A production method for preventing surface oxidation of blind hole plate

A technology of surface oxidation and production methods, which is applied in the direction of multilayer circuit manufacturing and circuit lamination, can solve the problems of inability to blow dry, dry, consume a lot of manpower, reduce production efficiency, etc., save resources and production time, overcome Oxidation of the surface and the effect of improving productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

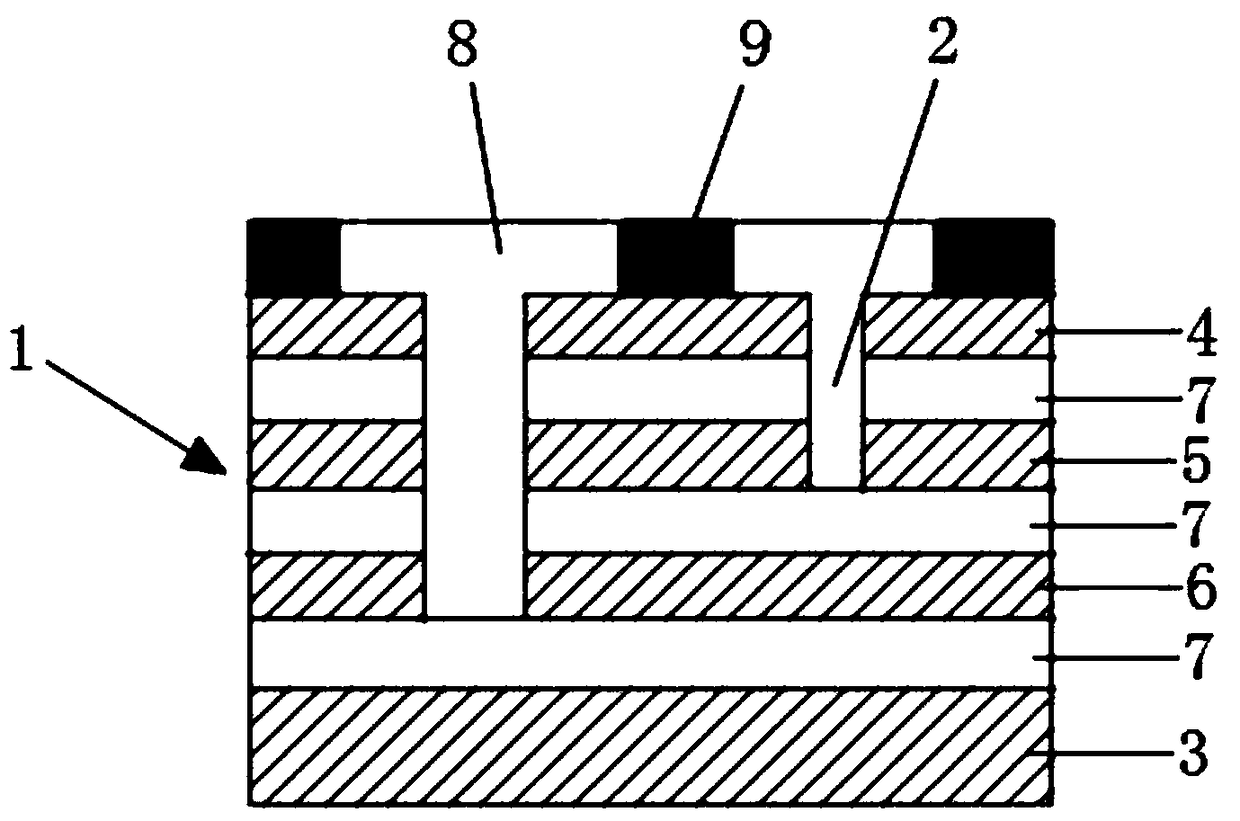

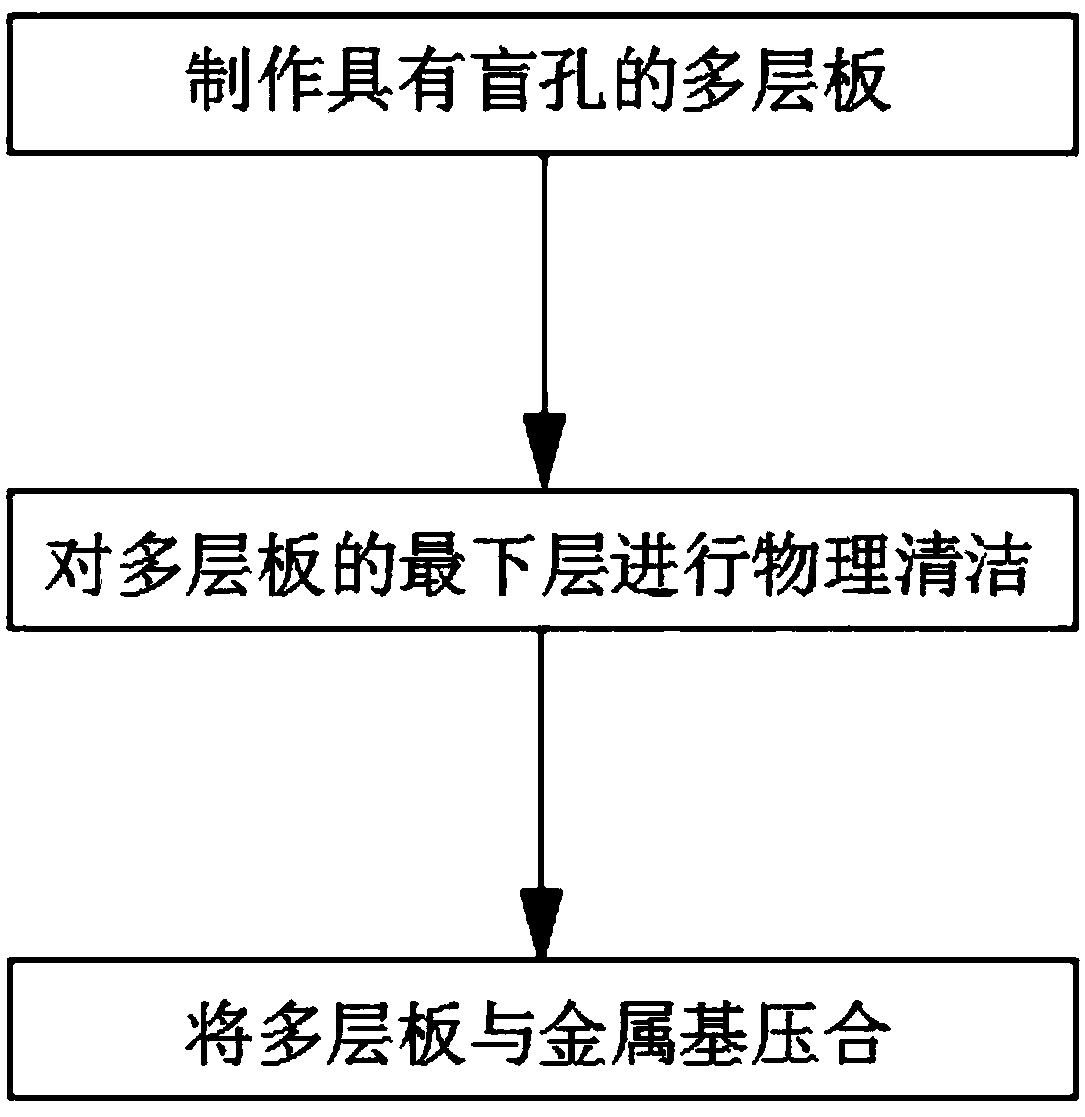

[0020] Such as Figure 1~2 As shown, the preparation method for preventing blind hole plate surface oxidation of the present invention comprises the following steps:

[0021] S1. Making a multi-layer board 1 with blind holes 2: that is, completing the drilling, wiring, solder resist layer 9 and immersion gold layer 8 of the first layer to the Nth layer;

[0022] S2. Physically clean the lowermost layer of the multilayer board 1, that is, pre-treatment;

[0023] S3. Laminating the multilayer board 1 with the dielectric layer 7 and the metal base 3 .

[0024] Because the multi-layer board 1 is very thin, only about 0.3mm, before step S2, one side of the multi-layer board 1 is pasted on the board by tape to prevent it from being drawn into the machine. The thickness of the plate is greater than or equal to 1.0 mm, and the plate may preferably be an e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com