Semiconductor adhesive film material for preparing lightning-protection shunt bars and preparation method thereof

A technology of semiconductor and shunt strips, which is applied in the field of semiconductor film materials and its preparation, can solve problems such as mismatch, complex process, and incompatibility, and achieve the effects of solving stability, good application prospects, and improving dielectric properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

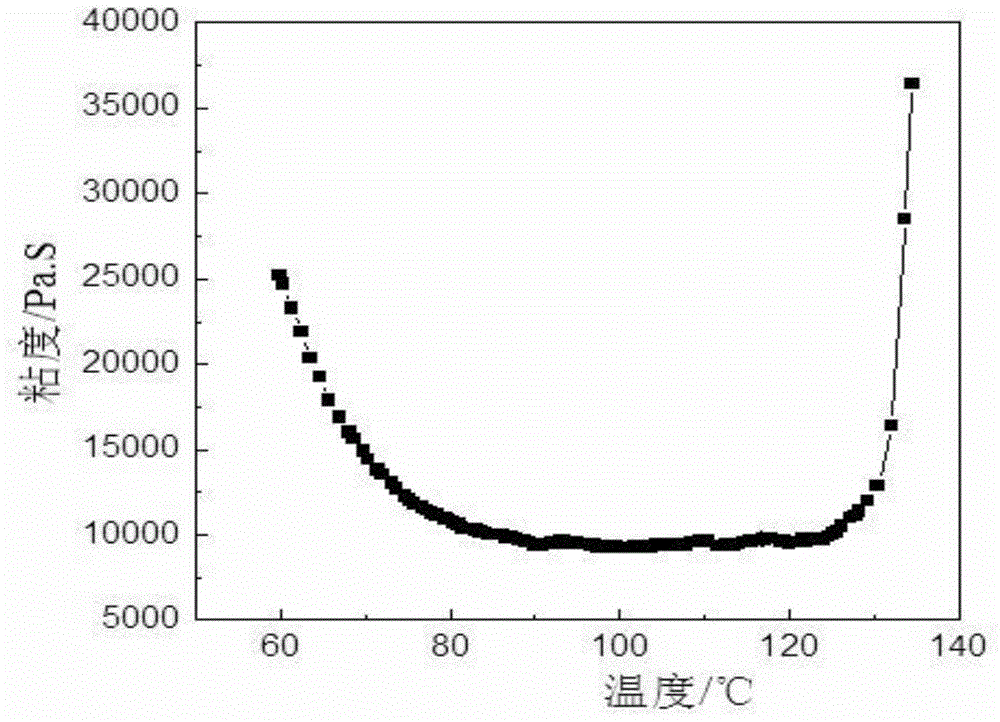

Image

Examples

specific Embodiment approach 1

[0021] Specific Embodiment 1: In this embodiment, a semiconductor film material used to prepare lightning protection shunt strips consists of 75 to 100 parts by weight of epoxy resin, 15 to 30 parts of thermoplastic resin, and 6 to 12 parts It consists of rubber elastic body, 15-25 parts of curing agent, 2-6 parts of accelerator, 6-12 parts of non-metallic conductive filler and 10-20 parts of non-metallic semiconductor filler.

specific Embodiment approach 2

[0022] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: a semiconductor adhesive film material used to prepare lightning protection shunt strips, in terms of parts by weight, consists of 80-90 parts of epoxy resin, 20-25 parts It consists of 8-10 parts of thermoplastic resin, 8-10 parts of rubber elastic body, 18-22 parts of curing agent, 2.5-3 parts of accelerator, 7-10 parts of non-metallic conductive filler and 14-16 parts of non-metallic semiconductor filler. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific embodiment three: the difference between this embodiment and specific embodiment one or two is that: the epoxy resin is composed of bisphenol A epoxy resin and tetrafunctional epoxy resin, and bisphenol A epoxy resin and tetrafunctional epoxy resin The mass ratio of functional epoxy resin is 4:1. Others are the same as in the first or second embodiment.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com