Patents

Literature

30results about How to "Overcome oxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

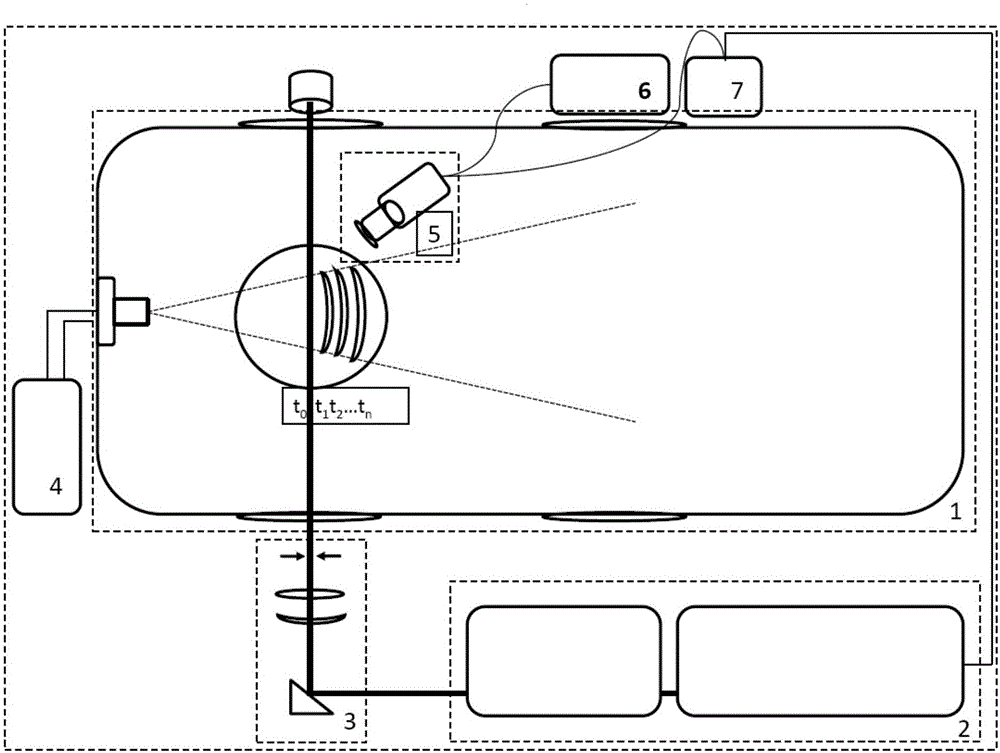

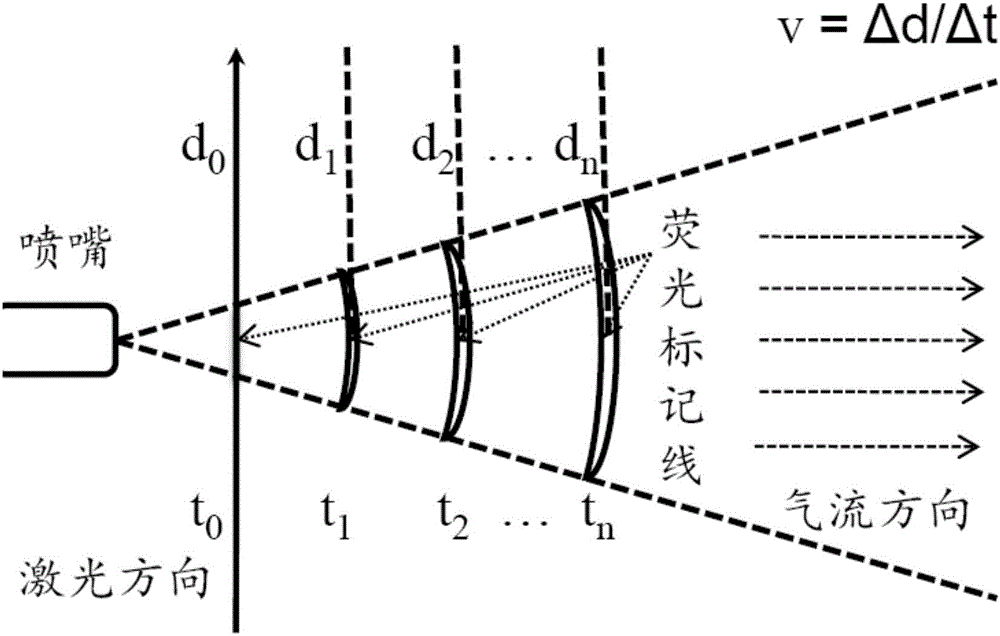

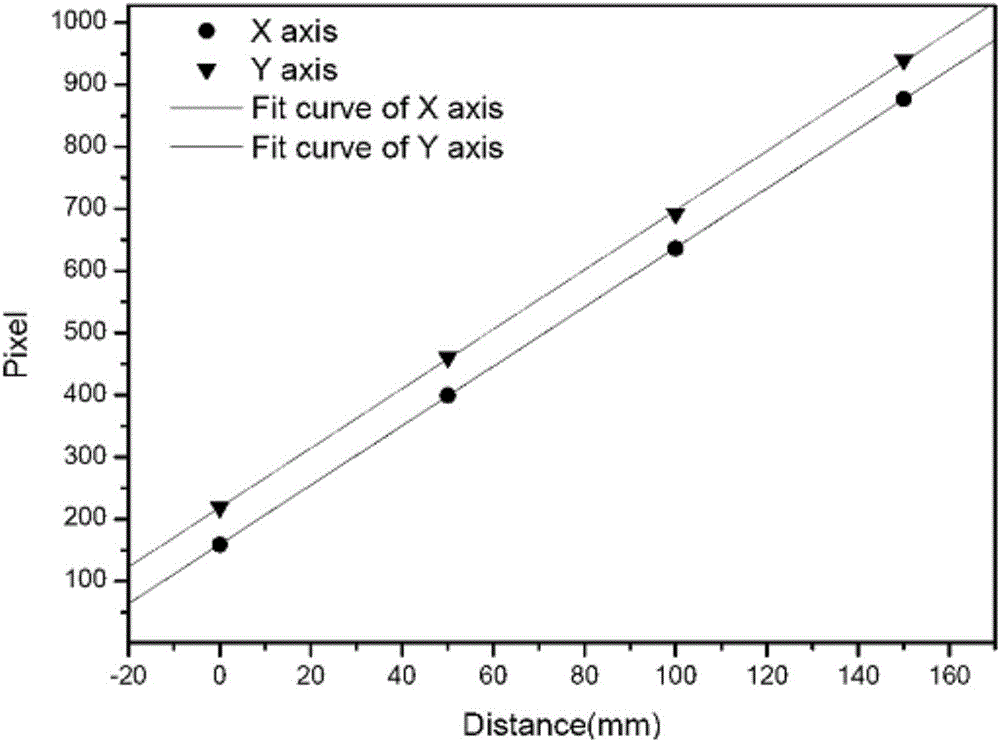

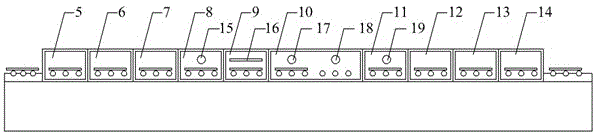

Single-beam-laser multidimensional speed measuring system and method of high-speed rarefied gas flow field

InactiveCN106771344AOvercome stabilityOvercome the influence of flow field componentsAerodynamic testingFluid speed measurementFluorescenceLaser light

The invention discloses a single-beam-laser multidimensional speed measuring system of a high-speed rarefied gas flow field. The single-beam-laser multidimensional speed measuring system comprises a high-speed rarefied gas wind tunnel (1), a laser light source module (2), a laser beam shaping module (3), a high-voltage arc discharge module (4), a fluorescent signal collecting and recording module (5), a data processing module (6) and a time sequence synchronous control module (7). The invention further provides an application method of the system.

Owner:INST OF MECHANICS - CHINESE ACAD OF SCI

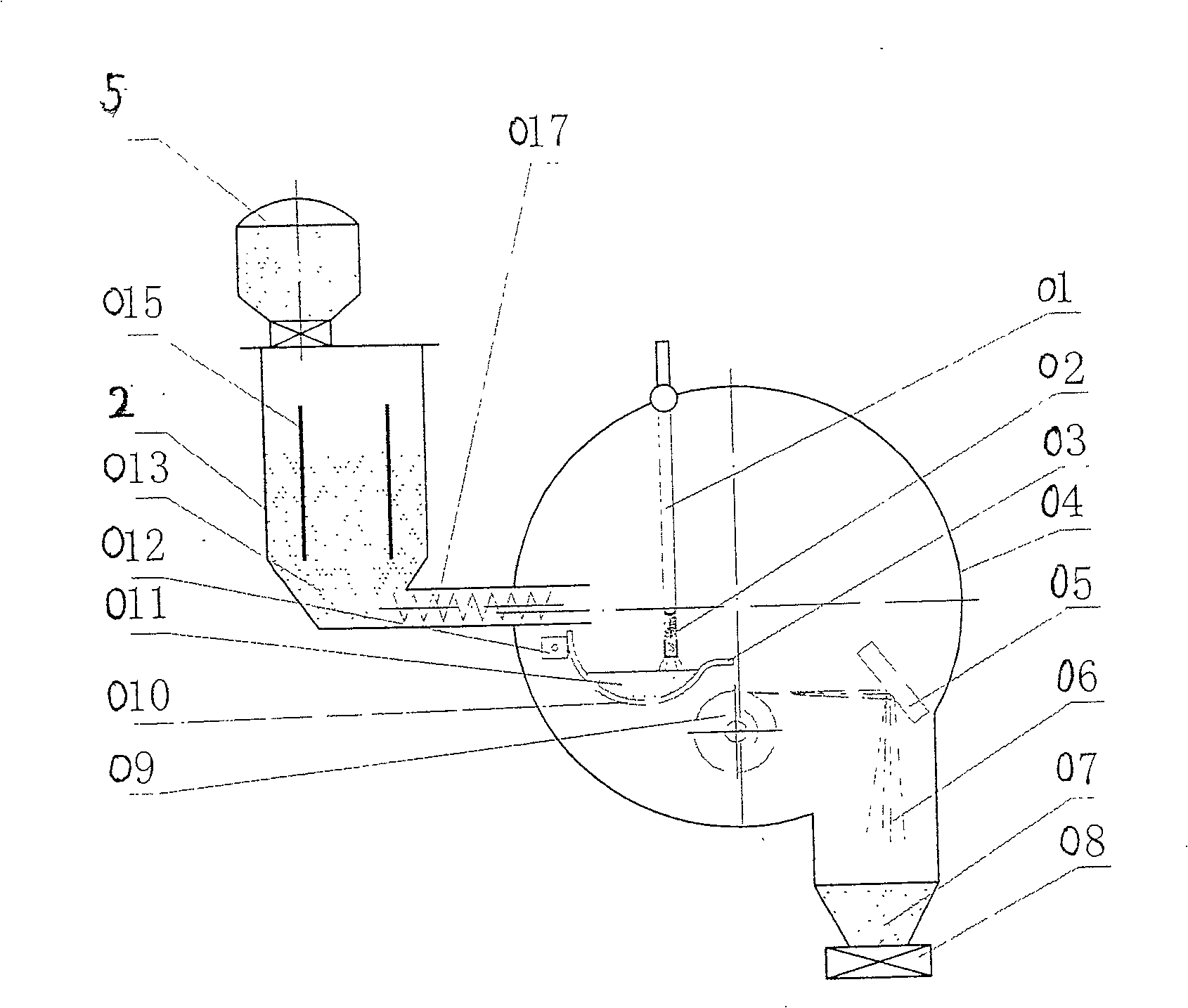

Modified high-speed steel roller and preparation method thereof

InactiveCN101797630AImprove wear resistanceShorten the production cycleRollsProcess efficiency improvementDuctile ironFerrochrome

The invention discloses a modified high-speed steel roller and a preparation method thereof. The modified high-speed steel roller is formed by adopting a centrifugal composite casting method and has a roller outer layer of high-speed steel and a roller inner layer of ductile iron or high-strength cast iron. The preparation method comprises the following steps of: forming the roller outer layer on a centrifugal casting machine; then, filling a static roller core with melted iron; and casting into a high-speed steel composite roller. The roller outer layer of the high-speed steel roller is prepared from raw materials in percentage by weight: 60-65 percent of M2 high-speed waste steel (W6Mo5Cr4V2), 1.0-1.4 percent of metal aluminum, 5.0-5.5 percent of boron iron, 9.2-9.4 percent of carbon ferrochrome iron, 0.2-0.4 percent of titanium iron, 1.0-1.2 percent of nickel-magnesium alloy and 18-23 percent of waste steel Q235. The roller can be produced by utilizing an electric furnace, has high hardness, simple and convenient process, low production cost and favorable wear resistance without adding noble iron alloy or quenching treatment and can have favorable economic benefits by popularization and use.

Owner:BEIJING UNIV OF TECH

All-in-one ceramic heating member and preparation technology thereof

ActiveCN104860683AAvoid insufficient combustionTo achieve the purpose of heating airManufacturing technologyRaw material

The invention relates to the technical field of ceramic heating member preparation technologies and especially relates to an all-in-one ceramic heating member and a preparation technology thereof. The all-in-one ceramic heating member comprises 50-95% of a ceramic raw material and 5-50% of a heating raw material. The ceramic raw material comprises 50-95% of Si3N4, 0.1-10% of MgO, 0.1-5% of Y2O3, 0.1-5% of Al2O3, 0.1-5% of SiO2, 0.1-5% of La2O3 and 0.1-5% of BN. The heating raw material comprises one or two of MoSi2 and TiC. The preparation technology comprises material blending, ball milling, drainage, molding, pre-sintering, sintering, polishing processing and electrode connection. The preparation technology has simple processes, is conducive to continuous production, has high production efficiency and a low production cost, and is conducive to large-scale production. The ceramic heating member has a long service life, stable power and high heating efficiency.

Owner:广东国研新材料有限公司

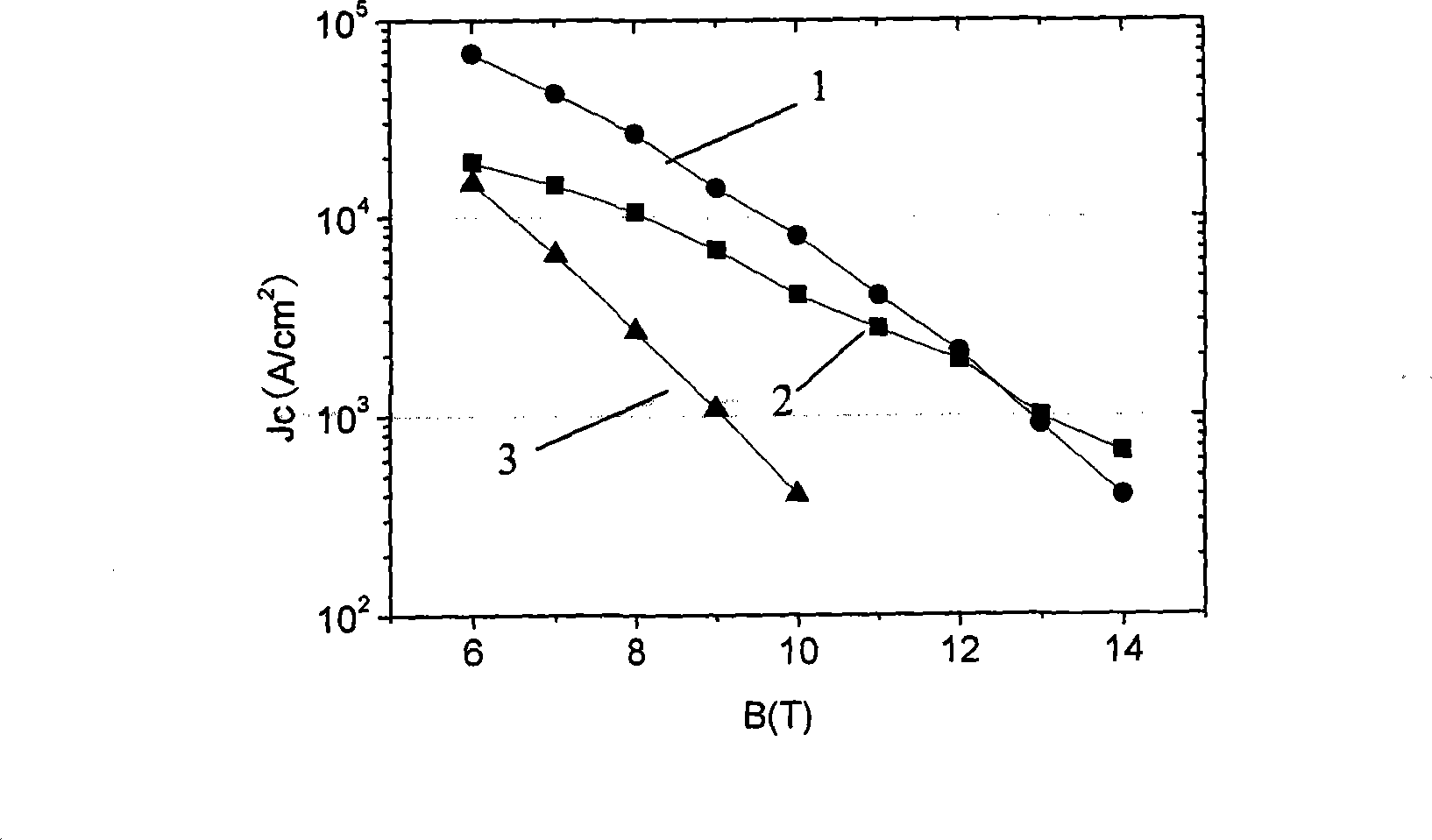

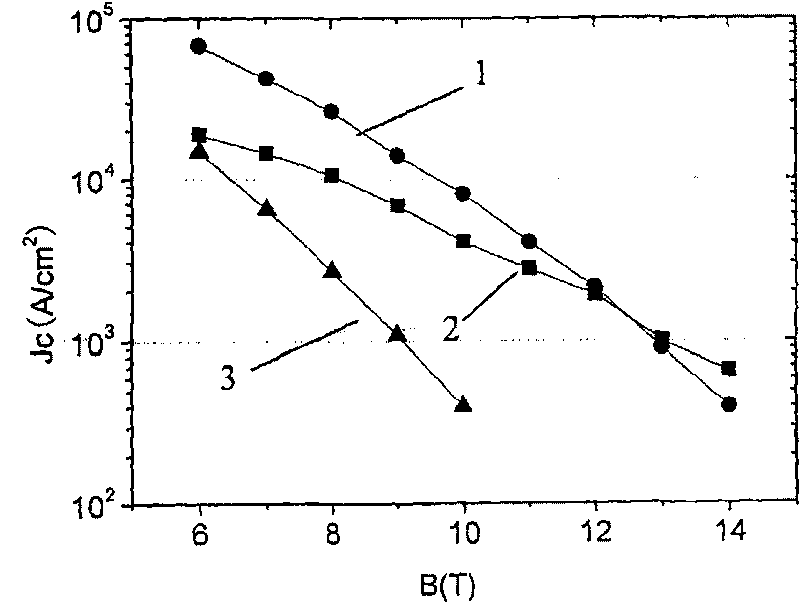

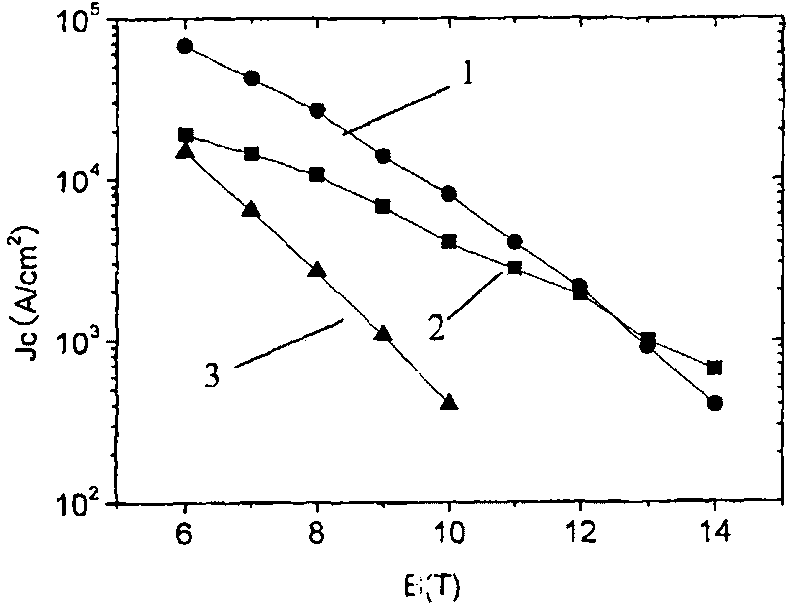

Method for preparing MgB2 superconducting material

InactiveCN101168441AImprove superconductivityOvercome oxidation and even spontaneous combustion problemsSuperconductor detailsMetal boridesSpontaneous combustionArgon atmosphere

A preparation method of MgB2 superconducting material, weighing Mg powder and B powder according to the molar ratio Mg:B=1:2, and simultaneously weighing an organic acid whose mass is 5%-30% of the total mass of Mg powder and B powder Or organic acid salt, dissolve in 5-50mL acetone or ethanol, mix the obtained solution with Mg powder and B powder, ball mill for 1-10 hours, and then dry in a vacuum oven. Press the obtained powder into tablets to obtain MgB2 superconducting block material; or put the powder into a metal tube or a metal composite tube, and after sealing, perform swaging, drawing and rolling in sequence with a deformation rate of 5% to obtain a MgB2 superconducting wire strip material; put the obtained superconducting block or wire strip in a vacuum furnace, under the protection of vacuum or argon atmosphere, heat treatment temperature is 650°C-950°C, keep warm for 0.5-2 hours, and finally make MgB2 superconducting material. The MgB2 superconducting material prepared by the invention effectively overcomes the problems of oxidation and spontaneous combustion of the refined magnesium powder after high-energy ball milling, and at the same time significantly improves the superconducting performance of the MgB2 superconducting material due to the introduction of dopants.

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

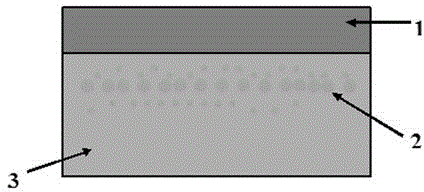

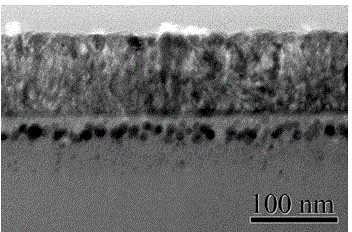

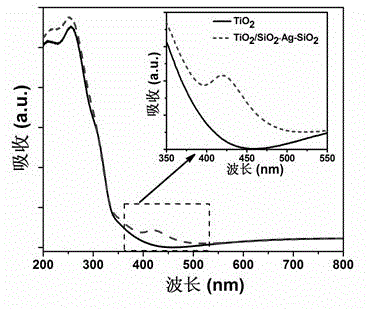

Preparation method for TiO2/SiO2-Ag-SiO2 nanocomposite film

InactiveCN102909008AOvercome oxidationPromote absorptionMetal/metal-oxides/metal-hydroxide catalystsSputteringComposite film

The invention provides a preparation method for a TiO2 / SiO2-Ag-SiO2 nanocomposite film. The method comprises the steps of: injecting Ag ions and then forming Ag nanoparticles in a quartz glass substrate; and then depositing a TiO2 film on the surface of a silica substrate by virtue of direct-current reactive magnetron sputtering so as to obtain the TiO2 / SiO2-Ag-SiO2 composite film. The Ag nanoparticles prepared by the method provided by the invention are inlaid in quartz glass, thus greatly overcoming the problem that the Ag nanoparticles are oxidized. Via the nanocomposite structure prepared by the method provided by the invention, the absorption of titanium dioxide to an ultraviolet ray part is greatly improved, so that the photocatalytic efficiency is improved. The preparation method can be widely applied to the field of optoelectronics.

Owner:HUBEI UNIV OF TECH

Scorpionfish-ink polysaccharide and its preparation

ActiveCN1895665AEasy extraction and separationOvercoming thermal instabilityOrganic active ingredientsPeptide/protein ingredientsChemical purityIon

A squid ink polyose is prepared proportionally from the ink sac of squid, food-class lipase and food-class papain through proportional mixing, enzyme hydrolyzing, filtering, depositing in edible alcohol or chemical-purity acetone, dissolving deposit in deionized water, recovering alcohol or acetone, drying the deposit, and pulverizing. It has high stability.

Owner:宁波超星海洋生物制品有限公司

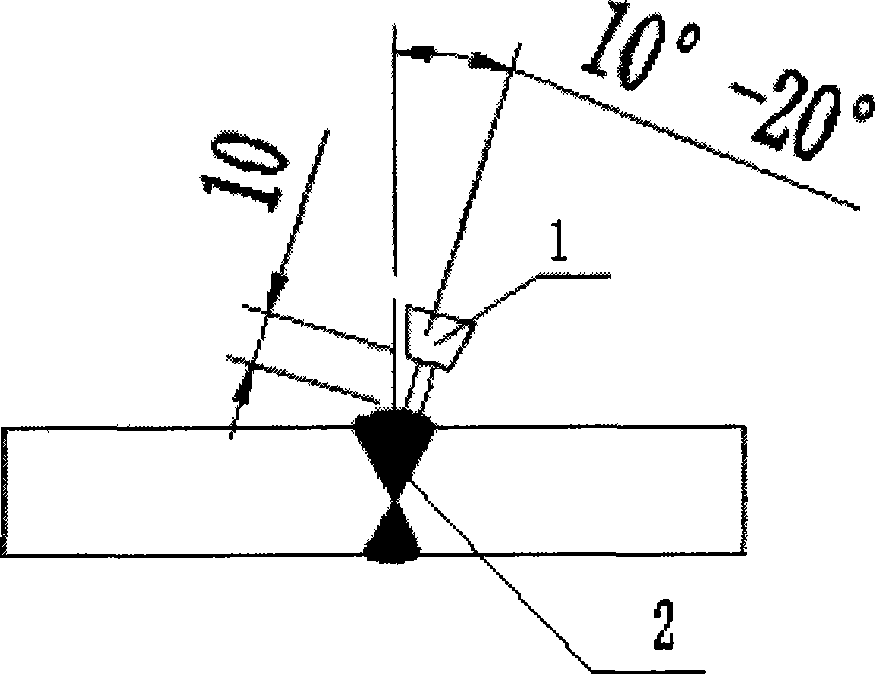

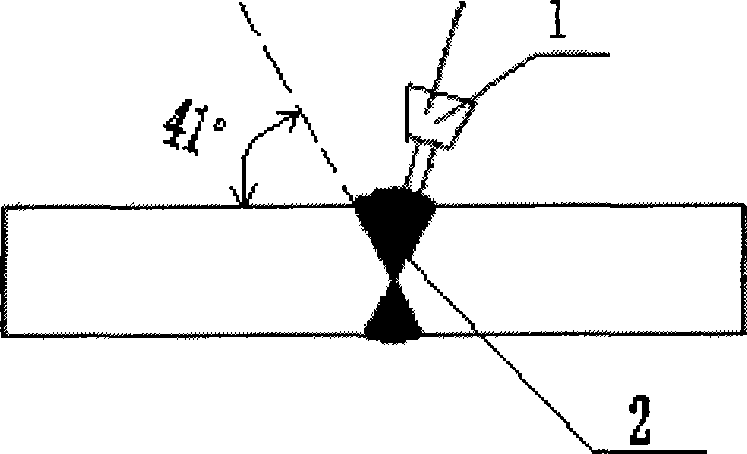

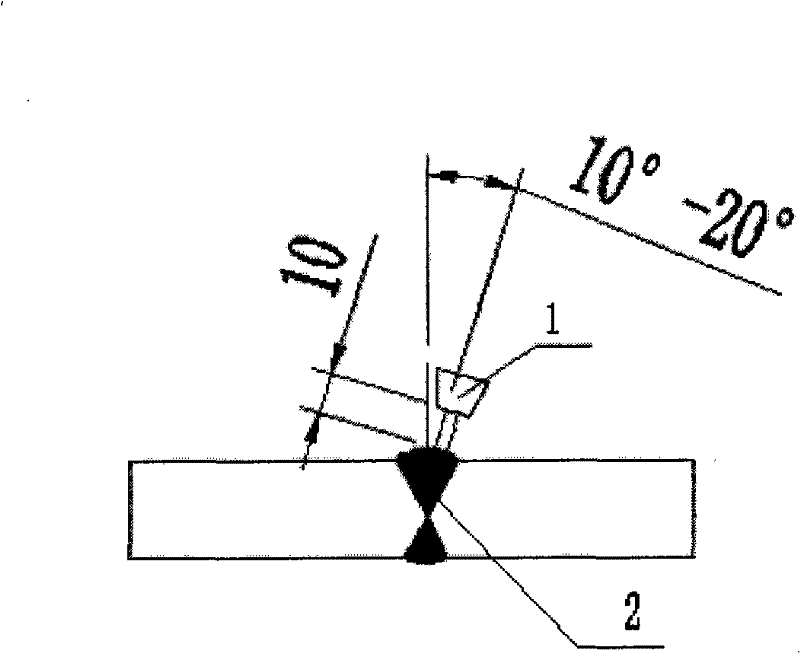

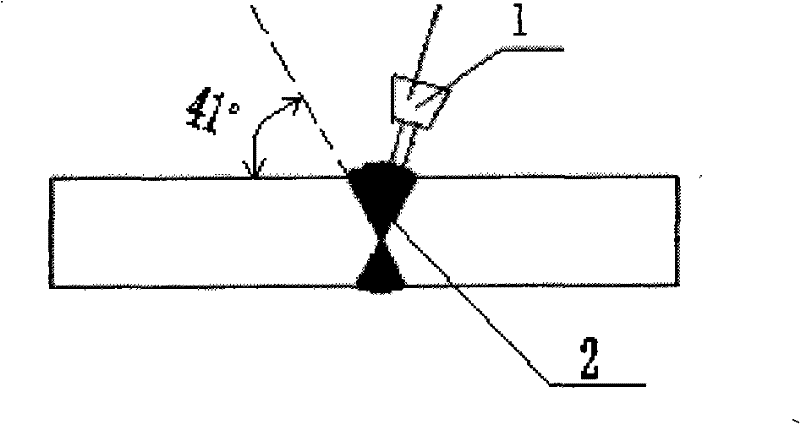

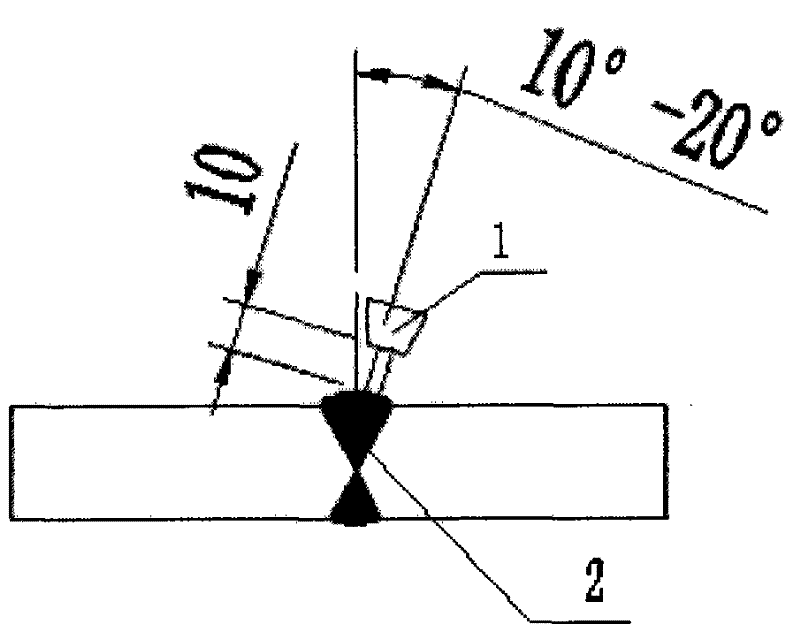

CO2 gas shielded welding method

The invention discloses a welding method for CO2 gas shielded welding, which selects a flux-cored wire with a deoxidizing agent component for welding, and comprises: before welding, removing moisture in the CO2 gas and cleaning impurities on a workpiece; and in the welding process, selecting reasonable welding conditions, current, voltage, electric arc and wire extending length, and controlling temperature and humidity of operating environment, wherein workpieces of which the thickness is less than 6mm are provided with I-shaped bevels; and workpieces of which the thickness is more than 6mm are provided with bevels between 40.5 and 41.5 DEG. The method solves the problems that the oxidability of the CO2 gas shielded welding and the size of air holes and bevels influence material using amount, the formation of weld of the CO2 gas shielded welding is poor, and the like by the prior welding method.

Owner:CHINA 19TH METALLURGICAL CORP

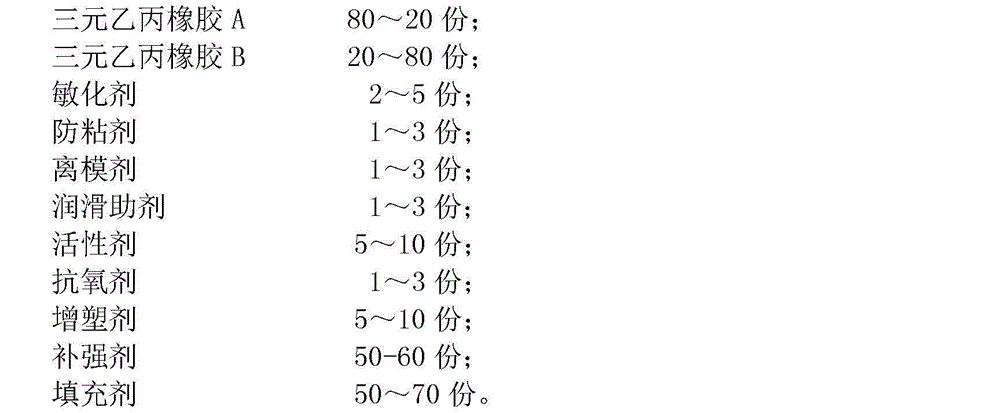

Irradiation cross-linking EPDM (Ethylene-Propylene-Diene Monomer) insulating eraser and preparation method thereof

The invention relates to an irradiation cross-linking EPDM (Ethylene-Propylene-Diene Monomer) insulating eraser and a preparation method thereof. The irradiation cross-linking EPDM insulating eraser comprises ingredients in parts by weight: 80-20 parts of EPDM A, 20-80 parts of EPDM B, 2-5 parts of sensitizer, 1-3 parts of anti-sticking agent, 1-3 parts of release agent, 1-3 parts of lubricating auxiliaries, 5-10 parts of active agent, 1-3 parts of antioxidant, 5-10 parts of plasticizer, 50-60 parts of reinforcing agent, and 50-70 parts of filling agent. According to the irradiation cross-linking EPDM insulating eraser and the preparation method thereof, by adopting a new sulfuration mode, namely irradiation cross-linking mode, the problems that the existing direct steam pipeline sulfuration mode causes the oxidation of a copper wire, water of a cable and surface pollution to the cable and the like can be thoroughly avoided.

Owner:FAR EAST CABLE +2

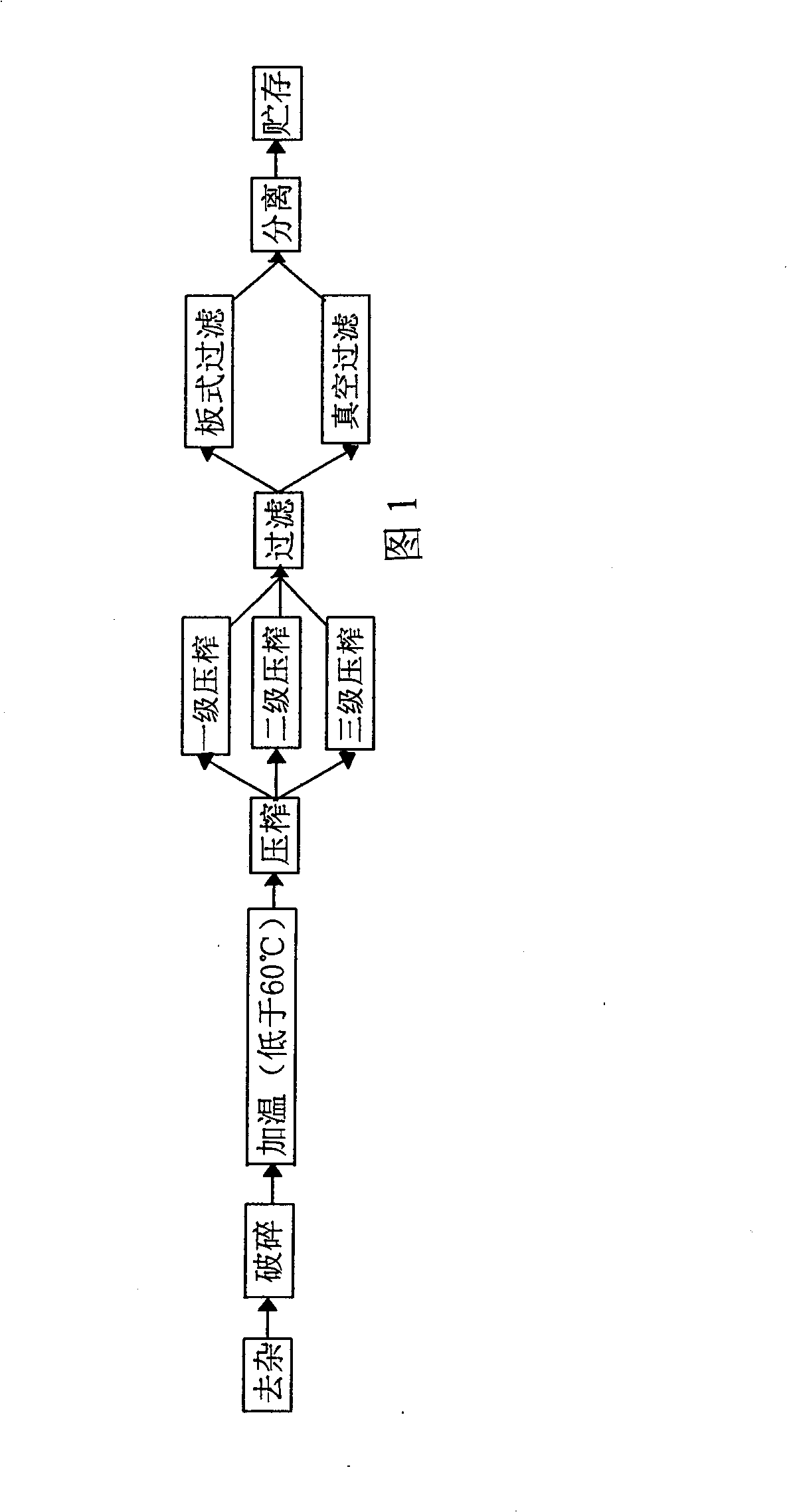

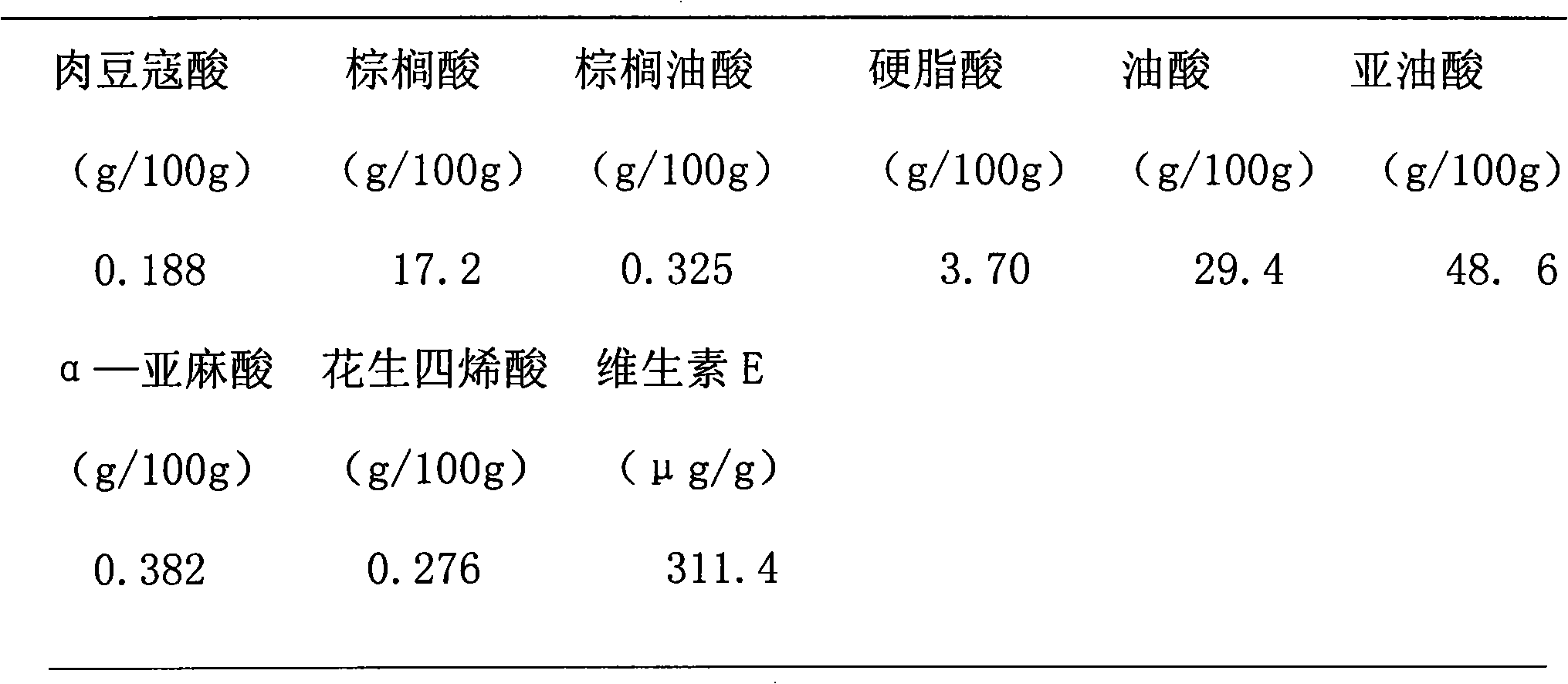

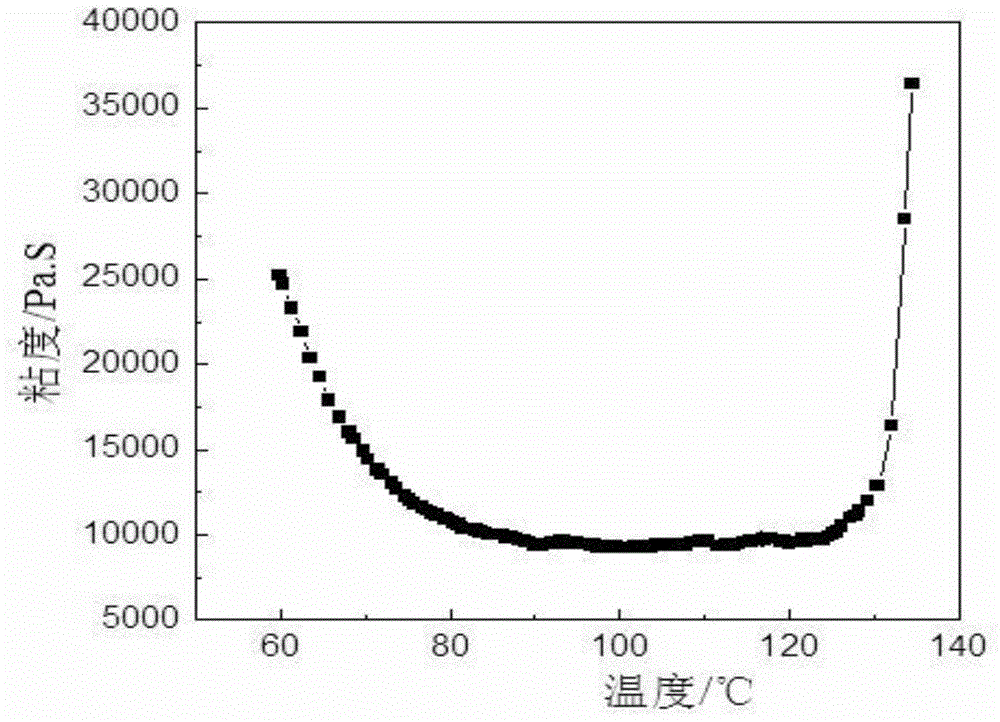

Preparation method for rose hip or seed oil

InactiveCN101343594AOvercome oxidationEasy to operateEssential-oils/perfumesFatty-oils/fats productionThree levelFrying-pans

The invention relates to a preparation method for rose fruit or rose seed oil, which comprises the main procedures: sorting and removing coarse rose fruit, crushing the rose fruit, removing husks, then breaking rose seeds into particles and heating the particles in a frying pan up to 40 DEG C to 60 DEG C to separate out the rose oil through one to three levels of squeezing, as well as separating out ester gum and phospholipid from the rose oil; and maintaining the purity of the rose oil through filtration, storage and purification.

Owner:周志忠

Semiconductor adhesive film material for preparing lightning-protection shunt bars and preparation method thereof

InactiveCN104356603AOvercome oxidationAvoid uneven dispersionElectrical resistance and conductanceEpoxy

The invention relates to a semiconductor adhesive film material and a preparation method thereof, particularly a semiconductor adhesive film material for preparing lightning-protection shunt bars and a preparation method thereof. The invention aims to solve the technical problems of complex technique, incompatibility and nonmatching property caused by co-gluing or secondary gluing when other adhesives are adopted in the existing technique. The material is composed of the following components in parts by weight: 75-100 parts of epoxy resin, 15-30 parts of thermoplastic resin, 6-12 parts of rubber elastomer, 15-25 parts of curing agent, 2-6 parts of accelerator, 6-12 parts of non-metal conducting filler and 10-20 parts of non-metal semiconductor filler. The method comprises the following steps: 1. weighing; 2. preparing a resin mixture; 3. blending and discharging; and 4. calendering to form the film. The semiconductor adhesive film material has the characteristics of the structural adhesive film and also has the characteristic of resistance value of the semiconductor adhesive material. The semiconductor adhesive film material is used for preparing lightning-protection shunt bars.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

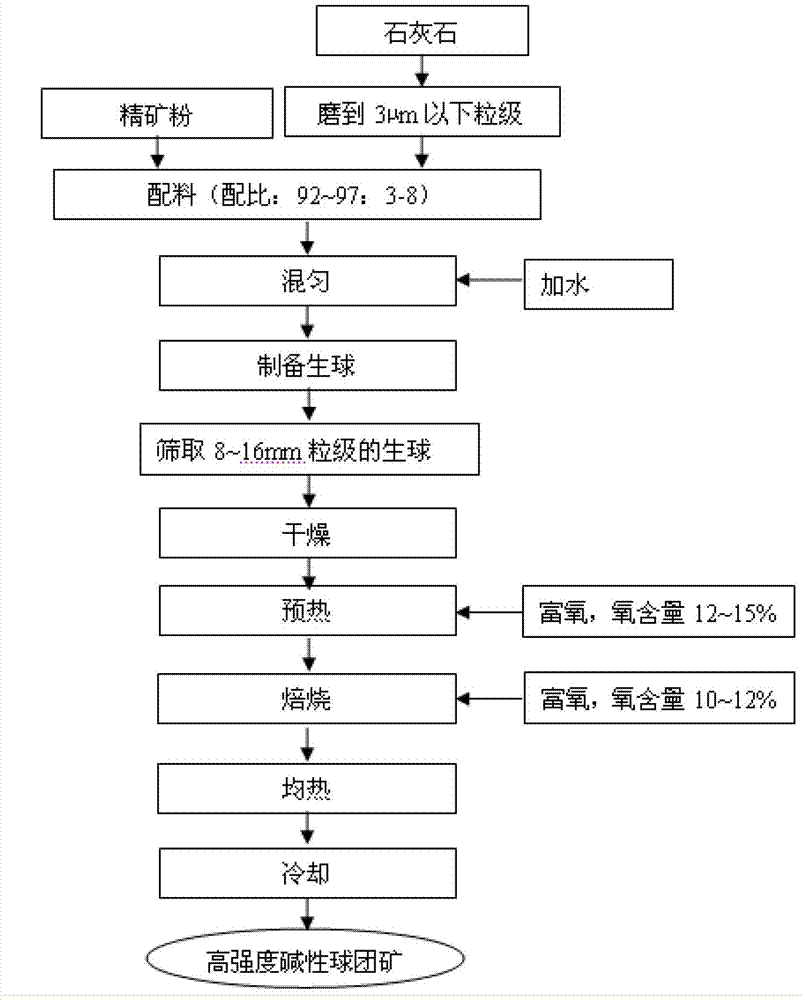

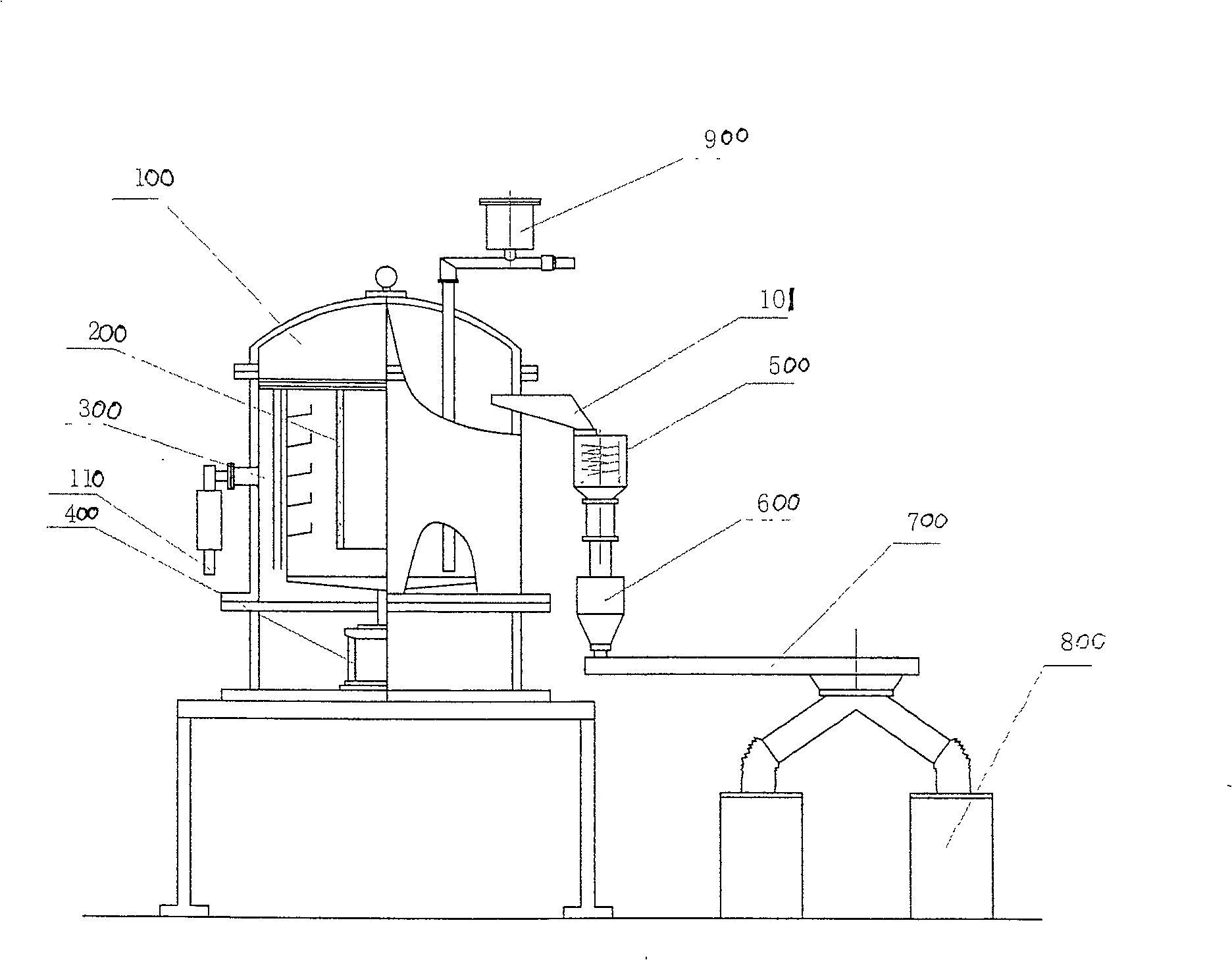

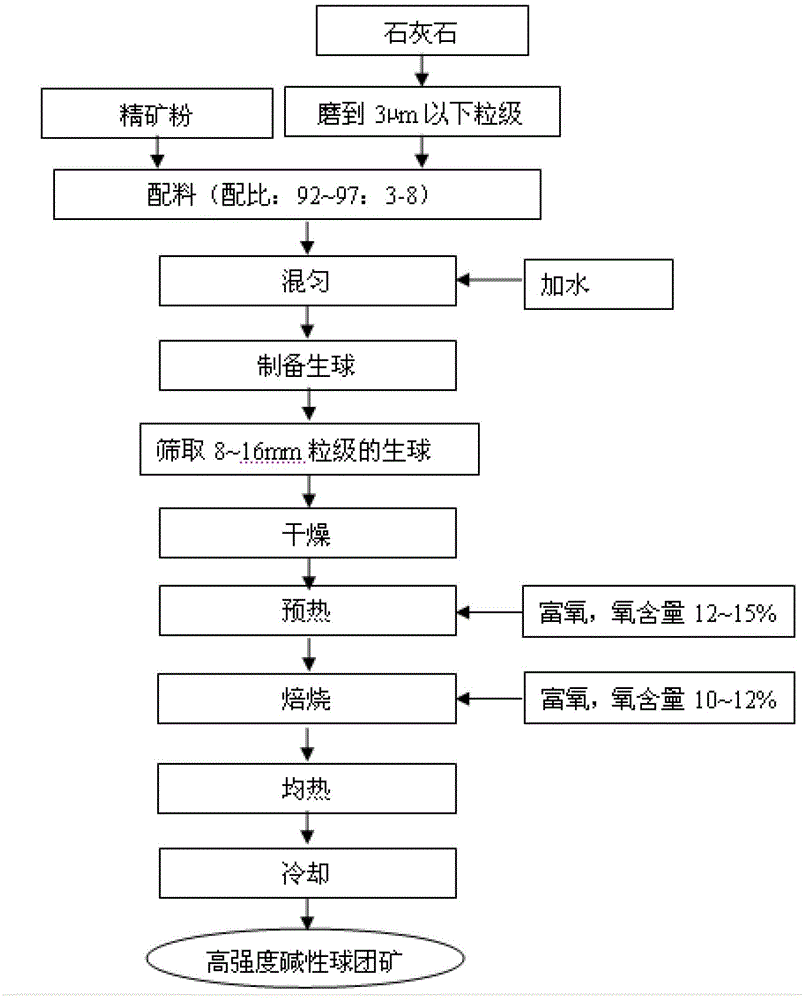

Method for improving compressive strength of alkali pellets prepared with limestone

ActiveCN103397175AOvercome oxidationOvercome the problem of recrystallizationAdhesiveCompressive strength

The invention relates to a method for improving the compressive strength of alkali pellets prepared with limestone. The method comprises the following steps of: grinding the limestone into superfine particle size of less than 3 microns, adding the limestone powder of superfine particles into pellet concentrate powder with the particle size of less than 74 microns, adding water, and mixing uniformly in a mixer, wherein an adhesive is not used in proportioning; and pelletizing the uniform mixture, and roasting the screened fresh pellets. The roasting process comprises drying, preheating, roasting, soaking and cooling; and oxygen enrichment is performed in the preheating and roasting processes, the oxygen content in the preheating process is kept between 12 and 15 percent, and the oxygen content in the roasting process is kept between 10 and 12 percent. The problem that the compressive strength of the alkali pellets prepared with the limestone obviously declines is effectively solved through the measures of grinding of the limestone, oxygen enrichment in the roasting process and the like.

Owner:SHOUGANG CORPORATION

Integrated member type methyl aromatic hydrocarbon selective oxidizing catalyst and its preparation and use

InactiveCN1820846AOvercome oxidationSolve environmental problemsCatalyst carriersFunctional group formation/introductionAdhesiveActive component

The integrated member type catalyst for selective oxidation of methyl aromatic hydrocarbon includes carrier, adhesive and active component. The active component is attached via the adhesive onto the carrier, and the carrier is porous honeycomb ceramic material, metal screen or corrugated metal sheet. The active component has the general expression of V1PaXbAlcMdCreOn. The catalyst is superior to available one, which has environmental pollution caused by liquid phase oxidation, complete oxidation and catalyst deactivation of 'hot point' in the catalyst bed, and has high selectivity and excellent industrial application foreground.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of scorpionfish-ink polysaccharide

ActiveCN100467061COvercoming thermal instabilityOvercome oxidationOrganic active ingredientsPeptide/protein ingredientsAlcoholPolysaccharide

Owner:宁波超星海洋生物制品有限公司

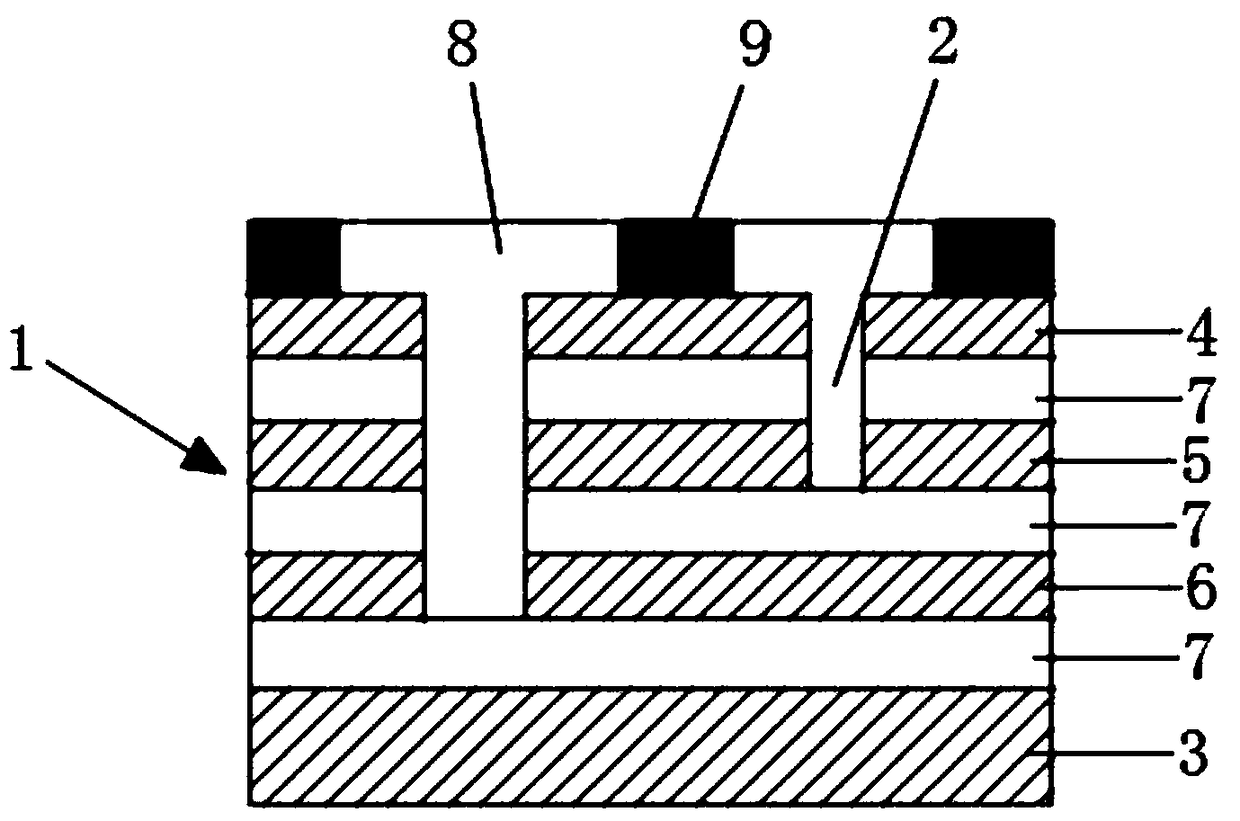

Method for preparing soft and hard combined circuit of plug-and-pull finger dual camera module type

PendingCN108882565AImprove problems such as sheddingOvercome oxidationMultilayer circuit manufactureSolder maskVacuum pressure

The invention discloses a method for preparing a soft and hard combined circuit of a plug-and-pull finger dual camera module, comprising the following process steps of: material cutting, drilling, VCPblack holes, inner layer circuit producing, covering film pressing, high temperature oil printing, plasma cleaning, PP copper foil assembling, laminated vacuum pressure transmitting, drilling, VCP copper sinking, outer layer circuit producing, solder mask producing, high temperature ink printing, nickel gold grinding, high temperature ink removing, blue glue printing, and nickel palladium gold sandblasting. According to the method for preparing soft and hard combined circuit of plug-and-pull finger dual camera module, the problem of oxidation and dirt on the gold surface of the plug-and-pullfinger can be effectively solved and the yield can be increased from 0% to 95% by pushing the nickel gold process of inner plug-and-pull finger.

Owner:ZHUHAI HAIXUN SOFT MULTILAYER PROTOTYPES

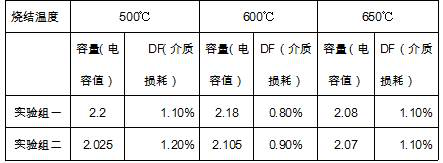

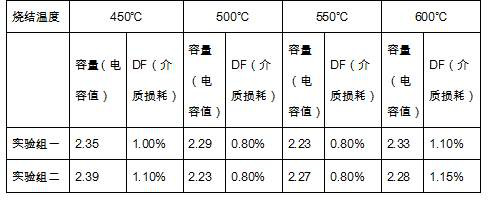

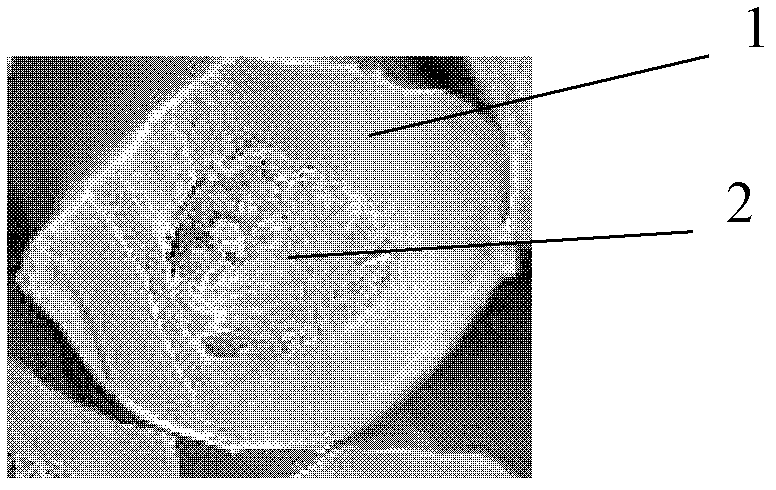

Conductive paste for electronic component

PendingCN113889293AOvercome oxidationLower sintering temperatureConductive materialMetal/alloy conductorsConductive pasteCapacitance

The invention discloses a conductive paste for an electronic component such as a single-layer or multi-layer capacitor, a varistor, a surge absorbing element and the like. The conductive paste comprises conductive metal powder, glass, resin, a solvent and a chemical additive. Through the mode, when the conductive paste for the electronic component is sintered in the air, copper is used for replacing part of silver metal, so that the problem of copper oxidation is solved, the sintering temperature can be reduced, energy is saved, the production cost and the manufacturing difficulty are reduced, the manufacturing time is shortened, and the working efficiency is improved.

Owner:XUANTAI ELECTRONICS SUZHOU

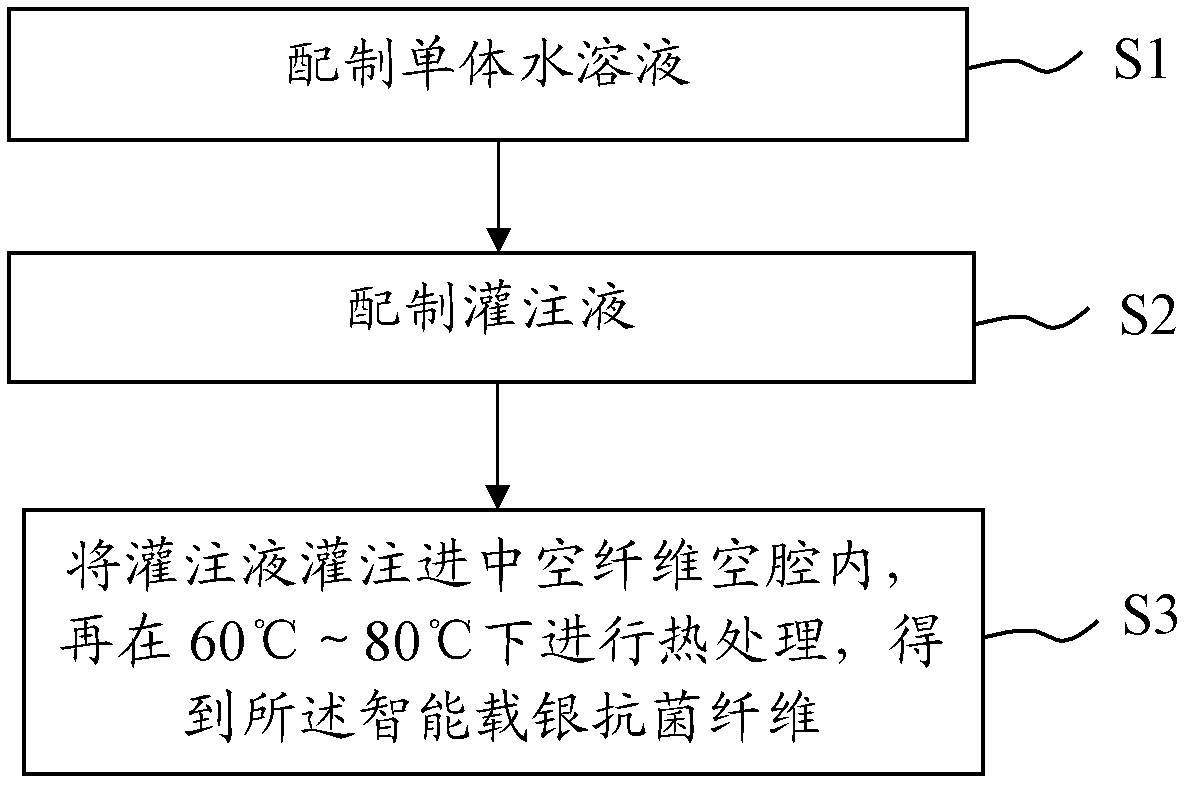

Intelligent silver-contained antibacterial fiber and preparation method and application thereof

The invention relates to an intelligent silver-contained antibacterial fiber and a preparation method and an application thereof. The intelligent silver-contained antibacterial fiber is of a core shell structure and comprises a core layer which takes a hollow fiber as a shell layer, is positioned in a cavity of the hollow fiber and is formed by silver-contained hydrogel; no through hole is arranged on the side wall of the hollow fiber; and elemental silver which occupies 0.1-10 percents of the intelligent silver-contained antibacterial fiber in total weight is contained in the silver-contained hydrogel. The intelligent silver-contained antibacterial fiber is safe and nontoxic and has the characteristic that the response is generated when the intelligent silver-contained antibacterial fiber is in contact with water, the release of silver ions is intelligently controlled, and the sterilization is quick and efficient. The preparation method of the intelligent silver-contained antibacterial fiber comprises the following steps of: pouring silver-contained hydrogel monomer solution from one end of the hollow fiber into the cavity of the hollow fiber and forming the silver-contained hydrogel core layer in the cavity of the hollow fiber through heat treatment. Manufactured process equipment is simple and can realize industrial production.

Owner:龚文忠

Electroconductive paste for silicon solar cell electrode and preparation method thereof

ActiveCN103700428BImprove photoelectric conversion efficiencyReduce manufacturing costFinal product manufactureNon-conductive material with dispersed conductive materialConductive pasteSilicon solar cell

Owner:CHANGZHOU SHICHUANG ENERGY CO LTD

Integrated member type methyl aromatic hydrocarbon selective oxidizing catalyst and its preparation and use

InactiveCN100435949COvercome oxidationSolve environmental problemsCatalyst carriersFunctional group formation/introductionAdhesiveActive component

The integrated member type catalyst for selective oxidation of methyl aromatic hydrocarbon includes carrier, adhesive and active component. The active component is attached via the adhesive onto the carrier, and the carrier is porous honeycomb ceramic material, metal screen or corrugated metal sheet. The active component has the general expression of V1PaXbAlcMdCreOn. The catalyst is superior to available one, which has environmental pollution caused by liquid phase oxidation, complete oxidation and catalyst deactivation of 'hot point' in the catalyst bed, and has high selectivity and excellent industrial application foreground.

Owner:ZHEJIANG UNIV OF TECH

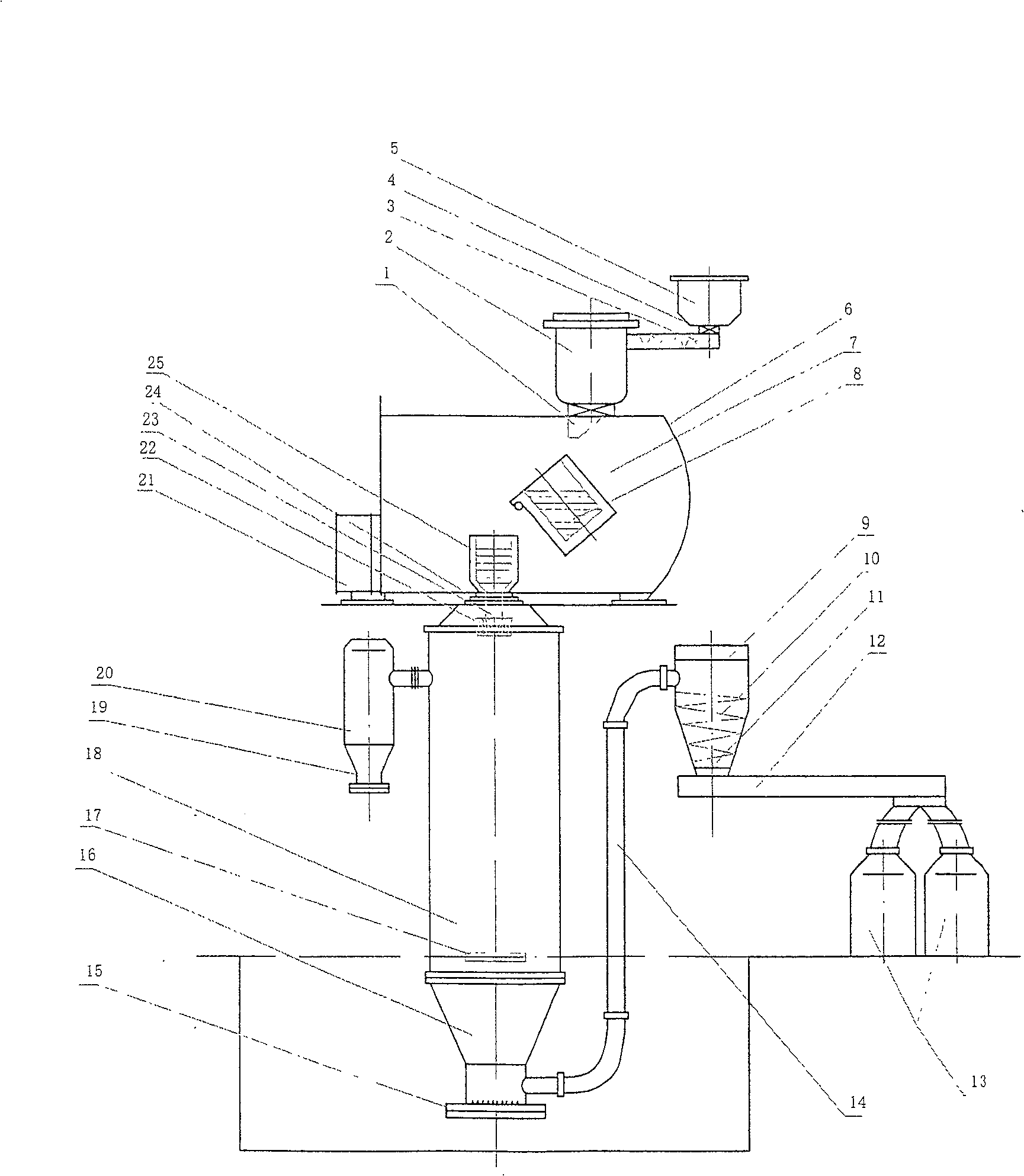

Method and apparatus for preparing rapid-solidified hydrogen-storage alloy powder material

InactiveCN100475390CSuitable for large-scale industrial productionReduce oxygen contentFuel cellsHigh pressureInduction furnace

The present invention provides a preparation method of quickly-coagulable hydrogen storage alloy powder and its equipment. Said preparation method includes four procedures of raw material preparation, smelting, making powder and hydrogenation treatment. Said invention also provides the concrete steps of the above-mentioned every procedure. Said equipment includes induction furnace or argon plasma arc furnace, atomized powder-making device and hydrogenation device, etc.

Owner:江苏申建氢能新材料有限公司

Method for improving compressive strength of alkali pellets prepared with limestone

The invention relates to a method for improving the compressive strength of alkali pellets prepared with limestone. The method comprises the following steps of: grinding the limestone into superfine particle size of less than 3 microns, adding the limestone powder of superfine particles into pellet concentrate powder with the particle size of less than 74 microns, adding water, and mixing uniformly in a mixer, wherein an adhesive is not used in proportioning; and pelletizing the uniform mixture, and roasting the screened fresh pellets. The roasting process comprises drying, preheating, roasting, soaking and cooling; and oxygen enrichment is performed in the preheating and roasting processes, the oxygen content in the preheating process is kept between 12 and 15 percent, and the oxygen content in the roasting process is kept between 10 and 12 percent. The problem that the compressive strength of the alkali pellets prepared with the limestone obviously declines is effectively solved through the measures of grinding of the limestone, oxygen enrichment in the roasting process and the like.

Owner:SHOUGANG CORPORATION

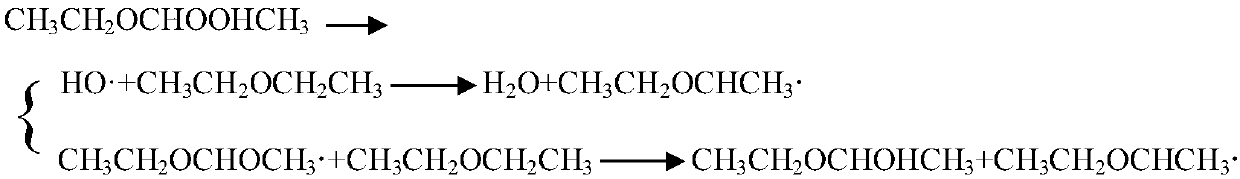

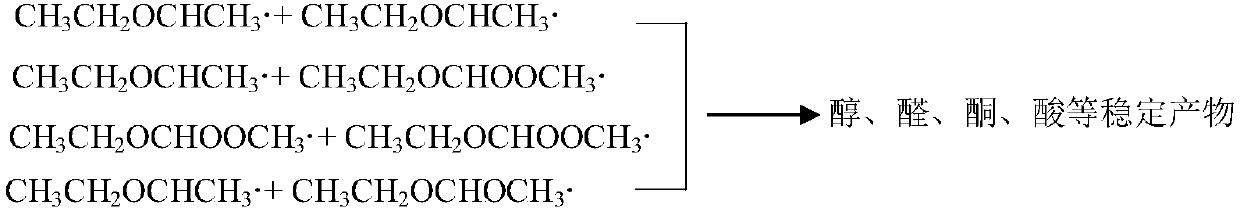

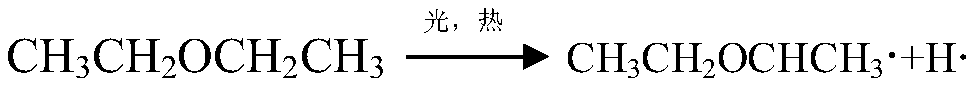

Diethyl ether purification method, and method for improving purity of nitrogen-containing organic matter by using diethyl ether

InactiveCN111153778AOvercome oxidationOvercoming the impurity of the recrystallized productEther separation/purificationHalogenated hydrocarbon preparationEtherFree radicals scavenger

The invention relates to a diethyl ether purification method. The method comprises the following steps: adding a free radical scavenger and a hydroperoxide decomposer into diethyl ether or adding a mixed solution of the free radical scavenger and the hydroperoxide decomposer into diethyl ether to purify the diethyl ether, and then purifying the purified diethyl ether mixed solution after a full reaction by adopting any one of a liquid separation extraction method, a filtering method or a re-evaporation method to obtain purified diethyl ether. The invention also discloses a method for improvingthe purity of the nitrogen-containing organic matter by using diethyl ether, and an application thereof. The diethyl ether used in the method is purified by using the purification method. The purified diethyl ether is used for cleaning the nitrogen-containing organic matter, so active free radicals and peroxydiethyl ether contained in the diethyl ether are removed, and generation of halogen elementary substances in the nitrogen-containing organic halide is effectively reduced, thereby the high-purity nitrogen-containing organic matter is obtained. The methods have the characteristics of simplicity, feasibility, low cost and the like.

Owner:HANGZHOU MICROQUANTA SEMICON CO LTD

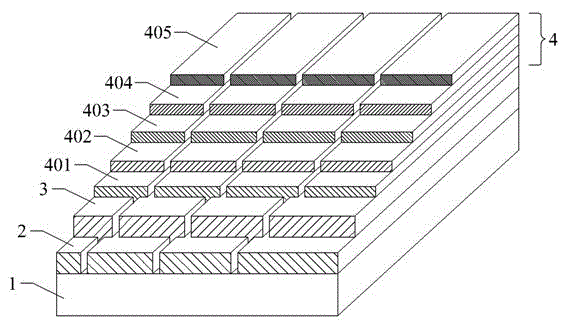

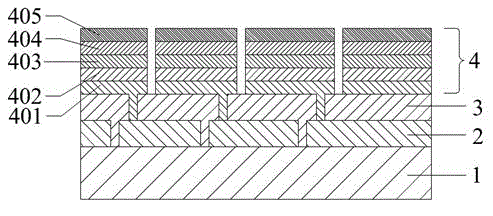

Film solar energy battery and manufacturing method thereof

InactiveCN103943696ASolve Adhesion ProblemsImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationAlloyEngineering

The invention belongs to the technical field of a solar energy battery, and relates to a film solar energy battery and a manufacturing method thereof, for solving the technical problems of welding performance of the back electrode of a film solar energy battery, adhesive force among each film layer and the like. The film solar energy battery is composed of multiple internally series-connected photoelectric units, comprises a front electrode, a photoelectric conversion layer and a back electrode which are sequentially stacked on a substrate, and is characterized in that the back electrode is of a multi-layer structure composed of a transparent conductive layer, a transition layer, a first reflection layer, a second reflection layer and a welding enhancement protective layer. The reflection layer of the back electrode is composed of two membranes, i.e., a silver membrane and an aluminum membrane, and the thickness of the silver membrane is smaller than the thickness of the aluminum membrane, so that the production cost can be effectively reduced; and the aluminum membrane is provided with a nickel copper film layer or a nickel-vanadium alloy film layer so that the back electrode can be protected, and the welding performance of the back electrode can also be improved.

Owner:SHEN ZHEN TRONY SCI & TECH DEV CO LTD

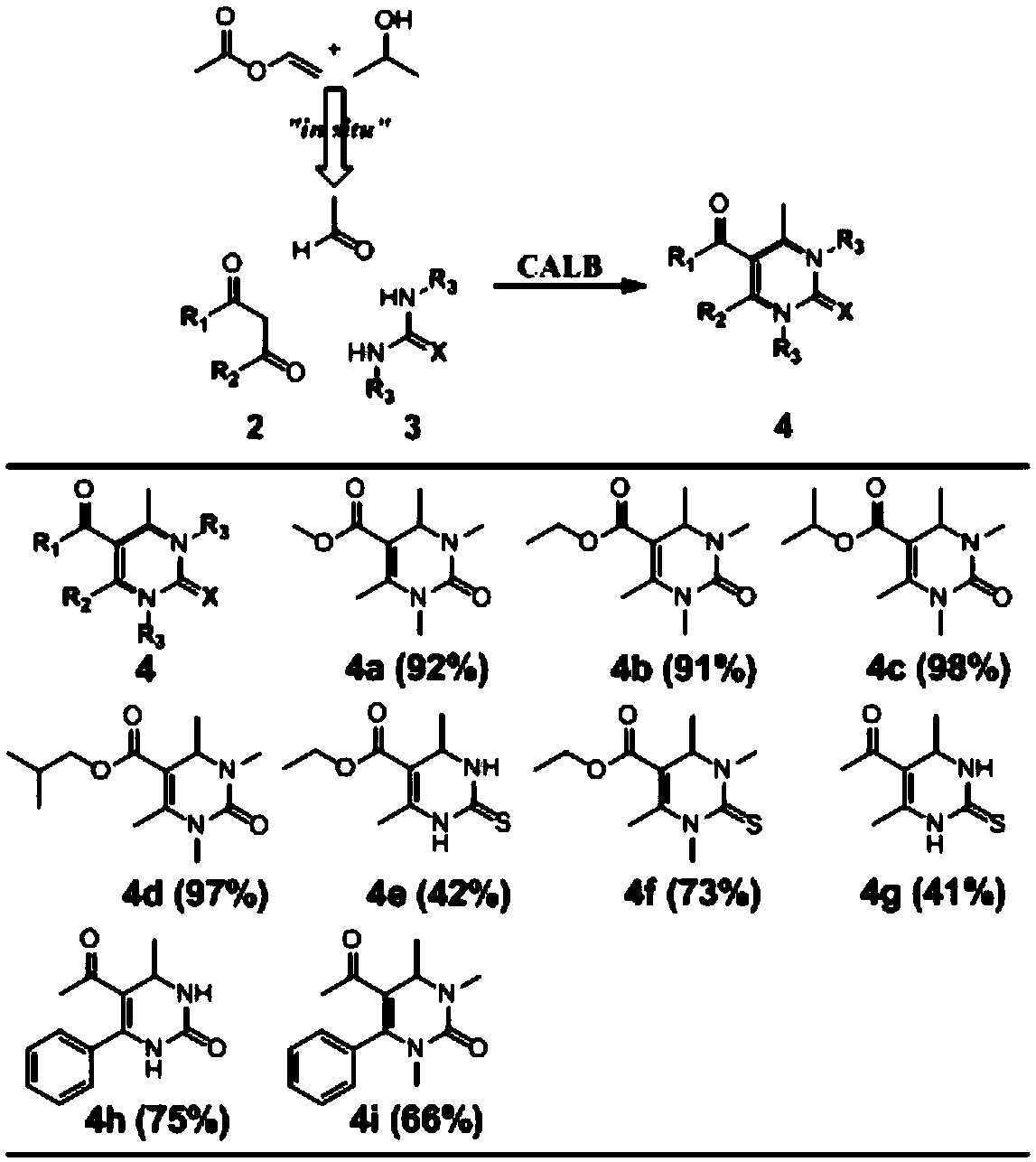

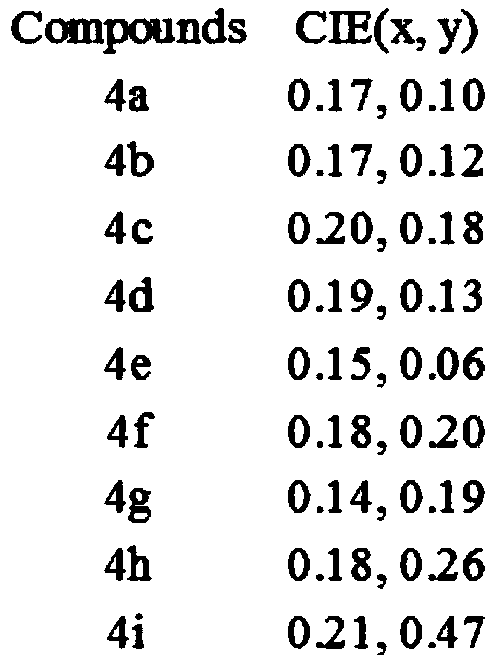

3,4-dihydropyrimidin-2(1h)-one and its derivatives as well as their synthesis method and application

ActiveCN106588782BThe reaction method is simpleImprove reaction efficiencyOrganic chemistryFermentationSynthesis methodsKetone

Owner:SICHUAN UNIV

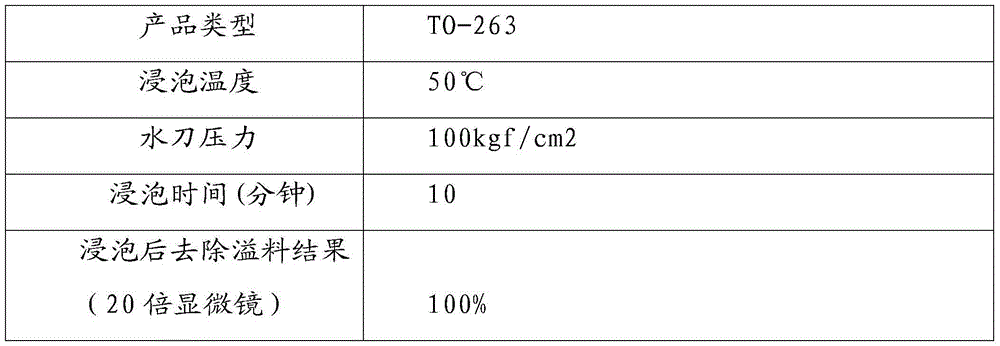

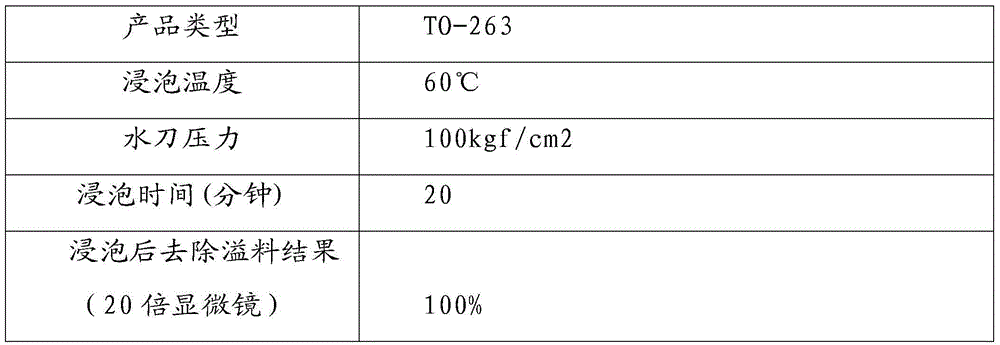

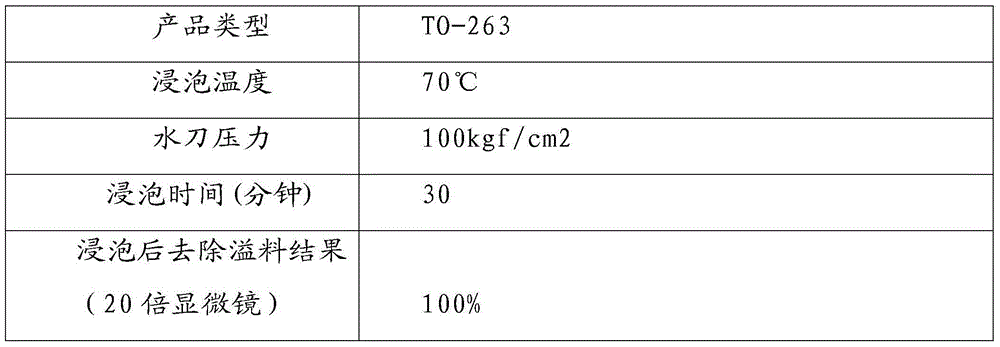

Low-temperature alkaline soak solution and preparation method thereof

InactiveCN105087191ASimple preparation processSmooth responseSemiconductor/solid-state device manufacturingSurface-active non-soap compounds and soap mixture detergentsPotassium hydroxideWastewater

The invention discloses a low-temperature alkaline soak solution and a preparation method thereof. The low-temperature alkaline soak solution comprises, by mass, 10 to 20% of potassium hydroxide, 5 to 15% of ethylene glycol monobutyl ether and 2 to 6% of surfactant, with the balance being pure water. The preparation method comprises the following steps: successively adding pure water, potassium hydroxide, ethylene glycol monobutyl ether and surfactant into a material mixing tank; carrying out uniform mixing under stirring so as to obtain a mixture solution; and introducing the mixture solution into a filter for filtering so as to finally obtain the low-temperature alkaline soak solution. The preparation method for the low-temperature alkaline soak solution has the characteristics of easiness, stable reaction, high production efficiency, no toxicity, low corrosivity, easy treatment of waste water, etc.

Owner:WUXI WELNEW MICRO ELECTRONICS

A semiconductor adhesive film material for preparing lightning protection shunt strips and its preparation method

InactiveCN104356603BOvercome oxidationAvoid uneven dispersionElectrical resistance and conductanceElastomer

The invention relates to a semiconductor adhesive film material and a preparation method thereof, particularly a semiconductor adhesive film material for preparing lightning-protection shunt bars and a preparation method thereof. The invention aims to solve the technical problems of complex technique, incompatibility and nonmatching property caused by co-gluing or secondary gluing when other adhesives are adopted in the existing technique. The material is composed of the following components in parts by weight: 75-100 parts of epoxy resin, 15-30 parts of thermoplastic resin, 6-12 parts of rubber elastomer, 15-25 parts of curing agent, 2-6 parts of accelerator, 6-12 parts of non-metal conducting filler and 10-20 parts of non-metal semiconductor filler. The method comprises the following steps: 1. weighing; 2. preparing a resin mixture; 3. blending and discharging; and 4. calendering to form the film. The semiconductor adhesive film material has the characteristics of the structural adhesive film and also has the characteristic of resistance value of the semiconductor adhesive material. The semiconductor adhesive film material is used for preparing lightning-protection shunt bars.

Owner:INST OF PETROCHEM HEILONGJIANG ACADEMY OF SCI

Method for preparing MgB2 superconducting material

InactiveCN101168441BOvercome oxidationImprove superconductivitySuperconductor detailsMetal boridesBall millEthanol

Owner:INST OF ELECTRICAL ENG CHINESE ACAD OF SCI

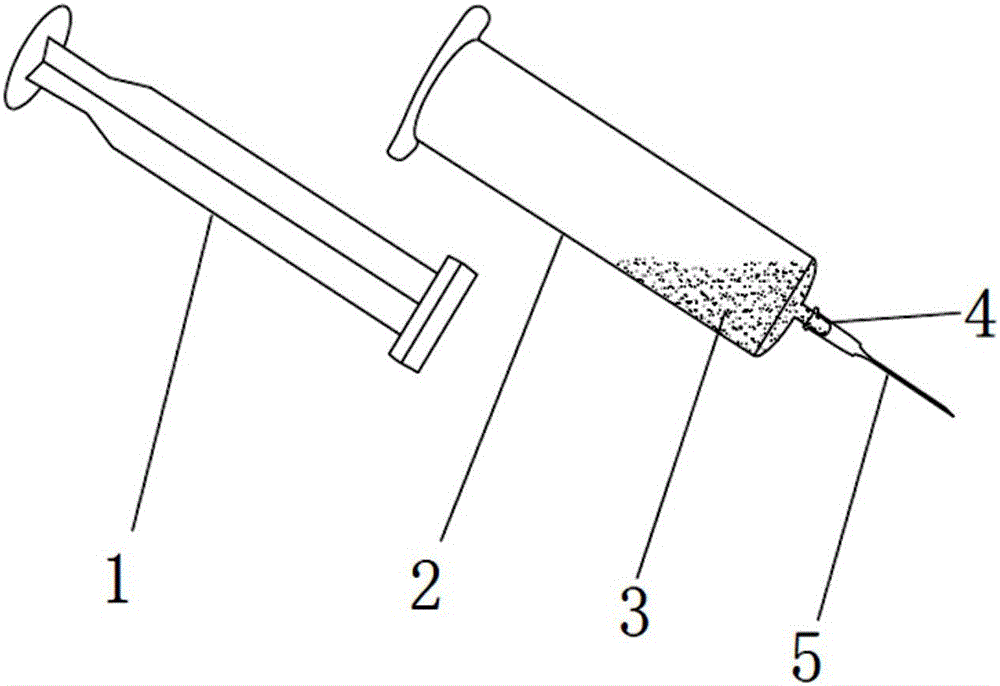

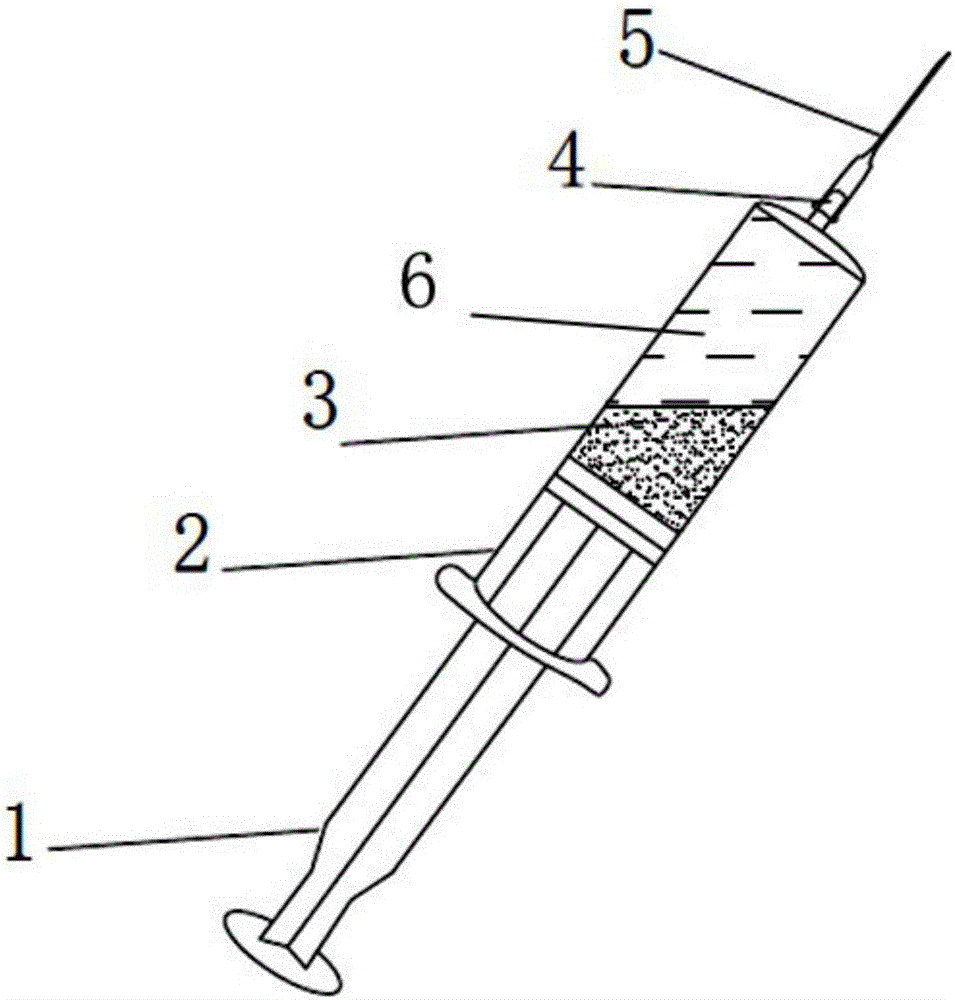

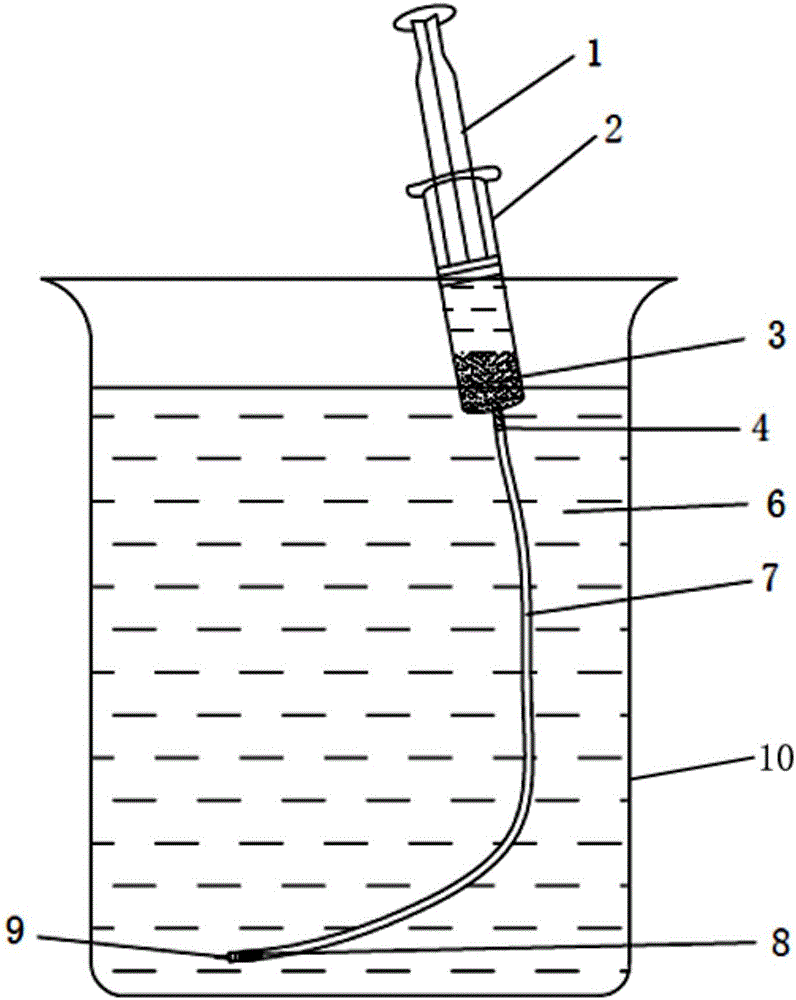

Filling method for cadmium column used for water nitrate determination

ActiveCN105784916AOvercome leaksOvercome oxidationChemical methods analysisWater qualityCadmium Cation

The invention provides a filling method for a cadmium column used for water nitrate determination and relates to determination of nitrate in water.A syringe piston is dismantled, and a syringe is filled with cadmium particles; the syringe sucks in a hydrochloric acid solution to be washed, oxide layers on the surfaces of the cadmium particles are removed, the acid solution is removed, and the syringe sucks in ultrapure water to be washed to be neutral; the syringe sucks in a copper sulfate solution for shaking soaking, the waste solution is removed, ultrapure water is used for shaking washing till no colloidal copper is contained, and the syringe sucks in ultrapure water which seals the cadmium particles; glass fibers are stuffed into the bottom of a reduction column, a connector is installed, and the whole reduction column is immersed in a water container to be filled with water; a syringe needle is taken down, a syringe nipple and the upper portion of the reduction column are connected, the syringe nipple is immersed in water downwards, the head of the syringe is beaten, the syringe piston is pushed to make the cadmium particles enter the reduction column, glass fibers are stuffed into the upper portion of the reduction column, and the connector is installed; the cadmium column is activated according to the method in GB17378.4-2007, the reduction rate of the cadmium column is determined, and then filling of the cadmium column is completed.

Owner:THIRD INST OF OCEANOGRAPHY STATE OCEANIC ADMINISTATION

An integrally formed ceramic heating body and its preparation process

ActiveCN104860683BAvoid insufficient combustionTo achieve the purpose of heating airMaterials scienceRaw material

The present invention relates to the technical field of preparation technology of a ceramic heating body, in particular to an integrally formed ceramic heating body and its preparation process. The integrally formed ceramic heating body is composed of 50-95% ceramic raw materials and 5-50% heating raw materials , the ceramic raw material is composed of 50‑95% Si 3 N 4 , 0.1-10% of MgO, 0.1-5% of Y 2 o 3 , 0.1‑5% Al 2 o 3 , 0.1‑5% SiO 2 , 0.1‑5% La 2 o 3 , 0.1‑5% BN composition, and the exothermic material is MoSi 2 , TiC or a mixture of two kinds; the preparation process of the ceramic heating body is mixing, ball milling, filtering, forming, pre-sintering, sintering, polishing and electrode connection processes. The manufacturing process is simple, which is conducive to continuous production and production. The efficiency is high, the production cost is low, and it is beneficial to realize large-scale production; the ceramic heating body of the present invention has long service life, stable power and high heating efficiency.

Owner:广东国研新材料有限公司

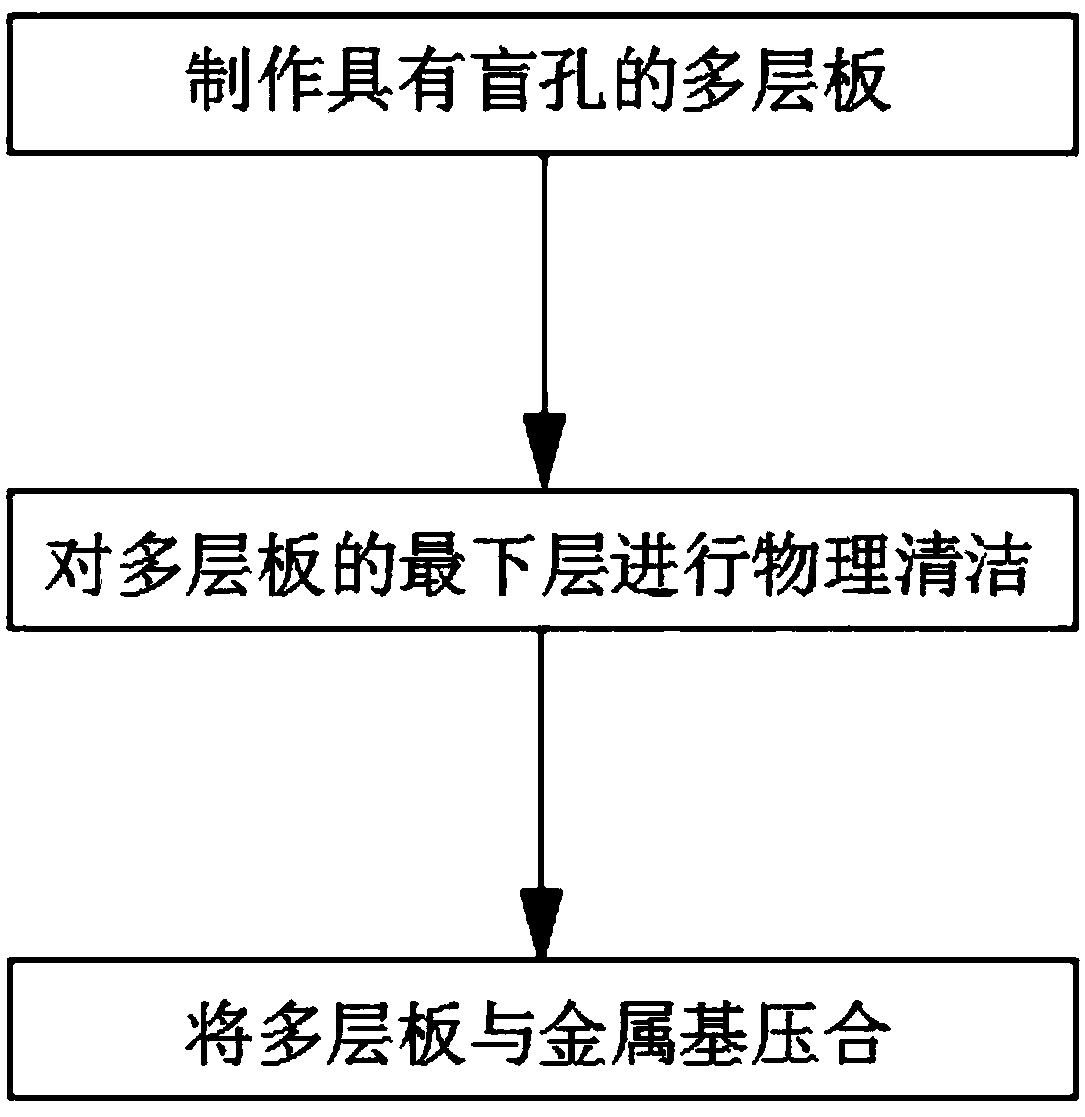

A production method for preventing surface oxidation of blind hole plate

ActiveCN105764275BOvercome oxidationSimple stepsMultilayer circuit manufactureCircuit laminationSurface oxidationEngineering

The invention relates to the field of printed circuit board manufacturing, in particular to a manufacturing method capable of protecting the surface of a blind hole board from oxidization.The manufacturing method mainly comprises a step S1 of manufacturing a multilayer board with blind holes; a step S2 of performing physical cleaning on a lowermost layer of the multilayer board; and a step S3 of performing press fit of the multilayer board and a metal base.The manufacturing method is simple in steps, the problem of oxidization of the surface of the blind hole board can be effectively solved, the problem that when the blind hole board is oxidized, manpower and material resources need to be spent for treatment is solved, resource and production time are greatly saved, and the production efficiency is improved.

Owner:KINWONG ELECTRONICS TECH LONGCHUAN

CO2 gas shielded welding method

Owner:CHINA 19TH METALLURGICAL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com