Irradiation cross-linking EPDM (Ethylene-Propylene-Diene Monomer) insulating eraser and preparation method thereof

A rubber and irradiation technology, applied in rubber insulators, organic insulators, etc., can solve the problems of unsmooth application of irradiation cross-linked rubber materials and inability to transfer to normal industrial production, etc. The problem of wire adhesion and the effect of avoiding copper wire oxidation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

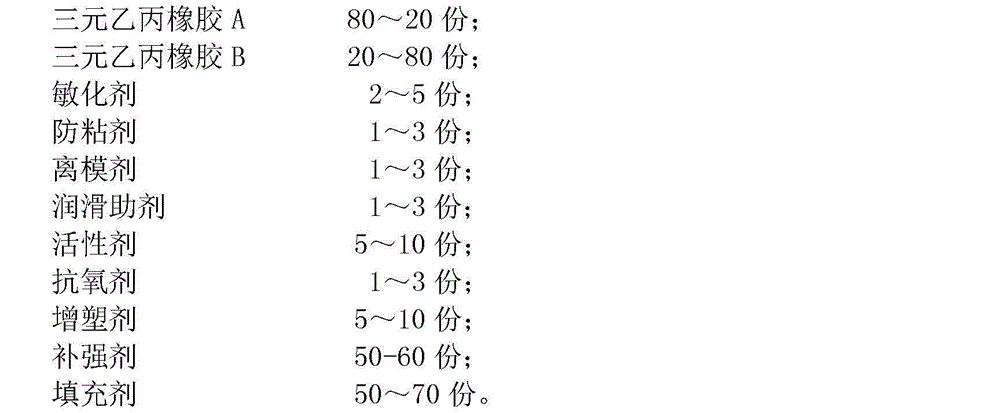

[0032] The composition of the radiation crosslinked EPDM insulating rubber of the present embodiment, the proportioning number of parts are shown in Table 1:

[0033] Table 1

[0034]

[0035] Prepare as follows:

[0036] (1) Ingredients: Accurately measure and weigh various materials according to the formula;

[0037] (2) Mixing: Add filler, EPDM rubber, active agent, antioxidant, lubricating aid, mold release agent, anti-adhesive agent, sensitizer, reinforcing agent and plasticizer to the Mix in the internal mixer for 2~3 minutes; then clean the bucket, press the top bolt and continue mixing for 7~8 minutes, the temperature of the glue output is 110~120°C; then turn it on the bag turner at least three times before opening; on the rubber filter machine Filter the glue, use a 20-mesh filter and a 40-mesh filter each;

[0038] (3) Sheeting: After filtering the rubber, press the sheet on the mill, pull it once and roll it; then roll the sheet on the calender, and finally t...

Embodiment 2)

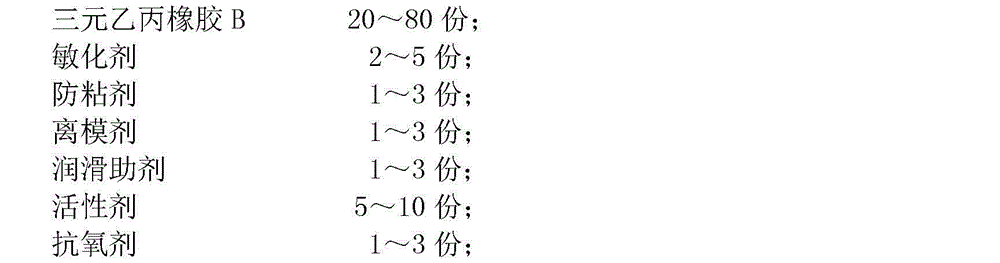

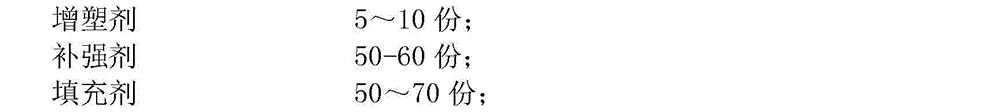

[0049] The composition of the radiation crosslinked EPDM insulating rubber of the present embodiment, the proportioning number of parts are shown in Table 4:

[0050] Table 4

[0051]

[0052] See Example 1 for the preparation steps.

[0053] Insulated wire core 1.5 mm 2The key points of the production process are shown in Table 2:

[0054] Refer to Example 1 for the irradiation process.

[0055] Insulated wire core 1.5 mm 2 After irradiation crosslinking, the properties of EPDM insulating rubber are shown in Table 5:

[0056] table 5

[0057]

Embodiment 3)

[0059] The composition of the radiation crosslinked EPDM insulating rubber of the present embodiment, the proportioning number of parts are shown in Table 6:

[0060] Table 6

[0061]

[0062] See Example 1 for the preparation steps.

[0063] Insulated wire core 1.5 mm 2 The key points of the production process are shown in Table 2:

[0064] Refer to Example 1 for the irradiation process.

[0065] Insulated wire core 1.5 mm 2 After irradiation crosslinking, the properties of EPDM insulating rubber are shown in Table 7:

[0066] Table 7

[0067]

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com