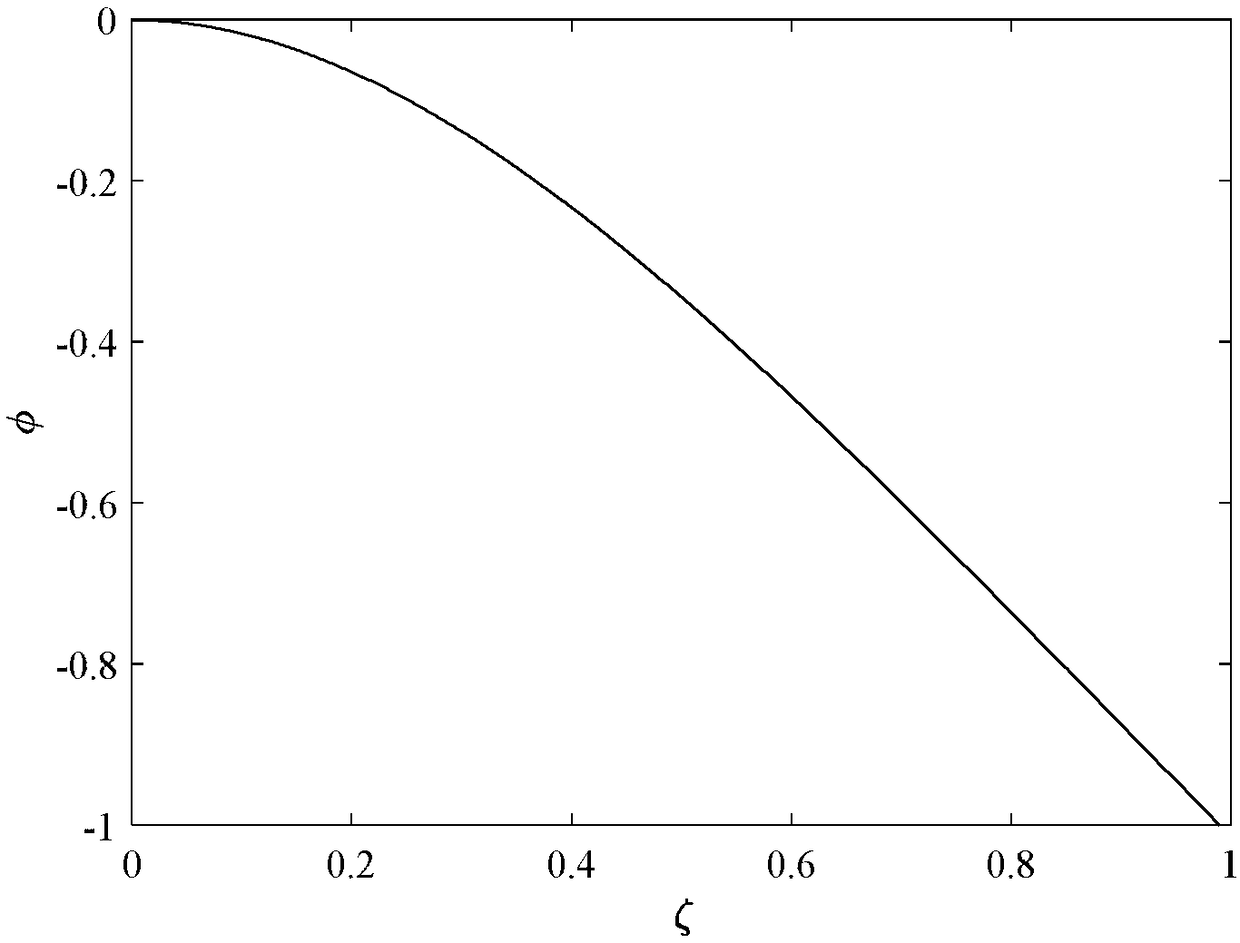

Composite material lamination beam layered damage position detection method

ActiveCN109001380AEasy to operateTesting manufactured objectsMaterial analysisLocation detectionRelative Change

The invention discloses a composite material lamination beam layered damage position detection method. The method comprises the following steps of measuring the inherent frequency before and after a first 10-order damage of the composite material lamination beam and the vibration type after damage; calculating the relative change rate of the inherent frequency, and standardizing the relative change rate of the inherent frequency; calculating the square of the first-order derivative of the vibration type, and performing standardization on the square; according to the standard inherent frequencyrelative change rate and the standard square of the first-order derivative of the vibration type, calculating first 10-order single-order layered damage indexes, and performing multiple multiplication on the first 10-order single-order layered damage indexes to obtain an overall layered damage index; and determining the layered damage position according to the position of the maximum value of theoverall layered damage index. The method can be used for analyzing the inherent frequency before and after layered damage of the composite material lamination beam and the vibration type after damage, so as to judge the layered damage position.

Owner:HOHAI UNIV

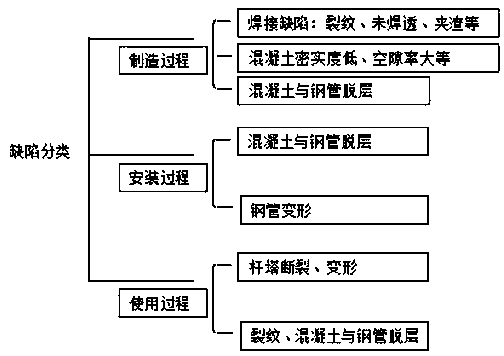

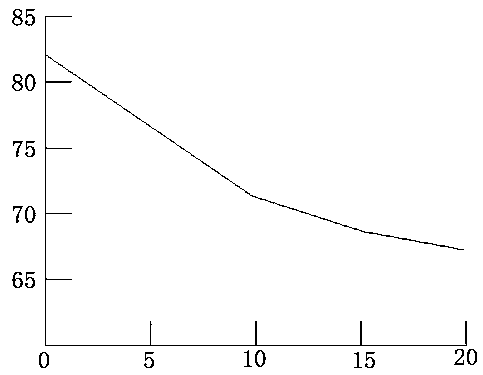

Qualitative and quantitative defect detection method for thin-walled centrifugal concrete steel tube tower

ActiveCN110879278AEasy constructionEconomically reasonableAnalysing solids using sonic/ultrasonic/infrasonic wavesTesting manufactured objectsTowerUltimate tensile strength

The invention provides a qualitative and quantitative defect detection method for a thin-walled centrifugal concrete steel tube tower. The method comprises the following steps: S1, introducing an advanced phased array defect imaging detection technology into steel tube pole weld joint detection, accurately judging the property, size and severity of defects, and achieving nondestructive evaluationof standard exceeding defects of a steel tube pole; S2, studying the influence of the welding temperature on the performance of the thin-walled centrifugal concrete steel tube tower; S3, testing the bonding condition of a concrete-filled steel tube by means of nondestructive testing; S4, determining a safety evaluation method for the allowable defect size of a defect-containing thin-walled centrifugal concrete steel tube tower; and S5, researching reinforcement schemes for the defect-containing thin-walled centrifugal concrete steel tube tower; and checking the strength of the defect-containing thin-walled centrifugal concrete steel tube tower under different reinforcement schemes, and comparing and analyzing the feasibility and economy of the different reinforcing schemes.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +1

Apparatus for measuring green-speed

InactiveUS6860139B2Accurate and consistent readingAvoid excessive errorTesting manufactured objectsUsing mechanical meansEngineeringGolf Ball

Method and apparatus for measuring the green-speed of a putting green including a golf ball rolling ramp. The ramp is supported by adjustable length legs above a green surface at a selected angle. A level vial attached to the apparatus is used to determine when the ramp is at the selected angle. A plurality of parallel grooves extend the entire length of the rolling ramp and allow for sequentially rolling a plurality of golf balls onto a putting green surface. Located at the upper end of each groove is a trigger mechanism for each of said grooves, including a trigger support block and a trigger arm pivotally movable thereon for releasing the golf balls into the grooves and down the ramp. The forward or release end of the ramp is curved for releasing the balls parallel to the local horizontal relative to the putting green surface.

Owner:PELZ DAVID T

Golf ball COR testing machine

The present invention comprises an automated machine for testing the physical properties of spherical objects. Preferably, the apparatus comprises a firing mechanism that includes an inner and outer barrel. An object inside the firing mechanism is propelled towards a striking surface that faces the firing mechanism. Two sensors located at predetermined points between the firing mechanism and the striking surface measure the inbound and outbound velocity of the object. A computing device then uses an algorithm to determine the COR of a given set of objects. An angular device uses gravity to direct the objects to a retrieval chute, which uses a tubing system to direct the objects for re-testing or collection.

Owner:ACUSHNET CO

Turf test apparatus

InactiveUS20050087003A1Reduce resistanceEarth material testingAcceleration measurementAccelerometerDrop tests

A drop test apparatus for determining the resiliency of playing surface comprising a missile for impacting the surface including a guide for providing substantially unrestricted free flight of the missile, a pair accelerometers carried by the missile for producing signals in response to impact with the surface, a converter adapted to receive the accelerometer signals, convert them into computer readable signals and a computer receiving the signals from the converter and producing a graph of the surface hardness.

Owner:TESTING SERVICES

Fatigue test apparatus for thin element of electronic device

InactiveUS20090260451A1Ensure qualityHeavy laborMaterial strength using steady bending forcesStructural/machines measurementComputerized systemEngineering

A fatigue test apparatus for thin workpiece includes a supporting module, a driving mechanism, a first connecting module, a second connecting module, a first holding post, a second holding post and a computer system. The first and second connecting modules are respectively fixed to two sides of the supporting module. Ends of the first holding post and the second holding post are fixed to the first and second connecting modules. The computer system electronically connects with and controls the driving mechanism. The first holding post and the second holding post are drive to rotate by the driving mechanism.

Owner:SHENZHEN FUTAIHONG PRECISION IND CO LTD +1

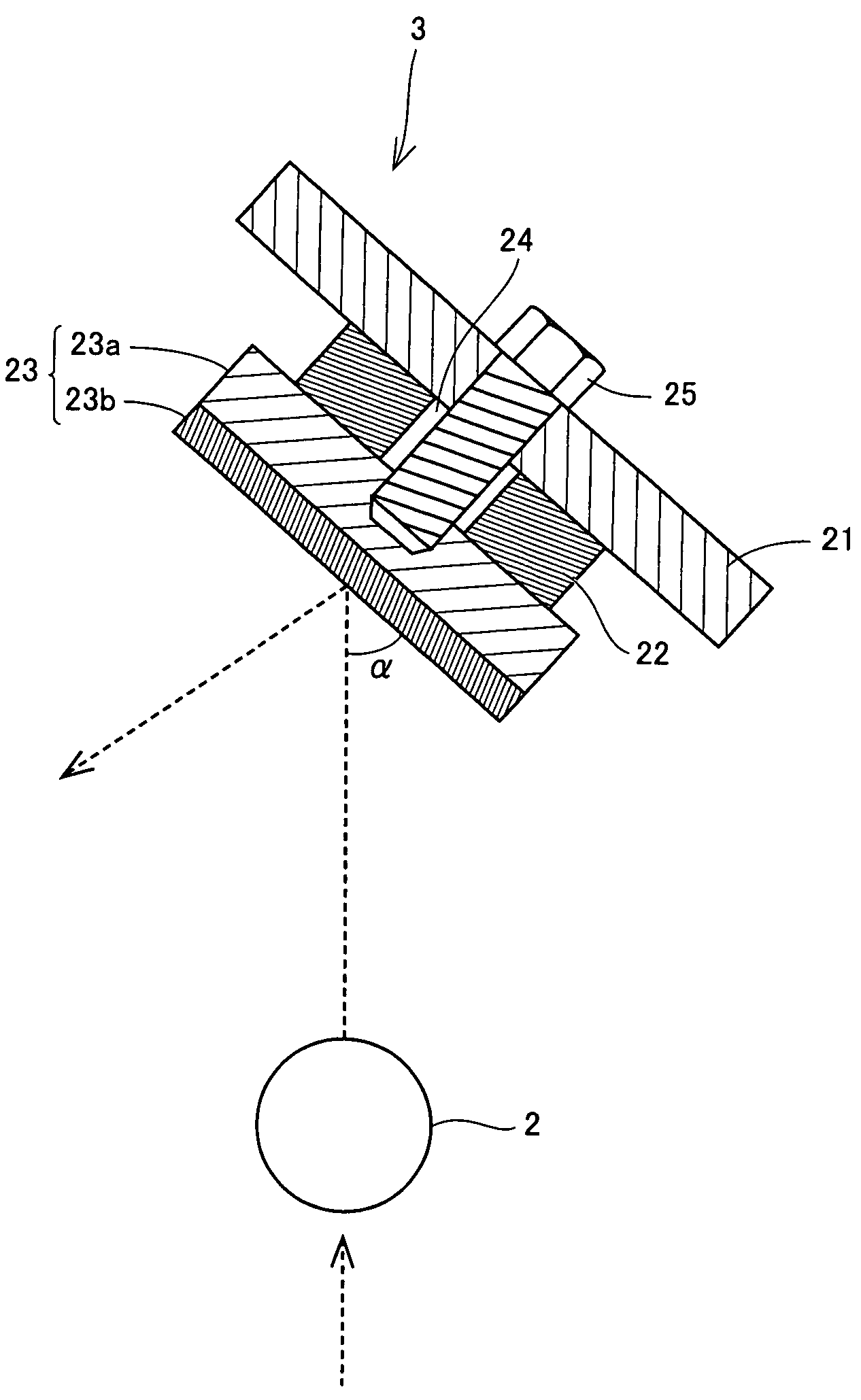

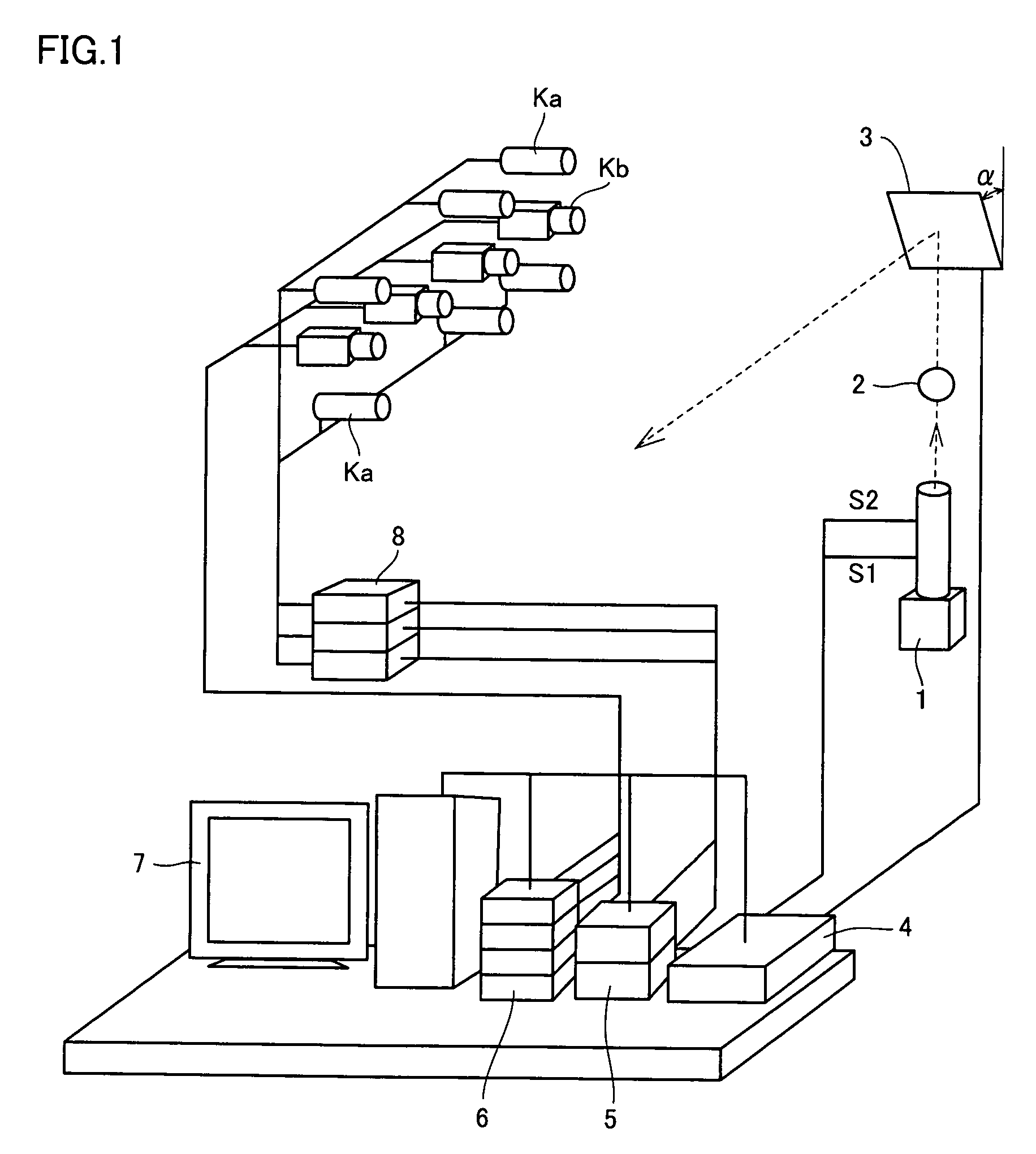

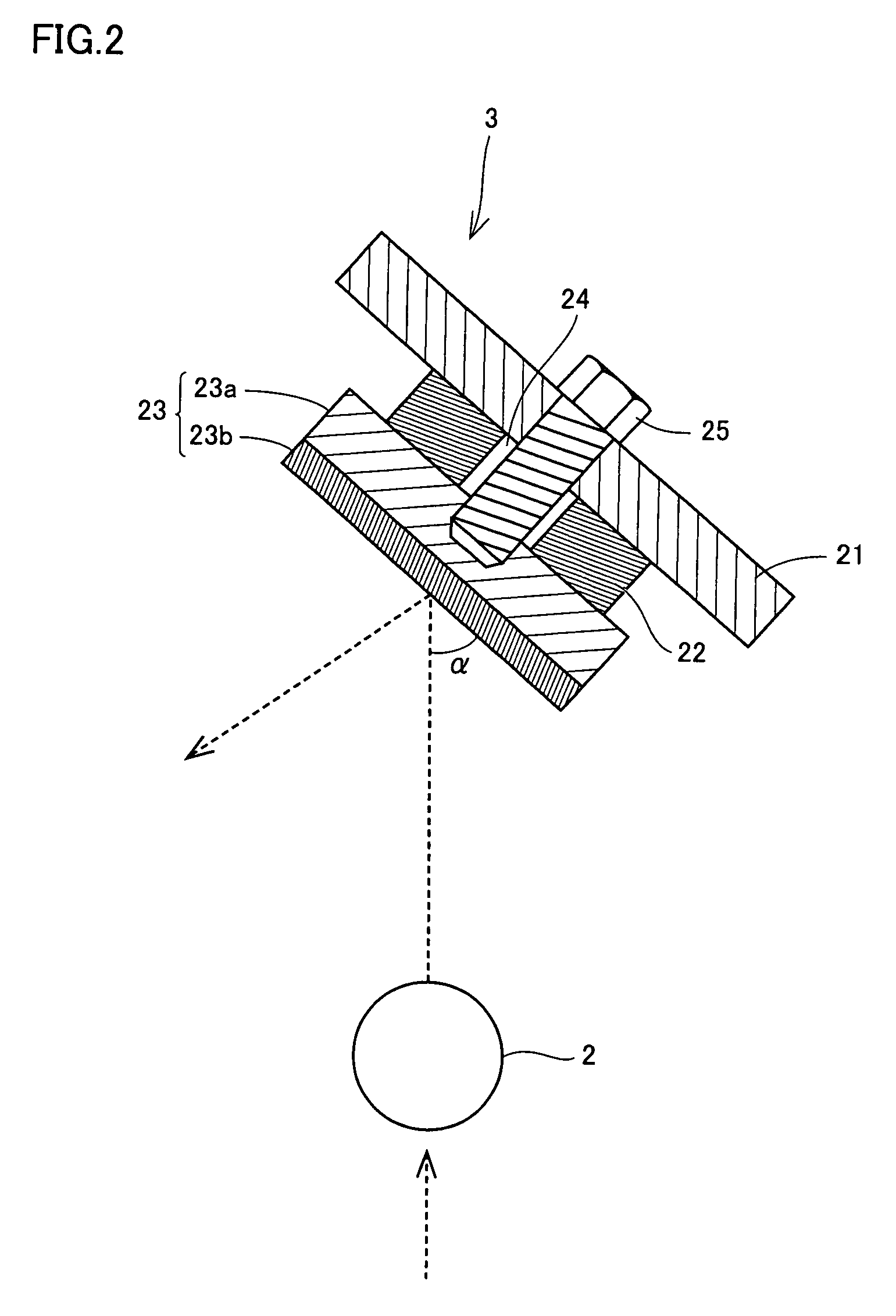

Method of measuring coefficient of dynamic friction between golf ball and collisional plate

InactiveUS7454948B2Designing can be facilitatedReadily spin rateMachine part testingMeasurement of torque/twisting force while tighteningTime functionRotation velocity

By bringing a golf ball into collision with a collisional plate and measuring a coefficient of dynamic friction at this collision, contact force at the time of collision between an actual golf club and the golf ball is analyzed and spin rate of the golf ball is estimated. This invention provides a method for measuring a coefficient of dynamic friction between a golf ball and a collisional plate when the golf ball collides with the collisional plate disposed aslant at a predetermined angle with respect to a flying direction of the golf ball. The method includes concurrently obtaining a time function Fn(t) of contact force in the direction perpendicular to the collisional plate, and a time function Ft(t) of contact force in the direction parallel with the collisional plate; and determining as a coefficient of dynamic friction, a maximum value of a time function M(t) of ratio between Fn(t) and Ft(t) represented by M(t)=Ft(t) / Fn(t).

Owner:SUMITOMO RUBBER IND LTD

Method and apparatus for testing shafts

ActiveUS20100313672A1Material strength using steady bending forcesTesting manufactured objectsGolf BallActuator

Methods and apparatus are provided for testing shafts, such as golf club shafts. In one embodiment, the invention can be characterized as a shaft tester comprising: a frame; a first shaft support supporting a first portion of a shaft at a first fixed position; a second shaft support supporting a second portion of the shaft at a second fixed position; and a third shaft support supporting a third portion of the shaft at a third fixed position. An actuator couples to the third shaft support to displace the third portion relative to the first and second portions to deflect the shaft. A sensor couples to one of the first, second and third supports outputting a signal corresponding to a force exerted by the shaft due. A controller controls displacement of the shaft. In some embodiments, the shaft is rotated while being deflected.

Owner:FUJIKURA COMPOSITE AMERICA

Testing device

InactiveUS20110247428A1Digital data processing detailsStructural/machines measurementEngineeringMechanical engineering

A testing device suitable for testing an electronic device is provided. The electronic device has a first body and a second body, wherein the first body is suitable for rotating relative to the second body. The testing device includes a carrying platform, a fixed frame, a clamping element, a first driving element, and a second driving element. The carrying platform carries the first body. The fixed frame is pivoted to the carrying platform. The clamping element is pivoted to the fixed frame for clamping the second body. The first driving element is disposed between the carrying platform and the fixed frame for driving the fixed frame to pivot relative to the carrying platform. The second driving element is disposed between the clamping element and the fixed frame for driving the clamping element to pivot relative to the fixed frame.

Owner:INVENTEC CORP

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com